Evaluation of Powder- and Extrusion-Based Metal Additive Manufacturing Processes for the Sustainable Fabrication of Spare Parts in Electromobility

Abstract

:1. Introduction

2. Materials and Methods

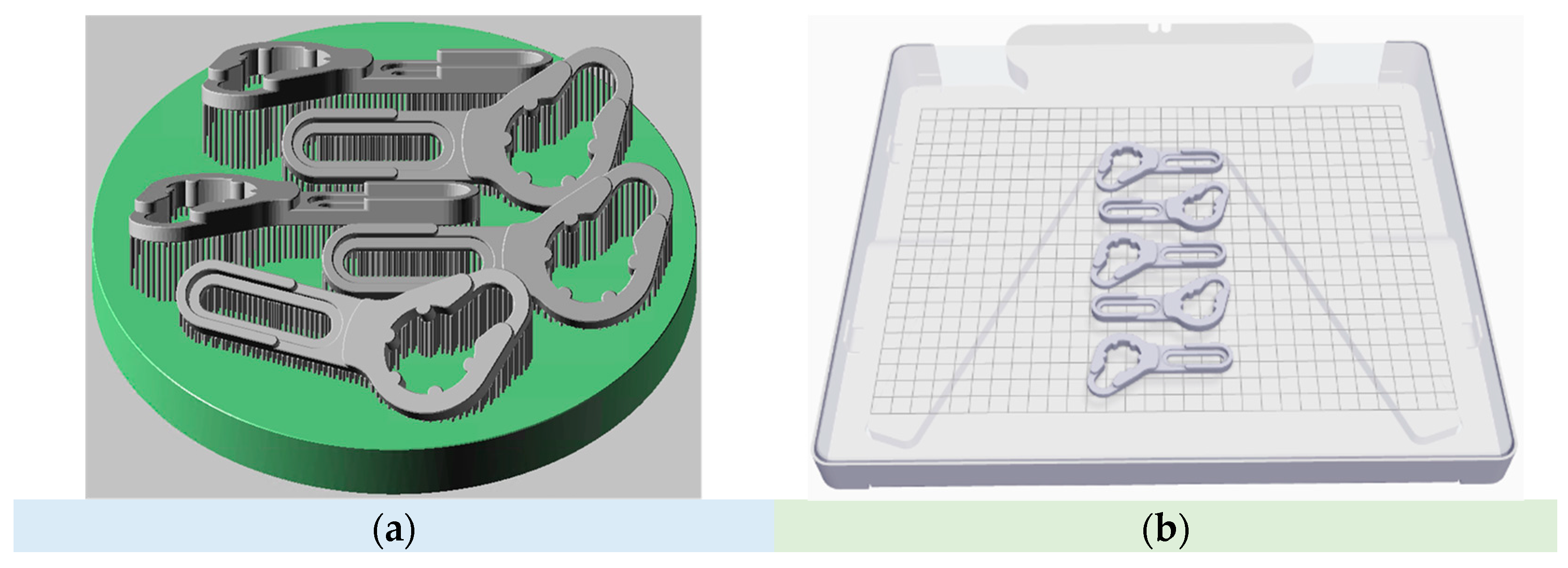

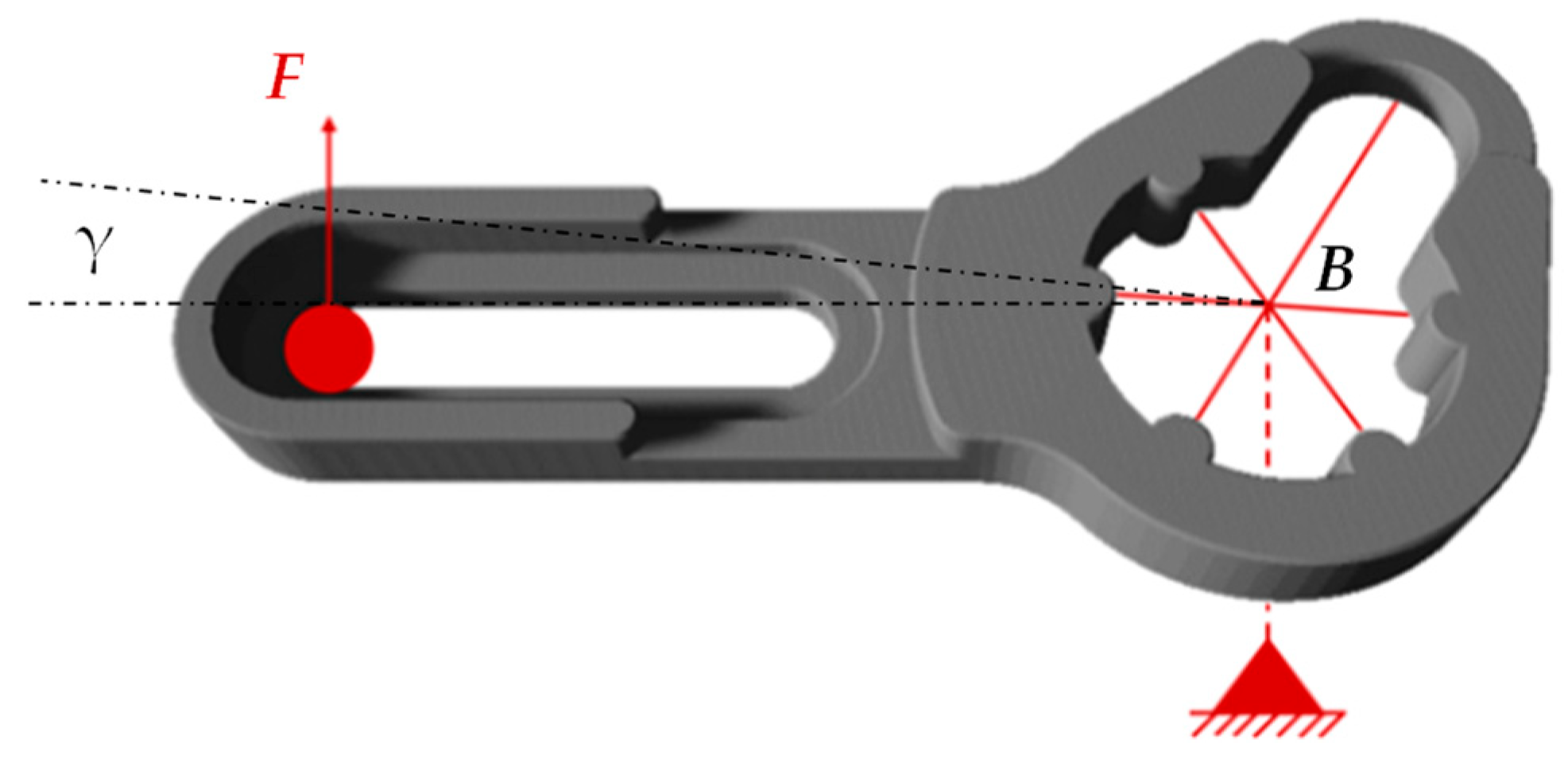

2.1. Use Case Torque Arm

