Capability Framework for Sustainable Manufacturing of Sports Apparel and Footwear

Abstract

:1. Introduction

2. Sustainable Manufacturing Framework (SMF)

3. Capability Assessment Tool (CAT)

- 1- walk-through assessment based on observing work practices,

- 2- response to written questions based on simulated workplace activities,

- 3- interview responses to pre-determined questions, and

- 4- work samples (e.g., a project report) indicating prior demonstration of capability.

| Rating | Descriptor | Example of Attainment |

|---|---|---|

| 1 | Unsatisfactory | Fail—Lack of any capability |

| 2 | Satisfactory | Pass—Just enough, minimal or marginal |

| 3 | Good | Developing capability above minimal or marginal can do basic things independently |

| 4 | Very Good | Proficient—Developed capability, can plan regular actions independently |

| 5 | Excellent | Mastery, excellent—Can lead changes, plan improvements, and grasp new techniques |

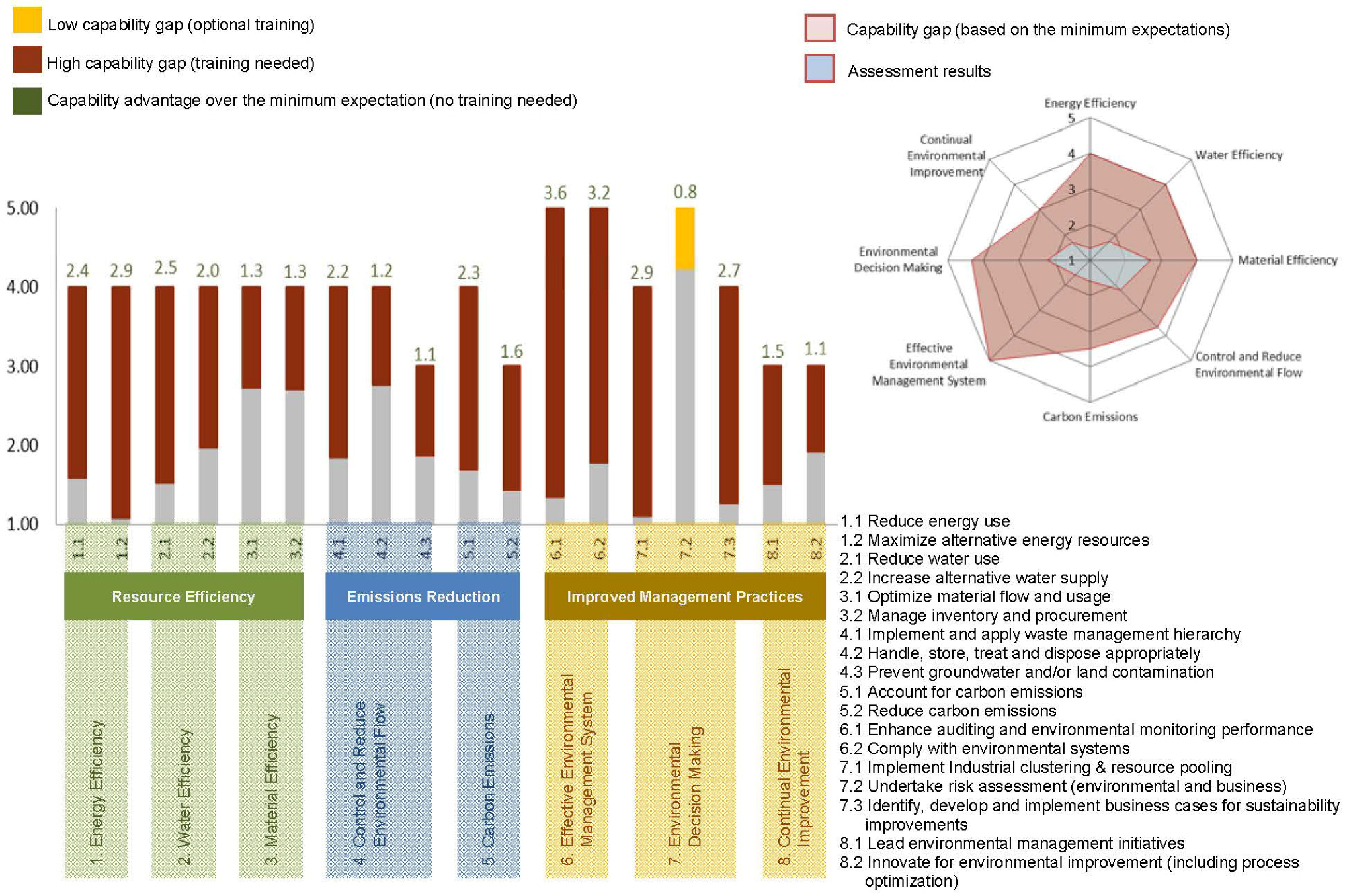

4. Capability Assessment and Gap Analysis

4.1. Capability Assessment and Gap Analysis Results

| Supplier Name | Industry Type | Short Description |

|---|---|---|

| A | Footwear, Tier 1 | Making sport shoes. The major manufacturing operations include cutting, stitching, gluing, finishing, and packaging. |

| B | Footwear, Tier 1 | Making sport shoes for major global sporting manufacturers. The main manufacturing operations include cutting, stitching, gluing, finishing, and packaging. |

| C | Footwear, Tier 2 | Making high-technology plastic shoe components. The major manufacturing processes include design, blending of raw materials, injection molding, and packaging. |

| D | Apparel, Tier 1 | Making sport clothing products with five major divisions including: fabric warehouse; cutting/patterns; sewing; finishing; and sampling. |

| E | Apparel, Tier 2 | Making textile products. The major manufacturing processes include desizing, scouring, washing, mercerizing, bleaching, printing and finishing. |

4.2. Discussion of Capability Assessment and Gap Analysis Results

- • Implement and apply waste management hierarchy

- • Enhance auditing and environmental monitoring performance

- • Reduce water and energy use and carbon emissions

- • Innovate for environmental improvement

- • 1.1 Reduce energy use

- • 1.2 Maximize alternative energy resources

- • 2.1 Reducing water use

- • 2.2 Maximize alternative water supply (excluding supplier B)

- • 4.1 Implement and apply waste management hierarchy

- • 4.2 Handle, store, treat, and dispose waste appropriately

- • 5.1 Account for carbon emissions

- • 5.2 Reduce carbon emissions

- • 6.1 Enhance auditing and environmental monitoring performance

