1. Introduction

Vast distances separating the dispersed populations of island countries in the Pacific Ocean have traditionally hindered their development due to the high cost for providing services, including the basic infrastructure required to address sanitation issues. The Federated States of Micronesia (FSM) alone consists of 607 islands scattered over more than one million square miles (three million square kilometers) of ocean [

1]. In addition to the geographical distances, cultural and linguistic heterogeneities among the island communities of the FSM, while serving as a hallmark of national identity, also potentially add to isolation effects. Located in the Caroline archipelago of the western Pacific (

Figure 1), the islands of the FSM are grouped into the four geopolitical states of (from east to west) Kosrae, Pohnpei, Chuuk, and Yap. The nation’s capital is located in Palikir on the island of Pohnpei. As of July 2013, the estimated population of the FSM is 106,104, with a reported distribution of Kosraean 6.2%, Pohnpeian 24.2%, Chuukese 48.8%, Yapese 5.2%, Yap outer islanders 4.5%, and others 11.1% [

2].

Figure 1.

Map of the Federated States of Micronesia located in the Caroline Islands of the western Pacific. Image source: Aotearoa at pl.wikipedia [

3].

Figure 1.

Map of the Federated States of Micronesia located in the Caroline Islands of the western Pacific. Image source: Aotearoa at pl.wikipedia [

3].

Effective management of wastewater treatment plays a crucial role in protecting the health of people and safeguarding the fragile environments of the Pacific islands [

4]. The existing treatment facilities in the FSM, though, are not adequately inventoried and the limited information that is available is largely esoteric in nature, thus making it difficult to evaluate their effectiveness. Accordingly, a knowledge base is needed to allow for comparisons of methods being used at different locations with the goal of building upon success and, where applicable, avoiding the duplication of mistakes in our quest for development of sustainable infrastructures throughout the region.

The objective of this study is to compile an inventory of the wastewater-related infrastructure in the FSM that would be of use in identifying where potential weaknesses exist and prioritizing for future water-sector projects. This objective is met by conducting field surveys to document the existing wastewater treatment systems in the population centers of Kosrae, Pohnpei, Chuuk, and Yap. Items to be targeted include the types of unit processes being used, degree of treatment being targeted, design capacities, degrees of treatment being achieved (removal efficiency, regulatory compliance), and locations where treated effluents are being discharged. Of equal concern is the handling of excess sludge generated at wastewater treatment plants, including the methods being used for treatment and disposal of waste sludge, or reuse of biosolids. In addition, characterization of industrial wastewater sources is also a critical issue.

2. Methodology

The methods employed over the course of this project involved civil and environmental engineering fieldwork. Prior to commencing fieldwork, points of contact were established in each state to clarify the purpose of the investigation to local authorities. Preliminary inquiries were then conducted to gather as much relevant information as possible by correspondence prior to commencing with visits.

Site visits started with meeting pertinent local officials on utility boards and other government agencies to review previously received preliminary information and gather additional information concerning locations and specific details of local facilities. Subsequently, visits were conducted to all known treatment facilities to document all pertinent factors and take photographs.

A concerted effort was made to glean a complete overview of the regional wastewater treatment and disposal practices including plans for future work from interviews with local officials and discussions with plant operators. Prior to leaving a particular area, every effort was made to synthesize the findings and see if any outstanding questions remained to be answered.

