Indoor Air Quality and Ventilation Energy in University Classrooms: Simplified Model to Predict Trade-Offs and Synergies

Abstract

:1. Introduction

1.1. Background and Context

1.2. State-of-the-Art Methods

1.2.1. Simulation Tools

1.2.2. Weather and Context

1.2.3. Time Dimension

1.2.4. Energy Savings

1.2.5. Scaling Up Simulation Case Studies

1.3. Practicalities of Modeling a Classroom

1.4. Research Gap and Contribution

1.5. Research Objectives

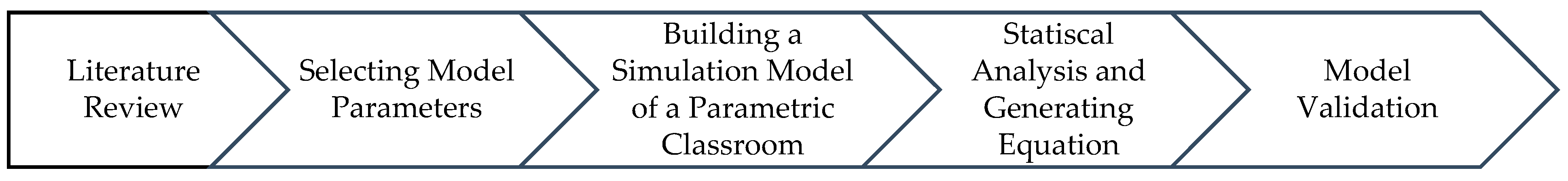

2. Methodology

2.1. Reviewing Recent Trends for Studying IAQ and Energy

2.2. Data Modeling and Simulation

2.3. Simplified Predictive Model Generation

2.4. Validation

3. Results and Analysis

3.1. Simulation Results

3.2. Statistical Analysis

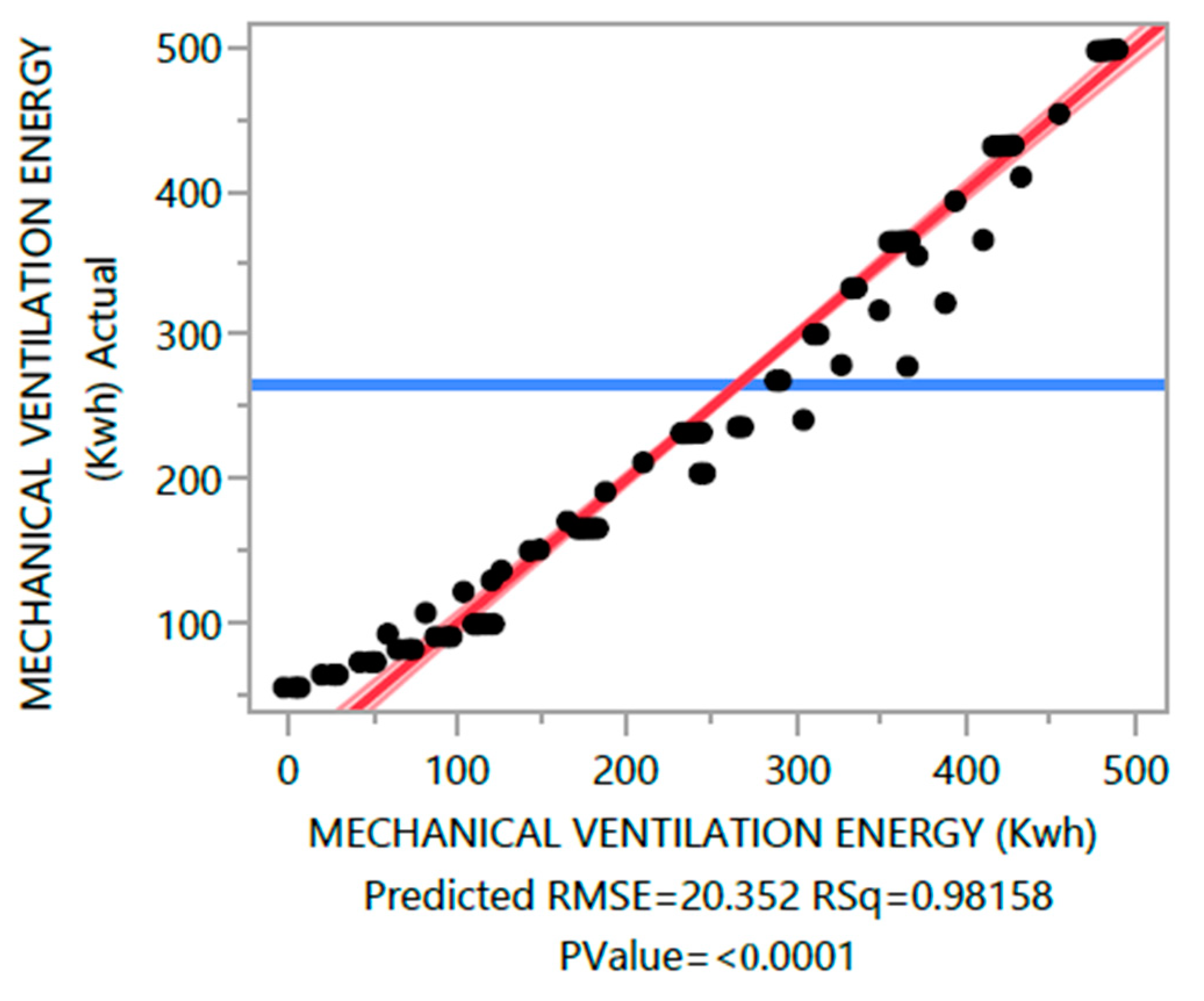

3.2.1. Least Fit of Squares Analysis

3.2.2. Analysis of Variance (ANOVA)

3.2.3. Parameter Estimates

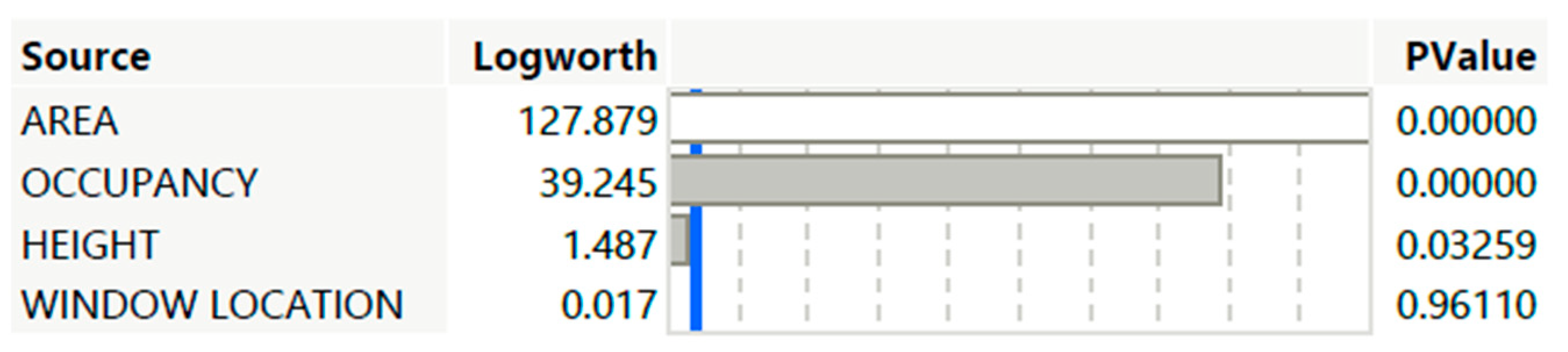

3.2.4. Effect Test

3.2.5. Simplified Predictive Model Generation

- North: 1.740;

- East: 0.837;

- South: −0.453;

- West: −0.449.

