Effect of Asphalt Pavement Base Layers on Transverse Shrinkage Cracking Characteristics

Abstract

:1. Introduction

2. Project and Survey Results

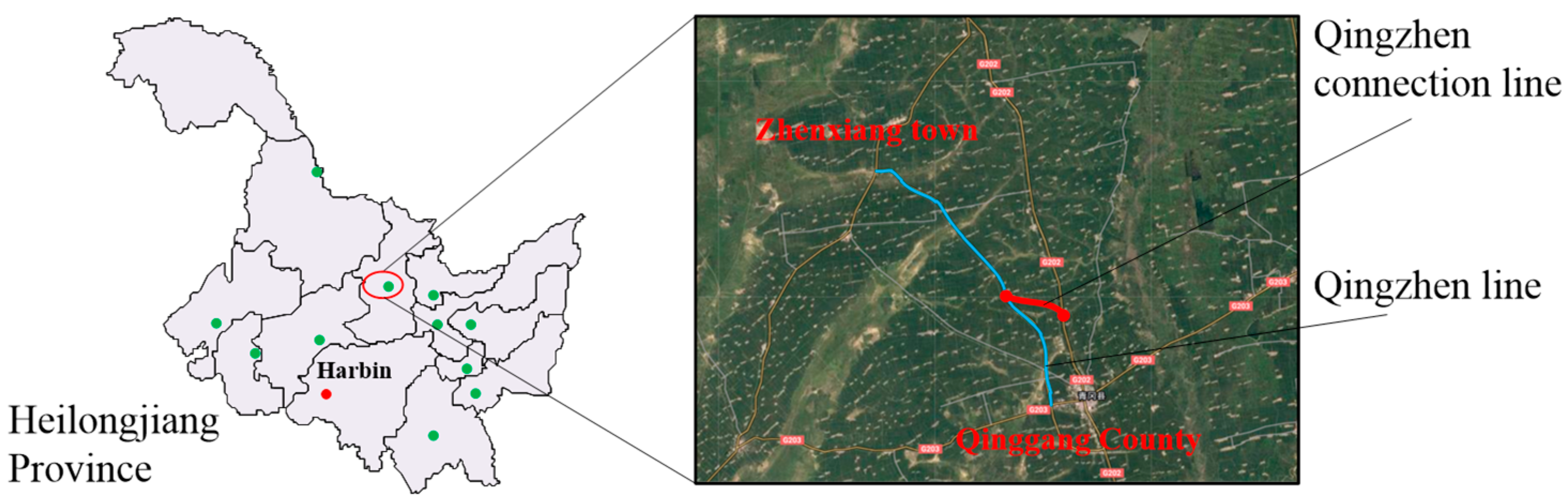

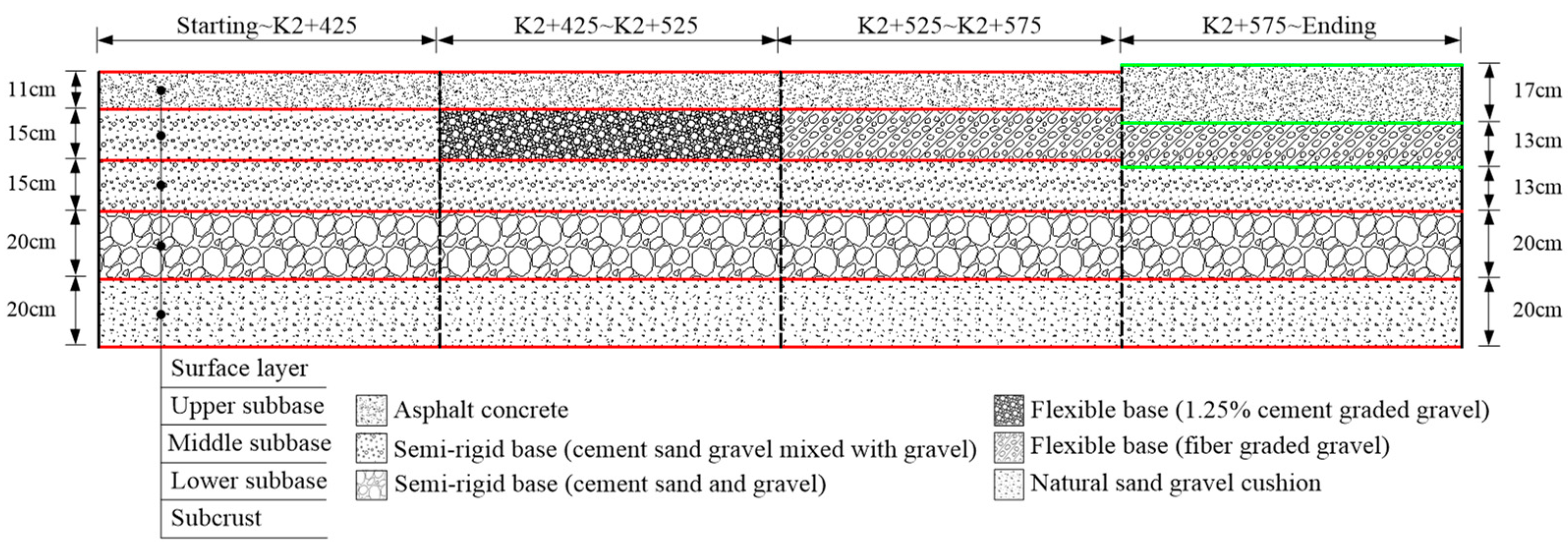

2.1. Test Section Project Information

2.2. Survey Results

3. Analysis of Transverse Shrinkage Cracking Characteristics in Asphalt Pavement

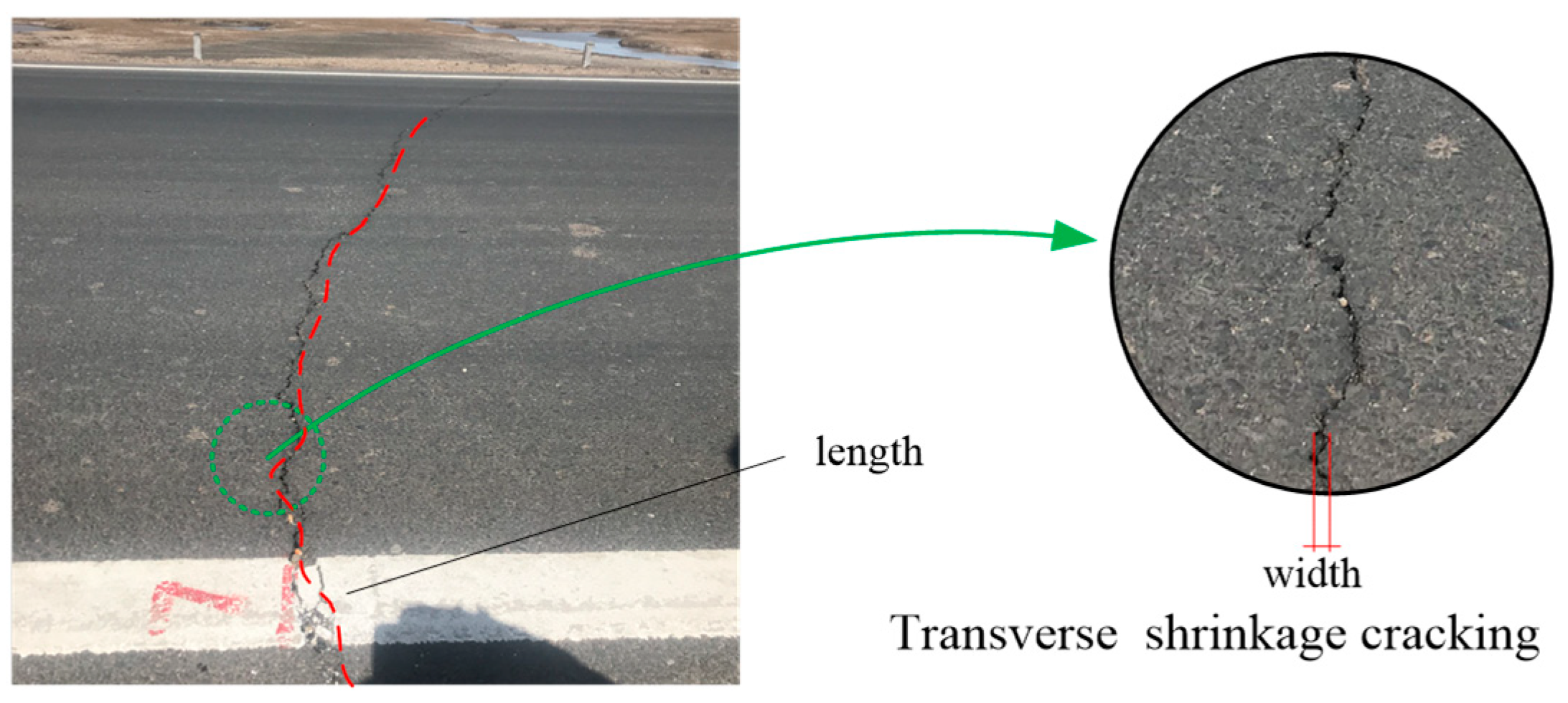

3.1. Characteristics of Transverse Shrinkage Cracking

- (1)

- It can evaluate the overall situation of transverse shrinkage cracking distribution in asphalt pavement more intuitively, accurately, and comprehensively.

- (2)

- It can directly judge the overall shrinkage state of the road surface and the rainwater infiltration amount on the road surface.

- (3)

- The method of calculating CAR directly without classification can make up for the weakness or defect of “single boundary and general and rough boundary”.