3. Highlights of Fieldwork Findings

3.1. Kosrae

In Kosrae State, matters related to water and wastewater are managed under the Department of Transportation and Infrastructure; it is hoped, though, that a Kosrae Utilities Authority (KUA) will be formed in the near future to focus solely on issues related to water and wastewater. There is one centralized wastewater treatment system on the island of Kosrae constructed in 1983 called the Tofol oxidation pond, which is a system of three ponds functioning in series (

Figure 2). Each pond has a footprint of approximately 150 by 50 ft (45 by 15 m); and with an assumed depth of 4 ft (1 m), this gives a total volume for the system of 90,000 ft

3 (700,000 gal, or 2000 m

3). Input to the system is from a sewer line servicing the nearby hospital, community college, and high school. The average inflow is estimated to be less than 1000 gal/day (4000 L/day) and the effluent (or treated outflow) discharges to the nearby Tofol River. By these numbers, the hydraulic retention time (HRT) would be approximately 700 days, or nearly 2 years; thus, the system does appear to have a luxuriously long HRT. Accordingly, the hydraulics of the system would be largely controlled by rainfall, evaporation, and infiltration, rather than wastewater flow. Water quality analyses are not being conducted, though the system does appear to be working well with evidence of fish flourishing in all three ponds; however, recently there had been some clogging in the 8-in (diameter) line between the first two ponds resulting in a brief overflow. As a natural safety-factor, the pond system is buffered by a mangrove bordering the site that would offer some assimilative capacity in the event of system failure.

Around 15 years ago, by government directive, 1165 septic tanks were installed on Kosrae, which brought the total coverage for wastewater treatment services in the state to 94% (

Table 1). Included in this total is an additional undocumented number of previously installed septic tanks. For a standard single-family unit, the new septic tank consists of a large first holding tank of 600 gal (2200 L) connected to a smaller second tank of 300 gal (1100 L), from which the effluent overflows into a leaching well of 400 gal (1500 L) containing a gravel bed (for a double-family unit, the volumes are scaled up by a factor of approximately 1.5). It is said that in some cases leaching fields were installed in place of the standard leaching well, but this could not be confirmed. Furthermore, in the densely populated Lelu Village—a residential bed-town—there is insufficient space for use of either leaching fields or wells, thus the basic design for septic tanks consists of only the first two compartments (

i.e., no leaching well), from which the effluent discharges to a sewer collection network servicing the whole island village. This entire effluent flow is then directed to a concrete collection pit with an estimated capacity of 1500 gal (5700 L), which discharges by gravity flow through a half-mile (ca. one kilometer) long outfall line into the ocean.

Figure 2.

Wastewater treatment system in Kosrae consisting of three oxidation ponds (only one pond shown). Image source: author.

Figure 2.

Wastewater treatment system in Kosrae consisting of three oxidation ponds (only one pond shown). Image source: author.

Installation of septic tanks has not been governed by any specific design standards for setbacks or density (

i.e., number of tanks per unit area). Typically, they have been constructed on a per-family basis and included an adjoining “out-house” consisting of a partially enclosed concrete structure with shower, sink, and toilet (

Figure 3). About twice a month a pump truck draws excess sludge from one septic tank and transports it to the oxidation ponds, thus the vast majority have not been serviced during the 15 or more years since their installation. Nonetheless, the septic-tank culture does appear to be functioning well. However, septic tanks only provide a primary level of treatment,

i.e., effluent is essentially raw sewage minus the solid material that has settled out in the tank, thus the impact of discharges on receiving water bodies (both the ocean and groundwater) would be a point of concern.

Table 1.

Numbers of septic tanks installed on Kosrae by government directive. Source: Department of Transportation and Infrastructure [

5].

Table 1.

Numbers of septic tanks installed on Kosrae by government directive. Source: Department of Transportation and Infrastructure [5].

| Village | Septic tanks installed | Approximate date of installation |

|---|

| Lelu | 350 | 1994 |

| Tafunsak | 340 | 1997 |

| Utwa | 200 | 1998 |

| Malem | 275 | 1999 |

| Total | 1,165 | — |

Figure 3.

Typical outhouse with adjoining septic tank in Lelu Village, Kosrae. Image source: author.

Figure 3.

Typical outhouse with adjoining septic tank in Lelu Village, Kosrae. Image source: author.