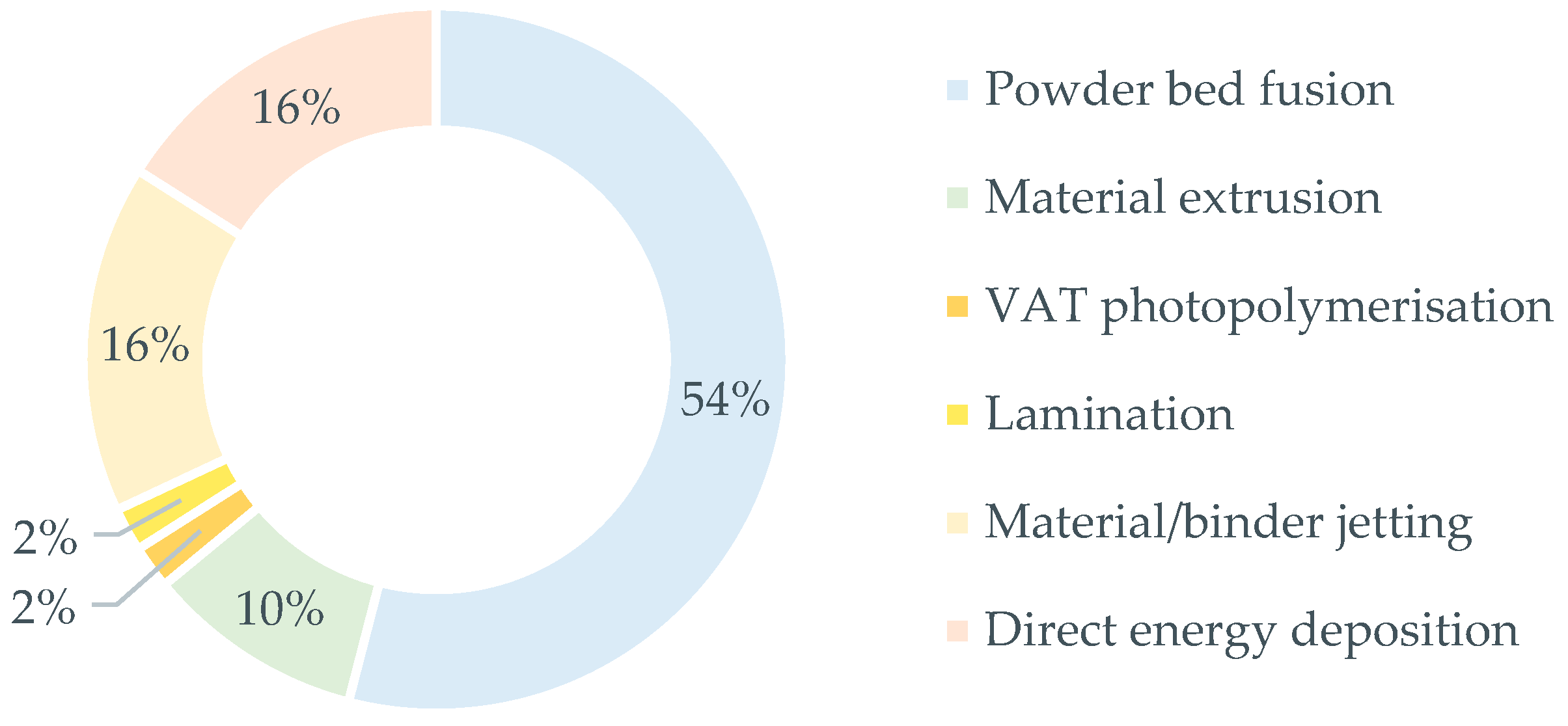

2.2. AM Processes Used

2.2.1. Powder Bed Fusion of Metals via Laser Beam

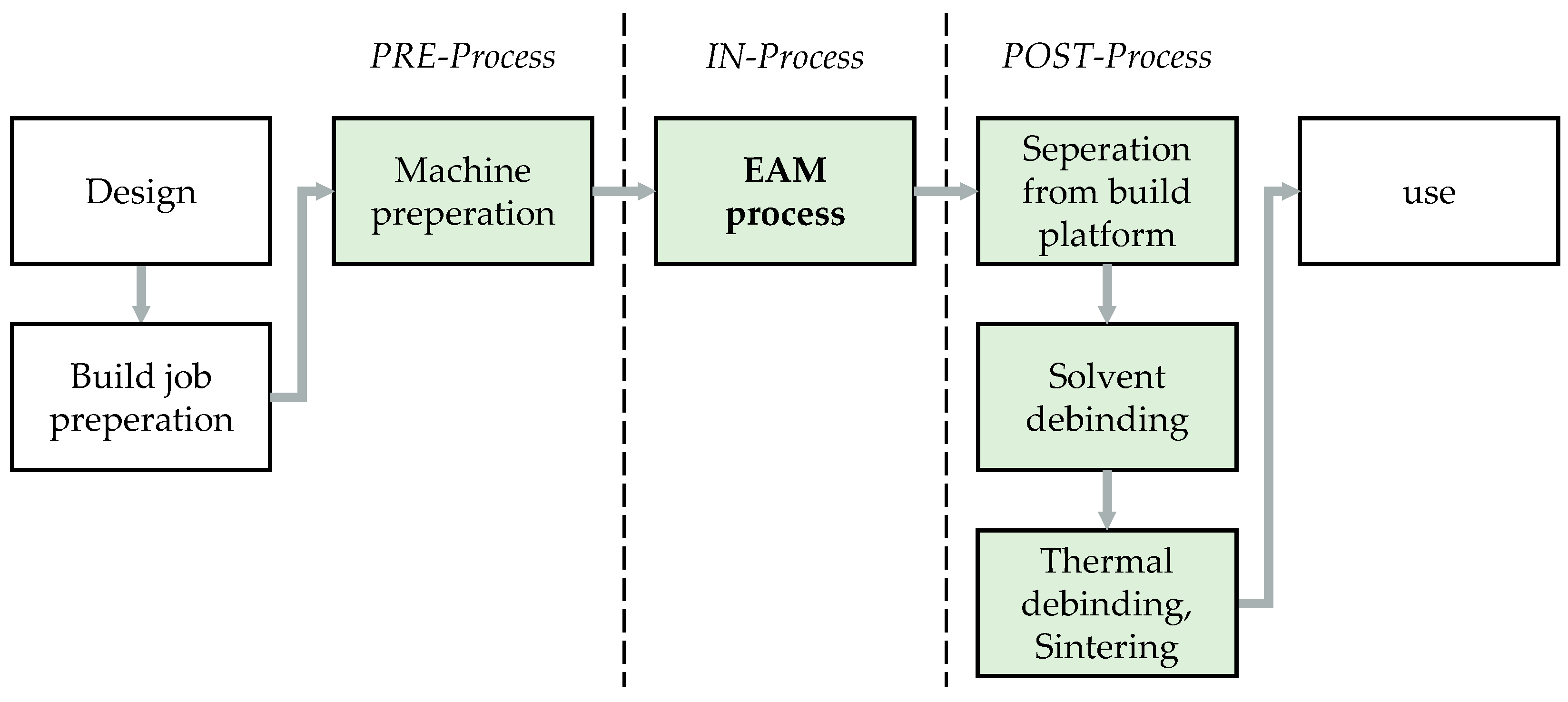

2.2.2. Metal Extrusion-Based Additive Manufacturing via Atomic Diffusion Additive Manufacturing

2.2.3. Comparison of Process Parameter

