Life-Cycle Assessment of Seismic Retrofit Strategies Applied to Existing Building Structures

Abstract

:1. Introduction

- An LCA for building materials and component combinations (bottom up).

- An LCA of the entire construction process (top down) [14].

- Costs.

- Structural performance.

- Speed of the installation process.

- Suspension time.

- Feasibility of the maintenance processes.

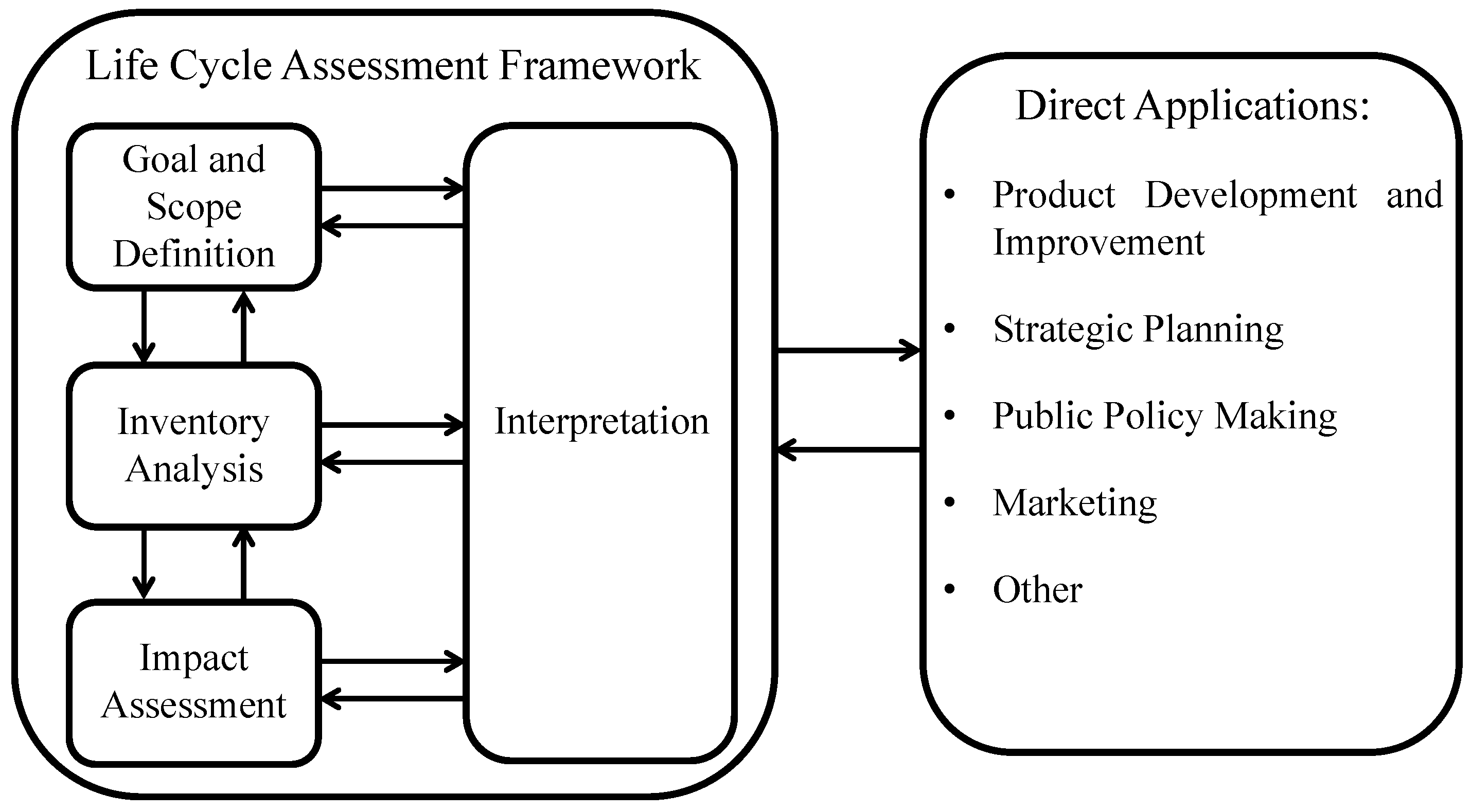

2. LCA Methodology

- (a)

- The development of tools and databases related to the impact of products, technologies, systems and processes.

- (b)

- The selection of construction products.

- (c)

- The evaluation of construction systems and procedures [6].

- (a)

- Goal and scope definition.

- (b)

- Inventory analysis or life-cycle inventory (LCI).

- (c)

- Impact assessment or life-cycle impact assessment (LCIA).

- (d)

- Interpretation of the results.