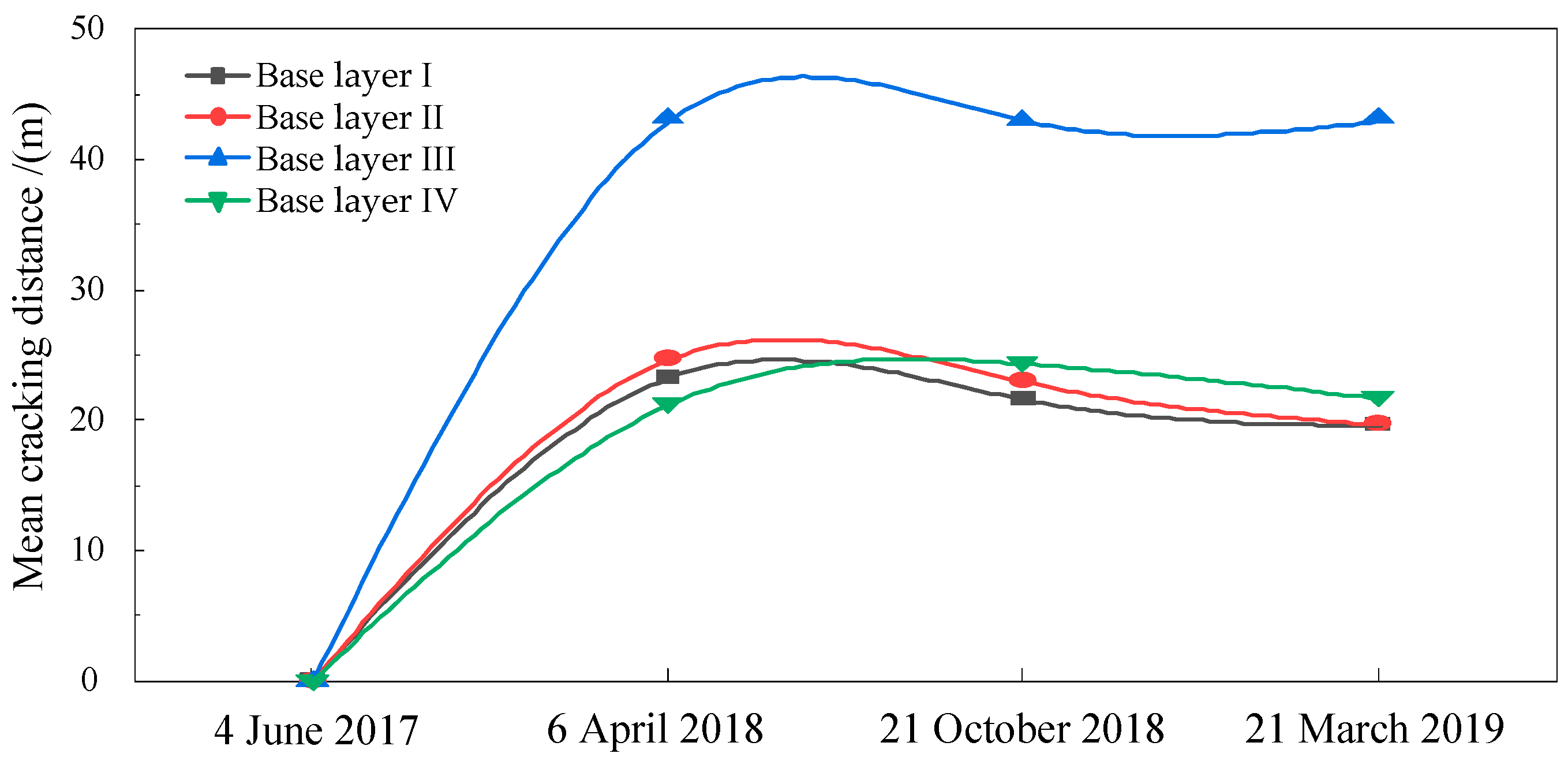

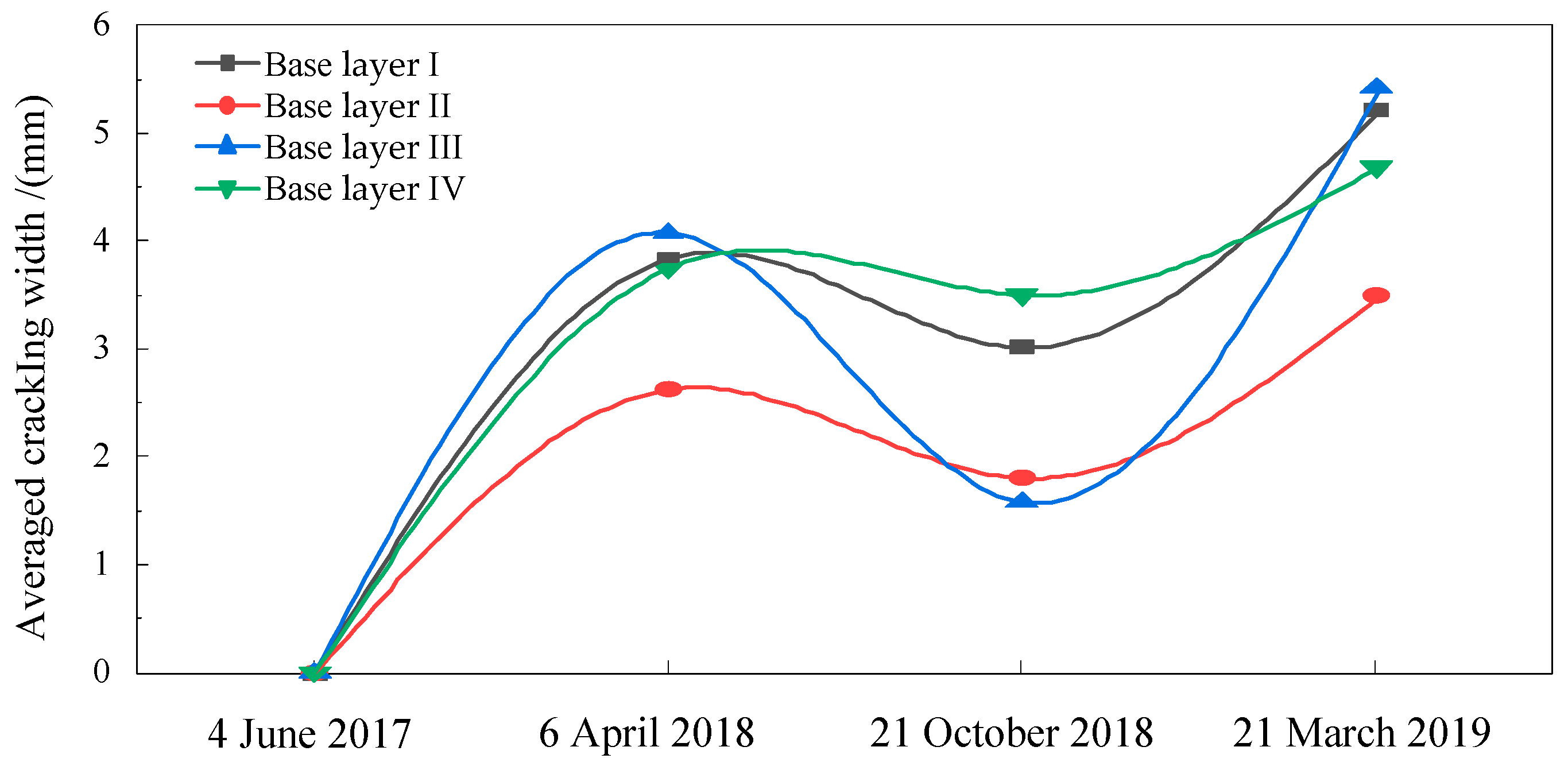

3.2. Effect of Base Layer Types on Transverse Shrinkage Cracking

4. Effect of Temperature on Transverse Shrinkage Cracking

4.1. Effect of Temperature on Transverse Shrinkage Cracking Evaluation Indexes

4.2. Characteristics of Temperature Shrinkage Coefficient

5. Conclusions

- (1)

- The study defined the cracking area ratio (CAR), which, for transverse shrinkage cracking, has a direct significance in that it can reflect the overall longitudinal shrinkage of the section.

- (2)

- The overall shrinkage of conventional cement sand gravel mixed with gravel (Base layer I) is larger, the anti-shrinkage cracking pavement performance of fiber graded gravel (Base layer III) is better, and the overall anti-shrinkage cracking performance of the asphalt pavement is not affected by 1.25% cement.

- (3)