2.3. Measurement of Resource Consumption and Process Time

2.4. Testing of the Manufactured Torque Arms

3. Results

3.1. Resource Requirements

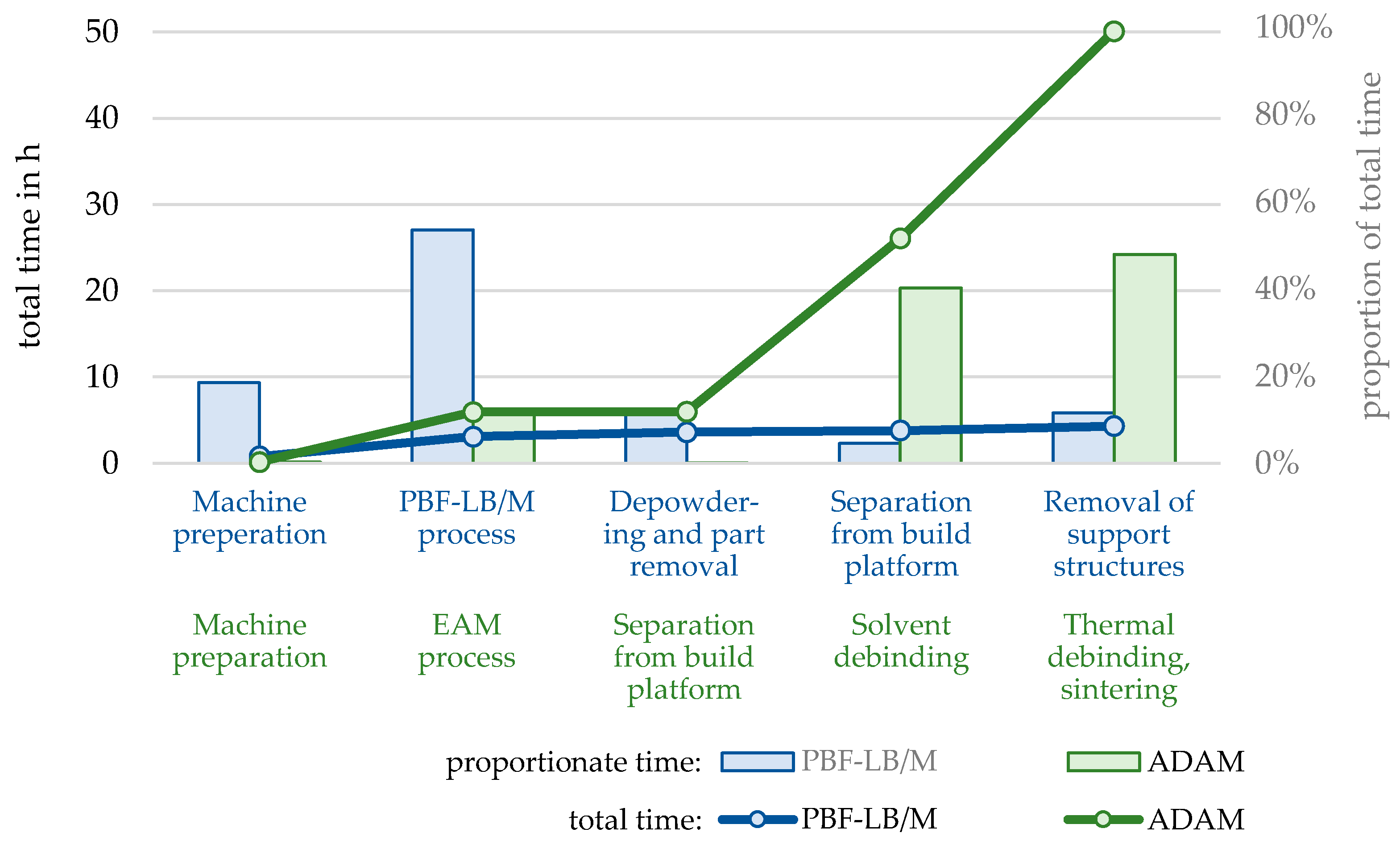

3.1.1. Lead Time

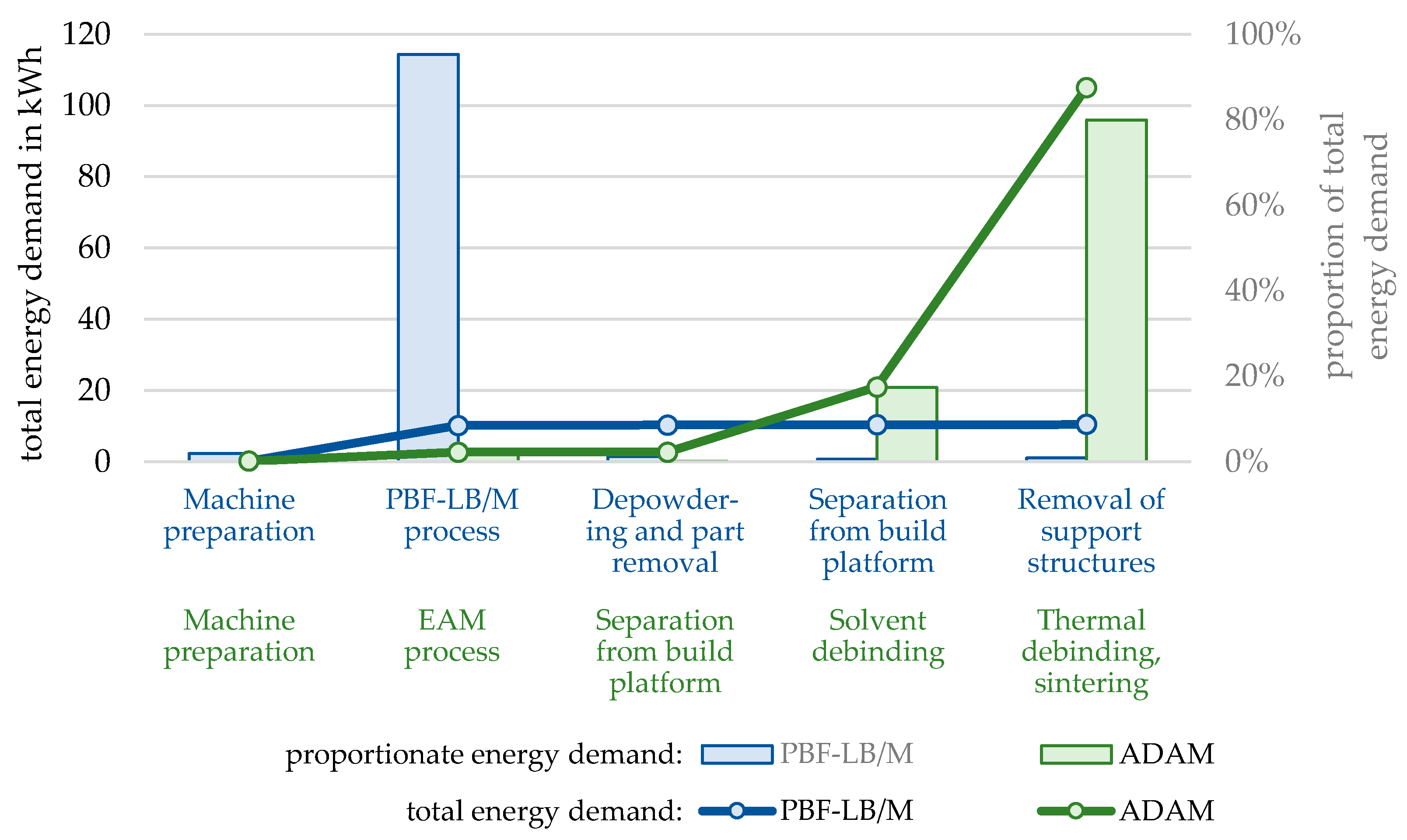

3.1.2. Energy Demand

3.1.3. Cost of Resource Consumption

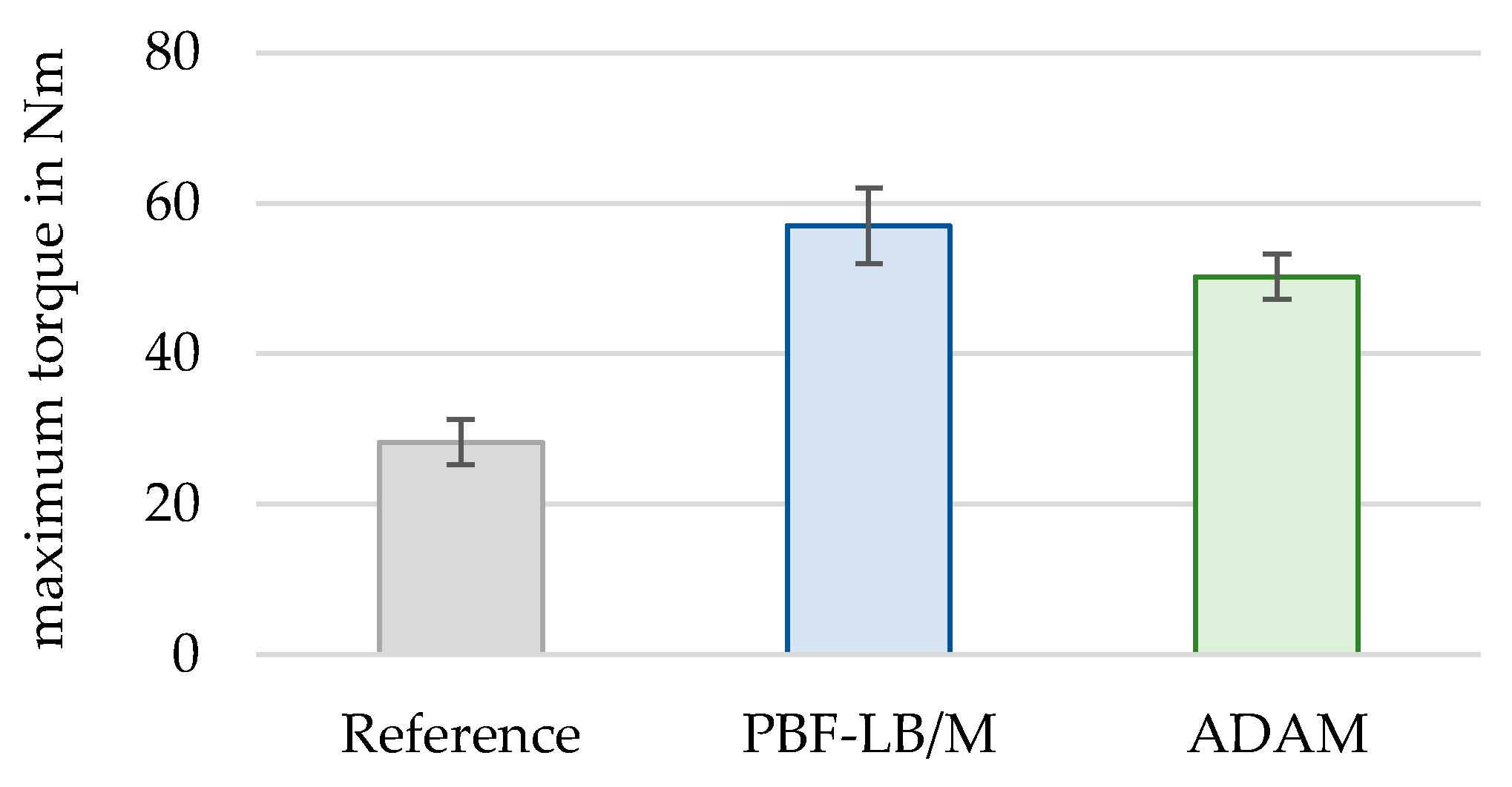

3.2. Testing of the Torque Arms

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pietrzak, K.; Pietrzak, O. Environmental Effects of Electromobility in a Sustainable Urban Public Transport. Sustainability 2020, 12, 1052. [Google Scholar] [CrossRef]

- ZIV Zweirad-Industrie-Verband e.V. Marktdaten Fahrräder und E-Bikes 2022: Mit Zahlen und Analysen zum Jahr 2022 in Kooperation mit dem VDZ Verband des deutschen Zweiradhandels Pressekonferenz|15 March 2023. 2023. Available online: https://www.ziv-zweirad.de/wp-content/uploads/2023/09/Pressemitteilung_ZIV_Marktdaten_230315.pdf (accessed on 15 April 2024).