- • 6.2 Comply with environmental systems

- • 7.1 Implement industrial clustering and resource pooling

- • 7.3 Identify, develop, and implement business cases for sustainability improvement

- • Measuring resource consumptions (e.g., energy and water)

- • Identifying resource/emission-intensive processes (i.e., hot spot analysis)

- • Identifying reasons behind resource/emission-intensive processes

- • Performing cost/benefit analysis by effectively taking economic, social, and environmental factors into account to improve their practices from sustainability point of view (i.e., business cases for sustainability improvement)

- • Setting up internal environmental targets, strategies, and timelines

- • Having a well-established company-based decision making framework/system to achieve the Companies’ sustainability targets

- • Continuously auditing and monitoring their environmental performance aimed at complying with environmental systems (effective environmental management system)

5. Training Hierarchy

- • identify critical processes to focus on or to identify WHICH processes are resource/emission-intensive;

- • identify the main reasons behind a critical process or to clarify WHY a process is resource/emission-intensive;

- • evaluate the actual costs/benefits of options or WHAT are the actual costs/benefits of the environmental improvement options; and

- • compare the various options against the decision criteria or HOW to select the most sustainable option based on the economic, environmental, and social criteria (triple bottom line analysis).

- • Measuring and reporting: This module aims to empower the suppliers’ knowledge and skills to measure, record, and report the resource consumption and emissions for the processes within their factories. The key training outcome of this module would be the suppliers’ capability to identify the most resource-intensive and emissions-intensive processes or conducting hotspot analysis.

- • Analyzing and benchmarking: This module aims to empower the suppliers’ knowledge and skills to analyze and benchmark the information collected in Module 1. The key training outcome of this module would be capabilities to identify:

- √ the reasons that a specific process is resource/emission intensive or conducting root-cause analysis, and

- √ the full costs/benefits of the resource efficiency or emissions reduction options or conducting full-costs accounting

- • Knowledge-based decision-making: This module aims to empower the suppliers’ knowledge and skills to make sustainable decisions in relation to the resource efficiency and emissions reduction projects. The key training outcome of this module would be the suppliers’ capability to conduct multi-criteria decision-making.