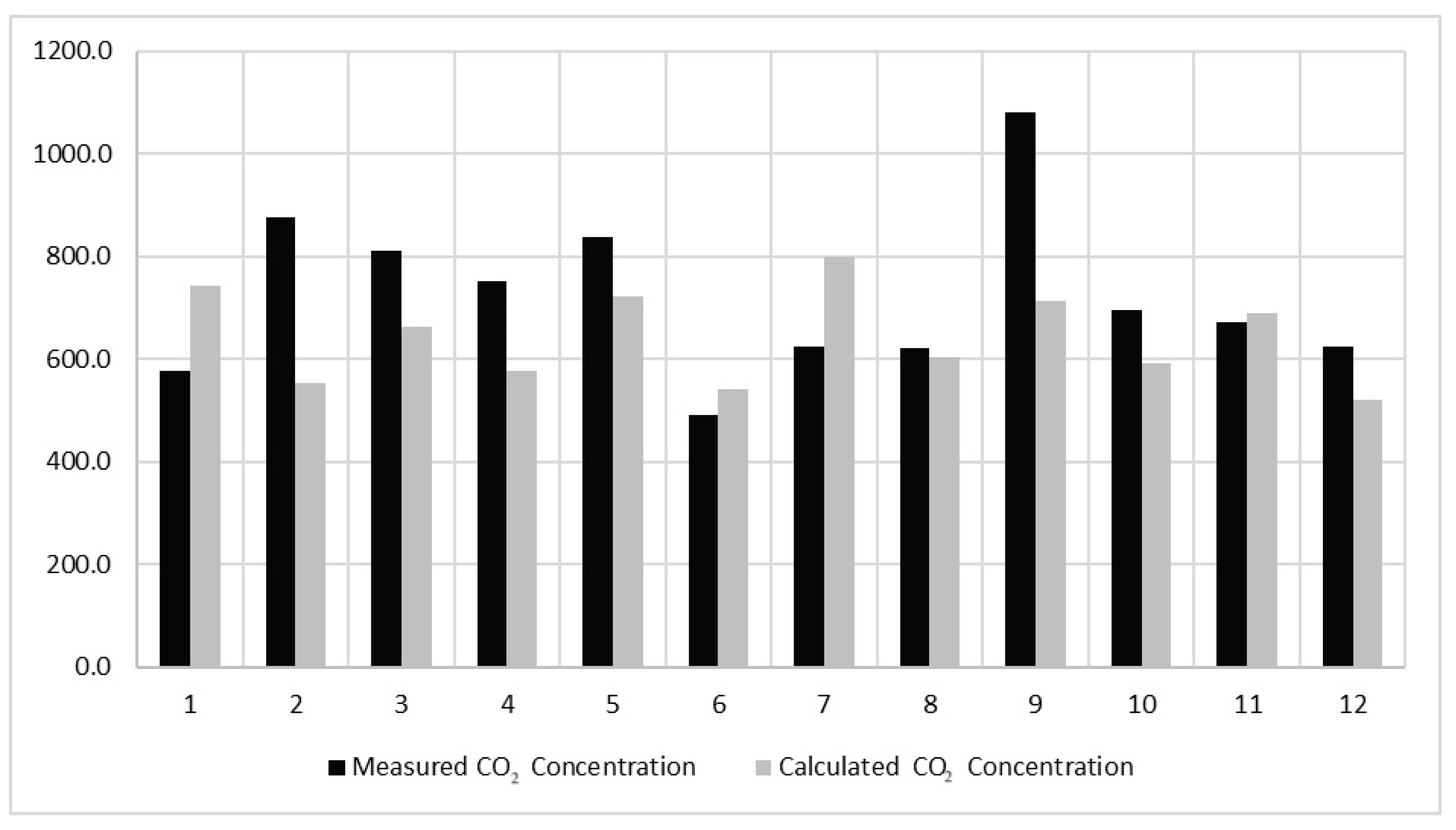

3.3. Sensitivity Analysis and Model Validation

3.3.1. Occupancy and CO2 Concentrations

3.3.2. CO2 Levels

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

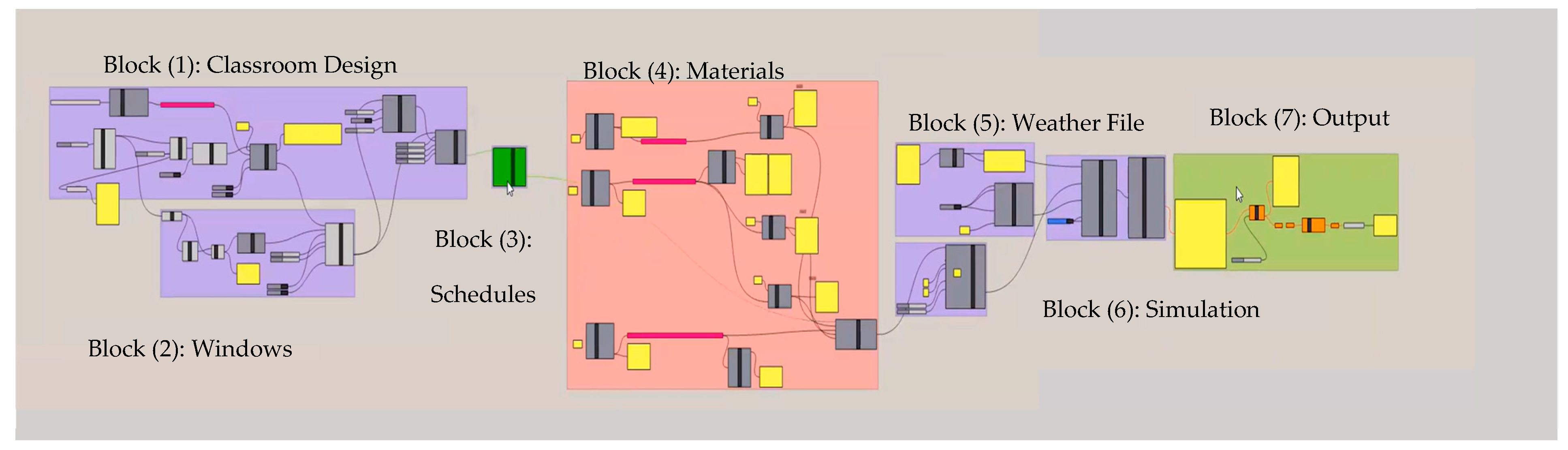

Appendix A. Parametric Model on Grasshopper

Appendix B. Actual Case Study of an HVAC System

Appendix C. Simulation Log

| # | Area (m2) | Height (m) | V (m3) | Glazing | Vent per Area | Occupancy (m2/Person) | Window Location | Mech. Vent. Energy (kWh) | Occupancy (Number) | Ventilation (m3/s) | Infiltration (m3/h) | Ventilation (m3/h) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 30 | 5 | 150 | 5.48 | 0.003 | 0.5 | N | 99.456375 | 15 | 0.09 | 52.5 | 324.00 |

| 2 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0.5 | N | 99.347542 | 15 | 0.09 | 36.75 | 324.00 |

| 3 | 30 | 4 | 120 | 5.48 | 0.003 | 0.5 | N | 99.380419 | 15 | 0.09 | 42 | 324.00 |

| 4 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0.5 | N | 99.416624 | 15 | 0.09 | 47.25 | 324.00 |

| 5 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0.5 | W | 99.349291 | 15 | 0.09 | 36.75 | 324.00 |

| 6 | 30 | 4 | 120 | 5.48 | 0.003 | 0.5 | W | 99.382889 | 15 | 0.09 | 42 | 324.00 |

| 7 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0.5 | W | 99.418808 | 15 | 0.09 | 47.25 | 324.00 |

| 8 | 30 | 5 | 150 | 5.48 | 0.003 | 0.5 | W | 99.458421 | 15 | 0.09 | 52.5 | 324.00 |

| 9 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0.5 | S | 99.345502 | 15 | 0.09 | 36.75 | 324.00 |

| 10 | 30 | 4 | 120 | 5.48 | 0.003 | 0.5 | S | 99.378382 | 15 | 0.09 | 42 | 324.00 |

| 11 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0.5 | S | 99.414593 | 15 | 0.09 | 47.25 | 324.00 |

| 12 | 30 | 5 | 150 | 5.48 | 0.003 | 0.5 | S | 99.454242 | 15 | 0.09 | 52.5 | 324.00 |

| 13 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0.5 | E | 99.333968 | 15 | 0.09 | 36.75 | 324.00 |

| 14 | 30 | 4 | 120 | 5.48 | 0.003 | 0.5 | E | 99.373617 | 15 | 0.09 | 42 | 324.00 |

| 15 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0.5 | E | 99.409878 | 15 | 0.09 | 47.25 | 324.00 |

| 16 | 30 | 5 | 150 | 5.48 | 0.003 | 0.5 | E | 99.446569 | 15 | 0.09 | 52.5 | 324.00 |

| 17 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0 | E | 55.394252 | 0 | 0.09 | 36.75 | 324.00 |

| 18 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0.1 | E | 64.194788 | 3 | 0.09 | 36.75 | 324.00 |

| 19 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0.2 | E | 72.988097 | 6 | 0.09 | 36.75 | 324.00 |

| 20 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0.3 | E | 81.77624 | 9 | 0.09 | 36.75 | 324.00 |

| 21 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0.4 | E | 90.557812 | 12 | 0.09 | 36.75 | 324.00 |

| 22 | 30 | 3.5 | 105 | 5.48 | 0.003 | 0.5 | E | 99.333968 | 15 | 0.09 | 36.75 | 324.00 |

| 23 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0 | E | 55.39301 | 0 | 0.09 | 47.25 | 324.00 |

| 24 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0.1 | E | 64.206429 | 3 | 0.09 | 47.25 | 324.00 |

| 25 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0.2 | E | 73.014132 | 6 | 0.09 | 47.25 | 324.00 |

| 26 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0.3 | E | 81.817604 | 9 | 0.09 | 47.25 | 324.00 |

| 27 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0.4 | E | 90.616154 | 12 | 0.09 | 47.25 | 324.00 |

| 28 | 30 | 4.5 | 135 | 5.48 | 0.003 | 0.5 | E | 99.409878 | 15 | 0.09 | 47.25 | 324.00 |

| 29 | 30 | 5 | 150 | 5.48 | 0.003 | 0 | E | 55.395737 | 0 | 0.09 | 52.5 | 324.00 |

| 30 | 30 | 5 | 150 | 5.48 | 0.003 | 0.1 | E | 64.215187 | 3 | 0.09 | 52.5 | 324.00 |

| 31 | 30 | 5 | 150 | 5.48 | 0.003 | 0.2 | E | 73.030106 | 6 | 0.09 | 52.5 | 324.00 |

| 32 | 30 | 5 | 150 | 5.48 | 0.003 | 0.3 | E | 81.839603 | 9 | 0.09 | 52.5 | 324.00 |

| 33 | 30 | 5 | 150 | 5.48 | 0.003 | 0.4 | E | 90.645351 | 12 | 0.09 | 52.5 | 324.00 |

| 34 | 30 | 5 | 150 | 5.48 | 0.003 | 0.5 | E | 99.446569 | 15 | 0.09 | 52.5 | 324.00 |

| 35 | 50 | 5 | 250 | 7.07 | 0.003 | 0.5 | N | 165.935582 | 25 | 0.15 | 87.5 | 540.00 |

| 36 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.5 | N | 165.706857 | 25 | 0.15 | 61.25 | 540.00 |

| 37 | 50 | 4 | 200 | 7.07 | 0.003 | 0.5 | N | 165.780357 | 25 | 0.15 | 70 | 540.00 |

| 38 | 50 | 4.5 | 225 | 7.07 | 0.003 | 0.5 | N | 165.854101 | 25 | 0.15 | 78.75 | 540.00 |

| 39 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.5 | W | 165.708247 | 25 | 0.15 | 61.25 | 540.00 |

| 40 | 50 | 4 | 200 | 7.07 | 0.003 | 0.5 | W | 165.781952 | 25 | 0.15 | 70 | 540.00 |

| 41 | 50 | 4.5 | 225 | 7.07 | 0.003 | 0.5 | W | 165.855924 | 25 | 0.15 | 78.75 | 540.00 |

| 42 | 50 | 5 | 250 | 7.07 | 0.003 | 0.5 | W | 165.937674 | 25 | 0.15 | 87.5 | 540.00 |

| 43 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.5 | S | 165.704227 | 25 | 0.15 | 61.25 | 540.00 |