- For fiber graded gravel with or without cement, the mean cracking distance and averaged cracking width of transverse shrinkage cracking vary greatly, but the CAR is similar.

- (4)

- Fiber graded gravel base can effectively relieve the load stress of asphalt pavement and prevent the upward reflection cracking in the middle and lower base.

- (5)

- Asphalt pavement with fiber graded gravel (Base layer III) shows good temperature shrinkage performance in the whole detection cycle, followed by Base layer II, Base layer IV, and Base layer I.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhuyan, M.R.-U.; Khattak, M.J. Performance Evaluation of Reflective Crack Mitigation Techniques for Soil-Cement Bases. Transp. Res. Rec. 2020, 2674, 901–914. [Google Scholar] [CrossRef]

- Chen, J.; Li, H.; Zhao, Z.; Hou, X.; Luo, J.; Xie, C.; Liu, H.; Ren, T.; Huang, X. Investigation of Transverse Crack Spacing in an Asphalt Pavement with a Semi-Rigid Base. Sci. Rep. 2022, 12, 18079. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Han, W.; Chen, L.; Zhang, Z.; Xue, Z.; Wei, J.; Yan, X.; Hu, G. Homogeneity Assessment of Asphalt Concrete Base in Terms of a Three-Dimensional Air-Launched Ground Penetrating Radar. Coatings 2021, 11, 398. [Google Scholar] [CrossRef]

- Pai, R.R.; Patel, S.; Bakare, M. Applicability of Utilizing Stabilized Native Soil as a Subbase Course in Flexible Pavement. Indian Geotech. J. 2020, 50, 289–299. [Google Scholar] [CrossRef]

- Souliman, M.I.; Gc, H.; Isied, M.; Walubita, L.F. Treated versus Untreated Aggregate Bases for Flexible Pavements: Nationwide Comparative Case Study. Transp. Res. Rec. 2020, 2674, 225–236. [Google Scholar] [CrossRef]

- Wang, X.; Zhong, Y. Reflective crack in semi-rigid base asphalt pavement under temperature-traffic coupled dynamics using XFEM. Constr. Build. Mater. 2019, 125, 280–289. [Google Scholar] [CrossRef]