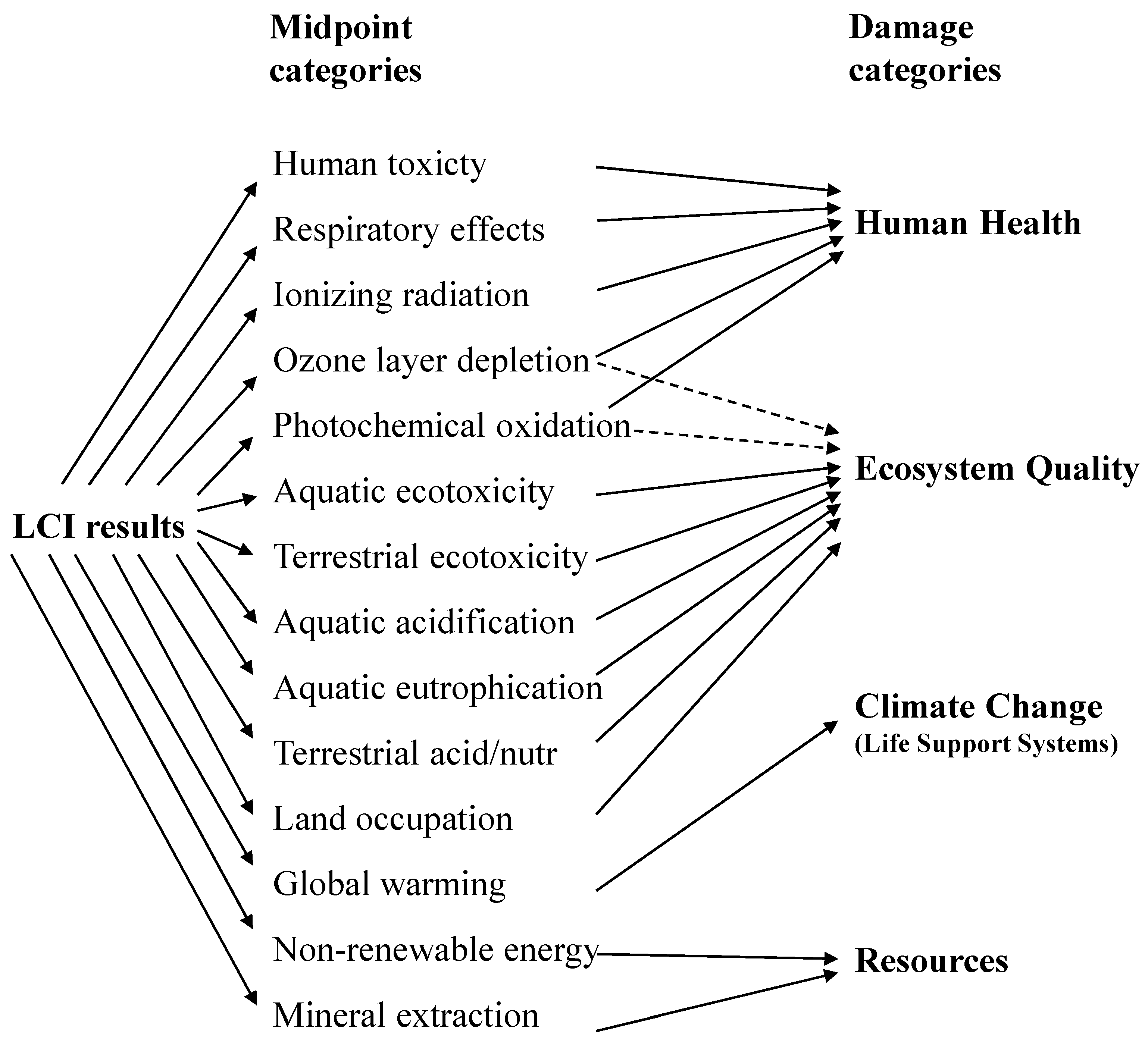

- (a)

- Classical impact assessment (e.g., Centre of Environmental Sciene – Leiden University (CML) [47] and Environmental Design of Industrial Products (EDIP) [48]), which collects LCI results in so-called midpoint categories. These points are located somewhere in the cause-effect chain between LCI results and the endpoint and limit uncertainties.

- (b)

