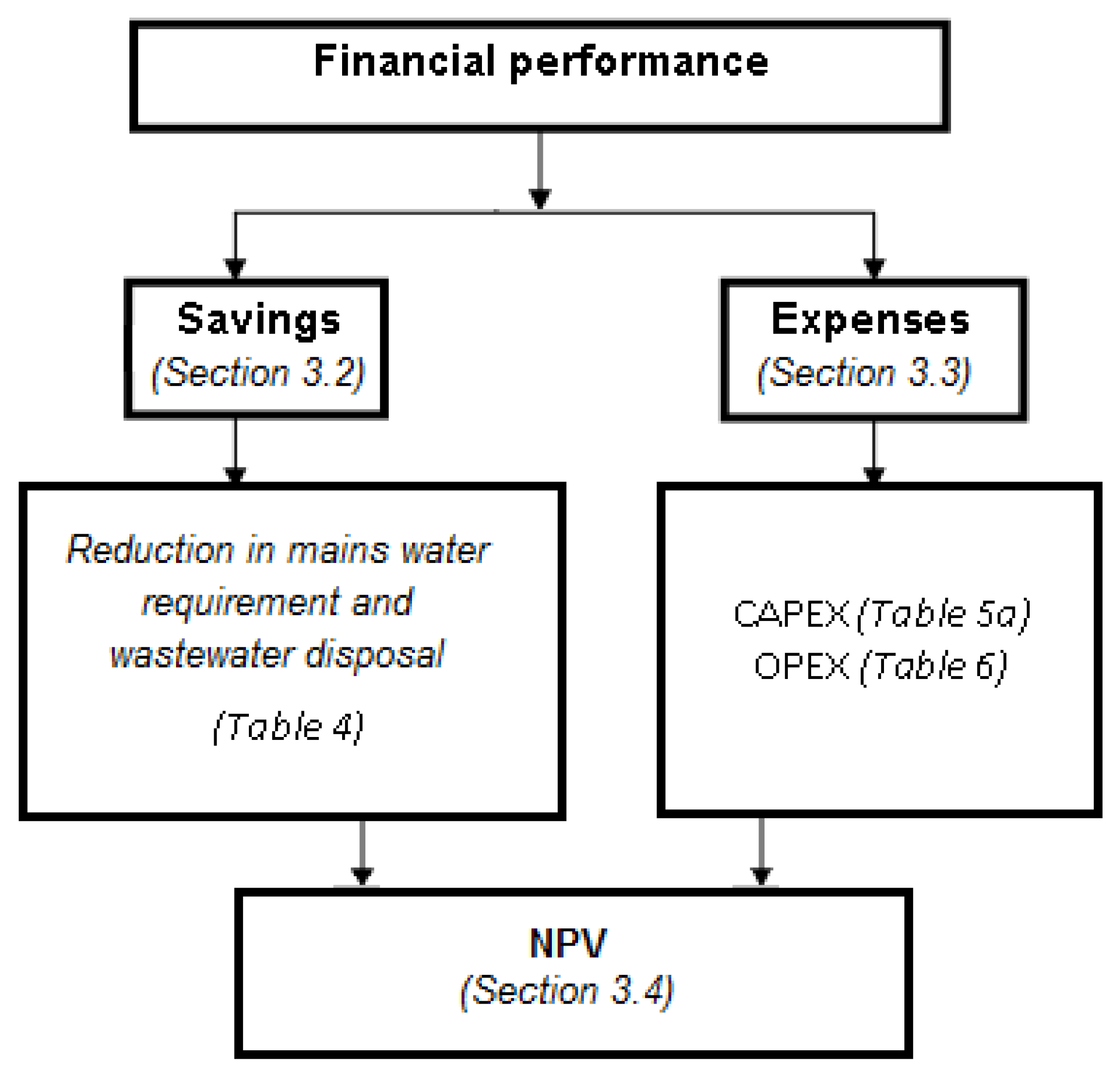

3.2. Savings: Main Water and Wastewater

Models that include a financial factor typically use the cost savings in main water supply (

i.e., due to replacement with recycled GW) and wastewater disposal (

i.e., due to reduced outflow requirements) as the main indicator of financial performance. These are commonly referred to as avoided costs and are the primary ways in which GW recycling systems offer the potential to save money on a private basis [

21,

46,

47].