- Decky, M.; Papanova, Z.; Juhas, M.; Kudelcikova, M. Evaluation of the Effect of Average Annual Temperatures in Slovakia between 1971 and 2020 on Stresses in Rigid Pavements. Land 2022, 11, 764. [Google Scholar] [CrossRef]

- Hou, F.; Li, T.; Li, X.; Li, Y.; Guo, M. Research on the Anti-Reflective Cracking Performance of a Full-Depth Asphalt Pavement. Sustainability 2021, 13, 9499. [Google Scholar] [CrossRef]

- Sha, D.C.; Pan, B.; Sun, Y.; Che, T.; Lu, J. Analysis of Moisture Damage Susceptibility of Semi-Rigid Base Materials Based on Hydrodynamic Pressure Erosion Test and Damage Constitutive Model. Can. J. Civ. Eng. 2020, 48, 449–457. [Google Scholar] [CrossRef]

- Tian, X.-G.; Han, H.-F.; Li, X.-W.; Wu, D.; Wei, D. Inversion Effect of Asphalt Pavement with Two Courses of Semi-Rigid Base. J. Highw. Transp. Res. Dev. Eng. Ed. 2018, 12, 22–27. [Google Scholar] [CrossRef]

- Qi, L.; Zhang, M.; Chen, M. Experimental Study on Road Performance Index of Graded-Gravel Flexible Base Course. J. Physics Conf. Ser. 2021, 2044, 012030. [Google Scholar] [CrossRef]

- Su, L.Y. Mechanics Analysis of Flexible Base Pavement Structure. Appl. Mech. Mater. 2014, 3307, 632–635. [Google Scholar] [CrossRef]

- Filho, W.U.; Gutiérrez Klinsky, L.M.; Motta, R.D.; Bariani Bernucci, L.L. Cold Recycled Asphalt Mixture using 100% RAP with Emulsified Asphalt-Recycling Agent as a New Pavement Base Course. Adv. Mater. Sci. Eng. 2020, 2020, 5863458. [Google Scholar] [CrossRef]

- Alaye, Q.E.; Ling, X.; Dong, Z.; Bambou, G. Evaluation of Mixture Performance Recycled Asphalt Pavement Materials as Base Layer with or without Rejuvenator into the Asphalt. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2020, 35, 579–597. [Google Scholar] [CrossRef]

- Gu, F.; Şahin, H.; Luo, X.; Luo, R.; Lytton, R.L. Estimation of Resilient Modulus of Unbound Aggregates Using Performance-Related Base Course Properties. J. Mater. Civil Eng. 2014, 27, 04014188. [Google Scholar] [CrossRef]

- Byun, Y.; Feng, B.; Qamhia, I.I.; Tutumluer, E. Aggregate Properties Affecting Shear Strength and Permanent Deformation Characteristics of Unbound–Base Course Materials. J. Mater. Civil Eng. 2020, 32, 04019332. [Google Scholar] [CrossRef]

- Jia, W.; Hu, M.; Liu, Z.; Li, T.; Chen, S.; Gao, J.Z. Experimental Study on Interlayer Mechanical Properties of Semi-Rigid Base Asphalt Pavement Using Interlayer Treatment Method. IOP Conf. Ser. Earth Environ. Sci. 2021, 719, 032070. [Google Scholar] [CrossRef]

- Cui, S. Analysis and research of flexible base course applied in Chengdu-Chongqing Expressway. In Proceedings of the 4th International Conference on Road & Airfield Pavement Technology, Kunming, China, 14–15 July 2022; People’s Communications Publishing House: Beijing, China, 2002; pp. 755–759. [Google Scholar]

- Jiang, X.; Zeng, C.; Gao, X.Y.; Liu, Z.; Qiu, Y. 3D FEM Analysis of Flexible Base Asphalt Pavement Structure Under Non-Uniform Tyre Contact Pressure. Int. J. Pavement Eng. 2019, 20, 999–1011. [Google Scholar] [CrossRef]

- Khan, M.A.; Biswas, N.; Banerjee, A.; Puppala, A.J. Field Performance of Geocell Reinforced Recycled Asphalt Pavement Base Layer. Transp. Res. Rec. 2020, 2674, 69–80. [Google Scholar] [CrossRef]

- Google Maps. Available online: https://www.google.com.hk/maps/?hl=zh-CN (accessed on 16 February 2023).