- Schlesinger, L.; Koller, J.; Oechsle, O.; Molenda, P. Remanufacturing of E-mobility Components-Five-Step Implementation Strategy to increase Sustainability within Circular Economy. In Proceedings of the 2021 11th International Electric Drives Production Conference (EDPC), Erlangen, Germany, 7–9 December 2021; pp. 1–8, ISBN 978-1-6654-1809-6. [Google Scholar]

- Inkermann, D.; Schering, J.; Cudok, A. Handlungsfelder und Maßnahmen zur Steigerung der Ressourceneffizienz von Pedelecs und E-Lastenrädern. In Smart Cities/Smart Regions–Technische, Wirtschaftliche und Gesellschaftliche Innovationen; Marx Gómez, J., Solsbach, A., Klenke, T., Wohlgemuth, V., Eds.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019; pp. 793–805. ISBN 978-3-658-25209-0. [Google Scholar]

- Mahr, A.; Koller, J.; Tarasova, A.; Taumann, S.; Ligner, A.; Lück, T.; Walczak, P.; Flothow, A.; Walczak, M. Additive Refabrikation in der Elektrofahrradbranche: Werterhaltung in der Urbanen Elektromobilität Mittels Additiver Refabrikation. 2022. Available online: https://www.ipa.fraunhofer.de/de/Publikationen/studien/Additive_Refabrikation_Elektrofahrradbranche.html (accessed on 15 April 2024).

- Häfner, C.; Koller, J.; Koop, C.; Klein, V. Zukunftstrend nachhaltige Elektrofahrräder?: Erhebung zur Kreislaufwirtschaft in der Elektrofahrradbranche. 2021. Available online: https://www.ipa.fraunhofer.de/de/Publikationen/studien/zukunftstrend_nachhaltige_elektrofahrraeder.html (accessed on 15 April 2024).

- Vidrova, Z. Supply chain management in the aspect of globalization. SHS Web Conf. 2020, 74, 4031. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.S.; Venkatesh, M.; Chiappetta Jabbour, C.J.; Benkhati, I. Building supply chain resilience and efficiency through additive manufacturing: An ambidextrous perspective on the dynamic capability view. Int. J. Prod. Econ. 2022, 249, 108516. [Google Scholar] [CrossRef]

- Li, Y.; Jia, G.; Cheng, Y.; Hu, Y. Additive manufacturing technology in spare parts supply chain: A comparative study. Int. J. Prod. Res. 2017, 55, 1498–1515. [Google Scholar] [CrossRef]

- Heinen, J.J.; Hoberg, K. Assessing the potential of additive manufacturing for the provision of spare parts. J. Oper. Manag. 2019, 65, 810–826. [Google Scholar] [CrossRef]

- Calignano, F.; Mercurio, V. An overview of the impact of additive manufacturing on supply chain, reshoring, and sustainability. Clean. Logist. Supply Chain. 2023, 7, 100103. [Google Scholar] [CrossRef]

- Nisar, M.M.; Zia, S.; Fenoon, M.; Alquabeh, O. Generative Design of a Mechanical Pedal. Int. J. Eng. Manag. Sci. 2021, 6, 48–58. [Google Scholar] [CrossRef]

- Correia Vasco, J.O.; de Amorim Almeida, H.; Gonçalves Rodrigues Marto, A.; Bento Capela, C.A.; Da Silva Craveiro, F.G.; Coelho da Rocha Terreiro Galha Bártolo, H.M.; de Jesus Coelho, L.M.; Simões Correia, M.A.; Nogueira Vieira, M.M.; Barreiros Ruben, R.M. (Eds.) Progress in Digital and Physical Manufacturing; Springer International Publishing: Cham, Switzerland, 2023; ISBN 978-3-031-33889-2. [Google Scholar]

- Ramazani, H.; Kami, A. Metal FDM, a new extrusion-based additive manufacturing technology for manufacturing of metallic parts: A review. Prog. Addit. Manuf. 2022, 7, 609–626. [Google Scholar] [CrossRef]

- Westerweel, B.; Basten, R.; Boer, J.; Houtum, G.-J. Printing Spare Parts at Remote Locations: Fulfilling the Promise of Additive Manufacturing. Prod. Oper. Manag. 2021, 30, 1615–1632. [Google Scholar] [CrossRef]

- Holmström, J.; Partanen, J.; Tuomi, J.; Walter, M. Rapid manufacturing in the spare parts supply chain. J. Manuf. Technol. Manag. 2010, 21, 687–697. [Google Scholar] [CrossRef]