A solid-waste landfill (Fukuoka type—semi-areobic landfill technology) was installed on Kosrae in 2010, which includes a leachate collection system. While the landfill, per se, would not be a part of this study, the leachate generated at the landfill would be of concern as an industrial wastewater. The leachate flow is mostly a function of the amount of rainfall over the exposed landfill and is collected in a catch pond with an impervious lining (see

Figure 4). Out-flow from the pond passes through a gravel-sand bed and is discharged into the coastal mangrove. The leachate is tested for chemical oxidation demand (COD—an aggregate indicator of organic compounds) and pH on a monthly basis with each testing event consisting of multiple measurements taken from the leachate and nearby environmental samples. Test results have consistently been below the imposed regulatory limits of 100 mg COD/L and pH of 10, which is attributable to diligent segregation of waste materials prior to deposition. In the event of a violation of effluent quality requirements, the public is to be alerted to avoid the discharge area. If discharge quality does become an issue in the future, some form of treatment process would have to be considered.

Figure 4.

Lined leachate catch pond at the “Fukuoka-type” landfill on Kosrae. Image source: author.

Figure 4.

Lined leachate catch pond at the “Fukuoka-type” landfill on Kosrae. Image source: author.

3.2. Pohnpei

In Pohnpei State, matters related to water and wastewater are managed by the Pohnpei Utilities Corporation (PUC). In Kolonia Village, the main business center on the island of Pohnpei, there is a municipal wastewater treatment plant consisting of a contact-stabilization type activated-sludge process, which is apparently about 60 years old (

Figure 5). The plant was designed for 700 house-hold connections, but is thought to be serving 2 to 3 times that number now. However, data analyses for wastewater have not been conducted for over a decade, thus the actual flow rate and treatment efficiency are not known. While the existing plant does appear to be functioning properly by visual inspection, the activated sludge in the aeration basin appears to be much too thin, which could be due to the hydraulic overload on the system in its current state. A new plant, though, of the same type with approximately the same capacity is currently under construction, which will run in parallel with the old plant, and should effectively double the current capacity. The outfall line discharges effluent into the adjoining crowded bay approximately 1000 ft (300 m) from the shore; however, there is a plan in effect to install a new outfall in the near future that would be about twice as long. From the site of the existing plant, though, construction of an outfall capable of discharging beyond the mouth of the bay into the open sea would not be practicable.

Figure 5.

Contact-stabilization type activated-sludge wastewater treatment plant on Pohnpei. Image source: author.

Figure 5.

Contact-stabilization type activated-sludge wastewater treatment plant on Pohnpei. Image source: author.

Influent to the wastewater treatment plant does not include industrial wastewater, though it does receive inputs from restaurants and kitchens and thus would include some fats, oils, and grease (FOG). However, there is a tuna-packaging plant in the industrial zone near the airport with its own wastewater treatment plant that is currently inoperative (

Figure 6). Ownership of that treatment plant is said to have been transferred to PUC about a decade ago, though the tuna-packaging plant is still in business and, apparently, discharging untreated industrial wastewater directly to the bay. Though not actively investigated in this study, it is known that there are a lot of piggeries on Pohnpei, from which runoff of swine waste into the bay (or elsewhere) is considered to be a significant problem. While there are said to be a couple of digesters for larger operations, the vast majority of this waste discharge appears to be going untreated.

Additionally, there is a solid-waste dump near the airport, concerning which there has been some discussion about the need to construct a proper landfill with leachate collection and the ability to generate energy from waste. Furthermore, the existing municipal wastewater treatment plant, discussed above, yields 500 to 600 gal (ca. 2000 L) of excess sludge per month, which is applied to a drying bed near the airport. After drying, the sludge is supposed to be transferred to the dump, though apparently it is always taken directly from the bed by local residents and used for agricultural purposes.

Figure 6.

Inoperative industrial wastewater treatment plant of tuna-packaging plant on Pohnpei. Image source: author.

Figure 6.

Inoperative industrial wastewater treatment plant of tuna-packaging plant on Pohnpei. Image source: author.

