Stationary Charging Station Design for Sustainable Urban Rail Systems: A Case Study at Zhuzhou Electric Locomotive Co., China

Abstract

:1. Introduction

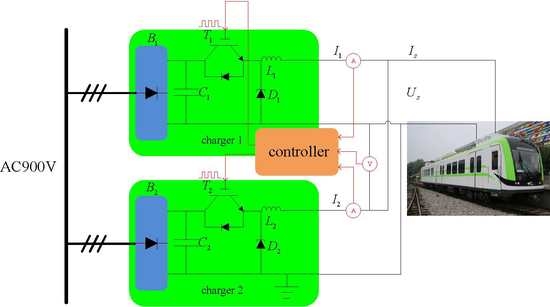

2. Charging Station Design

2.1. Schematic

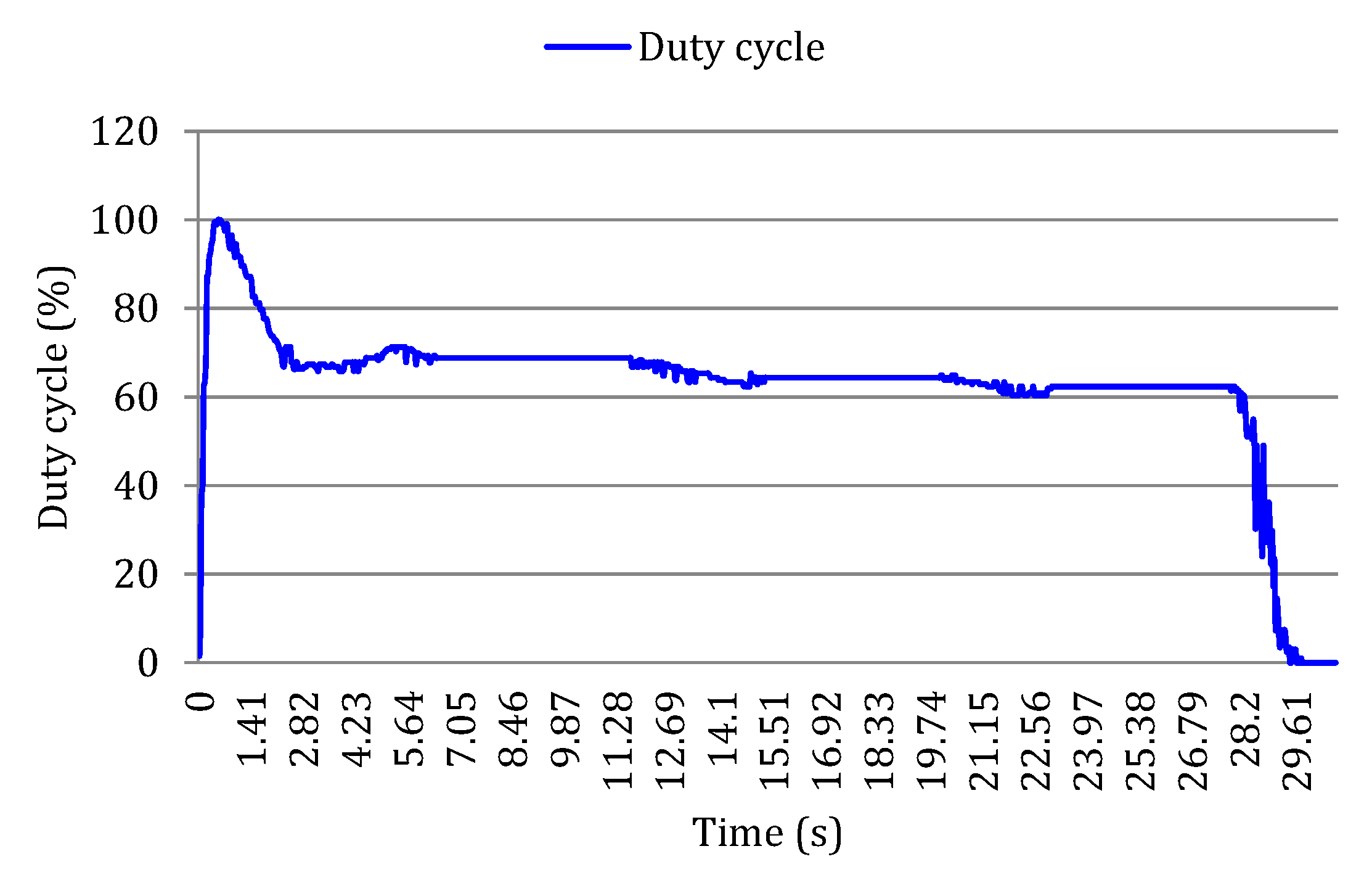

2.2. Control Strategy

2.3. Implementation

- Stage 1: The output current of the stationary charging station increases to the desired value Is*rapidly.

- Stage 2: The output current of the stationary charging station keeps constant at Is∗. The onboard EDLC stacks are charged with constant current Is∗.