- Thomas, D. Costs, Benefits, and Adoption of Additive Manufacturing: A Supply Chain Perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef] [PubMed]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Oettmeier, K.; Hofmann, E. Impact of additive manufacturing technology adoption on supply chain management processes and components. J. Manuf. Technol. Manag. 2016, 27, 944–968. [Google Scholar] [CrossRef]

- Attaran, M. Additive Manufacturing: The Most Promising Technology to Alter the Supply Chain and Logistics. J. Serv. Sci. Manag. 2017, 10, 189–206. [Google Scholar] [CrossRef]

- Naghshineh, B.; Carvalho, H. The implications of additive manufacturing technology adoption for supply chain resilience: A systematic search and review. Int. J. Prod. Econ. 2022, 247, 108387. [Google Scholar] [CrossRef]

- Kunovjanek, M.; Knofius, N.; Reiner, G. Additive manufacturing and supply chains—A systematic review. Prod. Plan. Control 2022, 33, 1231–1251. [Google Scholar] [CrossRef]

- Blösch-Paidosh, A.; Shea, K. Enhancing Creative Redesign Through Multimodal Design Heuristics for Additive Manufacturing. J. Mech. Des. 2021, 143, 102003. [Google Scholar] [CrossRef]

- Mani, M.; Lyons, K.W.; Gupta, S.K. Sustainability Characterization for Additive Manufacturing. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 419–428. [Google Scholar] [CrossRef] [PubMed]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Taddese, G.; Durieux, S.; Duc, E. Sustainability performance indicators for additive manufacturing: A literature review based on product life cycle studies. Int. J. Adv. Manuf. Technol. 2020, 107, 3109–3134. [Google Scholar] [CrossRef]

- Ingarao, G.; Priarone, P.C.; Deng, Y.; Paraskevas, D. Environmental modelling of aluminium based components manufacturing routes: Additive manufacturing versus machining versus forming. J. Clean. Prod. 2018, 176, 261–275. [Google Scholar] [CrossRef]

- Top, N.; Sahin, I.; Mangla, S.K.; Sezer, M.D.; Kazancoglu, Y. Towards sustainable production for transition to additive manufacturing: A case study in the manufacturing industry. Int. J. Prod. Res. 2022, 61, 4450–4471. [Google Scholar] [CrossRef]

- Schuhmann, D.; Rockinger, C.; Merkel, M.; Harrison, D.K. A Study on Additive Manufacturing for Electromobility. World Electr. Veh. J. 2022, 13, 154. [Google Scholar] [CrossRef]

- Baumers, M.; Tuck, C.; Wildman, R.; Ashcroft, I.; Rosamond, E.; Hague, R. Transparency Built-in. J. Ind. Ecol. 2013, 17, 418–431. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R. Sustainability in the Circular Economy: Insights and Dynamics of Designing Circular Business Models. Appl. Sci. 2022, 12, 1521. [Google Scholar] [CrossRef]

- Cainelli, G.; D’Amato, A.; Mazzanti, M. Resource efficient eco-innovations for a circular economy: Evidence from EU firms. Res. Policy 2020, 49, 103827. [Google Scholar] [CrossRef]

- Hallstedt, S.I. Sustainability criteria and sustainability compliance index for decision support in product development. J. Clean. Prod. 2017, 140, 251–266. [Google Scholar] [CrossRef]

- Singamneni, S.; LV, Y.; Hewitt, A.; Chalk, R.; Thomas, W.; Jordison, D. Additive Manufacturing for the Aircraft Industry: A Review. J. Aeronaut. Aerosp. Eng. 2019, 8, 351–371. [Google Scholar] [CrossRef]

- AMPOWER GmbH & Co. KG. AM Power Report 2024: Management Summary. 2024. Available online: https://additive-manufacturing-report.com (accessed on 15 April 2024).

- Hofmann, A.; Mahr, A.; Döpper, F.; Bay, C. Verzug bei pulverbettbasiertem Schmelzen von TiAl6V4/Distortion in laser beam melting–Influences of part geometry and heat treatment. wt 2021, 111, 372–377. [Google Scholar] [CrossRef]

- VDI-Gesellschaft Produktion und Logistik. VDI 3405 Blatt 6.1. Additive Fertigungsverfahren. Anwendersicherheit beim Betrieb der Fertigungsanlagen. Laser-Strahlschmelzen von Metallpulvern; Beuth Verlag GmbH: Berlin, Germany, 2019. [Google Scholar]

- VDI Verein Deutscher Ingenieure. VDI 3405 Additive Fertigungsverfahren–Grundlagen, Begriffe, Verfahrensbeschreibungen, 2014–12; Beuth-Verlag: Berlin, Germany, 2014. [Google Scholar]

- Rosnitschek, T.; Glamsch, J.; Lange, C.; Alber-Laukant, B.; Rieg, F. An Automated Open-Source Approach for Debinding Simulation in Metal Extrusion Additive Manufacturing. Designs 2021, 5, 2. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- Carminati, M.; Quarto, M.; D’Urso, G.; Giardini, C.; Maccarini, G. Mechanical Characterization of AISI 316L Samples Printed Using Material Extrusion. Appl. Sci. 2022, 12, 1433. [Google Scholar] [CrossRef]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- Mahr, A.; Bay, C.; Huber, T.; Döpper, F. Systematische Bewertung der materialspezifischen humantoxischen Gefährdungen bei additiven Fertigungsverfahren. In Proceedings of the 17th Rapid. Tech 3D Conference Erfurt, Erfurt, Germany, 22–23 June 2021; Kynast, M., Witt, G., Eichmann, M., Eds.; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2021; pp. 127–140. [Google Scholar]