6. Conclusion

Acknowledgments

Conflict of Interest

References

- De Bakker, F.; Nijhof, A. Responsible chain management: A capability assessment framework. Bus. Strategy Environ. 2002, 11, 63–75. [Google Scholar] [CrossRef]

- Kinderytė, L. Analysis and comparison of methodologies for corporate sustainability assessment. Environ. Res. Eng. Manag. 2008, 4, 66–75. [Google Scholar]

- S-CORE Sustainability—Competency, opportunity, reporting & evaluation. Available online: http://www.sustainability-core.com/ (accessed on 21 March 2011).

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Adidas, Environmental Statement 2010, Global Technology Center Scheinfeld: Scheinfeld, Germany, 2010.

- Adidas, Sustainability Report 2010, in the Real World Performance Counts, Adidas Group: Herzogenaurach, Germany, 2010.

- Adidas. Adidas strategy 2015 roadmap and targets. Available online: http://www.adidas-group.com/en/SER2010/environment/strategy-2015/roadmap-and-targets/Default.aspx (accessed on 20 March 2011).

- Adidas. The Adidas group environmental strategy 2015. Available online: http://www.adidas-group.com/en/sustainability/assets/environmental_statements/adidasGroup_EnvironmentalStrategy.pdf (accessed on 20 March 2011).

- Adidas Sustainability. Available online: http://www.adidas-group.com/en/sustainability/welcome.aspx (accessed on 20 March 2011).

- Adidas, Health and Safety Guidelines, Adidas Group, Social and Environmental Affairs: Herzogenaurach, Germany, 2010.

- Adidas, Guide to Best Environmental Practice, Adidas Group, Intechnica GmbH Environmental and management consultants: Nürnberg, Germany, 2005.

- Adidas. Environmental Guidelines; Adidas Group, Social & Environmental Affairs: Herzogenaurach, Germany, 2010.

- Adidas Environmental policy of the Adidas group. Available online: http://www.adidas-group.com/en/sustainability/assets/environmental_statements/adidas_Group_Environmental_Policy.pdf (accessed on 18 March 2010).

- Adidas Sea key performance indicators (kpis). Available online: http://www.adidas-group.com/en/ser2010/suppliers/monitoring-compliance/rating-suppliers/Default.aspx (accessed on 22 March 2011).

- Adidas, Excel Spreadsheet: Environmental Audit Checklist, Social & Environmental Affairs: Herzogenaurach, Germany, 2010.

- Adidas, Excel Spreadsheet: Adidas Group Remediation Guidelines for Common Environmental Issues, Social & Environmental Affairs: Herzogenaurach, Germany, 2010.

- Adidas, Environmental Metrics Reporting Tool Briefing Note, adidas AG: Herzogenaurach, Germany, 2010.

- Adidas, Occupational Health and Safety (OHS) Officer Guidance Note, Social & Environmental Affairs: Herzogenaurach, Germany, 2009.

- Wirman, C. Adidas Group Indonesia—Energy Efficiency Project; THS Consulting: Gelsenkirchen, Germany, 2009. [Google Scholar]

- THS, Energy Efficiency Project Case Study Footwear and Apparel, Adidas Group—Indonesia; THS Consulting: Gelsenkirchen, Germany, 2009.

- ANTA. National financial services training package—fnb99. Available online: http://training.qld.gov.au/resources/training-organisations/pdf/fnb99-financial-services-v6-0-jan-2004.pdf (accessed on 10 March 2011).

- Department of Education, Employment and Workplace Relations (DEWR), Nwp07 Water Training Package; Australian Government, Department of Education, Employment, and Workplace Relations, Government Skills Australia: Canberra, Australia, 2010.

- Department of Education, Employment and Workplace Relations (DEWR), Ict10 Integrated Telecommunications; Australian Government, Department of Education, Employment, and Workplace Relations, Innovation and Business Industry Skills Council: Canberra, Australia, 2007.

- Department of Education, Employment and Workplace Relations (DEWR), Pma08 Chemical, Hydrocarbons and Refining; Australian Government, Department of Education, Employment, and Workplace Relations, Manufacturing Skills Australia: Canberra, Australia, 2011.