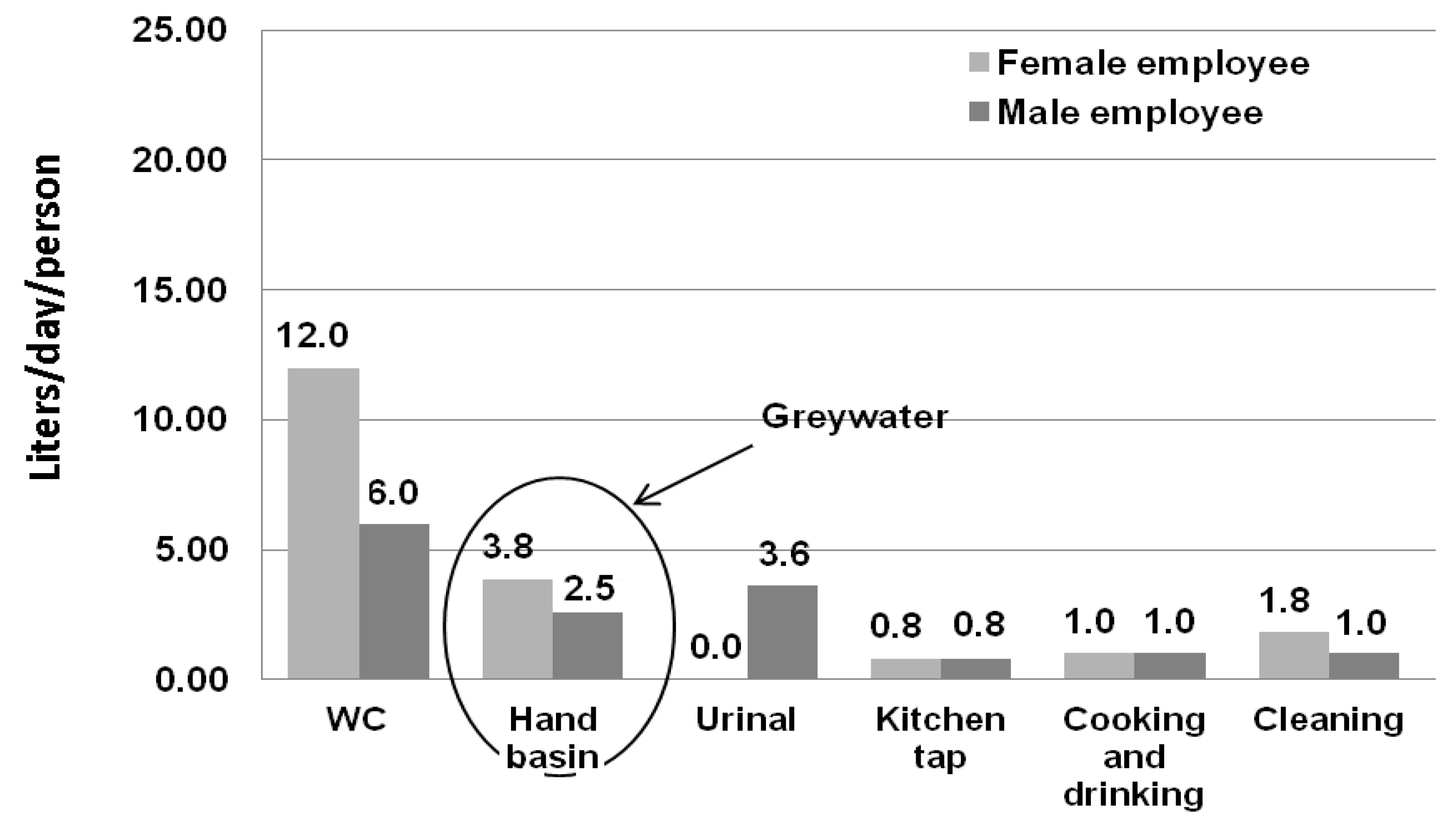

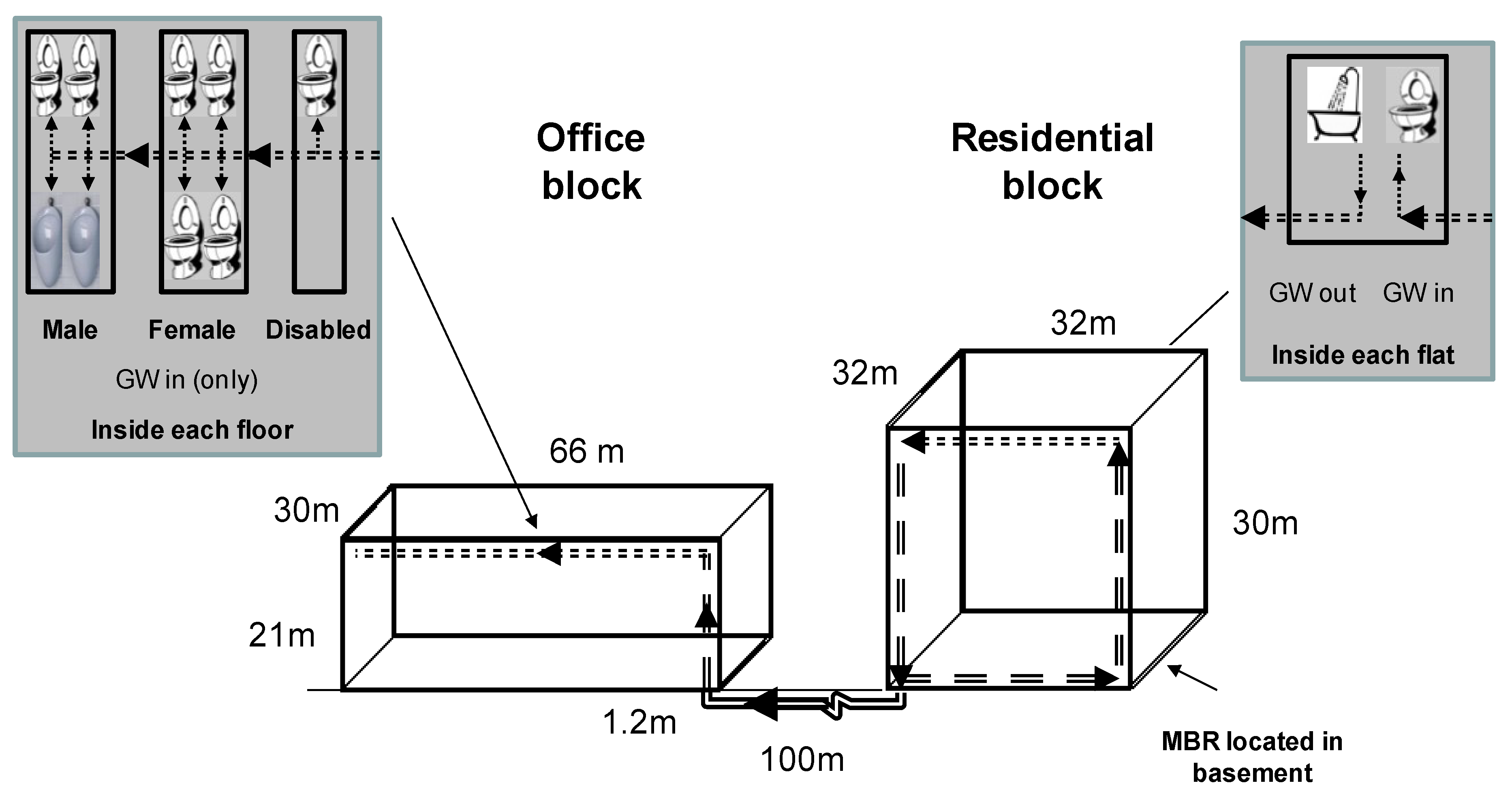

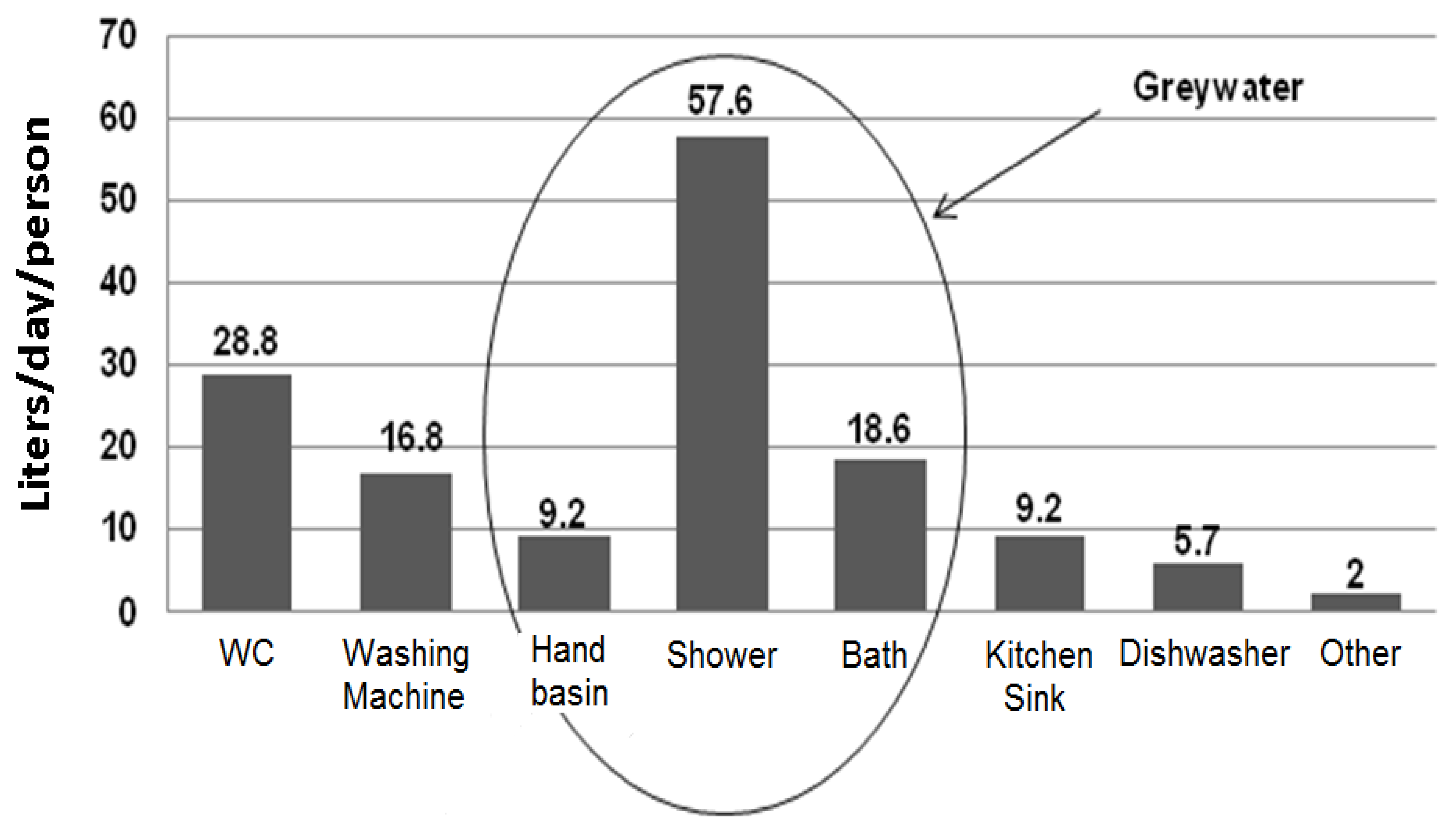

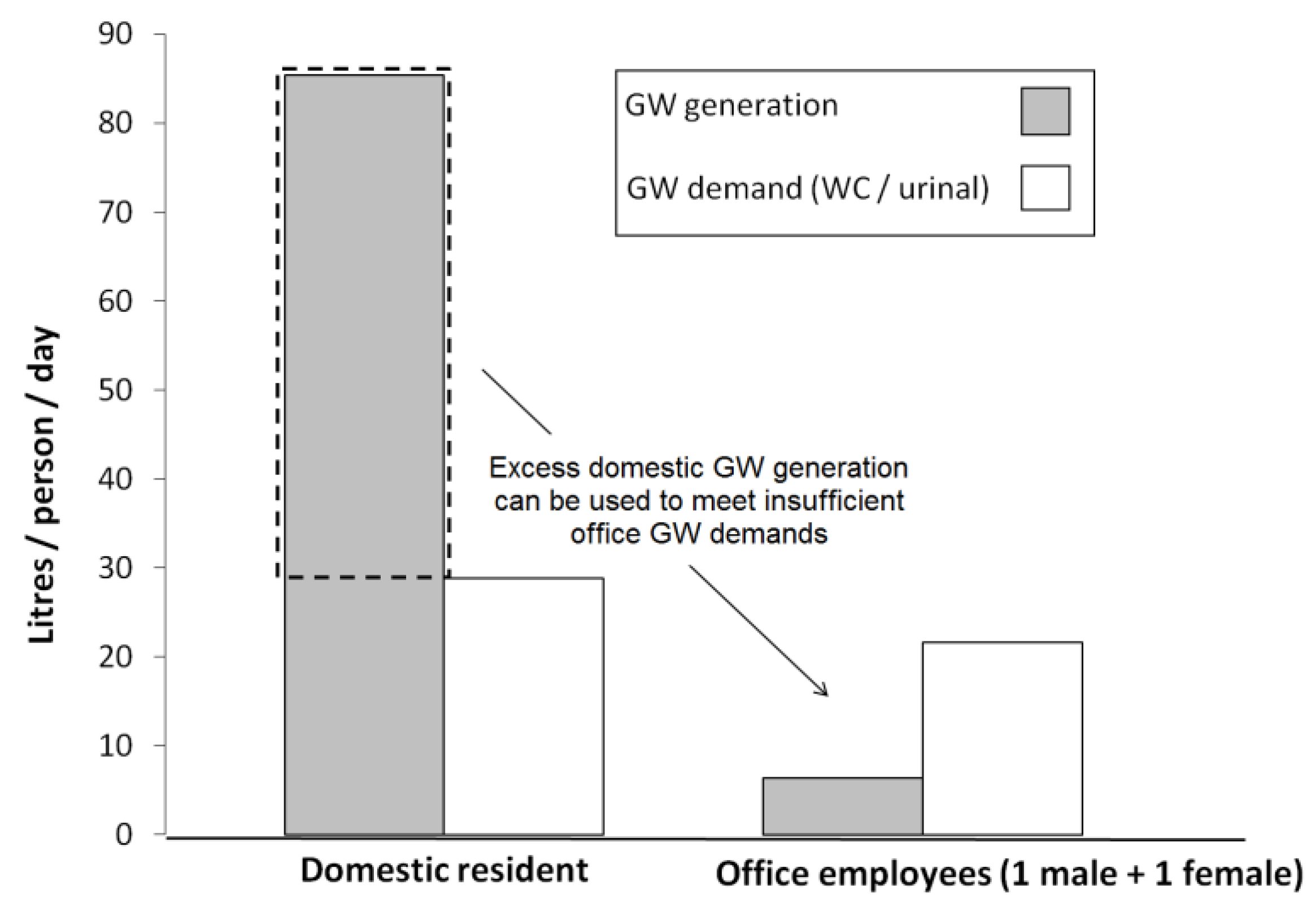

The simulation results from the following water flow module are used to provide quantification of the water saving potential for the mixed-use GW recycling system. The module has two components: annual GW supply (GWS) and annual GW demand (GWD). Equations 1 and 2 are used to calculate the volume of GW supply in residential (GWSR) and office block (GWSO). The GW supply component is contributed to from showering within the residential block and from hand basin(s) within the office block. (Other sub components, e.g., bathing, or washing machines, could be added by the user if so desired, but are not considered here.)

The input data for these equations is shown in

Table 2,

Table 3.

where:

Vs = total shower volume (l/use),

Fs = frequency of shower (uses/person/day),

R = number of residents, and

T = number of days used per year.

where:

VB = total hand basin volume (l/use),

FB = frequency of hand basin use (uses/employee/day),

E = number of employees (male or female),

[Please note for Scenarios 3a and 3b,

GWSO is not included within the analysis (

Figure 1c); hence, the total GW supply comes from Equation 1.]

The second component of the water flow module is for greywater demand. It is assumed that greywater is only used for toilet/urinal flushing. The total greywater demand for toilet flushing in residential (

GWDR) and toilet and urinal flushing in offices (

GWDO) is calculated by using Equation 3 and Equation 4:

where:

VT = volume of toilet flush (l/flush),

FT = frequency of toilet flush (uses/person/day),

where:

Vu = volume of urinal (lit/bowl/hr),

N = number of urinals in building,

H = hours of use per day.