3. Retrofit Strategies

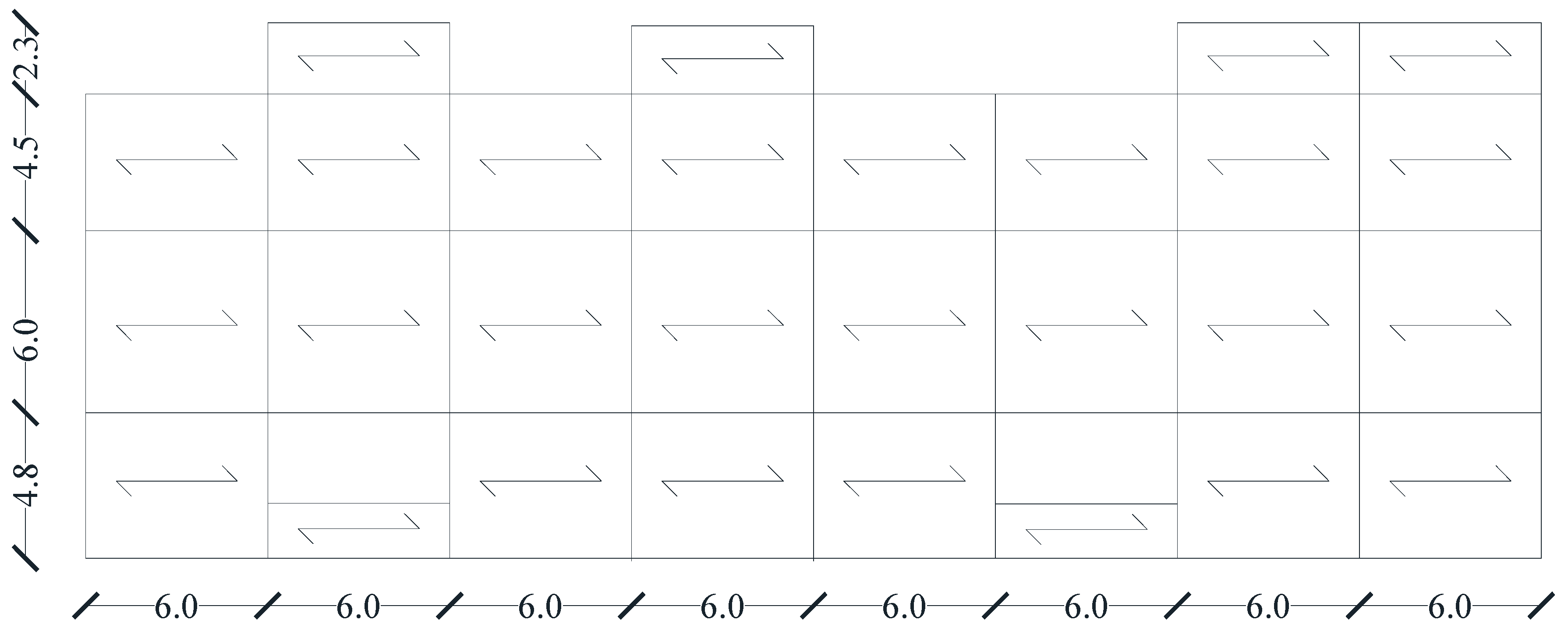

Design of the Seismic Strengthening Interventions

- ▪

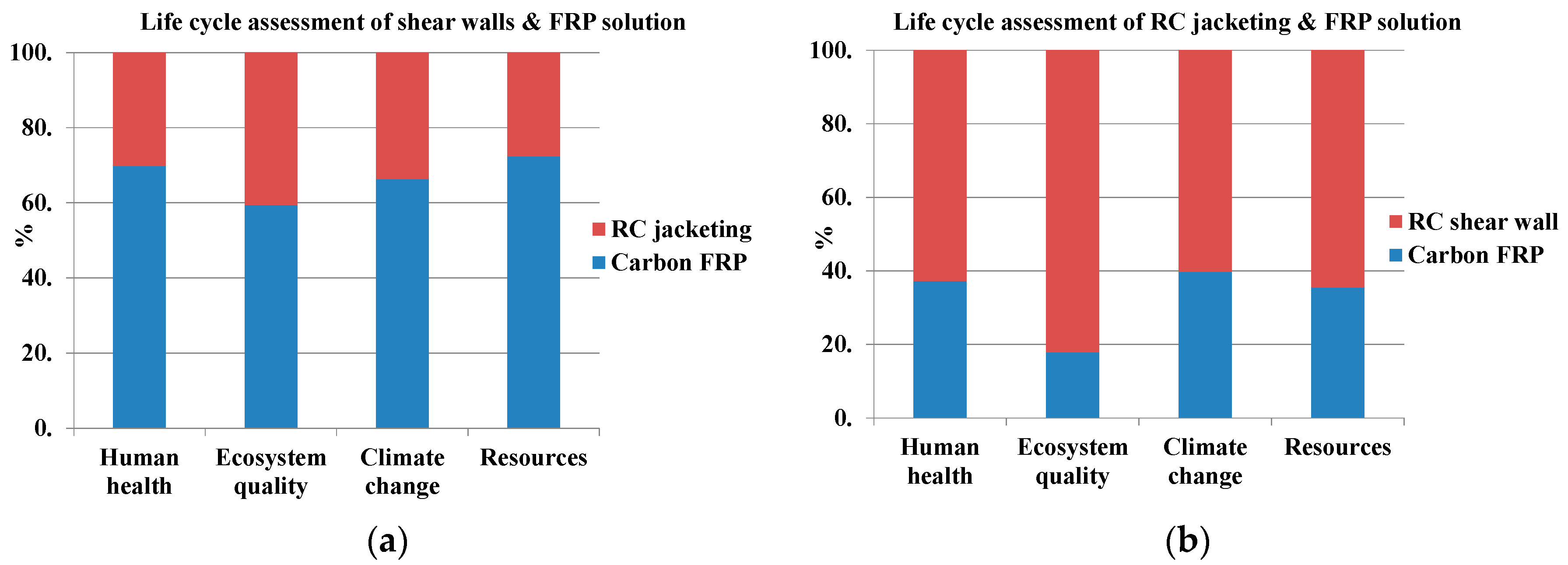

- FRP-based strengthening solution (i.e., shear strengthening of the beam-column joints, columns and beams using FRP sheets to prevent brittle failure mechanisms, and the confinement of columns at the ends by means of FRP wrapping to increase the structural global ductility); this strategy aims to increase the ductility and strength of the structure.

- ▪

- FRP-RC jacketing-based strengthening solution (i.e., RC jacketing of columns to increase the flexural and shear capacity of the members and the shear strengthening of the beam-column joints and beams using FRP sheets. This allows a slight increase in the building’s global stiffness that is to be balanced with the local increase in shear capacity in order to prevent brittle failure mechanisms).

- ▪

- Insertion of RC shear wall-based strengthening solution (i.e., insertion of two shear walls in the Y direction to sustain the seismic action); this strategy aims to increase the strength and stiffness of the structure.

- ▪

- Base isolation (i.e., inserting a horizontally flexible and dissipative interface on the first floor of the building, thus significantly reducing the demand rather than increasing the structural capacity).