- Decky, M.; Hodasova, K.; Papanova, Z.; Remisova, E. Sustainable Adaptive Cycle Pavements Using Composite Foam Concrete at High Altitudes in Central Europe. Sustainability 2022, 4, 9034. [Google Scholar] [CrossRef]

- Zhao, Z.G.; Liang, S.; Liu, J.; Sun, J.; Yu, T. Influence of Base Course Types on Axial Load Diffusion Performance for Asphalt Pavement Based on Measured Data. Case Stud. Constr. Mater. 2022, 17, e01644. [Google Scholar] [CrossRef]

- Gu, Y.; Ding, C.; Shen, J.; Wang, W. Low Temperature Crack Resistance of Stone Mastic Asphalt Affected by Its Nominal Maximum Size and Asphalt Binders. Appl. Sci. 2022, 12, 7444. [Google Scholar] [CrossRef]

- Wu, H.; Chen, C.; Zhang, W.; Wang, R. The Optimization Design of Mixing Ratio of ARAC-13 Rubber Asphalt Mixture based on Low Temperature Crack Resistance. IOP Conf. Ser. Earth Environ. Sci. 2019, 330, 042017. [Google Scholar] [CrossRef]

- JTG 5210-2018; Highway Performance Assessment Standards. Chinese Standard: Beijing, China, 2018.

- JTG D50-2017; Specifications for Design of Highway Asphalt Pavement. Chinese Standard: Beijing, China, 2017.

- Zhang, J.; Zheng, M.; Pei, J.; Zhang, J.; Li, R. Research on Low Temperature Performance of Emulsified Asphalt Cold Recycled Mixture and Improvement Measures Based on Fracture Energy. Materials 2020, 13, 3176. [Google Scholar] [CrossRef]

- Ahmad, T.; Khawaja, H. Review of Low-Temperature Crack (LTC) Developments in Asphalt Pavements. Int. J. Multiphys. 2018, 12, 169–187. [Google Scholar] [CrossRef]

- Judycki, J. Application of the new viscoelastic method of thermal stress calculation to the analysis of low-temperature cracking of ashpalt layers. Roads Bridg. Drog. I Mosty 2020, 19, 27–49. [Google Scholar] [CrossRef]

- Wu, J.; Li, F.; Ma, Q. Effect of Polyester Fiber on Air Voids and Low-Temperature Crack Resistance of Permeable Asphalt Mixture. Adv. Civil Eng. 2020, 2020, 2381504. [Google Scholar] [CrossRef]

- Hong, R.B.; Wu, J.R.; Cai, H.B. Low-Temperature Crack Resistance of Coal Gangue Powder and Polyester Fibre Asphalt Mixture. Constr. Build. Mater. 2019, 238, 117678. [Google Scholar] [CrossRef]

- Xiong, R.; Chen, S.F.; Guan, B.W.; Sheng, Y.P. Low-Temperature Crack Resistance of Fiber Reinforced Asphalt Mixture Under Sulfate and Dry-Wet Circle Corrosion Environment. J. Wuhan Univ. Technol. 2014, 36, 47–52. [Google Scholar] [CrossRef]

- Zhu, B.; Liu, H.B.; Li, W.J.; Wu, C.; Chai, C. Fracture Behavior of Permeable Asphalt Mixtures with Steel Slag under Low Temperature Based on Acoustic Emission Technique. Sensors 2020, 20, 5090. [Google Scholar] [CrossRef]

- Fedrigo, W.; Kleinert, T.R.; Núñez, W.P.; Graef, Â.G.; Pinto da Silva Filho, L.C.; Brito, L.A. Shrinkage of Cold Recycled Cement-Treated Mixtures of Asphalt Pavement Materials. J. Test. Eval. 2022, 51, 260. [Google Scholar] [CrossRef]

- Abraham, S.M.; Ransinchung, G.D.R.N. Durability Performance of Cementitious Mixes with Reclaimed Asphalt Pavement Aggregates. Transp. Dev. Econ. 2022, 8, 12. [Google Scholar] [CrossRef]

