Impact of Fracture–Seepage–Stress Coupling on the Sustainability and Durability of Concrete: A Triaxial Seepage and Mechanical Strength Analysis

Abstract

:1. Introduction

1.1. Importance of Concrete and Its Strength: Seepage Characteristics

1.2. Progress of Research on the Effect of Fracture in Rock on the Strength of Concrete

1.3. Progress of Seepage Characteristics of Fracture-Bearing Rock

2. Experiment Preparation and Experimental Program Design

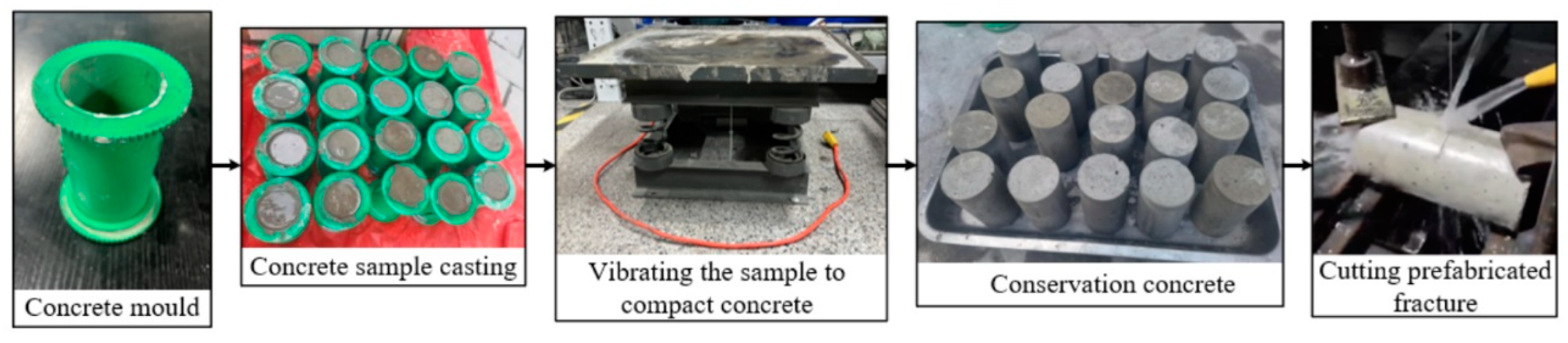

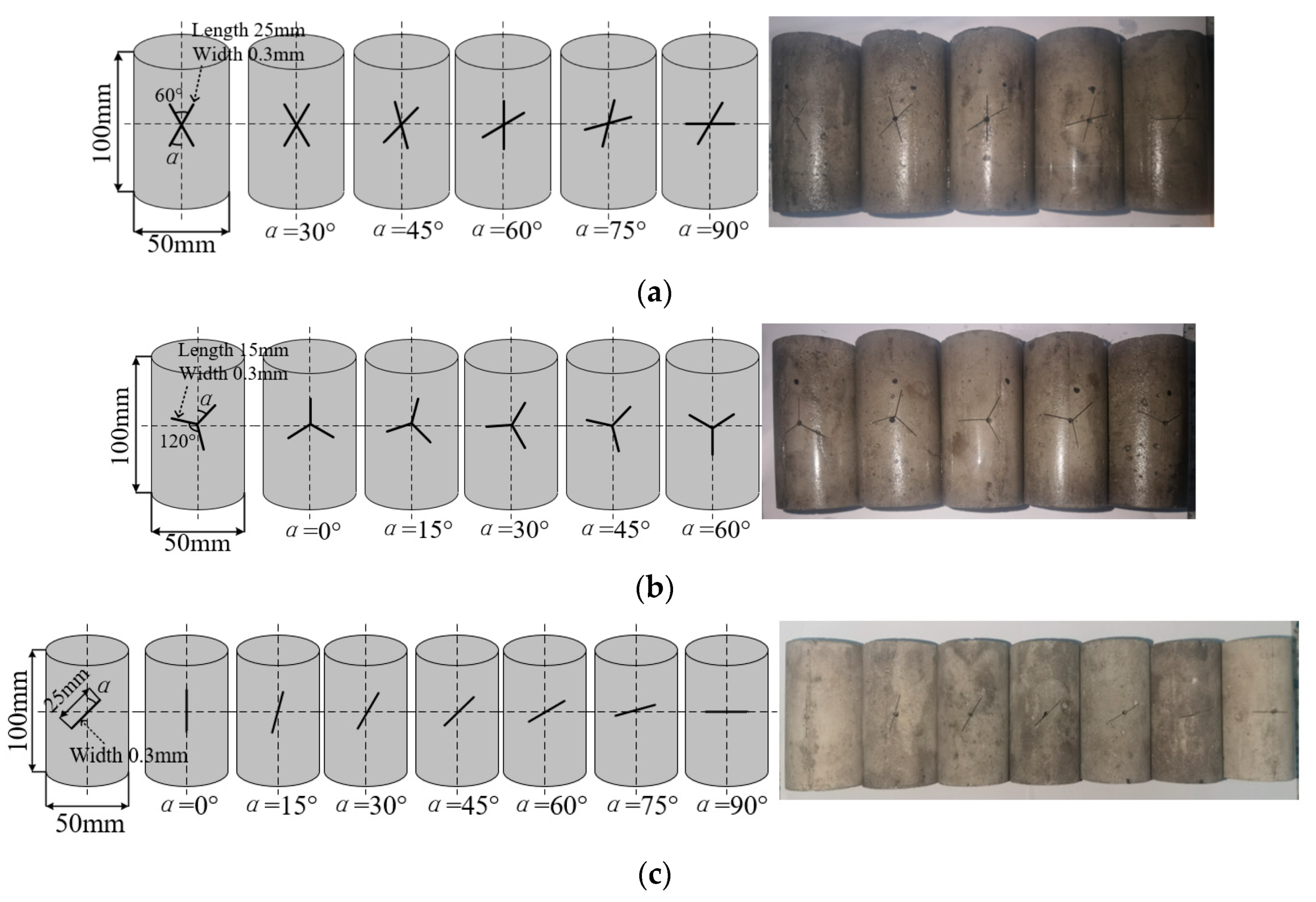

2.1. Sample Preparation

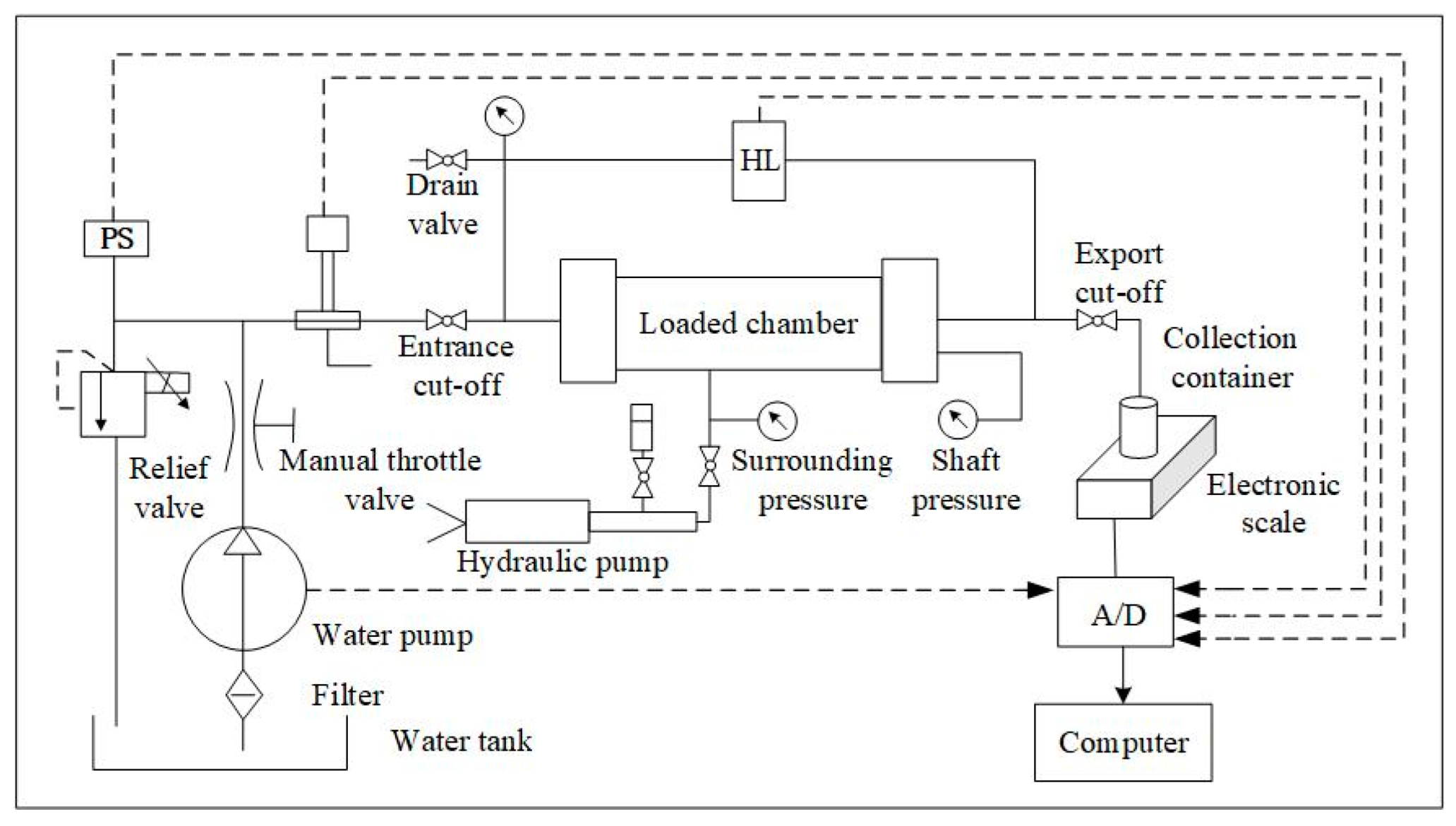

2.2. Experimental Equipment