Septic tanks on Pohnpei are typically constructed with an adjoining seepage well rather than a leaching field and it is said that drawing excess sludge from the tanks is almost non-existent—only one tank is serviced every 2 or 3 years—even though PUC does have a pump truck for that purpose. The capital area in Pilikir Village is served by a very large septic tank of approximately 120,000 gal (450 m3) with a footprint of approximately 20 by 40 ft (6 by 12 m) and a leaching field said to extend 100 yards (90 m). This facility appears to be intended for use by the government complex, though a lift-station has been installed to tie in nearby residences.

3.3. Chuuk

In Chuuk State, matters related to water and wastewater are managed by the Chuuk Public Utilities Corporation (CPUC). On the island of Weno (traditionally named Moen, the main population center located in the Chuuk Islands cluster, see

Figure 1) there is a contact-stabilization type activated-sludge wastewater treatment plant located near the airport. The plant appears to be of the same construction as the one on Pohnpei and is about 40 years old (commissioned in 1973); however, it has only been operated intermittently over the years and is currently shut down (

Figure 7). Untreated sewage thus bypasses the plant and is being discharged in the Chuuk lagoon, a world-famous diving site. The amount being discharged, though, may not be very great because much of the sewer collection network has been out of operation due to grinder-pump stations and lift stations being out of service, and currently under repair. CPUC is actively making progress towards getting the network back on line in preparation for the anticipated refurbishing of the old treatment plant. The Weno sewer collection system is the most extensive network in the FSM, covering the full extents of the northern and western shores of Weno Island.

Figure 7.

Inoperative wastewater treatment plant on Weno Island in Chuuk state. Image source: author.

Figure 7.

Inoperative wastewater treatment plant on Weno Island in Chuuk state. Image source: author.

There are, apparently, no industrial wastewater sources on Weno that would contribute to the soon-to-be-refurbished treatment plant other than FOG from restaurants and possibly discharges from laundromats and automotive shops. However, there are various farming activities, including household pigpens, which could constitute sources for agricultural wastewater that would require some form of treatment if environmental discharges become an issue.

For solid waste disposal, there is only a waste dump on Weno, without leachate collection. Additionally, CPUC is called to draw excess sludge from a septic tank only about once every three months; though they are currently making an effort to teach proper operation and maintenance of septic tanks and grease traps to local residents and businesses.

3.4. Yap

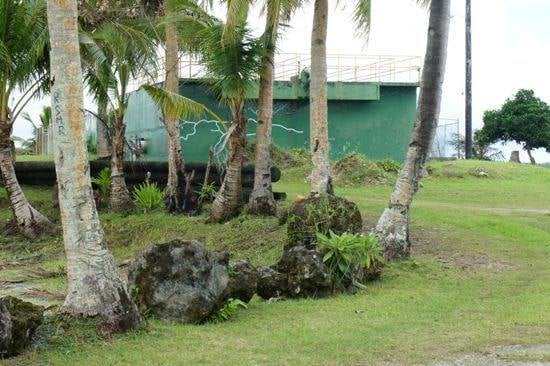

In Yap State, matters related to water and wastewater are managed by the Yap State Public Service Corporation (YSPSC). In Colonia, the main business center on the island of Yap, the municipal wastewater treatment plant consists of an Imhoff tank system, with dual units operating in parallel, which is about 40 years old (commissioned around 1974, see

Figure 8). While Imhoff tanks are relatively easy to operate and have very low energy requirements due to the absence of aeration and internal recycle, they provide only a primary level of treatment consisting of a limited removal of suspended solids. Data analyses of influent and effluent are not being performed; thus, treatment efficiency is not known. Furthermore, the amount of intermittent flow entering the plant on a daily basis is not known, making it difficult to estimate loading rates. In addition, the outfall line from the plant is known to be broken and is discharging the partially treated effluent into a shallow part of the bay about 500 ft (150 m) from shore.