- Stage 3: The output current of the stationary charging station decreases to zero rapidly. The charging is complete, and the stationary charging station can be disconnected from the vehicle.

| Algorithm 1 The flow chart of charging control procedure. | |

| 1: | Initialization; |

| 2: | Measure the output current Ii(k) and output voltage Us(k); |

| 3: | if Ii(k) < I∗ then |

| 4: | Update the control input τi(k) by |

| % cooperative PI charging control algorithm | |

| k = k + 1; | |

| goto Step 2; | |

| 5: | else |

| 6: | if Us(k) < Us∗ then |

| 7: | goto Step 4; |

| 8: | else |

| 9: | Set τi = 0; % the charging is complete; |

| 10: | end if |

| 11: | end if |

| 12: | End. |

- Digital IO: The digital IO is used to transmit commands from the control panel to the control board. The command signals include starting up, shutdown and switching modes.

- Analog IO: The analog IO is used to transmit measurements from sensors to the control board.

- Analog module: The analog module is used to preprocess the measurements from sensors before the measurements are stored and processed in the CPU.

- CPU module: The CPU module consists of two microcontrollers: FPGA XC3S50 and ARMLPC1766. XC3S50 is used to store and process data (including filtering, sequencing, etc.), and LPC1766 is used to run the charging control algorithm and to produce PWM control signals.

- RS485 module: The RS485 module is used to communicate with the personal computer (PC). All transient data in XC3S50 can be transmitted to the PC. Thus, it provides the flexibility of plotting the transient data in drawing software in teh PC.

- Optical interface: The optical interface is used to transmit PWM control signals from the control board to the IGBT driver. The advantage of the optical interface is that it can effectively shield the PWM control signals from electromagnetic interference.

3. Experimental Results

4. Concluding Remarks

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yusuf, S.; Saich, T. China Urbanizes: Consequences, Strategies, and Policies; World Bank Publications: Washington, DC, USA, 2008; pp. 125–153. [Google Scholar]

- Pan, H. Implementing Sustainable Urban Travel Policies in China. Transp. Sustain. 2013, 3, 43–76. [Google Scholar]

- He, W.; Zheng, R. Research on the Evaluation of China’s Automotive Industry Security: Based on Gray Model. Appl. Mech. Mater. 2014, 494, 192–196. [Google Scholar] [CrossRef]

- Zhao, Z.J. Making China’s Urban Transportation Boom Sustainable. In Paulson Policy Memorandum; The Paulson Institute: Chicago, IL, USA, 2014. [Google Scholar]

- Huang, C.F.; Xia, Y. Research on The Role of Urban Rail Transit in Promoting Economic Eevelopment. Procedia Eng. 2011, 21, 520–525. [Google Scholar] [CrossRef]

- Gonzàlez-Gil, A.; Palacin, R.; Batty, P. Sustainable Urban Rail Systems: Strategies and Technologies for Optimal Management of Regenerative Braking Energy. Energy Convers. Manag. 2013, 75, 374–388. [Google Scholar] [CrossRef]

- IEC. 60850: Railway Applications-Supply Voltages of Traction Systems, 3rd ed.; IEC: Geneva, Switzerland, 2007. [Google Scholar]

- Iannuzzi, D.; Pagano, E.; Tricoli, P. The Use of Energy Storage Systems for Supporting the Voltage Needs of Urban and Suburban Railway Contact Lines. Energies 2013, 6, 1802–1820. [Google Scholar] [CrossRef]

- Rufer, A.; Hotellier, D.; Barrade, P. A Supercapacitor-Based Energy Storage Substation for Voltage Compensation in Weak Transportation Networks. IEEE Trans. Power Deliv. 2004, 19, 629–636. [Google Scholar] [CrossRef]

- Barrero, R.; Tackoen, X.; Van Mierlo, J. Stationary or Onboard Energy Storage Systems for Energy Consumption Reduction in a Metro Network. Proc. Inst. Mech. Eng. Part F J Rail Rapid Transit 2010, 224, 207–225. [Google Scholar] [CrossRef]

- Iannuzzi, D.; Lauria, D.; Tricoli, P. Optimal Design of Stationary Supercapacitors Storage Devices for Light Electrical Transportation Systems. J. Optim. Eng. 2012, 13, 689–704. [Google Scholar]

- Ciccarelli, F.; Iannuzzi, D.; Lauria, D. Stationary Ultracapacitors Storage Device for Improving Energy Saving and Voltage Profile of Light Transportation Networks. Transp. Res. Part C Emerg. Technol. 2012, 21, 321–337. [Google Scholar] [CrossRef]

- Barrero, R.; Tackoen, X.; Van Mierlo, J. roving Energy Efficiency in Public Transport: Stationary Supercapacitor Based Energy Storage Systems for a Metro-Network. In Proceedings of the Vehicle Power Propulsion Conferene (VPPC 2008), Harbin, China, 3–5 September 2008.