2.3. Experimental Program

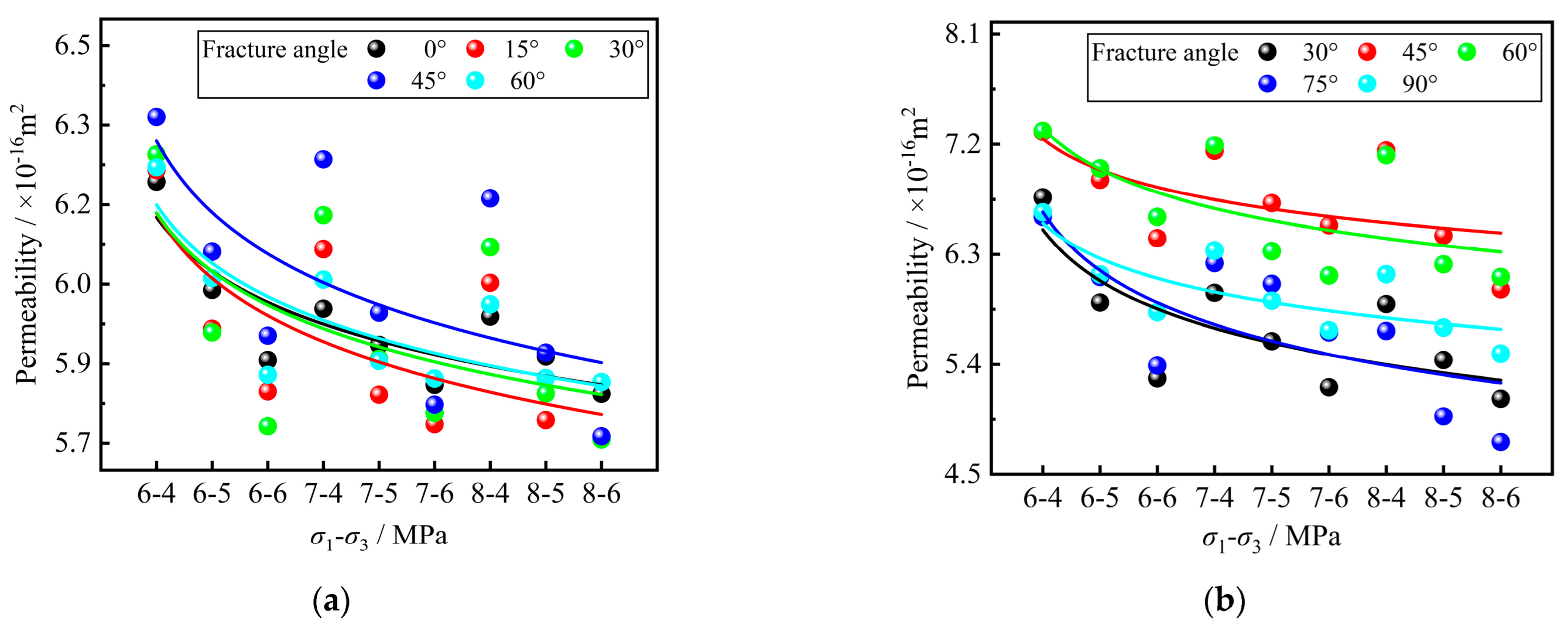

3. Characteristics of Seepage in Fracture-Containing Concrete

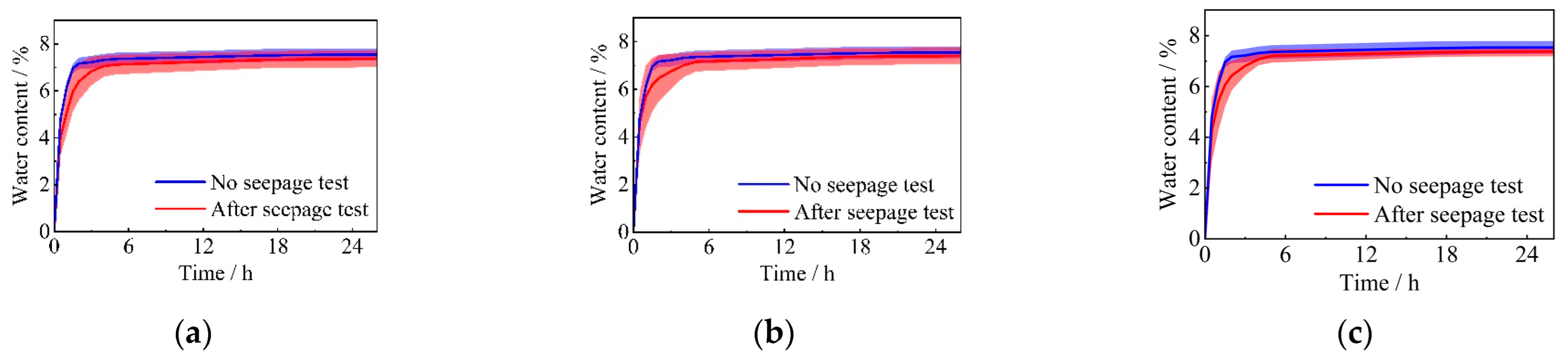

3.1. Investigation of Water Absorption Characteristics of Fracture-Containing Concrete Samples under Seepage–Stress Coupling

3.2. Seepage Characteristics of Concrete Samples Containing Fractures

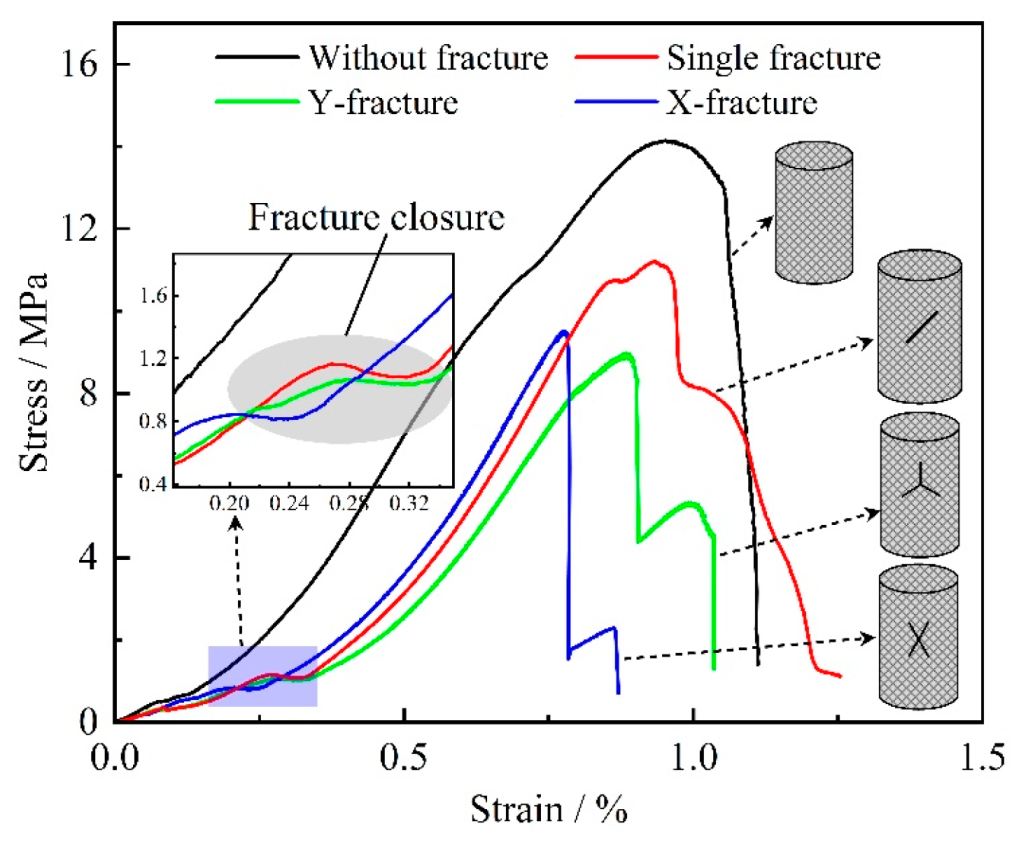

4. Degradation of Mechanical Properties of Fracture-Containing Concrete

4.1. Effect of Fracture–Seepage–Stress Coupling on the Strength of Concrete

4.1.1. Deterioration in Concrete Strength by Fractures in Concrete

4.1.2. Deterioration in Concrete Strength by Fracture–Seepage–Stress Coupling

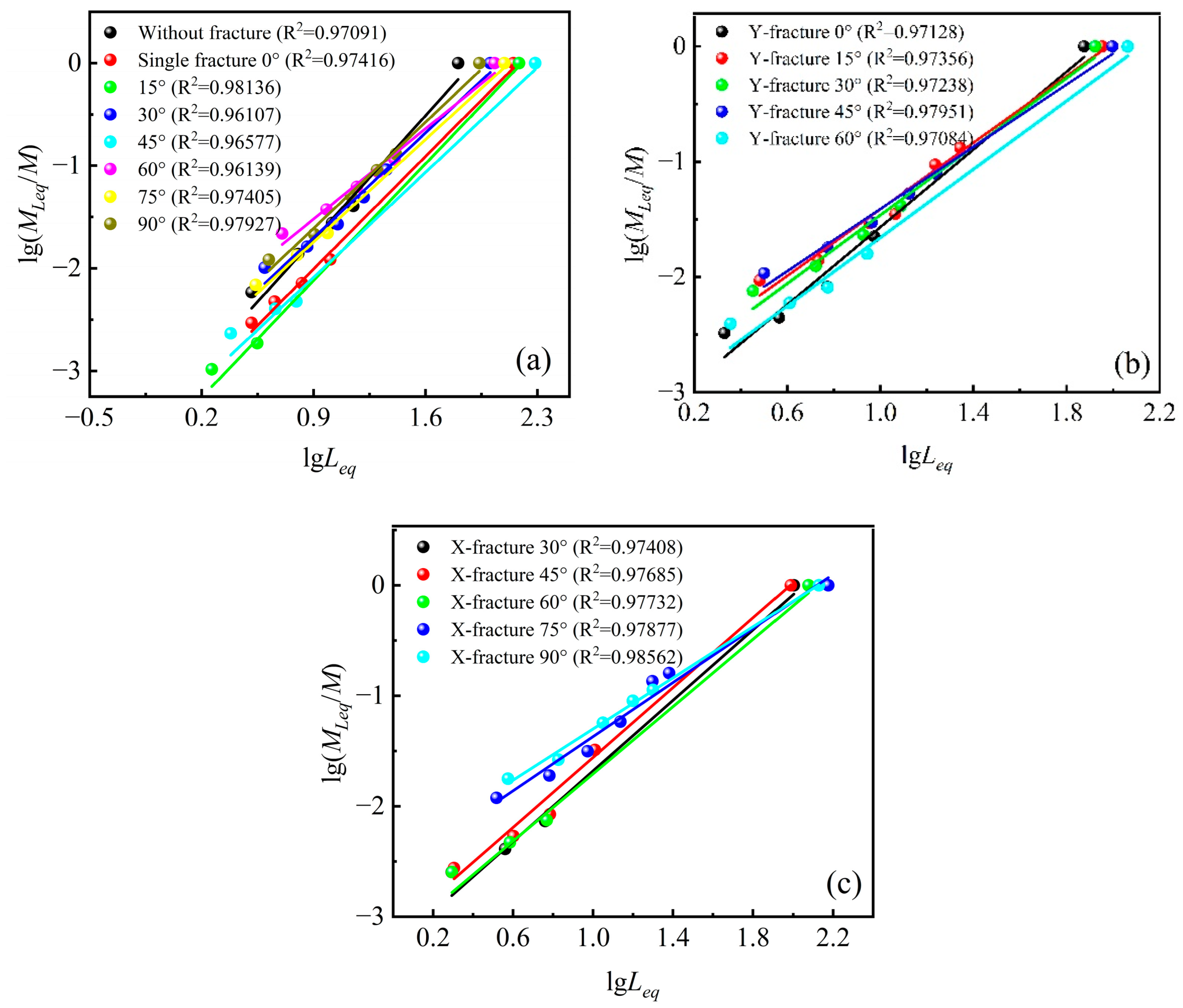

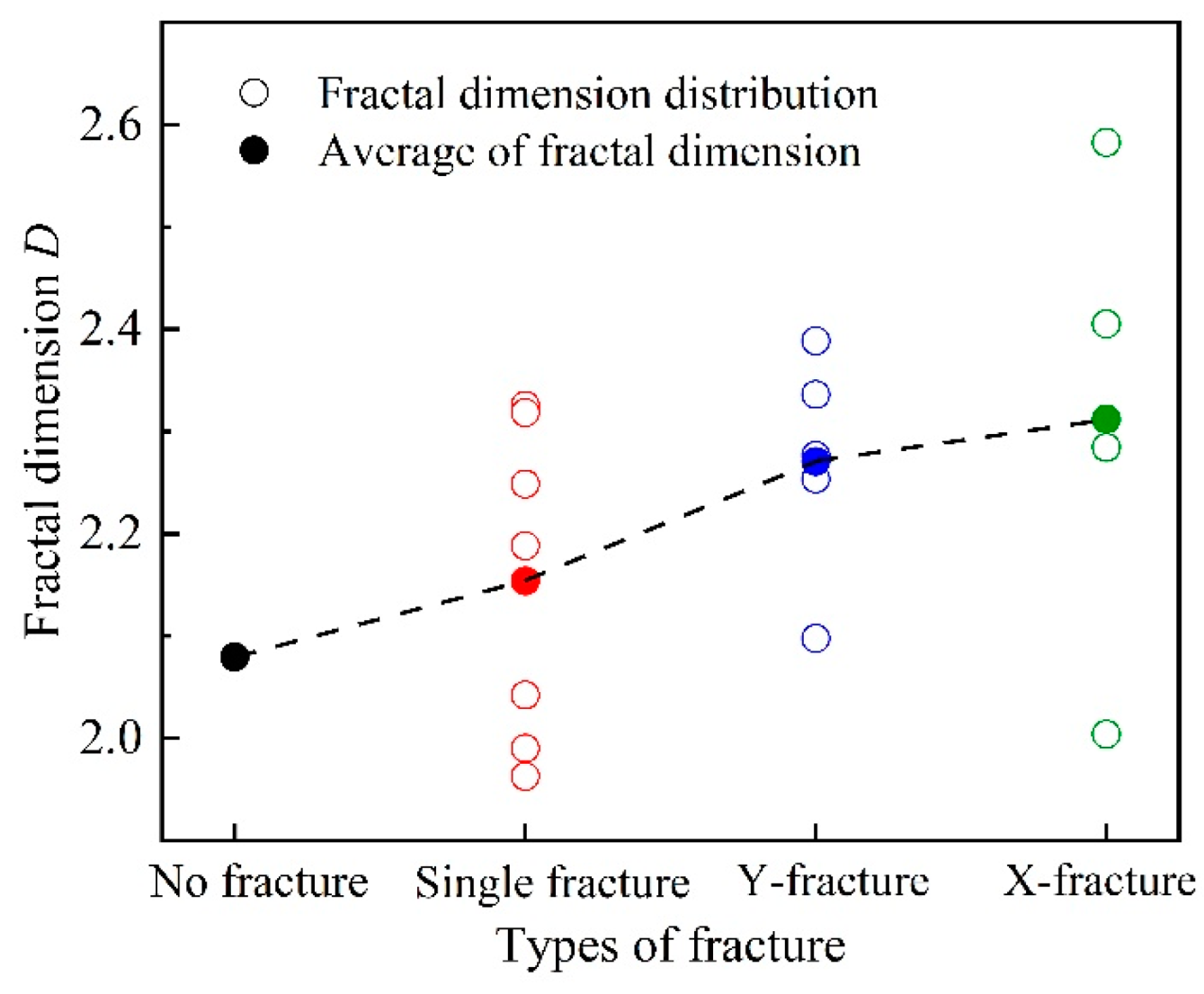

4.2. Damage Characteristics of Fracture-Containing Concrete under Fracture–Seepage–Stress Coupling

4.2.1. Characteristics of Crack Extension in Concrete with Fractures under Compression

4.2.2. Damage Fractals of Concrete Containing Fracture under Compression

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, C.; Zhang, B.; Zhu, W.; Wang, S.; Li, J.; Yang, L.; Lin, C. Fracture Propagation of Rock like Material with a Fluid-Infiltrated Pre-existing Flaw Under Uniaxial Compression. Rock Mech. Rock Eng. 2021, 54, 875–891. [Google Scholar] [CrossRef]

- Nolen-Hoeksema, R.C.; Gordon, R.B. Gordon Optical detection of crack patterns in the opening-mode fracture of marble. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1987, 24, 135–144. [Google Scholar] [CrossRef]

- Van Mier, J.; Man, H.K. Some Notes on Microcracking, Softening, Localization, and Size Effects. Int. J. Damage Mech. 2009, 18, 283–309. [Google Scholar] [CrossRef]

- Lajtai, E.Z. Unconfined Shear Strength of Discontinuous Rocks. In Proceedings of the 2nd ISRM Congress, Belgrade, Yugoslavia, 21–26 September 1970. [Google Scholar]

- Feng, G.; Zhu, C.; Wang, X.; Tang, S. Thermal effects on prediction accuracy of dense granite mechanical behaviors using modified maximum tangential stress criterion. J. Rock Mech. Geotech. 2023, 15, 1734–1748. [Google Scholar] [CrossRef]

- Feng, G.; Wang, X.C.; Kang, Y.; Zhang, Z.T. Effect of thermal cycling-dependent cracks on physical and mechanical properties of granite for enhanced geothermal system. Int. J. Rock Mech. Min. 2020, 134, 104476. [Google Scholar] [CrossRef]

- Wong, R.; Lin, P.; Tang, C.A. Experimental and numerical study on splitting failure of brittle solids containing single pore under uniaxial compression. Mech. Mater. 2006, 38, 142–159. [Google Scholar] [CrossRef]

- Qianqian, D.; Guowei, M.; Qiusheng, W.; Mingjie, X.; Qiaoyan, L. Different damage parameters on failure properties with non-straight marble under uniaxial compression. Electron. J. Geotech. Eng. 2015, 20, 6151–6167. [Google Scholar]

- Chen, D.; Yu, X.; Liu, R.; Li, S.; Zhang, Y. Triaxial mechanical behavior of early age concrete: Experimental and modelling research. Cem. Concr. Res. 2019, 115, 433–444. [Google Scholar] [CrossRef]

- Chen, D.; Yu, X.T.; Guo, M.Y.; Liao, Y.D.; Ouyang, F. Study on the mechanical properties of the mortars exposed to the sulfate attack of different concentrations under the triaxial compression with constant confining pressure. Constr. Build. Mater. 2017, 146, 445–454. [Google Scholar] [CrossRef]