There are no known industrial wastewater sources on Yap Island now; however, there are some activities at the petroleum refinery in Colonia that could be of concern. In addition, there are some relatively small fish-cleaning operations and possibly FOG discharges from older establishments (including restaurants) that are not equipped with grease traps, all of which could be contributing to the treatment demand of the Imhoff tank system. Furthermore, various farming activities, including household pigpens, could constitute sources for agricultural industrial wastewater that would require some form of treatment if environmental discharges become an issue.

Figure 8.

Imhoff tank wastewater treatment plant in Colonia Village, Yap, with a map of the sewer network painted on wall. Image source: author.

Figure 8.

Imhoff tank wastewater treatment plant in Colonia Village, Yap, with a map of the sewer network painted on wall. Image source: author.

For solid waste disposal, there is only a waste dump on Yap, which does not employ leachate collection; though a new landfill is under construction (at the time of this report), which will include a leachate collection system as employed on Kosrae. The landfill leachate will constitute an industrial wastewater, which will require monitoring and would require treatment if discharge standards are not met.

At the municipal wastewater treatment plant (the Imhoff tank system, discussed above) an unknown amount of excess sludge is periodically drawn from the tanks and applied to a drying bed. After drying, the sludge is supposed to be transferred to the dump, though apparently it is always taken by local residents and used for agricultural purposes.

Yap State has a relatively new pump truck that is used to draw excess sludge from a septic tank about once per month, the contents of which are delivered to the treatment plant (via the sewer). YSPSC and regulatory officials are actively working on evaluating and upgrading various issues including efficiency of wastewater treatment and installation and governance of septic tanks.

4. Discussion and Conclusions

The distribution of wastewater treatment services across the four states of the FSM is summarized in

Table 2. As shown, Kosrae has nearly complete coverage due to the extensive initiative to install septic tanks a few years ago. This apparent advantage over the other states, though, is influenced by the population and business activities in Kosrae being confined to only one island and thus not having inhabitants on outer islands, which would be largely accounted for under the “None” category. However, considering that septic tanks provide only a primary level of treatment, further treatment of the collected effluent from tanks in Lelu Village prior to discharge in the bay would be worth pursuing. In addition, investigating the means of extending the sewer collection line in Tofol Village to take advantage of the greatly under-loaded oxidation pond system would be a valuable avenue of inquiry.

Table 2.

Wastewater treatment services in the FSM (2010). Source: Office of SBOC [

6].

Table 2.

Wastewater treatment services in the FSM (2010). Source: Office of SBOC [6].

| State: | KOSRAE | POHNPEI | CHUUK | YAP |

|---|

| Households * | 1,143 | 6,289 | 7,024 | 2,311 |

| Sewer connections | 4% | 17% | 9% | 12% |

| Septic tanks | 94% | 35% | 31% | 31% |

| Other | <1% | 18% | 12% | 8% |

| None | 1.4% | 30% | 48% | 49% |

In Chuuk State, the relatively low coverage for sewer connections (9%) may increase soon due to ongoing repairs of the sewer network and the pending restoration of the central treatment plant on Weno Island. However, given the history of difficulties in maintaining operation of the activated-sludge based wastewater treatment plant and the numerous grinder and lift stations in the collection network, installation of a few strategically located pre-fabricated package treatment plants might prove to be a more effective pursuit. Relying mostly on attached-growth, or biofilm technology, package plants offer a secondary (or greater) level of treatment in compliance with most regulatory standards with relatively low O&M requirements. Furthermore, with package plants, flexibility in scale would be possible by adding on capacity with modular units on an as-needed basis. This approach could be applicable on other islands too, though feasibilities studies would be needed on a case-by-case basis.