[Please note the total demand in shared Scenarios 3a and 3b is found through the summation of GWDR and GWDO, i.e., Equations 3 and 4.].

Equation 4 can be used for calculating the toilet flushing demand for female employees without considering the urinal flushing. The net volume of saved water (

Ws) and wastewater (

WWs) is then calculated using Equations 5 or Equation 6:

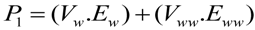

The value of water saved (S) is calculated using Equation 7:

where WP is the price of the main water and W

s is the volume of GW used. WWP is the wastewater disposal cost, and WW

s is the reduction in wastewater outflow. The ratio between water demand and wastewater generation is assumed stable at 0.98.

The various daily total flow rates for water (

i.e., the cumulative flows from both the office and residential blocks) and associated yearly costs/savings are shown in

Table 4. It can be seen that the highest potable mains water demands (79.8 m

3/day) and costs £74,900 come from Scenario 1, where no GW collection or recycling occurs. The potable mains water demands are reduced by 19% in Scenario 2a and 2b, where GW is sourced from individual buildings. The related costs are reduced by 18%. However, whilst 27.8 m

3/day of GW are collected, only 15.4 m

3/day (55% of available supplies) of treated GW are needed. However, there is insufficient GW to meet demands in Offices in Scenario 2a and 2b. In contrast, the potable main water demands in Scenario 3a and 3b are reduced by 28% and costs are reduced by 29%. [In this case, the 23.3 m

3/day demand for GW represents 94% of the available supply from domestic showers. Whilst this appears to be sufficient, it would likely not meet any additional system losses or significant fluctuations in demand encountered during the day. It is for this reason that GW is collected also from hand basins in residential blocks leading to a total supply of 28.9 m

3/day (

i.e., an oversupply of 24%).] Wastewater generation follows the same pattern as water demands, meaning that Scenario 1 has the highest outflow and Scenario 3a and 3b the lowest outflow.

Table 4.

Flow rates and related cost savings across scenarios.

Table 4.

Flow rates and related cost savings across scenarios.

| Various flows (units m3/day unless stated otherwise) | Scenario |

|---|

| 1 (Domestic, Office) | 2a | 2b | 3a | 3b |

|---|

| Potable mains water demand a | 79.8 (63.9, 15.9) | 64.4 | 64.4 | 57.4 | 57.4 |

| Domestic GW demand | 0.0 | 12.4 | 12.4 | 12.4 | 12.4 |

| Office GW demand | 0.0 | 10.7 | 10.7 | 10.7 | 10.7 |

| Domestic GW generation | 0.0 | 24.9 | 24.9 | 28.9 | 28.9 |

| Office GW generation | 0.0 | 2.9 | 2.9 | 0.0 | 0.0 |

| Total GW recycled and used | 0.0 | 15.4 | 15.4 | 23.1 | 23.1 |

| Wastewater generation a | 78.2 (62.6, 15.6) | 62.6 | 62.6 | 56.2 | 56.2 |

| WTP and WTTP charges (£K/yr) b, c | 74.9 (63.6, 11.3) | 61.2 | 61.2 | 53.3 | 53.3 |

| Total savings (£K/yr) | 0.0 | 13.6 | 13.6 | 21.5 | 21.5 |

3.3. Expenses: CAPEX and OPEX

The total expenditure is a function of capital cost (CAPEX,

Table 5), operational and maintenance costs (OPEX,

Table 7) [

29]. The various assumptions are shown in the tables, and where appropriate, a more detailed discussion follows.

In terms of CAPEX, the following assumptions were made:

The distance between buildings and the treatment plant determines the length of the greywater collection and distribution pipes and, thus, factors into the capital cost of system. The various pipework lengths are shown in

Table 6. It was found that doubling and tripling the distance between buildings (200/300 m) and the treatment plant increases the CAPEX of system by 0.2% and 0.4%, respectively. A concrete tank with inner lining is selected: the tank size is specified to meet the total volume of daily GW demands (

Table 4), plus an extra 10% to accommodate any losses in the treatment process (

i.e., in VFCW to account for evapo-transpiration (losses of 15 l/m²/d) and in MBR to account for functions like filter backwash—where treated water is at regular intervals flushed back through the filter to help keep filters clean [