| 44 | 50 | 4 | 200 | 7.07 | 0.003 | 0.5 | S | 165.776672 | 25 | 0.15 | 70 | 540.00 |

| 45 | 50 | 4.5 | 225 | 7.07 | 0.003 | 0.5 | S | 165.851337 | 25 | 0.15 | 78.75 | 540.00 |

| 46 | 50 | 5 | 250 | 7.07 | 0.003 | 0.5 | S | 165.93283 | 25 | 0.15 | 87.5 | 540.00 |

| 47 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.5 | E | 165.699277 | 25 | 0.15 | 61.25 | 540.00 |

| 48 | 50 | 4 | 200 | 7.07 | 0.003 | 0.5 | E | 165.776301 | 25 | 0.15 | 70 | 540.00 |

| 49 | 50 | 4.5 | 225 | 7.07 | 0.003 | 0.5 | E | 165.851709 | 25 | 0.15 | 78.75 | 540.00 |

| 50 | 50 | 5 | 250 | 7.07 | 0.003 | 0.5 | E | 165.928939 | 25 | 0.15 | 87.5 | 540.00 |

| 51 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0 | E | 92.523592 | 0 | 0.15 | 61.25 | 540.00 |

| 52 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.1 | E | 107.184297 | 5 | 0.15 | 61.25 | 540.00 |

| 53 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.2 | E | 121.829663 | 10 | 0.15 | 61.25 | 540.00 |

| 54 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.3 | E | 136.465162 | 15 | 0.15 | 61.25 | 540.00 |

| 55 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.4 | E | 151.088121 | 20 | 0.15 | 61.25 | 540.00 |

| 56 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.5 | E | 165.699277 | 25 | 0.15 | 61.25 | 540.00 |

| 57 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0 | E | 92.523592 | 0 | 0.15 | 61.25 | 540.00 |

| 58 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.1 | E | 107.184297 | 5 | 0.15 | 61.25 | 540.00 |

| 59 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.2 | E | 121.829663 | 10 | 0.15 | 61.25 | 540.00 |

| 60 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.3 | E | 136.465162 | 15 | 0.15 | 61.25 | 540.00 |

| 61 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.4 | E | 151.088121 | 20 | 0.15 | 61.25 | 540.00 |

| 62 | 50 | 3.5 | 175 | 7.07 | 0.003 | 0.5 | E | 165.699277 | 25 | 0.15 | 61.25 | 540.00 |

| 63 | 70 | 5 | 350 | 8.37 | 0.003 | 0.5 | N | 232.429805 | 35 | 0.21 | 122.5 | 756.00 |

| 64 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0.5 | N | 232.065867 | 35 | 0.21 | 85.75 | 756.00 |

| 65 | 70 | 4 | 280 | 8.37 | 0.003 | 0.5 | N | 232.185658 | 35 | 0.21 | 98 | 756.00 |

| 66 | 70 | 4.5 | 315 | 8.37 | 0.003 | 0.5 | N | 232.30669 | 35 | 0.21 | 110.25 | 756.00 |

| 67 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0.5 | W | 232.066975 | 35 | 0.21 | 85.75 | 756.00 |

| 68 | 70 | 4 | 280 | 8.37 | 0.003 | 0.5 | W | 232.187003 | 35 | 0.21 | 98 | 756.00 |

| 69 | 70 | 4.5 | 315 | 8.37 | 0.003 | 0.5 | W | 232.306836 | 35 | 0.21 | 110.25 | 756.00 |

| 70 | 70 | 5 | 350 | 8.37 | 0.003 | 0.5 | W | 232.431537 | 35 | 0.21 | 122.5 | 756.00 |

| 71 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0.5 | S | 232.062849 | 35 | 0.21 | 85.75 | 756.00 |

| 72 | 70 | 4 | 280 | 8.37 | 0.003 | 0.5 | S | 232.182547 | 35 | 0.21 | 98 | 756.00 |

| 73 | 70 | 4.5 | 315 | 8.37 | 0.003 | 0.5 | S | 232.30209 | 35 | 0.21 | 110.25 | 756.00 |

| 74 | 70 | 5 | 350 | 8.37 | 0.003 | 0.5 | S | 232.422452 | 35 | 0.21 | 122.5 | 756.00 |

| 75 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0.5 | E | 232.061082 | 35 | 0.21 | 85.75 | 756.00 |

| 76 | 70 | 4 | 280 | 8.37 | 0.003 | 0.5 | E | 232.179658 | 35 | 0.21 | 98 | 756.00 |

| 77 | 70 | 4.5 | 315 | 8.37 | 0.003 | 0.5 | E | 232.30081 | 35 | 0.21 | 110.25 | 756.00 |

| 78 | 70 | 5 | 350 | 8.37 | 0.003 | 0.5 | E | 232.422629 | 35 | 0.21 | 122.5 | 756.00 |

| 79 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0 | E | 129.674876 | 0 | 0.21 | 85.75 | 756.00 |

| 80 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0.1 | E | 150.191721 | 7 | 0.21 | 85.75 | 756.00 |

| 81 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0.2 | E | 170.685195 | 14 | 0.21 | 85.75 | 756.00 |

| 82 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0.3 | E | 191.161827 | 21 | 0.21 | 85.75 | 756.00 |

| 83 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0.4 | E | 211.621263 | 28 | 0.21 | 85.75 | 756.00 |

| 84 | 70 | 3.5 | 245 | 8.37 | 0.003 | 0.5 | E | 232.061082 | 35 | 0.21 | 85.75 | 756.00 |

| 85 | 110 | 5 | 550 | 10.49 | 0.003 | 0.5 | N | 365.421861 | 55 | 0.33 | 192.5 | 1188.00 |

| 86 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0.5 | N | 364.776239 | 55 | 0.33 | 134.75 | 1188.00 |

| 87 | 110 | 4 | 440 | 10.49 | 0.003 | 0.5 | N | 364.986756 | 55 | 0.33 | 154 | 1188.00 |

| 88 | 110 | 4.5 | 495 | 10.49 | 0.003 | 0.5 | N | 365.203369 | 55 | 0.33 | 173.25 | 1188.00 |

| 89 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0.5 | W | 364.77453 | 55 | 0.33 | 134.75 | 1188.00 |

| 90 | 110 | 4 | 440 | 10.49 | 0.003 | 0.5 | W | 364.991718 | 55 | 0.33 | 154 | 1188.00 |

| 91 | 110 | 4.5 | 495 | 10.49 | 0.003 | 0.5 | W | 365.204406 | 55 | 0.33 | 173.25 | 1188.00 |

| 92 | 110 | 5 | 550 | 10.49 | 0.003 | 0.5 | W | 365.421019 | 55 | 0.33 | 192.5 | 1188.00 |

| 93 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0.5 | S | 364.77031 | 55 | 0.33 | 134.75 | 1188.00 |

| 94 | 110 | 4 | 440 | 10.49 | 0.003 | 0.5 | S | 364.983043 | 55 | 0.33 | 154 | 1188.00 |

| 95 | 110 | 4.5 | 495 | 10.49 | 0.003 | 0.5 | S | 365.199504 | 55 | 0.33 | 173.25 | 1188.00 |

| 96 | 110 | 5 | 550 | 10.49 | 0.003 | 0.5 | S | 365.417884 | 55 | 0.33 | 192.5 | 1188.00 |

| 97 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0.5 | E | 364.771001 | 55 | 0.33 | 134.75 | 1188.00 |

| 98 | 110 | 4 | 440 | 10.49 | 0.003 | 0.5 | E | 364.986002 | 55 | 0.33 | 154 | 1188.00 |

| 99 | 110 | 4.5 | 495 | 10.49 | 0.003 | 0.5 | E | 365.201258 | 55 | 0.33 | 173.25 | 1188.00 |

| 100 | 110 | 5 | 550 | 10.49 | 0.003 | 0.5 | E | 365.416269 | 55 | 0.33 | 192.5 | 1188.00 |

| 101 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0 | E | 204.01407 | 0 | 0.33 | 134.75 | 1188.00 |

| 102 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0.1 | E | 236.234717 | 11 | 0.33 | 134.75 | 1188.00 |

| 103 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0.2 | E | 268.416684 | 22 | 0.33 | 134.75 | 1188.00 |

| 104 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0.3 | E | 300.567908 | 33 | 0.33 | 134.75 | 1188.00 |

| 105 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0.4 | E | 332.685749 | 44 | 0.33 | 134.75 | 1188.00 |

| 106 | 110 | 3.5 | 385 | 10.49 | 0.003 | 0.5 | E | 364.771001 | 55 | 0.33 | 134.75 | 1188.00 |

| 107 | 110 | 4 | 440 | 10.49 | 0.003 | 0 | E | 204.068733 | 0 | 0.33 | 154 | 1188.00 |

| 108 | 110 | 4 | 440 | 10.49 | 0.003 | 0.1 | E | 236.313743 | 11 | 0.33 | 154 | 1188.00 |

| 109 | 110 | 4 | 440 | 10.49 | 0.003 | 0.2 | E | 268.526533 | 22 | 0.33 | 154 | 1188.00 |

| 110 | 110 | 4 | 440 | 10.49 | 0.003 | 0.3 | E | 300.711562 | 33 | 0.33 | 154 | 1188.00 |

| 111 | 110 | 4 | 440 | 10.49 | 0.003 | 0.4 | E | 332.864193 | 44 | 0.33 | 154 | 1188.00 |

| 112 | 110 | 4 | 440 | 10.49 | 0.003 | 0.5 | E | 364.986002 | 55 | 0.33 | 154 | 1188.00 |

| 113 | 130 | 5 | 650 | 11.40 | 0.003 | 0.5 | N | 431.91331 | 65 | 0.39 | 227.5 | 1404.00 |

| 114 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0.5 | N | 431.12554 | 65 | 0.39 | 159.25 | 1404.00 |

| 115 | 130 | 4 | 520 | 11.40 | 0.003 | 0.5 | N | 431.392029 | 65 | 0.39 | 182 | 1404.00 |

| 116 | 130 | 4.5 | 585 | 11.40 | 0.003 | 0.5 | N | 431.65122 | 65 | 0.39 | 204.75 | 1404.00 |

| 117 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0.5 | W | 431.123197 | 65 | 0.39 | 159.25 | 1404.00 |

| 118 | 130 | 4 | 520 | 11.40 | 0.003 | 0.5 | W | 431.387844 | 65 | 0.39 | 182 | 1404.00 |

| 119 | 130 | 4.5 | 585 | 11.40 | 0.003 | 0.5 | W | 431.652072 | 65 | 0.39 | 204.75 | 1404.00 |

| 120 | 130 | 5 | 650 | 11.40 | 0.003 | 0.5 | W | 431.911875 | 65 | 0.39 | 227.5 | 1404.00 |

| 121 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0.5 | S | 431.118957 | 65 | 0.39 | 159.25 | 1404.00 |

| 122 | 130 | 4 | 520 | 11.40 | 0.003 | 0.5 | S | 431.383241 | 65 | 0.39 | 182 | 1404.00 |

| 123 | 130 | 4.5 | 585 | 11.40 | 0.003 | 0.5 | S | 431.647121 | 65 | 0.39 | 204.75 | 1404.00 |

| 124 | 130 | 5 | 650 | 11.40 | 0.003 | 0.5 | S | 431.909052 | 65 | 0.39 | 227.5 | 1404.00 |

| 125 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0.5 | E | 431.120509 | 65 | 0.39 | 159.25 | 1404.00 |

| 126 | 130 | 4 | 520 | 11.40 | 0.003 | 0.5 | E | 431.387716 | 65 | 0.39 | 182 | 1404.00 |

| 127 | 130 | 4.5 | 585 | 11.40 | 0.003 | 0.5 | E | 431.647724 | 65 | 0.39 | 204.75 | 1404.00 |

| 128 | 130 | 5 | 650 | 11.40 | 0.003 | 0.5 | E | 431.9086 | 65 | 0.39 | 227.5 | 1404.00 |

| 129 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0 | E | 241.196055 | 0 | 0.39 | 159.25 | 1404.00 |

| 130 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0.1 | E | 279.263922 | 13 | 0.39 | 159.25 | 1404.00 |

| 131 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0.2 | E | 317.288769 | 26 | 0.39 | 159.25 | 1404.00 |

| 132 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0.3 | E | 355.273763 | 39 | 0.39 | 159.25 | 1404.00 |

| 133 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0.4 | E | 393.217346 | 52 | 0.39 | 159.25 | 1404.00 |

| 134 | 130 | 3.5 | 455 | 11.40 | 0.003 | 0.5 | E | 431.120509 | 65 | 0.39 | 159.25 | 1404.00 |

| 135 | 150 | 5 | 750 | 12.25 | 0.003 | 0.5 | N | 498.406658 | 75 | 0.45 | 262.5 | 1620.00 |

| 136 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.5 | N | 497.472386 | 75 | 0.45 | 183.75 | 1620.00 |

| 137 | 150 | 4 | 600 | 12.25 | 0.003 | 0.5 | N | 497.781796 | 75 | 0.45 | 210 | 1620.00 |

| 138 | 150 | 4.5 | 675 | 12.25 | 0.003 | 0.5 | N | 498.094218 | 75 | 0.45 | 236.25 | 1620.00 |

| 139 | 150 | 5 | 750 | 12.25 | 0.003 | 0.5 | N | 498.406658 | 75 | 0.45 | 262.5 | 1620.00 |

| 140 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.5 | N | 497.472386 | 75 | 0.45 | 183.75 | 1620.00 |

| 141 | 150 | 4 | 600 | 12.25 | 0.003 | 0.5 | N | 497.781796 | 75 | 0.45 | 210 | 1620.00 |

| 142 | 150 | 4.5 | 675 | 12.25 | 0.003 | 0.5 | N | 498.094218 | 75 | 0.45 | 236.25 | 1620.00 |

| 143 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.5 | W | 497.472322 | 75 | 0.45 | 183.75 | 1620.00 |

| 144 | 150 | 4 | 600 | 12.25 | 0.003 | 0.5 | W | 497.782294 | 75 | 0.45 | 210 | 1620.00 |

| 145 | 150 | 4.5 | 675 | 12.25 | 0.003 | 0.5 | W | 498.094864 | 75 | 0.45 | 236.25 | 1620.00 |

| 146 | 150 | 5 | 750 | 12.25 | 0.003 | 0.5 | W | 498.40161 | 75 | 0.45 | 262.5 | 1620.00 |

| 147 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.5 | S | 497.465197 | 75 | 0.45 | 183.75 | 1620.00 |

| 148 | 150 | 4 | 600 | 12.25 | 0.003 | 0.5 | S | 497.77766 | 75 | 0.45 | 210 | 1620.00 |

| 149 | 150 | 4.5 | 675 | 12.25 | 0.003 | 0.5 | S | 498.089904 | 75 | 0.45 | 236.25 | 1620.00 |

| 150 | 150 | 5 | 750 | 12.25 | 0.003 | 0.5 | S | 498.399117 | 75 | 0.45 | 262.5 | 1620.00 |

| 151 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.5 | E | 497.466408 | 75 | 0.45 | 183.75 | 1620.00 |

| 152 | 150 | 4 | 600 | 12.25 | 0.003 | 0.5 | E | 497.783577 | 75 | 0.45 | 210 | 1620.00 |

| 153 | 150 | 4.5 | 675 | 12.25 | 0.003 | 0.5 | E | 498.09154 | 75 | 0.45 | 236.25 | 1620.00 |

| 154 | 150 | 5 | 750 | 12.25 | 0.003 | 0.5 | E | 498.397156 | 75 | 0.45 | 262.5 | 1620.00 |

| 155 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0 | E | 278.382222 | 0 | 0.45 | 183.75 | 1620.00 |

| 156 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.1 | E | 322.298688 | 15 | 0.45 | 183.75 | 1620.00 |

| 157 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.2 | E | 366.159428 | 30 | 0.45 | 183.75 | 1620.00 |

| 158 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.3 | E | 409.980488 | 45 | 0.45 | 183.75 | 1620.00 |

| 159 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.4 | E | 453.747715 | 60 | 0.45 | 183.75 | 1620.00 |

| 160 | 150 | 3.5 | 525 | 12.25 | 0.003 | 0.5 | E | 497.466408 | 75 | 0.45 | 183.75 | 1620.00 |

References

- Adeleke, J.; Moodley, D. An Ontology for Proactive Indoor Environmental Quality Monitoring and Control. In Proceedings of the 2015 Annual Research Conference on South African Institute of Computer Scientists and Information Technologists, Stellenbosch, South Africa, 28 September 2015; pp. 1–10. [Google Scholar]

- Chen, S.; Zhang, G.; Xia, X.; Setunge, S.; Shi, L. A Review of Internal and External Influencing Factors on Energy Efficiency Design of Buildings. Energy Build. 2020, 216, 109944. [Google Scholar] [CrossRef]

- Almeida, R.M.S.F.; Pinto, M.; Pinho, P.G.; de Lemos, L.T. Natural Ventilation and Indoor Air Quality in Educational Buildings: Experimental Assessment and Improvement Strategies. Energy Effic. 2016, 10, 839–854. [Google Scholar] [CrossRef]

- Sadrizadeh, S.; Yao, R.; Yuan, F.; Awbi, H.; Bahnfleth, W.; Bi, Y.; Cao, G.; Croitoru, C.; de Dear, R.; Haghighat, F.; et al. Indoor Air Quality and Health in Schools: A Critical Review for Developing the Roadmap for the Future School Environment. J. Build. Eng. 2022, 57, 104908. [Google Scholar] [CrossRef]

- Asere, L.; Blumberga, A. Energy Efficiency—Indoor Air Quality Dilemma in Educational Buildings: A Possible Solution. Environ. Clim. Technol. 2020, 24, 357–367. [Google Scholar] [CrossRef]

- Settimo, G.; Avino, P. The Dichotomy between Indoor Air Quality and Energy Efficiency in Light of the Onset of the COVID-19 Pandemic. Atmosphere 2021, 12, 791. [Google Scholar] [CrossRef]

- ANSI/ASHRAE/IES Standard 90.1-2022 Changes. Available online: https://www.ashrae.org/technical-resources/bookstore/ansi-ashrae-ies-standard-90-1-2022-changes (accessed on 17 December 2023).

- Standards 62.1 & 62.2. Available online: https://www.ashrae.org/technical-resources/bookstore/standards-62-1-62-2 (accessed on 23 September 2021).

- CDC Coronavirus Disease 2019 (COVID-19). Available online: https://www.cdc.gov/coronavirus/2019-ncov/communication/guidance-list.html (accessed on 23 September 2021).

- U.S. Environmental Protection Agency. Science and Technical Resources Related to Indoor Air and Coronavirus (COVID-19). Available online: https://www.epa.gov/coronavirus/science-and-technical-resources-related-indoor-air-and-coronavirus-covid-19 (accessed on 12 August 2021).

- REHVA. Available online: https://www.rehva.eu/about-us/who-we-are/about-rehva (accessed on 23 September 2021).

- WHO Technical Guidance. Available online: https://www.who.int/emergencies/diseases/novel-coronavirus-2019/technical-guidance (accessed on 23 September 2021).