- Xie, H.P.; Yang, J.U. Criteria for Strength and Structural Failure of Rocks Based on Energy Dissipation and Energy Release Principles. Chin. J. Rock Mech. Eng. 2005, 24, 3003–3010. [Google Scholar]

- Yuangao, L.; Weiyuan, Z.; Jidong, Z.; Qiang, Y. Discontinuous Bifurcation Model of Damage Localization for Jointed Rocks and its Application. Acta Mech. Sin. Chin. Ed. 2003, 35, 411–418. [Google Scholar]

- Li, J.C.; Li, T.C.; Wang, G.; Bai, S.W. CT scanning test of built-in fracture extension under uniaxial compression. J. Rock Mech. Eng. 2007, 26, 484–492. [Google Scholar]

- Wang, W.H.; Wang, X.J.; Jiang, H.T.; Yan, Z.; Li, S.R. Mechanical properties of rock-like samples with different inclination fracture under uniaxial compression. Sci. Technol. Bull. 2014, 32, 48–53. [Google Scholar]

- Lin, P.; Huang, K.J.; Wang, R.K.; Zhou, W.Y. Crack extension and damage behaviour of samples with single crack defects at different angles. J. Rock Mech. Eng. 2005, 5652–5657. Available online: https://www.researchgate.net/publication/294743512_Crack_growth_mechanism_and_failure_behavior_of_specimen_containing_single_flaw_with_different_angles (accessed on 9 December 2023).

- Xie, Q.T.; Guo, J.Z.; Wang, J.L.; Chen, Y.G. Crack extension measurement in sandstone specimens with inclined single cracks under uniaxial compression. Geotechnics 2011, 32, 2917–2921. [Google Scholar]

- Bian, H.; Qin, X.W.; Luo, W.J.; Ma, C.; Zhu, J.; Lu, C.; Zhou, Y.F. Evolution of hydrate habit and formation properties evolution during hydrate phase transition in fractured-porous medium. Fuel 2022, 324, 124436. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, J.; Peng, S.J.; Zhang, Q.W.; Chen, C.C. Strain localisation and seepage characteristics of rock under triaxial compression by 3D digital image correlation. Int. J. Rock Mech. Min. 2022, 152, 105064. [Google Scholar] [CrossRef]

- Hudson, J.A.; Cornet, F.H.; Christiansson, R. ISRM Suggested Methods for rock stress estimation—Part 1: Strategy for rock stress estimation. Int. J. Rock Mech. Min. 2003, 40, 991–998. [Google Scholar] [CrossRef]

- Shi, Z.; Yao, Q.; Wang, W.; Su, F.; Li, X.; Zhu, L.; Wu, C. Size Effects of Rough Fracture Seepage in Rocks of Different Scales. Water-Sui 2023, 15, 1912. [Google Scholar] [CrossRef]

- Gray, W.G.; Miller, C.T. Examination of Darcy’s law for flow in porous media with variable porosity. Environ. Sci. Technol. 2004, 38, 5895–5901. [Google Scholar] [CrossRef]

- Zhang, D.; Yao, H. Disease Analysis and solutions of the prestressed concrete bridge cracks. In Proceedings of the 2nd International Conference on Civil Engineering, Architecture and Building Materials (CEABM 2012), Yantai, China, 25–27 May 2012; Volume 178–181, pp. 2398–2400. [Google Scholar]

- Shaikh, F.U. A Effect of Cracking on Corrosion of Steel in Concrete. Int. J. Concr. Struct. Mater. 2018, 12, 3. [Google Scholar] [CrossRef]

- Combrinck, R.; Steyl, L.; Boshoff, W.P. Influence of concrete depth and surface finishing on the cracking of plastic concrete. Constr. Build. Mater. 2018, 175, 621–628. [Google Scholar] [CrossRef]

- Yang, J.Y.; Guo, Y.C.; Tan, J.J.; Shen, A.Q.; Wu, H.; Li, Y.; Lyu, Z.H.; Wang, L.S. Strength deterioration and crack dilation behavior of BFRC under dynamic fatigue loading. Case Stud. Constr. Mater. 2022, 16, e01051. [Google Scholar] [CrossRef]

- Ting, S.; Yang, L.; IOP. Chloride ion erosion experiment research in cracked concrete. In Proceedings of the 2nd International Conference on Materials Science, Energy Technology and Environmental Engineering (MSETEE), Zhuhai, China, 28–30 April 2017; Volume 81. [Google Scholar]

- Gao, Y.; Zou, C. CT study on meso-crack propagation of gradient composite concrete subjected to sulfate erosion. Mag. Concr. Res. 2015, 67, 1127–1134. [Google Scholar] [CrossRef]

- Guo, J.; Wang, K.; Guo, T.; Yang, Z.; Zhang, P. Effect of Dry-Wet Ratio on Properties of Concrete Under Sulfate Attack. Materials 2019, 12, 2755. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Hong, J.W. Morphological aspects of crack growth in rock materials with various flaws. Int. J. Numer. Anal. Met. 2019, 43, 1854–1866. [Google Scholar] [CrossRef]