43,

47]. In each case, two tanks are adopted (one before and one after treatment); to level fluctuations in inflow and on the demand side. Filters are included to remove the solid particles, such as hair and skin from the raw greywater, before it enters the treatment systems, either MBR or VFCW; MBR consists of a compact unit, which combines activated sludge treatment for the removal of biodegradable pollutants and a membrane for solid/liquid separation [

49]. MBR is commonly used in large buildings, such as multi-storey buildings [

50,

51,

52], student accommodation [

6], stadiums [

50] and communal residential buildings [

27]. GW treatment facilities are fed by gravity and pumping is only required for redistribution of treated GW. An MBR still requires a pump, but the energy demand is included in the energy demand value for MBR treatment (see

Table 7). The pumps are designed based on the required daily flow in the system and total dynamic head (including operating head required by toilet fixtures), friction losses in the system and elevation difference between pump and the last fixture in the last floor based on the assumed buildings description. The CombiBloc centrifuge pump was selected based on the estimated required flow and total dynamic head from Johnsons Pump Company in the UK [

53]. The main barrier is its high energy requirement (see later); VFCW replicates natural wetlands, improving water quality through physical, chemical and biological treatment mechanisms [

54]. The main barriers to implementing constructed wetlands are the land requirement, scarce in urban areas, and the cost of the system increases proportionally to the land area required. Although, in the present study, the VFCW system was selected for GW treatment, because it requires less space (1 to 2 m

2 per employee) than other constructed wetlands configurations, in addition, it offers a more appropriate and robust treatment within urban settings [

55]. Both MBR and VFCW are not inappropriate to a UK setting [

4,

30,

55,

56]. The various sizes of VFCW are shown in

Table 8. It can be seen that a much larger bed is required for Scenario 3b, as more GW volume is collected, treated and used. In Scenario 3, it can be seen that the CAPEX of the VFCW is much higher. This is because the economy of scale does not apply for this type of system, and the ratio between investment in the treatment system is proportional to the treated volume flow (even if in Scenario 2, two different units need to be constructed). For the MBR, the CAPEX for the treatment system drastically decreases from Scenario 2a to 3a, because in 3a, only one (larger) unit is required compared to two (smaller) units in 2a. However, the volume flow and, hence, the required membrane area in 3a is still bigger than in 2a.

Table 5.

Generic CAPEX compared across scenarios.

Table 5.

Generic CAPEX compared across scenarios.

| Various costs (£K) | Scenario |

|---|

| 1 | 2a | 2b | 3a | 3b |

|---|

| Pipe work a,b | - | 14.5 | 15.4 | 11.8 | 12.5 |

| Pump(s) c | - | 0.31 | 0.29 | 0.31 | 0.31 |

| Storage tank(s) d | - | 2.8 | 2.8 | 3.1 | 3.1 |

| Filter(s) | - | 0.23 | 0.14 | 0.58 | 0.58 |

| Installation e | - | 1.0 | 1.0 | 1.0 | 1.0 |

| Treatment system | - | 65.8 f

Domestic = 41.2 (12.4 m3/d)

Office = 24.6 (2.96 m3/d) | 44.2 g

Domestic = 33.8 (12.4 m3/d)

Office = 10.4 (2.96 m3/d) | 49.2 f | 66.3 g |

| Total CAPEX | - | 84.6 | 63.8 | 65.9 | 83.8 |

Table 6.

Various pipe sizes and lengths (in m) adopted in scenarios.

Table 6.

Various pipe sizes and lengths (in m) adopted in scenarios.

| Pipe type (Diameter -mm) | Scenario |

|---|

| 1 | 2a | 2b | 3a | 3b |

|---|

| PVC (12.50) | - | 10,324 | 10,324 | 8,394 | 8,394 |

| PVC (18.75) | - | 390 | 352 | - | - |

| PVC (25.00) | - | 352 | 352 | 352 | 983 |

| PVC (31.25) | - | 180 | 350 | 125 | 175 |

| PVC (50.00) | - | 33 | 84 | 33 | 84 |

| PVC (62.5) | - | 97 | 84 | 97 | 84 |

| PVC (100.0) | - | 58 | 58 | - | 82 |

Table 7.

Annual OPEX compared across scenarios.

Table 7.