- Ma’bdeh, S.N.; Al-Zghoul, A.; Alradaideh, T.; Bataineh, A.; Ahmad, S. Simulation Study for Natural Ventilation Retrofitting Techniques in Educational Classrooms—A Case Study. Heliyon 2020, 6, e05171. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.-R.; Han, J.; Chen, X.; Li, Q.-Y.; Lee, C.-C.; Fung, Y.-H. Interaction between Thermal Comfort, Indoor Air Quality and Ventilation Energy Consumption of Educational Buildings: A Comprehensive Review. Buildings 2021, 11, 591. [Google Scholar] [CrossRef]

- de la Hoz-Torres, M.L.; Aguilar, A.J.; Ruiz, D.P.; Martínez-Aires, M.D. Analysis of Impact of Natural Ventilation Strategies in Ventilation Rates and Indoor Environmental Acoustics Using Sensor Measurement Data in Educational Buildings. Sensors 2021, 21, 6122. [Google Scholar] [CrossRef] [PubMed]

- McLeod, R.S.; Mathew, M.; Salman, D.; Thomas, C.L.P. An Investigation of Indoor Air Quality in a Recently Refurbished Educational Building. Front. Built Environ. 2022, 7, 769761. [Google Scholar] [CrossRef]

- Underhill, L.J.; Dols, W.S.; Lee, S.K.; Fabian, M.P.; Levy, J.I. Quantifying the Impact of Housing Interventions on Indoor Air Quality and Energy Consumption Using Coupled Simulation Models. J. Expo. Sci. Amp. Environ. Epidemiol. 2020, 30, 436–447. [Google Scholar] [CrossRef]

- Chen, Y.; Gu, L.; Zhang, J. EnergyPlus and CHAMPS-Multizone Co-Simulation for Energy and Indoor Air Quality Analysis. Build. Simul. 2015, 8, 371–380. [Google Scholar] [CrossRef]

- Cony-Renaud-Salis, L.; Belhaj, N.; Ramalho, O.; Abadie, M. Analysis of the Need of Detailed Modelling for the Assessment of Indoor Air Quality in Residential Buildings. E3S Web Conf. 2019, 111, 04043. [Google Scholar] [CrossRef]

- Yang, L.; Ye, M.; He, B.-J. CFD Simulation Research on Residential Indoor Air Quality. Sci. Total Environ. 2014, 472, 1137–1144. [Google Scholar] [CrossRef] [PubMed]

- Heibati, S.; Maref, W.; Saber, H.H. Assessing the Energy and Indoor Air Quality Performance for a Three-Story Building Using an Integrated Model, Part One: The Need for Integration. Energies 2019, 12, 4775. [Google Scholar] [CrossRef]

- Ma, M.; Cao, C.; Xu, Y.; Liu, Z.; Zeng, L.; Zhang, C.; Gao, J. Using CONTAM to Design Ventilation Strategy of Negative Pressure Isolation Ward Considering Different Height of Door Gaps. Energy Built Environ. 2024, 5, 32–45. [Google Scholar] [CrossRef]

- Dols, W.S.; Polidoro, B.J. CONTAM User Guide and Program Documentation Version 3.2; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015; p. 12. [Google Scholar]

- Kim, M.K.; Choi, J.-H. Can Increased Outdoor CO2 Concentrations Impact on the Ventilation and Energy in Buildings? A Case Study in Shanghai, China. Atmos. Environ. 2019, 210, 220–230. [Google Scholar] [CrossRef]

- Zhang, H.; Srinivasan, R.; Yang, X. Simulation and Analysis of Indoor Air Quality in Florida Using Time Series Regression (TSR) and Artificial Neural Networks (ANN) Models. Symmetry 2021, 13, 952. [Google Scholar] [CrossRef]

- Berouine, A.; Ouladsine, R.; Bakhouya, M.; Essaaidi, M. Towards a Real-Time Predictive Management Approach of Indoor Air Quality in Energy-Efficient Buildings. Energies 2020, 13, 3246. [Google Scholar] [CrossRef]

- Ibrahim, D.M.; Almhafdy, A.; Al-Shargabi, A.A.; Alghieth, M.; Elragi, A.; Chiclana, F. The Use of Statistical and Machine Learning Tools to Accurately Quantify the Energy Performance of Residential Buildings. PeerJ Comput. Sci. 2022, 8, e856. [Google Scholar] [CrossRef]

- Jindal, A.; Kumar, N.; Rodrigues, J.J.P.C. A Heuristic-Based Smart HVAC Energy Management Scheme for University Buildings. IEEE Trans. Ind. Inform. 2018, 14, 5074–5086. [Google Scholar] [CrossRef]

- Shea, R.P.; Kissock, K.; Selvacanabady, A. Reducing University Air Handling Unit Energy Usage through Controls-Based Energy Efficiency Measures. Energy Build. 2019, 194, 105–112. [Google Scholar] [CrossRef]

- Justo Alonso, M.; Dols, W.S.; Mathisen, H.M. Using Co-Simulation between EnergyPlus and CONTAM to Evaluate Recirculation-Based, Demand-Controlled Ventilation Strategies in an Office Building. Build. Environ. 2022, 211, 108737. [Google Scholar] [CrossRef]

- Pastor-Fernández, A.; Cerezo-Narváez, A.; Montero-Gutiérrez, P.; Ballesteros-Pérez, P.; Otero-Mateo, M. Use of Low-Cost Devices for the Control and Monitoring of CO2 Concentration in Existing Buildings after the COVID Era. Appl. Sci. 2022, 12, 3927. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, H.; Lin, B.; Yu, J. Real-Time Monitoring and Controlling Strategies of Indoor Environment in the Frontline Hospitals during COVID-19 Pandemic. Chin. Sci. Bull. 2021, 66, 424–432. [Google Scholar] [CrossRef]

- Scislo, L.; Szczepanik-Scislo, N. Near Real-Time Access Monitoring Based on IoT Dynamic Measurements of Indoor Air Pollutant. In Proceedings of the 2023 IEEE 12th International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS), Dortmund, Germany, 7–9 September 2023; IEEE: Dortmund, Germany, 2023; pp. 729–734. [Google Scholar]

- Todeschi, V.; Boghetti, R.; Kämpf, J.H.; Mutani, G. Evaluation of Urban-Scale Building Energy-Use Models and Tools—Application for the City of Fribourg, Switzerland. Sustainability 2021, 13, 1595. [Google Scholar] [CrossRef]

- Hong, T.; Chen, Y.; Luo, X.; Luo, N.; Lee, S.H. Ten Questions on Urban Building Energy Modeling. Build. Environ. 2020, 168, 106508. [Google Scholar] [CrossRef]

- Chatzidiakou, L.; Archer, R.; Beale, V.; Bland, S.; Carter, H.; Castro-Faccetti, C.; Edwards, H.; Finneran, J.; Hama, S.; Jones, R.L.; et al. Schools’ Air Quality Monitoring for Health and Education: Methods and Protocols of the SAMHE Initiative and Project. Dev. Built Environ. 2023, 16, 100266. [Google Scholar] [CrossRef]

- Zagatti, E.; Russo, M.; Pietrogrande, M.C. On-Site Monitoring Indoor Air Quality in Schools: A Real-World Investigation to Engage High School Science Students. J. Chem. Educ. 2020, 97, 4069–4072. [Google Scholar] [CrossRef]

- Zauli-Sajani, S.; Marchesi, S.; Boselli, G.; Broglia, E.; Angella, A.; Maestri, E.; Marmiroli, N.; Colacci, A. Effectiveness of a Protocol to Reduce Children’s Exposure to Particulate Matter and NO2 in Schools during Alert Days. Int. J. Environ. Res. Public Health 2022, 19, 11019. [Google Scholar] [CrossRef]

- Heydon, J.; Chakraborty, R. Can Portable Air Quality Monitors Protect Children from Air Pollution on the School Run? An Exploratory Study. Env. Monit. Assess. 2020, 192, 195. [Google Scholar] [CrossRef]

- Chitaru, G.-M.; Istrate, A.; Catalina, T. Numerical Analysis of the Impact of Natural Ventilation on the Indoor Air Quality and Thermal Comfort in a Classroom. E3S Web Conf. 2019, 111, 01023. [Google Scholar] [CrossRef]

- Abdel-Salam, M.M.M. Investigation of Indoor Air Quality at Urban Schools in Qatar. Indoor Built Environ. 2019, 28, 278–288. [Google Scholar] [CrossRef]

- Kapalo, P.; Klymenko, H.; Zhelykh, V.; Adamski, M. Investigation of Indoor Air Quality in the Selected Ukraine Classroom—Case Study. In Proceedings of the CEE 2019; Blikharskyy, Z., Koszelnik, P., Mesaros, P., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 168–173. [Google Scholar]

- Associates, R.M. Rhinoceros 3D. Available online: https://www.rhino3d.com/ (accessed on 28 January 2024).

- Standard 90.1-2007; Energy Standard for Buildings Except Low-Rise Residential Buildings. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Peachtree Corners, GA, USA, 2007.

- Statistical Software. Available online: https://www.jmp.com/en_us/home.html (accessed on 23 January 2024).

- Standard Least Squares Models. Available online: https://www.jmp.com/support/help/en/17.2/index.shtml#page/jmp/standard-least-squares-models.shtml (accessed on 23 January 2024).

- Least Squares Method: What It Means, How to Use It, with Examples. Available online: https://www.investopedia.com/terms/l/least-squares-method.asp (accessed on 23 January 2024).

- Greenwood, M.; Banner, K. One-Way ANOVA Sums of Squares, Mean Squares, and F-Test—Mark Greenwood and Katharine Banner. Available online: https://arc.lib.montana.edu/book/statistics-with-r-textbook/item/56 (accessed on 10 June 2023).

- Schober, P.; Boer, C.; Schwarte, L.A. Correlation Coefficients: Appropriate Use and Interpretation. Anesth. Analg. 2018, 126, 1763. [Google Scholar] [CrossRef]

- Parameter Estimates > Linear Fit > Fit Model > Statistical Reference Guide|Analyse-It® 6.15 Documentation. Available online: https://analyse-it.com/docs/user-guide/fit-model/linear/parameter-estimates (accessed on 23 January 2024).

- Persily, A.; Polidoro, B.J. Indoor Carbon Dioxide Metric Analysis Tool; National Institute of Standards and Technology (U.S.): Gaithersburg, MD, USA, 2022; p. NIST TN 2213. [Google Scholar]

- Amazon.Com: Qingping Air Quality Monitor, Indoor Air Quality Meter Detects PM2.5, Temperature, CO2, and Humidity, Smart Air Quality Sensor for Bedroom, A Rechargeable Device with 2 Colors, Smart Home: Industrial & Scientific. Available online: https://www.amazon.com/Qingping-Monitor-Quality-Temperature-Humidity/dp/B0967TNJL4?th=1 (accessed on 19 February 2024).