- Silva, B.G.D.; Einstein, H.H. Modeling of crack initiation, propagation and coalescence in rocks. Int. J. Fract. 2013, 182, 167–186. [Google Scholar] [CrossRef]

- Rhc, W.; Kt, C. Crack coalescence in a rock-like material containing two cracks. Int. J. Rock Mech. Min. 1998, 35, 147–164. [Google Scholar]

- Xie, H.P.; Gao, F.; Zhou, H.W.; Zuo, J.P. Fractal study of rock fracture and fragmentation. J. Disaster Prev. Mitig. Eng. 2003, 1–9. Available online: https://kns.cnki.net/KXReader/Detail?invoice=Ytr%2FJrSeUr7dE1unRvbIcxIZDvXD4kYuSm%2FDvinUguvfj3BIAvt3a8sFLwvQnkEQlJeL2HXfbfl5H4XGk%2FIHLW7aV2tVZZbJt9oq%2FpDGqplpJVrSJfRtwpK8L5bFcpXF9KqXdRZ72naQQLGthNT5tNW2UwoXm24v%2Bu7bTY77hhM%3D&DBCODE=CJFQ&FileName=DZXK200304000&TABLEName=cjfd2003&nonce=3AA62C61C3594E6A8D149487A5BD609B&TIMESTAMP=1706602578386&uid= (accessed on 9 December 2023).

- He, M.C.; Yang, G.X.; Miao, J.L.; Jia, X.N.; Jiang, T.T. Classification of debris in rock explosion experiments and its research method. J. Rock Mech. Eng. 2009, 28, 1521–1529. [Google Scholar]

| No. | Fracture Morphology | Fracture Angle/° | Surrounding Stress σ2 (σ3)/MPa | Axial Stress σ1/MPa | Seepage Stress Pw/MPa |

|---|---|---|---|---|---|

| 1 | Without fracture | / | 4, 5, 6 | 6, 7, 8 | 3 |

| 2 | Single fracture | 0, 15, 30, 45, 60, 75, 90 | |||

| 3 | Y-fracture | 0, 15, 30, 45, 60 | |||

| 4 | X-fracture | 30, 45, 60, 75, 90 |

| No. | Fracture Morphology | Fracture Angle/° | Strength Average/MPa | Strength Decay/% |

|---|---|---|---|---|

| A1 | Without fracture | / | 13.02 | / |

| B1 | Single fracture | 0 | 10.89 | 16.36 |

| B2 | 15 | 10.29 | 20.97 | |

| B3 | 30 | 9.87 | 24.19 | |

| B4 | 45 | 9.50 | 27.04 | |

| B5 | 60 | 9.18 | 29.49 | |

| B6 | 75 | 8.91 | 31.57 | |

| B7 | 90 | 8.75 | 32.80 | |

| C1 | Y-fracture | 0 | 8.06 | 38.10 |

| C2 | 15 | 9.31 | 28.49 | |

| C3 | 30 | 9.41 | 27.73 | |

| C4 | 45 | 9.23 | 29.11 | |

| C5 | 60 | 8.22 | 36.87 | |

| D1 | X-fracture | 30 | 8.19 | 37.10 |

| D2 | 45 | 8.27 | 36.48 | |

| D3 | 60 | 7.83 | 39.86 | |

| D4 | 75 | 7.93 | 39.09 | |

| D5 | 90 | 8.25 | 36.64 |

| Fracture Morphology | Average Strengths of Concrete Samples/MPa | Strength Decay/% | |

|---|---|---|---|

| No Seepage Experiment | After the Seepage Experiment | ||

| Without fracture | 14.15 | 13.02 | 7.99 |

| Single fracture | 11.16 | 9.50 | 14.87 |

| Y-fracture | 9.01 | 8.06 | 10.54 |

| X-fracture | 9.48 | 8.19 | 13.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Z.; Wu, C.; Wang, F.; Li, X.; Shan, C.; Xu, Y. Impact of Fracture–Seepage–Stress Coupling on the Sustainability and Durability of Concrete: A Triaxial Seepage and Mechanical Strength Analysis. Sustainability 2024, 16, 1187. https://doi.org/10.3390/su16031187

Shi Z, Wu C, Wang F, Li X, Shan C, Xu Y. Impact of Fracture–Seepage–Stress Coupling on the Sustainability and Durability of Concrete: A Triaxial Seepage and Mechanical Strength Analysis. Sustainability. 2024; 16(3):1187. https://doi.org/10.3390/su16031187

Chicago/Turabian StyleShi, Zhuolin, Chengle Wu, Furong Wang, Xuehua Li, Changhao Shan, and Yingnan Xu. 2024. "Impact of Fracture–Seepage–Stress Coupling on the Sustainability and Durability of Concrete: A Triaxial Seepage and Mechanical Strength Analysis" Sustainability 16, no. 3: 1187. https://doi.org/10.3390/su16031187