| AM Process | Parameter | Value |

|---|---|---|

| PBF-LB/M | Machine | Orlas Creator RA (O.R. Lasertechnologie Inc., Dieburg, Germany) |

| Material | TiAl6V4 | |

| Particle size distribution | d10 = 19.2 μm d50 = 32.9 μm d90 = 42.5 μm | |

| Inert gas | Argon | |

| Layer thickness | 25 µm | |

| Laser power | 106.75 W | |

| Scan speed | 600 mm/s | |

| Hatch distance | 50 µm | |

| Laser focus diameter | 40 µm | |

| Part orientation | 30° inclination to the build platform | |

| EAM | Machine | Markforged Metal X (Markforged Inc., Boston, MA, USA) |

| Material | D2-Steel | |

| Layer thickness | 100 µm | |

| Infill | Approx. 37% | |

| Infill pattern | Triangular | |

| Wall layers | 4 (0.51 mm post sintered) | |

| Roof and Floor Layers | 4 (1.00 mm post sintered) | |

| Part orientation | Parallel to build platform |

| PBF-LB/M | ADAM | |||

|---|---|---|---|---|

| Process phase | Process step | Main materials used | Process step | Main materials used |

| PRE-process | Machine preparation (fill metal powder in PBF-LB/M machine, inert PBF-LB/M machine) | metal powder, argon | Machine preparation (clamp filaments in printer, insert printing paper, activate vacuum pump) | printing paper, metal filament, ceramic release filament * |

| IN- process | PBF-LB/M process | metal powder, energy, argon, gas filter, coating lip | EAM process | metal filament, ceramic release filament |

| POST-process | Depowdering and part removal (remove loose metal powder from printed components, remove build platform from PBF-LB/M machine) | metal powder | Separation from build platform (Remove the printed components from printing paper) | |

| Separation from build platform (remove components from build platform manually) | metal powder | Solvent debinding (remove most of the organic binder material during debinding process) | Novec 72DA (3M, Saint Paul, MN, USA) (debinding fluid), energy | |

| Removal of support structures (remove support structures from components manually) | metal powder | Thermal debinding, sintering | argon, argon mix-gas, energy, gas filter, | |

| Resource | Measuring Device |

|---|---|

| metal powder, filaments | Measuring scale—type 572-57 (Kern & Sohn GmbH, Balingen, Germany) |

| process gases | Thermal mass flow meter—type GSM-B5BGYQM4 (vögtlin instruments, Muttenz, Switzerland) |

| energy | Power analyzer—type C.A 8335 QUALISTAR+ (Chauvin Arnoux, Asnières-Sur-Seine, France) |

| time | Power analyzer—type C.A 8335 QUALISTAR+ (Chauvin Arnoux, Asnières-Sur-Seine, France); stopwatch |

| gas filter | proportional utilization rate |

| Resource | Amount | Absolute Costs |

|---|---|---|

| Metal powder | 104 g resp. 23.6 cm3 (components) | 22.36 EUR |

| 148.3 g resp. 56.2 cm3 (losses) | 31.88 EUR | |

| Process gas filter | 0.02 pieces | 1.80 EUR |

| Coating lip | 1 piece | 7.70 EUR |

| Argon | 640 L | 1.82 EUR |

| Energy demand | 10.49 kWh | 2.78 EUR |

| PBF-LB/M machine | 3.61 h | 72.58 EUR |

| Total | 140.92 EUR |

| Resource | Amount | Absolute Costs |

|---|---|---|

| Metal-filament D2 | 67.2 g resp. 16.8 cm3 (components) | 26.04 EUR |

| Ceramic release filament | - | - |

| Debinding fluid Novec 72 DA | approx. 0.2 L | 9.56 EUR |

| Argon | 700 L | 1.99 EUR |

| Argon-mix gas | 300 L | 4.05 EUR |

| Exhaust gas filter | 0.1 piece(s) | 2.50 EUR |

| Gas purification filter | 0.02 piece(s) | 14.00 EUR |

| Energy demand | 105.01 kWh | 27.83 EUR |

| EAM machine | 5.97 h | 68.11 EUR |

| Total | 141.12 EUR |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahr, A.; Schütt, T.; Rosnitschek, T.; Tremmel, S.; Döpper, F. Evaluation of Powder- and Extrusion-Based Metal Additive Manufacturing Processes for the Sustainable Fabrication of Spare Parts in Electromobility. Sustainability 2024, 16, 3425. https://doi.org/10.3390/su16083425

Mahr A, Schütt T, Rosnitschek T, Tremmel S, Döpper F. Evaluation of Powder- and Extrusion-Based Metal Additive Manufacturing Processes for the Sustainable Fabrication of Spare Parts in Electromobility. Sustainability. 2024; 16(8):3425. https://doi.org/10.3390/su16083425

Chicago/Turabian StyleMahr, Alexander, Thomas Schütt, Tobias Rosnitschek, Stephan Tremmel, and Frank Döpper. 2024. "Evaluation of Powder- and Extrusion-Based Metal Additive Manufacturing Processes for the Sustainable Fabrication of Spare Parts in Electromobility" Sustainability 16, no. 8: 3425. https://doi.org/10.3390/su16083425