- Cao, S.-J.; Deng, H.-Y. Investigation of Temperature Regulation Effects on Indoor Thermal Comfort, Air Quality, and Energy Savings toward Green Residential Buildings. Sci. Technol. Built Environ. 2019, 25, 309–321. [Google Scholar] [CrossRef]

- Anastasi, G.; Bartoli, C.; Conti, P.; Crisostomi, E.; Franco, A.; Saponara, S.; Testi, D.; Thomopulos, D.; Vallati, C. Optimized Energy and Air Quality Management of Shared Smart Buildings in the COVID-19 Scenario. Energies 2021, 14, 2124. [Google Scholar] [CrossRef]

- Balocco, C.; Leoncini, L. Energy Cost for Effective Ventilation and Air Quality for Healthy Buildings: Plant Proposals for a Historic Building School Reopening in the COVID-19 Era. Sustainability 2020, 12, 8737. [Google Scholar] [CrossRef]

- Azuma, K.; Yanagi, U.; Kagi, N.; Kim, H.; Ogata, M.; Hayashi, M. Environmental Factors Involved in SARS-CoV-2 Transmission: Effect and Role of Indoor Environmental Quality in the Strategy for COVID-19 Infection Control. Environ. Health Prev. Med. 2020, 25, 66. [Google Scholar] [CrossRef]

- Tzoutzas, I.; Maltezou, H.C.; Barmparesos, N.; Tasios, P.; Efthymiou, C.; Assimakopoulos, M.N.; Tseroni, M.; Vorou, R.; Tzermpos, F.; Antoniadou, M.; et al. Indoor Air Quality Evaluation Using Mechanical Ventilation and Portable Air Purifiers in an Academic Dentistry Clinic during the COVID-19 Pandemic in Greece. Int. J. Environ. Res. Public Health 2021, 18, 8886. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, N.; Meena, C.S.; Raj, B.P.; Saini, L.; Kumar, A.; Gopalakrishnan, N.; Kumar, A.; Balam, N.B.; Alam, T.; Kapoor, N.R.; et al. Indoor Air Quality Improvement in COVID-19 Pandemic: Review. Sustain. Cities Soc. 2021, 70, 102942. [Google Scholar] [CrossRef]

- Chihib, M.; Salmerón-Manzano, E.; Manzano-Agugliaro, F. Benchmarking Energy Use at University of Almeria (Spain). Sustainability 2020, 12, 1336. [Google Scholar] [CrossRef]

- Anand, P.; Cheong, D.; Sekhar, C. A Review of Occupancy-Based Building Energy and IEQ Controls and Its Future Post-COVID. Sci. Total Environ. 2022, 804, 150249. [Google Scholar] [CrossRef] [PubMed]

- Tahmasebi, F.; Wang, Y.; Cooper, E.; Godoy Shimizu, D.; Stamp, S.; Mumovic, D. Window Operation Behaviour and Indoor Air Quality during Lockdown: A Monitoring-Based Simulation-Assisted Study in London. Build. Serv. Eng. Res. Technol. 2022, 43, 5–21. [Google Scholar] [CrossRef]

- Mahdavi, A.; Bochukova, V.; Berger, C. A Pragmatic Theory of Occupants’ Indoor-Environmental Control Behaviour. Front. Sustain. Cities 2021, 3, 748288. [Google Scholar] [CrossRef]

- Litardo, J.; Hidalgo-Leon, R.; Soriano, G. Energy Performance and Benchmarking for University Classrooms in Hot and Humid Climates. Energies 2021, 14, 7013. [Google Scholar] [CrossRef]

- da Silva Costa, M.L.; Freire, M.R.; da Silva, K.F.; Freires, F.G.M. Analysis of Energy Consumption Related to the Use of Air Conditioning in University Buildings in a Tropical Climate. Rev. De Gestão Soc. E Ambient. 2022, 16, e03025. [Google Scholar] [CrossRef]

| Block No. | Title | Description | Reference Figures in Appendix A |

|---|---|---|---|

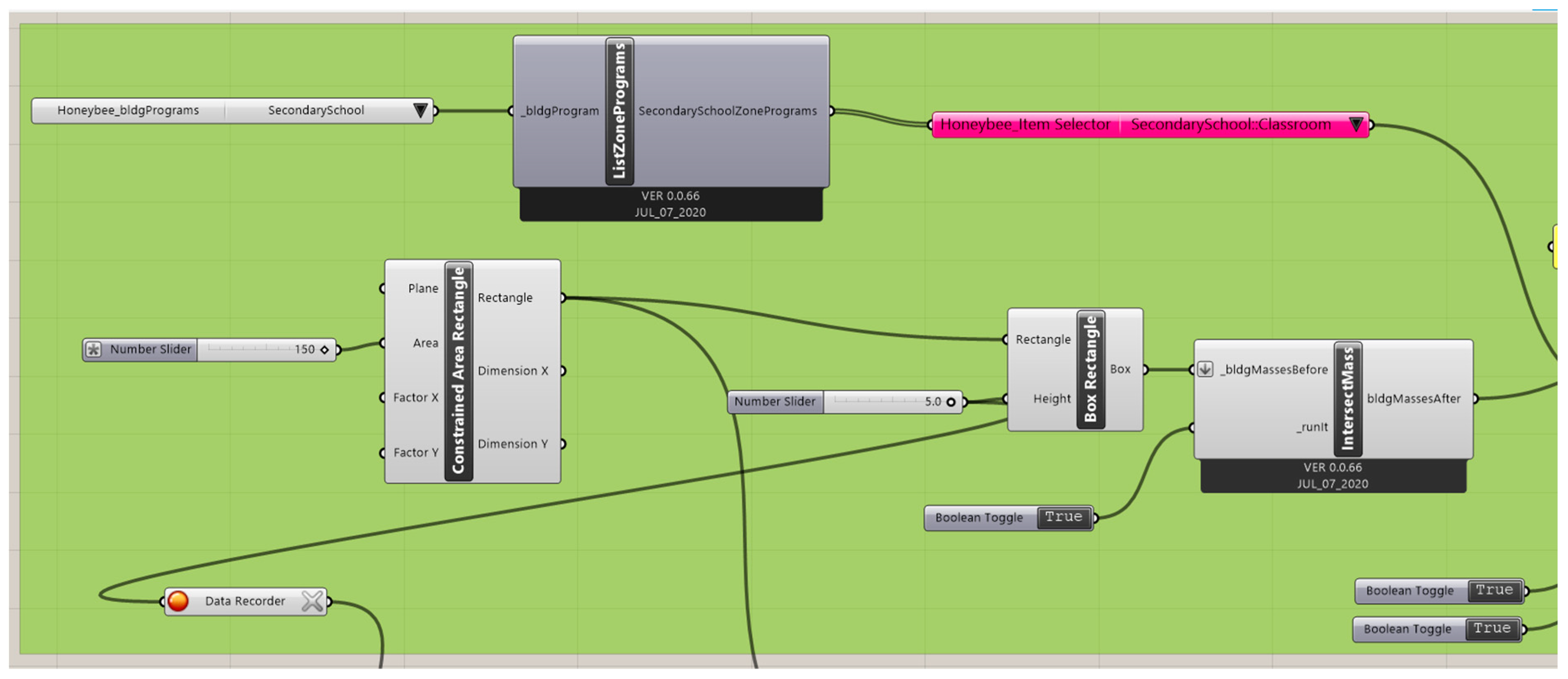

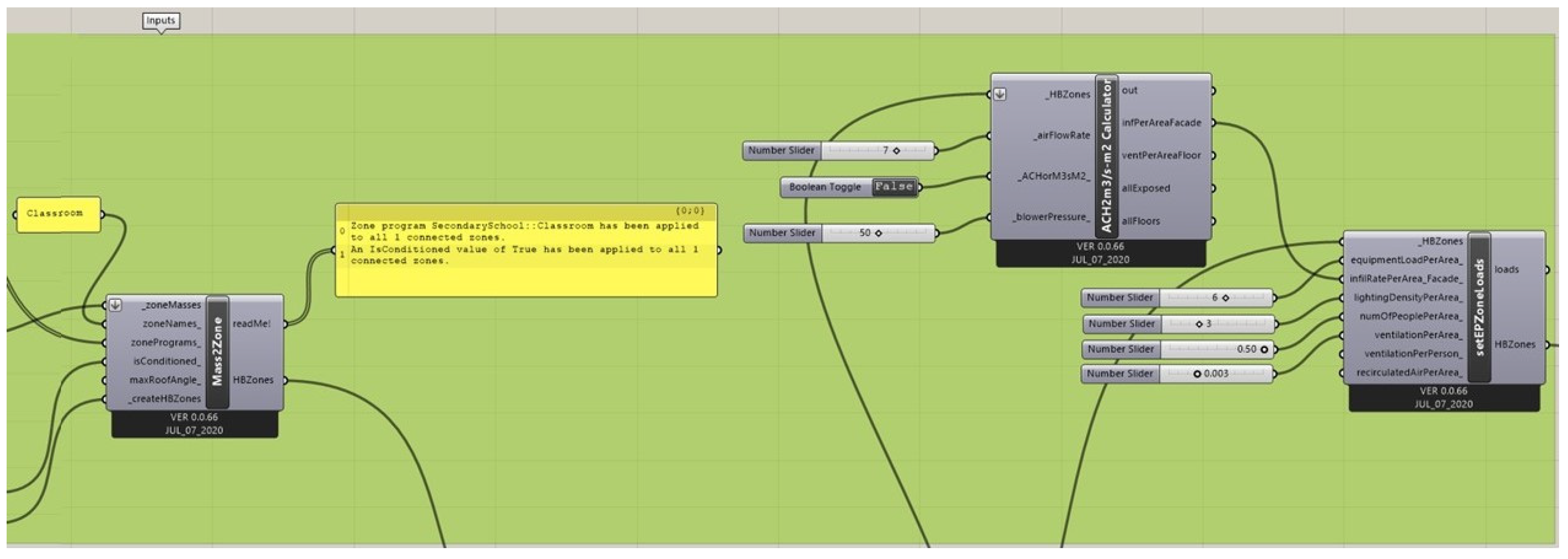

| Block (1) | Classroom Design | Changes the model parameters by incorporating a secondary school classroom prototype from honey-bee plugin, and the changeable parameters include the height and area. | Figure A2 |

| The model classroom also includes sub-variable of air flow rate (7 h−1) at pressure difference of (50 Pa), as well as another block related to zone loads (equipment load per area (6 W/m2), and lighting density per area (3 W/m2), and ventilation rate per area 0.0003 (m3/s.m2)) according to ASHRAE 60. The mechanical ventilation parameters represented are in line with the actual case study’s HVAC system, which is referenced in Appendix B. | Figure A3 | ||