- Ciccarelli, F.; del Pizzo, A.; Iannuzzi, D. Improvement of Energy Efficiency in Light Railway Vehicles Based on Power Management Control of Wayside Lithium-ion Capacitor Storage. IEEE Trans. Power Electron. 2014, 29, 275–286. [Google Scholar] [CrossRef]

- Ciccarelli, F.; Iannuzzi, D.; Spina, I. Comparison of Energy Management Control Strategy based on Wayside ESS for LRV application. In Proceedings of the 39th Annual Conference of the IEEE Industrial Electronics Society IECON2013, Vienna, Austria, 10–14 November 2013; pp. 1548–1554.

- Hannan, M.A.; Azidin, F.A.; Mohamed, A. Hybrid Electric Vehicles and Their Challenges: A Review. Renew. Sustain. Energy Rev. 2014, 29, 135–150. [Google Scholar] [CrossRef]

- Barrero, R.; Tackoen, X.; van Mierlo, J. Analysis and Configuration of Supercapacitor Based Energy Storage System onboard Light Rail Vehicles. In Proceedings of the 2008 Power Electronics and Motion Control Conference, Poznan, Poland, 1–3 September 2008; pp. 1512–1517.

- Bulucea, C.A.; Nicola, D.A.; Brandusa, C.; Cismaru, D. Energy and Exergy Efficiencies in Urban Electric Transportation Systems. Wseas Trans. Environ. Dev. 2008, 4, 247–259. [Google Scholar]

- Nicola, D.A.; Rosen, M.A.; Bulucea, C.A.; Brandusa, C. Some Sustainability Aspects of Energy Conversion in Urban Electric Trains. Sustainability 2010, 2, 1389–1407. [Google Scholar] [CrossRef]

- Song, M.; Wu, N.; Wu, K. Energy Consumption and Energy Efficiency of the Transportation Sector in Shanghai. Sustainability 2014, 6, 702–717. [Google Scholar] [CrossRef]

- Bulucea, C.A.; Brandusa, C. Experimental Characterization of Environmental Impacts from Underground Electric Metro in Braking Regime. In Proceedings of the 7th WSEAS/IASME International Conference on Electric Power Systems, High Voltages,Electric Machines, Venice, Italy, 21–23 November 2007; pp. 254–255.

- Chen, W.; Ruan, X.; Yan, H. DC/DC Conversion Systems Consisting of Multipleconverter Modules: Stability, Control, and Experimental Verifications. IEEE Trans. Power Electron. 2009, 24, 1463–1474. [Google Scholar] [CrossRef]

- Baumann, M.; Kolar, J.W. Parallel Connection of Two Three-Phase Three-Switch Buck-Type Unity-Power-Factor Rectifier Systems with Dc-Link Current Balancing. IEEE Trans. Ind. Electron. 2007, 54, 3042–3053. [Google Scholar] [CrossRef]

- De, B.K.; Bolsens, B.; van, K.J. A Voltage and Frequency Droop Control Method for Parallel Inverters. IEEE Trans. Power Electron. 2007, 22, 1107–1115. [Google Scholar] [CrossRef]

- Wang, J.B. Study of Cable Resistance and Remote-Sensing Scheme in Parallel DC-DC Converter System via Primary Droop Current-Sharing Control. IET Power Electron. 2012, 5, 885–898. [Google Scholar] [CrossRef]

- Anand, S.; Fernandes, B.G. Modified Droop Controller for Paralleling of DC-DC Converters in Standalone DC System. IET Power Electron. 2012, 5, 782–789. [Google Scholar] [CrossRef]

- Mazumder, S.K.; Tahir, M.; Acharya, K. Master-Slave Current-Sharing Control of a Parallel DC-DC Converter System over an RF Communication Interface. IEEE Trans. Ind. Electron. 2008, 55, 59–66. [Google Scholar] [CrossRef]

- Li, P.; Lehman, B. A Design Method for Paralleling Current Mode Controlled DC-DC Converters. IEEE Trans. Power Electron. 2004, 19, 748–756. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Peng, J.; Liu, W.; Huang, Z. Stationary Charging Station Design for Sustainable Urban Rail Systems: A Case Study at Zhuzhou Electric Locomotive Co., China. Sustainability 2015, 7, 465-481. https://doi.org/10.3390/su7010465

Li H, Peng J, Liu W, Huang Z. Stationary Charging Station Design for Sustainable Urban Rail Systems: A Case Study at Zhuzhou Electric Locomotive Co., China. Sustainability. 2015; 7(1):465-481. https://doi.org/10.3390/su7010465

Chicago/Turabian StyleLi, Heng, Jun Peng, Weirong Liu, and Zhiwu Huang. 2015. "Stationary Charging Station Design for Sustainable Urban Rail Systems: A Case Study at Zhuzhou Electric Locomotive Co., China" Sustainability 7, no. 1: 465-481. https://doi.org/10.3390/su7010465