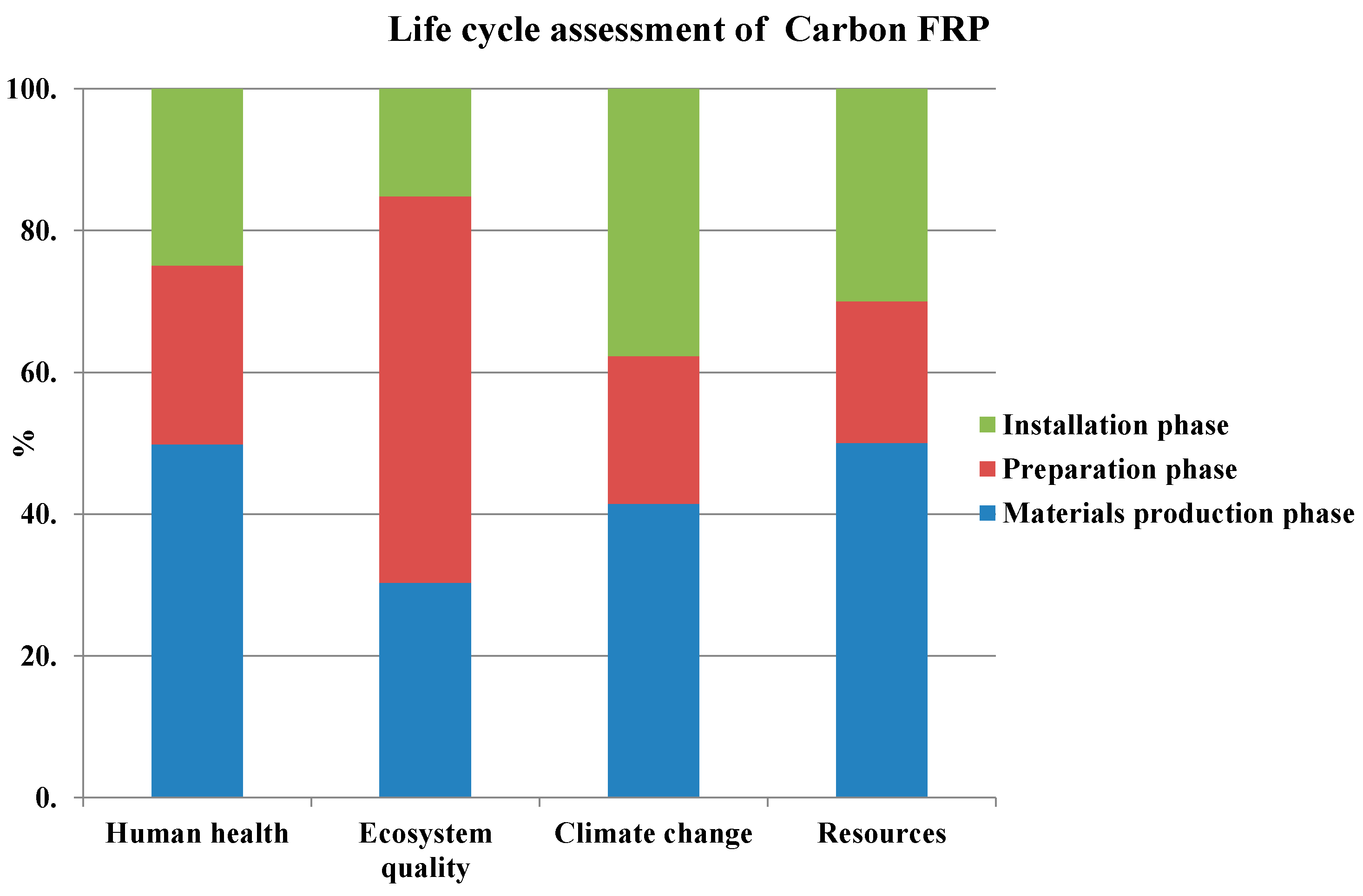

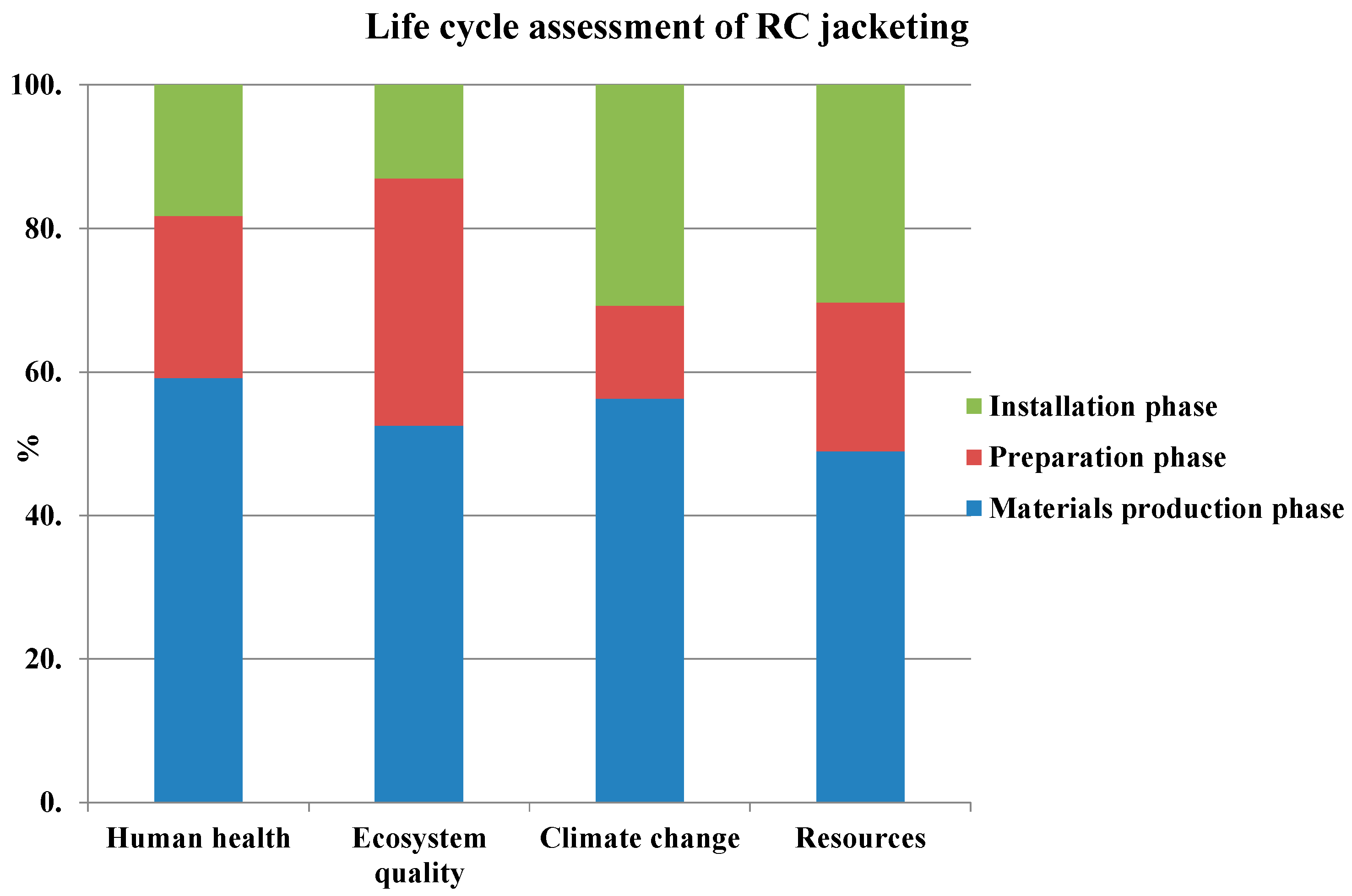

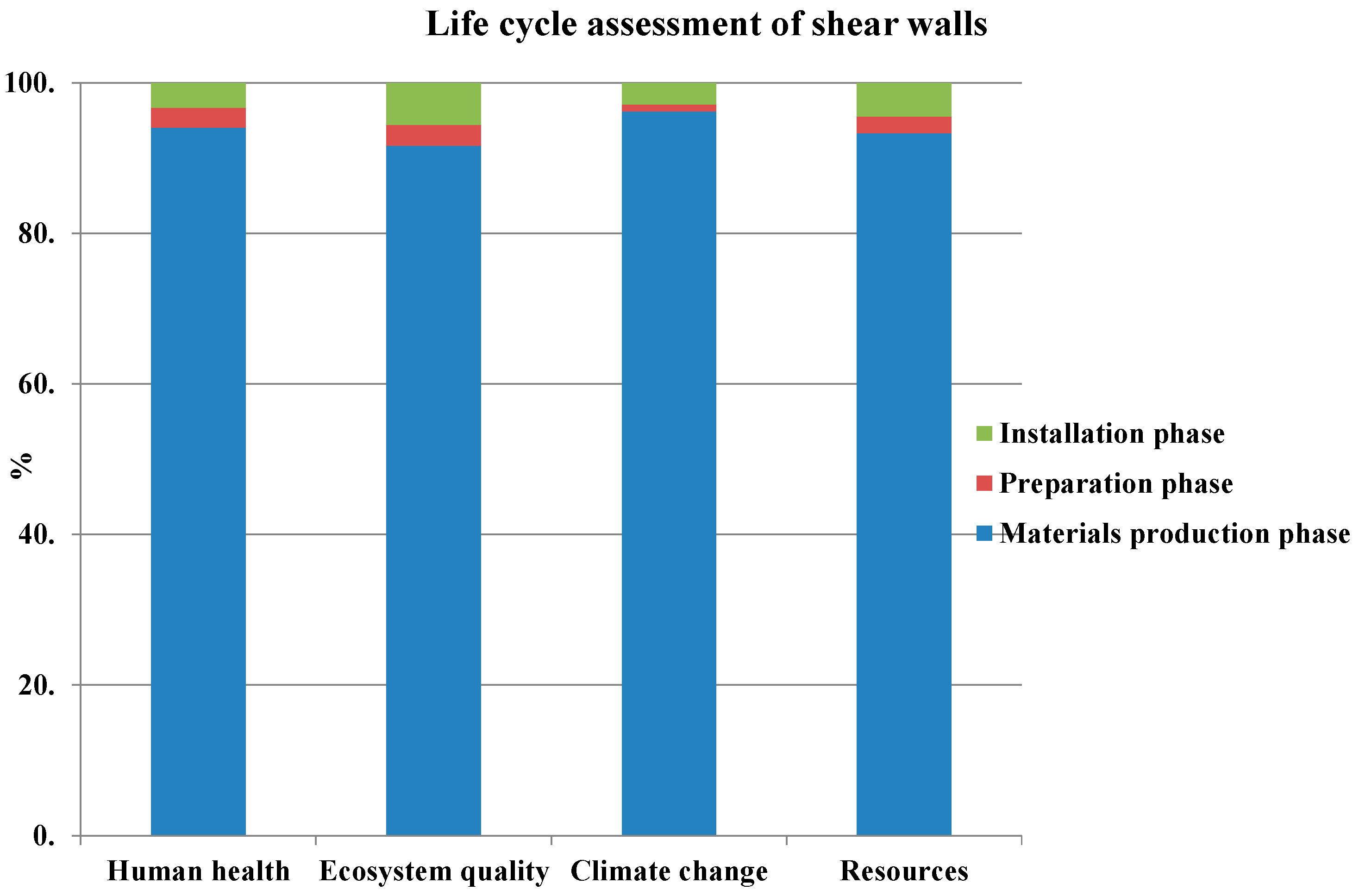

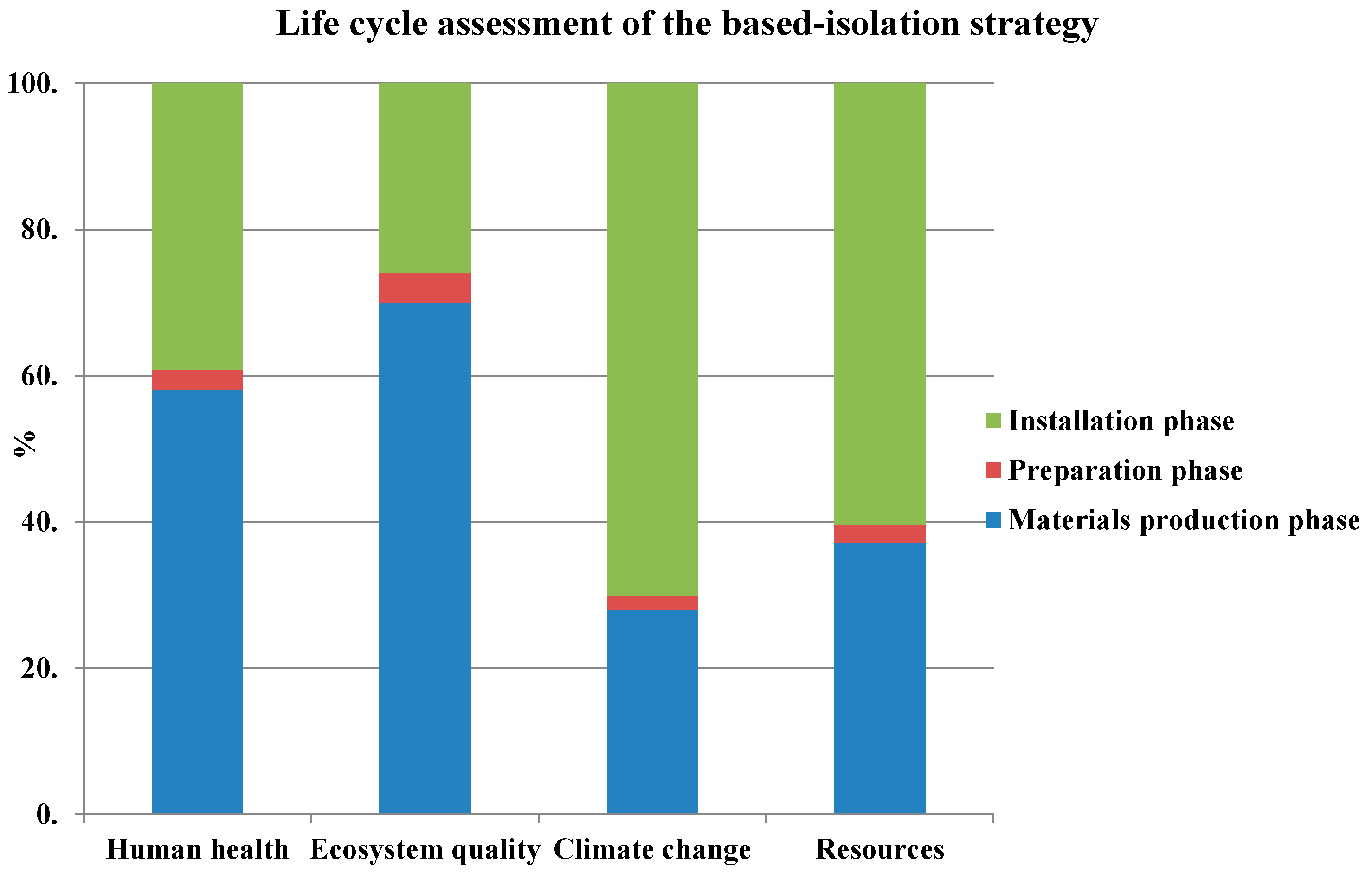

4. Life-Cycle Assessment of the Strengthening Strategies

4.1. Goal and Scope Definition

- (a)

- Materials production phase (extraction and production of the materials and construction phases).

- (b)

- Preparation phase (building demolition, material disposal and transport).

- (c)

- Installation phase (application of the technique).

4.2. Inventory Analysis (LCI)

- The distance between the construction and landfill sites is assumed to be 20 km.

- The material-supplying site is located 5 km from the construction site.

- The transport of the building materials from/to the construction site is assumed to be carried out by a lorry (EURO3).