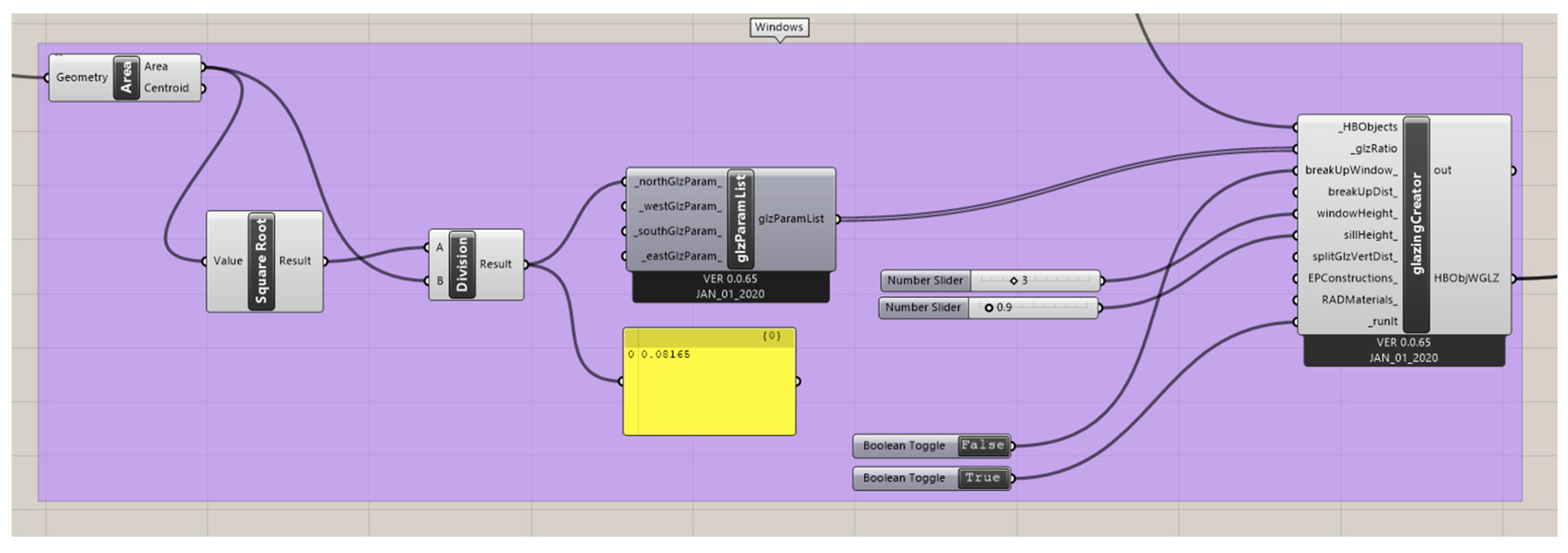

| Block (2) | Windows | The opening-to-wall ratio was specified as the classroom area’s square root. Other specified parameters included the window height (3 m) and windowsill height (0.9 m). In addition, the orientation of the opening was altered per the four main directions. | Figure A4 |

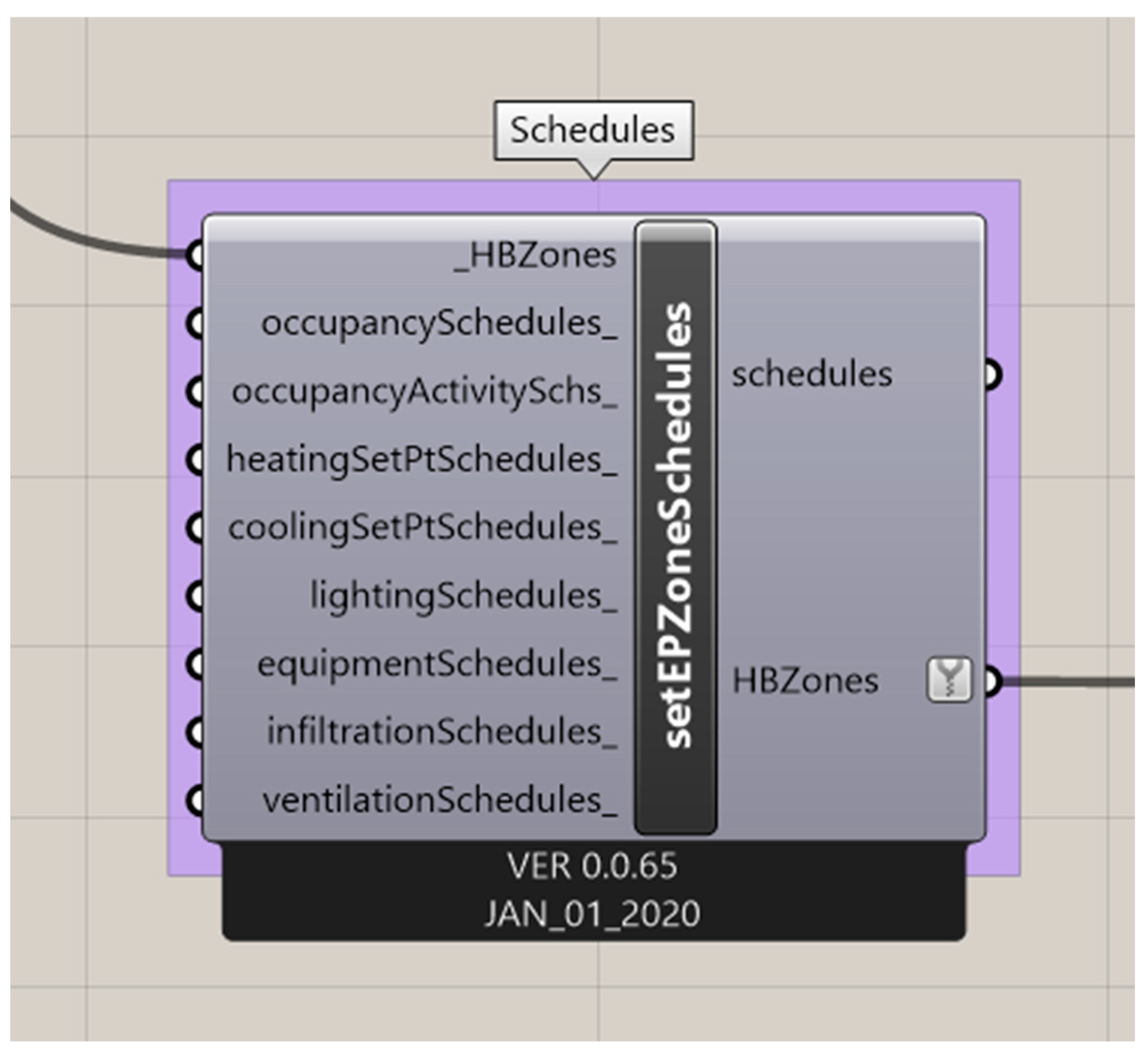

| Block (3) | Schedule | The schedule was also predefined and the parameters were preset according to ASHRAE 90 [44] in relation to occupancy schedules, occupancy activities’ schedules, heating and cooling, lighting, equipment, infiltration schedules, and ventilation schedules. | Figure A5 |

| Block (4) | Materials | Materials of built environment: walls, roof, floors, and windows. | Figure A6 and Figure A7 |

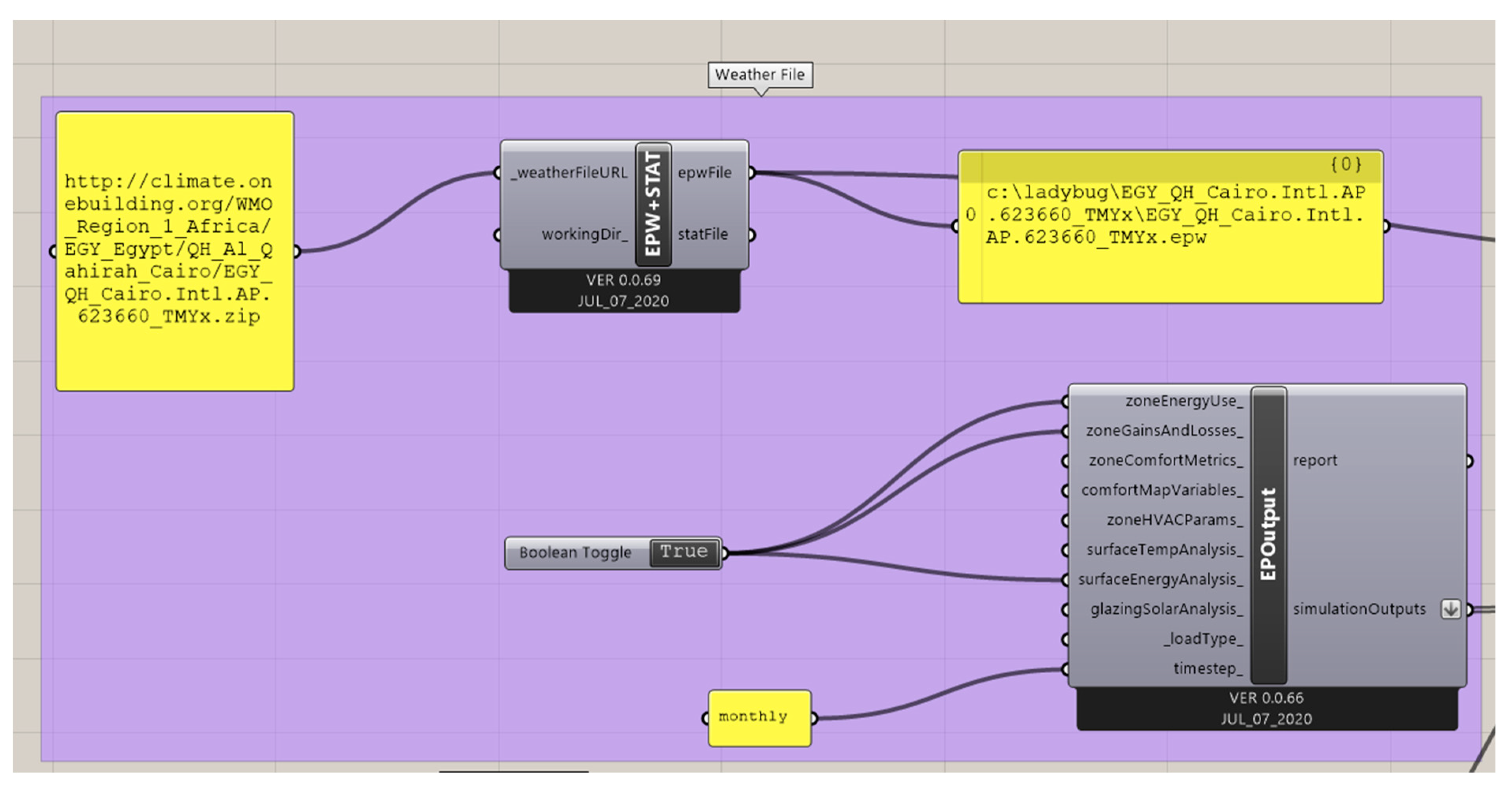

| Block (5) | Weather File | Includes the weather file imported from climate.onebuilding.org for the African region, including Cairo and Egypt. The file is further specified for the New Cairo region, Cairo International Airport as indicated by the ladybug file—refer to Image 8. | Figure A8 |

| Block (6) | Simulation | Refers to exact conditions of simulation, including the HVAC systems, simulation outputs, simulation run, and the exact calculations in terms of energy—mechanical ventilation energy. | Figure A9 |