On the island of Yap, it would be beneficial to find a cost-effective means of upgrading the well-functioning Imhoff tank system so as to provide a more advanced level of treatment. One positive feature of the existing system, though, is that no energy input is required to operate the plant (following the last lift-station in the collection network). However, to achieve a secondary level of treatment, aeration of the tank would be necessary to enhance biological activity, which would constitute significant energy consumption and operational cost. Furthermore, for traditional biological treatment, pumping is required to retain and circulate the biomass (activated sludge) in the system, which would be yet an additional energy requirement. However, another method to harness biological treatment power that requires less energy input would be to use an attached-growth process, which eliminates the internal pumping requirement to retain effective biomass [

7,

8]. As a relatively simple retrofit, a frame with the attachment medium, or fabric, could be fitted to the existing tank. As a point of inquiry, though, some testing would be necessary to see what level of aeration (if any) would be required to achieve adequate results. Fortuitously, the existing Imhoff tank system consists of two parallel units, which would allow for retrofitting only one unit and making a comparison of results. However, as an unavoidable tradeoff for improved effluent quality, some increase in waste sludge production would occur; there are, though, some beneficial uses of waste sludge worth considering (see below).

A repeatedly encountered question during discussions with local regulators and operators addressed a need to define the required treatment levels for sewage sludge so that it can be considered safe for use as a biosolids product. Currently, at locations where settled sludge is collected and put on a drying bed, it is quickly whisked away and used for agricultural purposes despite the lack of adequate treatment, thus stressing the need for regulatory supervision. Though not binding in the FSM, the US EPA offers widely accepted definitions for different classes of biosolids that could serve as a guideline [

9]. Exceptional quality (

i.e., Class A) biosolids, which have no crop-harvesting restrictions, consist of treated residuals that contain no detectable levels of pathogens and low levels of heavy metals. Technologies that can meet Class A standards must process the biosolids for a sufficient length of time at a temperature high enough to yield a product in keeping with the required pathogen cut. Composting is one such method, which can offer an environmentally friendly method to recycle the nutrients and organic matter found in municipal wastewater solids [

10]. A recent pilot project on the island of Guam demonstrated the feasibility of composting manure mixed with other organic materials, which when used as a soil amendment resulted in enhanced agricultural productivity as compared to use of synthetic fertilizers; furthermore, use of the compost helped correct various unfavorable soil properties commonly found on tropical Pacific islands [

11].

In addition, the technologies involved in deriving energy from waste sludge (and solid waste in general) are becoming more and more practicable for small scale applications. For remotely located island communities, in particular, where petroleum-based fuels are so costly, the impetus clearly exists for making progress toward energy independence, in addition to protecting the environment. While this approach might not be fully feasible at this time, before long a study on this topic would be in order.

Apart from the inoperative treatment plant at the tuna-packaging plant on Pohnpei, there do not appear to be any pressing issues concerning industrial wastewater treatment. With improvements to local economies, though, the (re)emergence of tuna packing and other industries on the islands may occur, along with the wastewater they yield, which will have to be followed closely. In addition, swine farming operations are known to be a source of agricultural industrial pollution on Pohnpei and, to a lesser degree, on the other islands as well. Apart from a few larger operations, much of the problem consists of runoff from pigpens at the household level, thus collection and transport of the waste to a central treatment facility would not be practicable. In this case, as a low-cost, eco-friendly solution, the use of vetiver grass merits consideration. This robust, yet non-invasive, grass can be planted strategically to intercept waste runoff and serve as a natural treatment system and a protective buffer [

12], and has specifically demonstrated effectiveness for treatment of piggery waste in a pond application [

13]. Furthermore, vetiver grass has been evaluated for use in watershed management in southern Guam [

14].

Wastewater treatment requirements vary for different communities throughout the FSM; however, some underlying similarities among these tropical islands do exist. Accordingly, comparisons of methods being used and the results obtained at different locations will be of value for planning purposes. Such information is needed to assist in decision making for future improvements with a goal of developing sustainable wastewater treatment infrastructures in Micronesia and throughout the communities of the western Pacific.