4.3. Impact Assessment (LCIA)

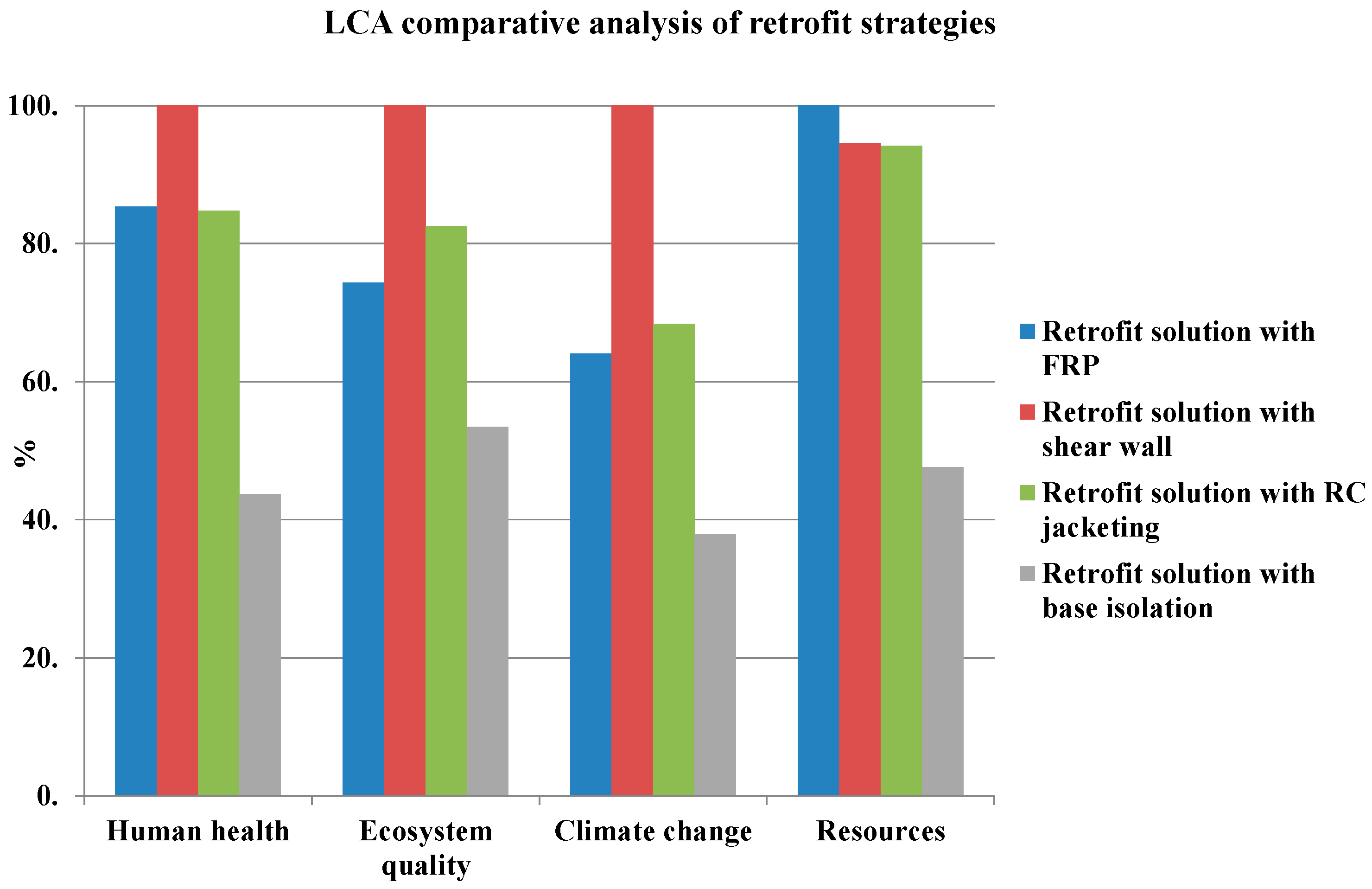

- Climate change (CC): this evaluates substances that contribute to global warming.

- Human health (HH): this evaluates the consequences of the release of substances that affect human beings.

- Ecosystem quality (EQ): this evaluates the potential consequences for the health of an ecosystem.

- Resource depletion (RD): this measures the depletion due to mineral extraction and the consumption of resources (renewable and non-renewable).

4.4. Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Building Services and Environmental Engineer. Building Services and Environmental Engineer; BSEE: London, UK, 2001; p. 16. [Google Scholar]

- Asif, M.; Muneer, T.; Kelley, R. Life cycle assessment: A case study of a dwelling home in Scotland. Build. Environ. 2007, 42, 1391–1394. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Building and Climate Change: Status, Challenges and Opportunities; Sustainable Building and Construction Initiative; UNEP: Nairobi, Kenya, 2007; p. 87. [Google Scholar]

- Pulselli, R.M.; Simoncini, E.; Pulselli, F.M.; Bastianoni, S. Energy analysis of building manufacturing, maintenance and use: Building indices to evaluate housing sustainability. Energy Build. 2007, 39, 620–628. [Google Scholar] [CrossRef]

- Nassèn, J.; Holmberg, J.; Wadeskog, A.; Nyman, M. Direct and indirect energy use and carbon emission in the production phase of buildings: An input-output analysis. Energy 2007, 32, 1593–1602. [Google Scholar] [CrossRef]

- Caruso, M.C.; Menna, C.; Asprone, D.; Prota, A.; Manfredi, G. Methodology for life cycle sustainability assessment of building structures. ACI Struct. Mater. J. 2006, in press. [Google Scholar]

- ITACA Protocol Website. Available online: http://www.itaca.org/valutazione_sostenibilita.asp# (accessed on 13 May 2016).

- Khasreen, M.M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Taborianski, V.M.; Prado, R.T.A. Comparative evaluation of the contribution of residential water heating systems to the variation of green-house gases stock in the atmosphere. Build. Environ. 2004, 39, 645–652. [Google Scholar] [CrossRef]

- Mora, R.; Bitsuamlak, G.; Horvat, M. Integrated life-cycle design of building enclosures. Build. Environ. 2011, 46, 1469–1479. [Google Scholar] [CrossRef]

- Gustavsson, L.; Sathre, R. Variability in energy and carbon dioxide balances of wood and concrete building materials. Build. Environ. 2006, 41, 940–951. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Erlandsson, M.; Borg, M. Generic LCA-methodology applicable for buildings, constructions and operation services—Today practice and development needs. Build. Environ. 2003, 38, 919–938. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Jalayer, F.; Prota, A.; Manfredi, G. Assessment of ecological sustainability of a building subjected to potential seismic events during its lifetime. Int. J. Life Cycle Assess. 2012, 18, 504–515. [Google Scholar] [CrossRef]

- Jönsson, A.; Tillman, A.M.; Svensson, T. Life cycle assessment of flooring materials: Case study. Build. Environ. 1997, 3, 245–255. [Google Scholar] [CrossRef]

- Ximenes, F.A.; Grant, T. Quantifying the greenhouse benefits of the use of wood products in two popular house designs in Sydney, Australia. Int. J. Life Cycle Assess. 2013, 18, 891–908. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, Z.; Chen, Y. Study of the environmental impacts based on the green tax—Applied to several types of building materials. Build. Environ. 2005, 2, 227–237. [Google Scholar] [CrossRef]

- Esin, T. A study regarding the environmental impact analysis of the building materials production process (in Turkey). Build. Environ. 2007, 11, 3860–3871. [Google Scholar] [CrossRef]

- Asdrubali, F. The role of life cycle assessment (LCA) in the design of sustainable buildings: Thermal and sound insulating materials. In Proceedings of the Euronoise 2009, Edinburgh, UK, 26–28 October 2009.