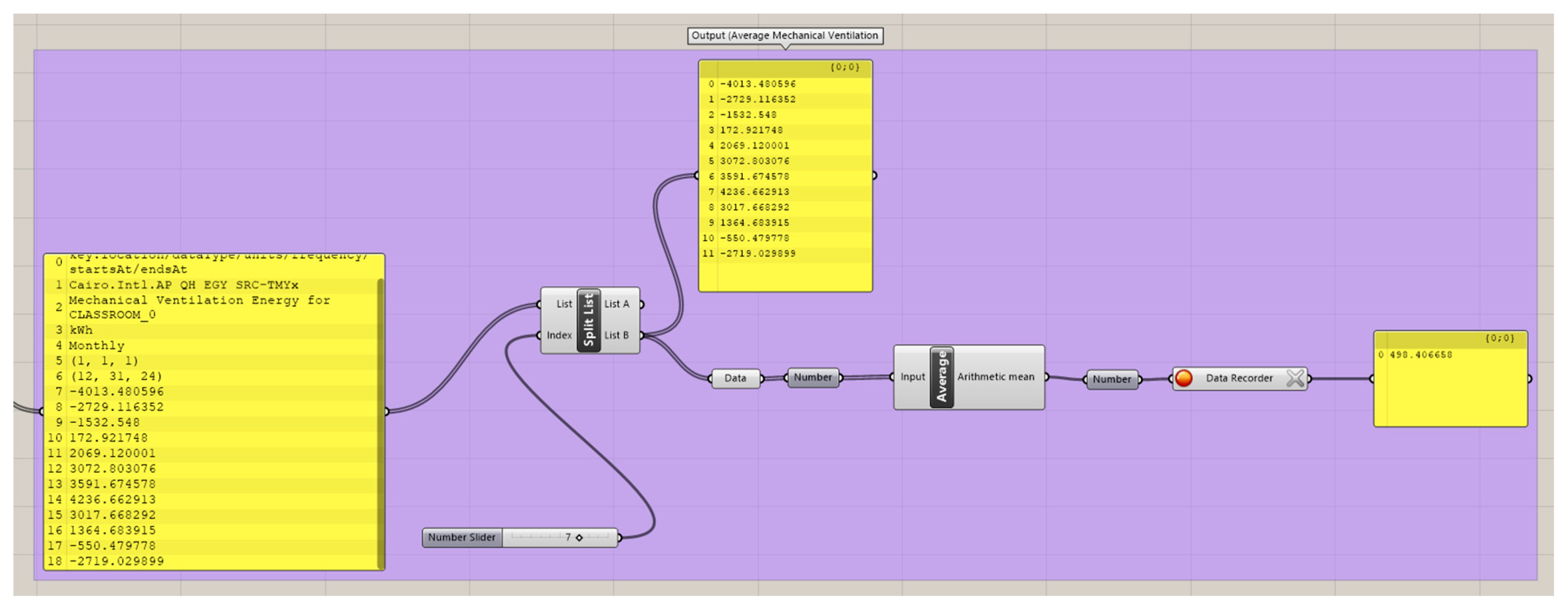

| Block (7) | Output | (Annual mechanical ventilation energy), specified averages and data recording plugins yielded the final output file—in Appendix C. | Figure A10 |

| Parameter Group | Sub-Parameters | Unit | Range (Min–Max) | Interval | Reference/Notes |

|---|---|---|---|---|---|

| Classroom Volume | Area | m2 | 30–150 | 20 | Common classroom sizes based on the available references |

| Height | m | 3.5–5 | 0.5 | ||

| Occupancy | Occupant Density | m2/Person | 0–0.5 | 0.1 | Max based on ASHRAE 90 |

| HVAC Systems | HVAC Type | - | VAC—Split | - | Assumed only to be mechanical |

| ACH50 | h−1/Person | 7 | - | Based on ASHRAE 60 | |

| Total Number of Simulations | 160 | ||||

| Summary of Fit | |

|---|---|

| RSquared | 0.981576 |

| RSquared Adj | 0.980853 |

| Root-Mean-Squared Error | 20.35204 |

| Mean of Response | 265.3232 |

| Observations (or Sum Wgts) | 160 |

| Analysis of Variance | ||||

|---|---|---|---|---|

| Source | DF | Sum of Squares | Mean Square | F Ratio |

| Model | 6 | 3,376,279.4 | 562,713 | 1358.536 |

| Error | 153 | 63,373.5 | 414 | Prob > F |

| C. Total | 159 | 3,439,652.9 | <0.0001 * | |

| Parameter Estimates | ||||

|---|---|---|---|---|

| Term | Estimate | Std Error | t Ratio | Prob > |t| |

| Intercept | −115.485 | 13.41495 | −8.61 | <0.0001 * |

| Area | 3.065693 | 0.037237 | 82.33 | <0.0001 * |

| Height | 6.328062 | 2.934173 | 2.16 | 0.0326 * |

| Occupancy | 223.5958 | 12.32417 | 18.14 | <0.0001 * |

| Window Location [E] | −0.83728 | 2.962314 | −0.28 | 0.7778 |

| Window Location [N] | 1.740038 | 3.346727 | 0.52 | 0.6039 |

| Window Location [S] | −0.45377 | 3.511829 | −0.13 | 0.8974 |

| Sum of Fit | |||||

|---|---|---|---|---|---|

| Source | No. of Parameters | DF | Sum of Squares | F Ratio | Prob > F |

| Area | 1 | 1 | 6778.231 | 2807581 | <0.0001 * |

| Height | 1 | 1 | 1926.6 | 4.6513 | 0.0326 * |

| Occupancy | 1 | 1 | 136341.3 | 329.1633 | <0.0001 * |

| Window Location | 3 | 3 | 121.6 | 0.0979 | 0.9611 |

| Least Squares Mean of Window Location | |||

|---|---|---|---|

| Level | Least Sq Mean | Std Error | Mean |

| E | 264.75637 | 2.4706845 | 225.664 |

| N | 267.33369 | 4.0444331 | 327.137 |

| S | 265.13989 | 4.3188978 | 298.666 |

| W | 265.14466 | 4.3188978 | 298.671 |

| Model Validation | ||||||||

|---|---|---|---|---|---|---|---|---|

| Lecture (Number) | Occupancy (Number) | Average Outdoor Temperature (°C) | Average Outdoor CO2 Concentration | Average Indoor Temperature (°C) | Measured CO2 Concentration (ppm) | Calculated CO2 Concentration (ppm) | CO2 Difference (Δppm) | Temperature Difference (Δ°C)) |

| 1 | 28 | 26.0 | 435.5 | 17.6 | 578.0 | 742.0 | −164.0 | 8.5 |

| 2 | 12 | 28.2 | 419.3 | 21.6 | 877.0 | 553.0 | 324.0 | 6.7 |

| 3 | 22 | 28.3 | 416.8 | 22.5 | 811.0 | 662.0 | 149.0 | 5.8 |

| 4 | 11 | 20.1 | 453.7 | 23.5 | 752.0 | 577.0 | 175.0 | −3.4 |

| 5 | 24 | 20.5 | 452.8 | 26.4 | 839.0 | 724.0 | 115.0 | −5.9 |

| 6 | 8 | 19.4 | 453.1 | 26.1 | 491.0 | 543.0 | −52.0 | −6.6 |

| 7 | 28 | 18.5 | 489.7 | 22.5 | 626.0 | 801.0 | −175.0 | −4.0 |

| 8 | 12 | 18.9 | 468.8 | 25.4 | 621.0 | 604.0 | 17.0 | −6.5 |

| 9 | 22 | 18.4 | 467.0 | 24.9 | 1080.0 | 714.0 | 366.0 | −6.5 |

| 10 | 8 | 15.9 | 501.1 | 25.1 | 695.0 | 591.0 | 104.0 | −9.2 |

| 11 | 24 | 29.8 | 424.2 | 22.1 | 672.0 | 691.0 | −19.0 | 7.7 |

| 12 | 8 | 28.8 | 430.0 | 21.6 | 625.0 | 521.0 | 104.0 | 7.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shoukry, F.; Raafat, R.; Tarabieh, K.; Goubran, S. Indoor Air Quality and Ventilation Energy in University Classrooms: Simplified Model to Predict Trade-Offs and Synergies. Sustainability 2024, 16, 2719. https://doi.org/10.3390/su16072719

Shoukry F, Raafat R, Tarabieh K, Goubran S. Indoor Air Quality and Ventilation Energy in University Classrooms: Simplified Model to Predict Trade-Offs and Synergies. Sustainability. 2024; 16(7):2719. https://doi.org/10.3390/su16072719

Chicago/Turabian StyleShoukry, Farah, Rana Raafat, Khaled Tarabieh, and Sherif Goubran. 2024. "Indoor Air Quality and Ventilation Energy in University Classrooms: Simplified Model to Predict Trade-Offs and Synergies" Sustainability 16, no. 7: 2719. https://doi.org/10.3390/su16072719