- Department of Education, Employment and Workplace Relations (DEWR), Prm04 Asset Maintenance Training Package; Australian Government, Department of Education, Employment, and Workplace Relations, Construction and Property Services Industry Skills Council: Canberra, Australia, 2009.

- Department of Education, Employment and Workplace Relations (DEWR), Psp04 Public Sector Training Package; Australian Government, Department of Education, Employment, and Workplace Relations, Government Skills Australia: Canberra, Australia, 2010.

- Department of Education, Employment and Workplace Relations (DEWR), Tli07 Transport and Logistics Training Package; Australian Government, Department of Education, Employment, and Workplace Relations, Transport and Logistics Industry Skills Council: Canberra, Australia, 2007.

- DEST, Mcm04 Competitive Manufacturing Training Package; Australian Government, Department of Education, Employment, and Workplace Relations, Manufacturing Skills Australia: Canberra, Australia, 2006.

- Global Social Compliance Programme (GSCP), Environmental Implementation Guidelines; Global Social Compliance Program, facilitated by the The Consumer Goods Forum: Issy‐les‐Moulineaux, France, 2010.

- International Organization for Standardization (ISO), Environmental Management Systems— Requirements with Guidance for Use; ISO 14001; ISO: Geneva, Switzerland, 2004.

- International Organization for Standardization (ISO), Guidelines for Quality and/or Environmental Management Systems Auditing; ISO 19011; ISO: Geneva, Switzerland, 2002.

- National Technical Information Service (NTIS), Bcpps5004a: Conduct a Water Audit and Identify Water-Saving Initiatives; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Bsbpur501a: Develop, Implement and Review Purchasing Strategies; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Bsbmgt608b: Manage Innovation and Continuous Improvement; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Cpccbc4019a: Apply Sustainable Building Design Principles to Water Management Systems; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Icpsu261c: Follow Ohs Practices and Identify Environmental Hazards; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Icpsu323b: Dispose of Waste; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- NTIS, Ictsus7235a: Use Ict to Improve Sustainability Outcomes; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Rtc1701a: Follow Basic Chemical Safety Rules; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Srxres004b: Minimise Waste and Pollution and Their Environmental Impact; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Srxres005b: Achieve an Efficient Use of Resources; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Tdtu601a: Conduct Environmental Audits; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- National Technical Information Service (NTIS), Thcghs04b: Handle Hazardous Materials Safely; National Training Information Service, Unit of Competency: Alexandria, VA, USA, 2011.

- Authors, Green and Energy Efficiency Training Units; State Training Services, NSW Department of Education and Communities: Sydney, Australia, 2011.

- Adidas. Strategy 2015, impacts along the value chain. Available online: http://www.adidas-group.com/en/SER2010/environment/strategy-2015/impacts-along-the-value-chain/Default.aspx (accessed on 29 March 2011).

- Australian Quality Training Framework (AQTF). Australian qualification training framework publications. Available online: http://www.training.com.au/pages/menuitem5cbe14d51b49dd34b225261017a62dbc.aspx (accessed on 13 March 2011).

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Subic, A.; Shabani, B.; Hedayati, M.; Crossin, E. Capability Framework for Sustainable Manufacturing of Sports Apparel and Footwear. Sustainability 2012, 4, 2127-2145. https://doi.org/10.3390/su4092127

Subic A, Shabani B, Hedayati M, Crossin E. Capability Framework for Sustainable Manufacturing of Sports Apparel and Footwear. Sustainability. 2012; 4(9):2127-2145. https://doi.org/10.3390/su4092127

Chicago/Turabian StyleSubic, Aleksandar, Bahman Shabani, Mehdi Hedayati, and Enda Crossin. 2012. "Capability Framework for Sustainable Manufacturing of Sports Apparel and Footwear" Sustainability 4, no. 9: 2127-2145. https://doi.org/10.3390/su4092127

APA StyleSubic, A., Shabani, B., Hedayati, M., & Crossin, E. (2012). Capability Framework for Sustainable Manufacturing of Sports Apparel and Footwear. Sustainability, 4(9), 2127-2145. https://doi.org/10.3390/su4092127