- Cabeza, L.F.; Rincon, L.; Vilarino, V.; Perez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector. A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Adalberth, K.; Almgren, A.; Petersen, E.H. Life cycle assessment of four multi-family buildings. Int. J. Low Energy Sustain. Build. 2001, 2, 1–21. [Google Scholar]

- Xing, S.; Xu, Z.; Jun, G. Inventory analysis of LCA on steel- and concrete-construction office buildings. Energy Build. 2008, 40, 1188–1193. [Google Scholar] [CrossRef]

- Pajchrowski, G.; Noskowiak, A.; Lewandowska, A.; Strykowski, W. Wood as a building material in the light of environmental assessment of full life cycle of four buildings. Constr. Build. Mater. 2014, 52, 428–436. [Google Scholar] [CrossRef]

- Guggemos, A.A.; Horvath, A. Comparison of environmental effects of steel-and concrete-framed buildings. J. Infrastruct. Syst. 2005, 2, 93–101. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S.H. Environmental life cycle assessment of a commercial office building in Thailand. Int. J. Life Cycle Assess. 2008, 6, 498–511. [Google Scholar] [CrossRef]

- Blengini, G.A. Life cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build. Environ. 2009, 2, 319–330. [Google Scholar] [CrossRef]

- Pushkar, S. Life Cycle Assessment of Flat Roof Technologies for Office Buildings in Israel. Sustainability 2016, 8, 54. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, M.; Cellura, M.; Mistretta, M. Energy and environmental benefits in public buildings as a result of retrofit actions. Renew. Sustain. Energy Rev. 2011, 15, 460–470. [Google Scholar] [CrossRef]

- Asadi, E.; da Silva, M.G.; Henggeler, C.; Dias, L. Multi-objective optimization for building retrofit strategies: A model and an application. Energy Build. 2012, 44, 81–87. [Google Scholar] [CrossRef]

- Ascione, F.; de Rossi, F.; Vanoli, G.P. Energy retrofit of historical buildings: Theoretical and experimental investigations for the modelling of reliable performance scenarios. Energy Build. 2011, 43, 1925–1936. [Google Scholar] [CrossRef]

- Biekšaa, D.; Šiupšinskas, G.; Martinatis, V.; Jaraminiene, E. Energy efficiency challenges in multi-apartment building renovation in Lithuania. J. Civ. Eng. Manag. 2011, 17, 467–475. [Google Scholar] [CrossRef]

- Xing, Y.; Hewitt, N.; Griffiths, P. Zero carbon buildings refurbishment—A hierarchical pathway. Renew. Sustain. Energy Rev. 2011, 15, 3229–3236. [Google Scholar] [CrossRef]

- Zšilaitytea, L.; Martinaitis, V. Search for optimal solution of public building renovation in terms of life cycle. J. Environ. Eng. Landsc. 2010, 18, 102–110. [Google Scholar] [CrossRef]

- Moliner, E.; Fabregat, J.; Cseh, M.; Vidal, R. Life cycle assessment of a fiber-reinforced polymer made of glass fiber phenolic resin with brominated flame retardant. In Proceedings of the 1st Symposium of the Spanish LCA Network: LCA & Bioenergy, Madrid, Spain, 15 October 2013.

- Zhang, C.; Lin, W.X.; Abududdin, M.; Caning, L. Environmental evaluation of FRP in UK highway bridge deck replacement applications based on a comparative LCA study. Adv. Mater. Res. 2012, 374, 43–48. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Rodrigues, C.; Freire, F. Integrated life-cycle assessment and thermal dynamic simulation of alternative scenarios for the roof retrofit of a house. Build. Environ. 2014, 81, 204–215. [Google Scholar] [CrossRef] [Green Version]

- Perini, K. Retrofitting with vegetation recent building heritage applying a design tool—The case study of a school building. Front. Archit. Res. 2013, 2, 267–277. [Google Scholar] [CrossRef]

- Allacker, K. Environmental and economic optimization of the floor on grade in residential buildings. Int. J. Life Cycle Assess. 2012, 17, 813–827. [Google Scholar] [CrossRef]

- Waheed, B.; Khan, F.; Veitch, B. Linkage-based frameworks for sustainability assessment: Making a case for driving force-pressure-state exposure- effect-action (DPSEEA) frameworks. Sustainability 2009, 1, 441–463. [Google Scholar] [CrossRef]

- Sahely, H.R.; Kennedy, C.A.; Adams, B.J. Developing sustainability criteria for urban infrastructure systems. Can. J. Civ. Eng. 2005, 32, 71–85. [Google Scholar] [CrossRef]

- Foxon, T.J.; Mcilkenny, G.; Gilmour, D.; Oltean-Dumbrava, C.; Souter, N.; Ashley, R.; Butler, D.; Pearson, R.; Jowitt, P.; Moir, J. Sustainability criteria for decision support in the UK water industry. J. Environ. Plan. Manag. 2002, 45, 285–301. [Google Scholar] [CrossRef]

- Juan, Y.K.; Kim, J.H.; Roper, K.; Castro-Lacouture, D. GA-based decision support system for housing condition assessment and refurbishment strategies. Autom. Constr. 2009, 18, 394–401. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 14040: Environmental Management-Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14044: Environmental Management-Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14042: Environmental Management-Life Cycle Assessment—Life Cycle Impact Assessment; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Guinèe, J.B.; Gorrèe, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; van Oers, L.; Sleeswijk, A.W.; Suh, S.; de Haes, H.A.U.; de Bruijn, H.; et al. Life Cycle Assessment: An Operational Guide to the ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Hauschild, M.; Wenzel, H. Scientific Background. In Environmental Assessment of Products; Chapman & Hall: London, UK, 1998; Volume 2. [Google Scholar]

- Goedkoop, M.; Spriensma, R. The Eco-Indicator 99: A Damage Oriented Method for Life Cycle Assessment, Methodology Report, 2nd ed.; PR Consultants: Amersfoort, The Netherlands, 2000. [Google Scholar]

- Steen, B. A systematic Approach to Environmental Priority Strategies in Product Development (EPS). 2000-General System Characteristics & 2000-Models and Data. Chalmers, CPM Report: 1999, 4 and 5. Available online: http://eps.esa.chalmers.se/download.html (accessed on May 2016).

- Ny, H.; MacDonald, J.P.; Broman, G.; Yamamoto, R.; Robert, K.H. Sustainability constraints as system boundaries: An approach to making life-cycle management strategic. J. Ind. Ecol. 2006, 10, 61–77. [Google Scholar] [CrossRef]

- Jorgensen, A.; le Bocq, A.; Nazarkina, L.; Hauschild, M. Methodologies for Social Life Cycle Assessment. Int. J. LCA 2008, 13, 96–103. [Google Scholar] [CrossRef]

- Mont, O.; Bleischwitz, R. Sustainable Consumption and Resource Management in the light of Life cycle Thinking. Eur. Environ. 2007, 17, 59–76. [Google Scholar] [CrossRef]

- Guch, P.; Baumann, H. The life cycle costing (LCC) approach: A conceptual discussion of its usefulness for environmental decision-making. Build. Environ. 2004, 39, 571–580. [Google Scholar]

- Canter, L.W. Environmental Impact Assessment; McGraw Hill: New York, NY, USA, 1996. [Google Scholar]

- European Standard. Eurocode 8: Design of Structures for Earthquake Resistance—Part 3: Assessment and Retrofitting of Buildings; Ref. No. EN 1998-3:2005: E; CEN: Brussels, Belgium, 2005. [Google Scholar]

- Fajfar, P. Capacity spectrum method based on inelastic demand spectra. Earthq. Eng. Struct. Dyn. 1999, 28, 979–993. [Google Scholar] [CrossRef]

- Ministero delle Infrastrutture. Approvazione delle Nuove Norme Tecniche per le Costruzioni; Serie Generale n.29 del 4-2-2008—Suppl. Ordinario n. 30; Gazzetta Ufficiale della Repubblica Italiana: Rome, Italy, 2008.

- Vitiello, U.; Asprone, D.; Di Ludovico, M.; Prota, A. Life-cycle cost optimization of the seismic retrofit of existing RC structure. Bull. Earthq. Eng. 2016. [Google Scholar] [CrossRef]

- Hedemann, J.; König, U. Technical Documentation of the Ecoinvent Database; Final Report Ecoinvent Data v2.2 No. 4; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Consiglio Nazionale delle Ricerche. Guide for the Design and Construction of Externally Bonded FRP System for Strengthening Existing Structures; CNR-DT 200; Consiglio Nazionale delle Ricerche: Rome, Italy, 2004. [Google Scholar]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. Impact 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

| Columns | Beams in Y Direction | Beams in X Direction | |

|---|---|---|---|

| First storey | 0.50 × 0.30, LR: 4Ø14, TR: Ø8/25 cm | 0.60 × 0.30, LR: 4Ø22, TR: Ø8/25 cm | 0.35 × 0.24, LR: 4Ø14, TR: Ø8/25 cm |

| Second storey | 0.50 × 0.30, LR: 4Ø14, TR: Ø8/25 cm | 0.60 × 0.30, LR: 4Ø22, TR: Ø8/25 cm | 0.35 × 0.24, LR: 4Ø14, TR: Ø8/25 cm |

| Third storey | 0.50 × 0.30, LR: 4Ø14, TR: Ø8/25 cm | 0.60 × 0.30, LR: 4Ø22, TR: Ø8/25 cm | 0.35 × 0.24, LR: 4Ø14, TR: Ø8/25 cm |

| Mode | Period | UX | UY | RZ |

|---|---|---|---|---|

| Unitless | S | Unitless | Unitless | Unitless |

| 1 | 1.317 | 83.50% | 0.01% | 0.10% |

| 2 | 0.651 | 0.02% | 18.57% | 68.98% |

| 3 | 0.614 | 0.00% | 69.60% | 18.25% |

| Strengthening Strategies | Cradle-To-Gate System Boundary | ||

|---|---|---|---|

| Materials Production Phase | Preparation Phase | Installation Phase | |

| FRP Solution |

|

|

|

| RC Jacketing Solution |

|

|

|

| RC Shear Walls Solution |

|

|

|

| Base-Isolation Solution |

|

|

|

| Midpoint Category | Midpoint Reference Substance | Damage Category | Damage Unit |

|---|---|---|---|

| Human toxicity (carcinogens + non-carcinogen) | kgeq chloroethylene into air | Human health | DALY (Disability Adjusted Life Years per kgemitted) |

| Respiratory (inorganics) | kgeq PM2.5 into air | Human health | |

| Ionizing radiations | Bqeq carbon-14 into air | Human health | |

| Ozone layer depletion | kgeq CFC-11 into air | Human health | |

| Photochemical oxidation | kgeq ethylene glycol into air | Human health | |

| Ecosystem quality | PDF × m2 × yr (PDF is the Potentially Disappeared Fraction) | ||

| Aquatic ecotoxicity | kgeq triethylene glycol into water | Ecosystem quality | |

| Terrestrial ecotoxicity | kgeq triethylene glycol into water | Ecosystem quality | |

| Terrestrial acidification/nutrification | kgeq SO2 into air | Ecosystem quality | |

| Aquatic acidification | kgeq SO2 into air | Ecosystem quality | |

| Aquatic eutrophication | kgeq PO43− into water | Ecosystem quality | |

| Land occupation | m2eq organic arable land year | Ecosystem quality | |

| Global warming | kgeq CO2 into air | Climate change | kgeq CO2 into air |

| Non-renewable energy | MJ Total primary non–renewable or kgeq crude oil (860 kg/m3) | Resources | MJ (Mega-Joule) |

| Mineral extraction | MJ additional energy or kgeq iron (in ore) | Resources |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vitiello, U.; Salzano, A.; Asprone, D.; Di Ludovico, M.; Prota, A. Life-Cycle Assessment of Seismic Retrofit Strategies Applied to Existing Building Structures. Sustainability 2016, 8, 1275. https://doi.org/10.3390/su8121275

Vitiello U, Salzano A, Asprone D, Di Ludovico M, Prota A. Life-Cycle Assessment of Seismic Retrofit Strategies Applied to Existing Building Structures. Sustainability. 2016; 8(12):1275. https://doi.org/10.3390/su8121275

Chicago/Turabian StyleVitiello, Umberto, Antonio Salzano, Domenico Asprone, Marco Di Ludovico, and Andrea Prota. 2016. "Life-Cycle Assessment of Seismic Retrofit Strategies Applied to Existing Building Structures" Sustainability 8, no. 12: 1275. https://doi.org/10.3390/su8121275