- Chen, J.; Li, Z.; Zhao, Z.; Huang, X.; Chen, J.; Liu, Z. Investigation on Temperature Shrinkage Characteristics of the Combined Structure in Asphalt Pavement. Front. Mater. 2022, 9, 1055641. [Google Scholar] [CrossRef]

| Date | Test Section | Section Length L/(m) | Number of Transverse Cracks | Total Width Bs/(mm) |

|---|---|---|---|---|

| 6 April 2018 | Starting~K2+425 | 188 | 8 | 30.8 |

| K2+425~K2+525 | 105 | 4 | 10.5 | |

| K2+525~K2+575 | 122 | 3 | 12.3 | |

| K2+575~Ending | 126 | 6 | 22.5 | |

| 21 October 2018 | Starting~K2+425 | 241 | 11 | 33.3 |

| K2+425~K2+525 | 105 | 4 | 7.3 | |

| K2+525~K2+575 | 122 | 3 | 4.8 | |

| K2+575~Ending | 196 | 8 | 28.0 | |

| 21 March 2019 | Starting~K2+425 | 241 | 12 | 62.5 |

| K2+425~K2+525 | 105 | 5 | 17.5 | |

| K2+525~K2+575 | 122 | 3 | 16.3 | |

| K2+575~Ending | 196 | 9 | 42.3 |

| Date | Base Layer | Base Layer I | Base Layer II | Base Layer III | Base Layer IV |

|---|---|---|---|---|---|

| 6 April 2018 | Mean cracking distance/(m) | 23.4 | 24.8 | 43.3 | 21.3 |

| Averaged cracking width/(mm) | 3.84 | 2.63 | 4.08 | 3.75 | |

| CAR (cm/100 m) | 1.64 | 1.01 | 1.00 | 1.79 | |

| 21 October 2018 | Mean cracking distance/(m) | 21.7 | 23.1 | 43.1 | 24.5 |

| Averaged cracking width/(mm) | 3.02 | 1.81 | 1.58 | 3.50 | |

| CAR (cm/100 m) | 1.38 | 0.69 | 0.39 | 1.43 | |

| 21 March 2019 | Mean cracking distance/(m) | 19.7 | 19.8 | 43.2 | 21.8 |

| Averaged cracking width/(mm) | 5.21 | 3.50 | 5.42 | 4.69 | |

| CAR (cm/100 m) | 2.59 | 1.67 | 1.33 | 2.16 |

| Date | Base Layer I | Base Layer II | Base Layer III | Base Layer IV |

|---|---|---|---|---|

| 6 April 2018 | 10.3 × 10−6 | 6.3 × 10−6 | 6.3 × 10−6 | 11.2 × 10−6 |

| 21 October 2018 | 30.7 × 10−6 | 15.3 × 10−6 | 8.67 × 10−6 | 31.8 × 10−6 |

| 21 March 2019 | 15.7 × 10−6 | 10.1 × 10−6 | 8.1 × 10−6 | 13.1 × 10−6 |

| Ranges | 6.0 × 10−6–9.0 × 10−6 | 6.0 × 10−6–9.0 × 10−6 | 6.0 × 10−6–9.0 × 10−6 | 6.0 × 10−6–9.0 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, M.; Yang, H.; Zhao, Z.; Yu, T. Effect of Asphalt Pavement Base Layers on Transverse Shrinkage Cracking Characteristics. Sustainability 2023, 15, 7178. https://doi.org/10.3390/su15097178

Xing M, Yang H, Zhao Z, Yu T. Effect of Asphalt Pavement Base Layers on Transverse Shrinkage Cracking Characteristics. Sustainability. 2023; 15(9):7178. https://doi.org/10.3390/su15097178

Chicago/Turabian StyleXing, Mingming, Hongwei Yang, Zhenguo Zhao, and Tengjiang Yu. 2023. "Effect of Asphalt Pavement Base Layers on Transverse Shrinkage Cracking Characteristics" Sustainability 15, no. 9: 7178. https://doi.org/10.3390/su15097178