Annual OPEX compared across scenarios.

| Various costs (£K) | Scenario |

|---|

| 1 | 2a | 2b | 3a | 3b |

|---|

| Water quality analysis a | - | 1.38 | 1.38 | 0.69 | 0.69 |

| Energy (distribution system) b, c | - | 0.07 | 0.07 | 0.144 | 0.144 |

| Energy (treatment system) b, d | - | 1.06 | 0.08 | 1.81 | 0.017 |

| Equipment renewal (distribution system) e | - | 0.027 | 0.027 | 0.023 | 0.023 |

| Equipment renewal (treatment system) f | - | 0.487 | 0.058 [17.7] | 0.265 | 0.08 [26.6] |

| Consumable cost g | - | 0.160 | 0.762 | 0.243 | 1.239 |

| Labour cost h | - | 0.753 | 2.614 | 0.824 | 3.556 |

| Sludge disposal i | - | 0.08 | - | 0.04 | - |

| Total OPEX | - | 4.02 | 4.99 | 4.04 | 5.74 |

Table 8.

Materials adopted in constructed wetland (CW) bed; volumes of each shown.

Table 8.

Materials adopted in constructed wetland (CW) bed; volumes of each shown.

| Bedding material (diameter, mm) | Depth (m) | Scenario |

|---|

| 1 | 2a | 2b | 3a | 3b |

|---|

| Sand (0.5) | 0–0.3 | - | - | 401 m3 | - | 602 m3 |

| Gravel—fine (6) | 0.3–0.4 | - | - | 152 m3 | - | 229 m3 |

| Gravel—medium (24.4) | 0.4–0.65 | - | - | 382 m3 | - | 573 m3 |

| Cobbles—coarse (90.0) | 0.65–0.75 | - | - | 134 m3 | - | 201 m3 |

In terms of OPEX the following assumptions were made:

The energy requirements for distribution system were calculated using Equations 8 to 10. The respective parameters used therein are presented in

Table 4. In all scenarios, there is an energy requirement related to (pipeline) delivery of mains water and removal of wastewater, as shown in Equation 8:

Were

Vw is the volume of potable water delivered (m

3),

Ew is the energy requirements per m

3 of potable water delivered (0.73 kWh/m

3),

Vww is the volume of wastewater removed (m

3) and

Eww is the energy requirements per m

3 of wastewater removed (0.19 kWh/m

3) [

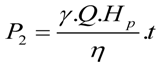

64]. The energy requirement for pumping water through the treatment process and from the final storage tank to point of end-use was estimated using Equation 9:

Where P

2 is the energy delivered to the pump,

![Sustainability 05 02887 i003]()

is the specific weight of water (N/m

3), Q is the flow rate (m

3/s), η is the overall pump efficiency (

i.e., mechanical and hydraulic), which is assumed to be 65% [

65], t is the time interval for pump operation and H

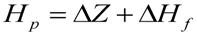

p is the required head to be supplied by the pump (m), as shown in Equation 10:

where ΔZ is the elevation difference (the maximum value is equal to the height of the top floor of the building plus the depth of buried pipe underground). ΔH

f is the head lost in pipes due to friction and is estimated by using the Hazen-Williams equation [

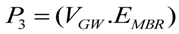

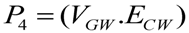

65]. The energy for treating GW via MBR and VFCW is calculated using Equation 11 and 12, respectively:

where

VGW is the volume of GW treated (m

3) and

EMBR (1.5kWh/m

3) [

51,

52,

57] and

ECW (0.014kWh/m

3) [

59] are the energy requirements for treating GW either through MBR or VFCW, respectively.

A design life of 15 years was assumed for both systems [

26,

49]. For example, replacement materials were assumed as follows: pumps were replaced after 10 years, filters every five years, membranes for MBR after two years [

57] and the bed and plant for VFCW are rebuilt after six years.

is the specific weight of water (N/m3), Q is the flow rate (m3/s), η is the overall pump efficiency (i.e., mechanical and hydraulic), which is assumed to be 65% [65], t is the time interval for pump operation and Hp is the required head to be supplied by the pump (m), as shown in Equation 10:

is the specific weight of water (N/m3), Q is the flow rate (m3/s), η is the overall pump efficiency (i.e., mechanical and hydraulic), which is assumed to be 65% [65], t is the time interval for pump operation and Hp is the required head to be supplied by the pump (m), as shown in Equation 10: