Timber Chips as the Insulation Material for Energy Saving in Prefabricated Offices

Abstract

:1. Introduction

2. Methodology

- (1)

- The successive transition method and the trapezoid hold function, which can adjust itself to the time-discrete domain.

- (2)

- Dimensionless equations which are used to calculate convective heat transfer coefficients for every part of the unit.

- (3)

- Long-wave and short-wave absorption coefficients which make it possible to simulate the net absorption of radiant heat and transmitted solar radiation.

- (4)

- A multi-layer window model, which defines the overall transmittance, absorption and reflectance of solar radiation.

- (5)

- A network airflow model which is used to calculate ventilation quantities.

2.1. Simulation Model

2.2. Details of Inner Heating and Materials for Simulation

2.3. Details of the Materials for Actual Measurement

3. Results of Simulation

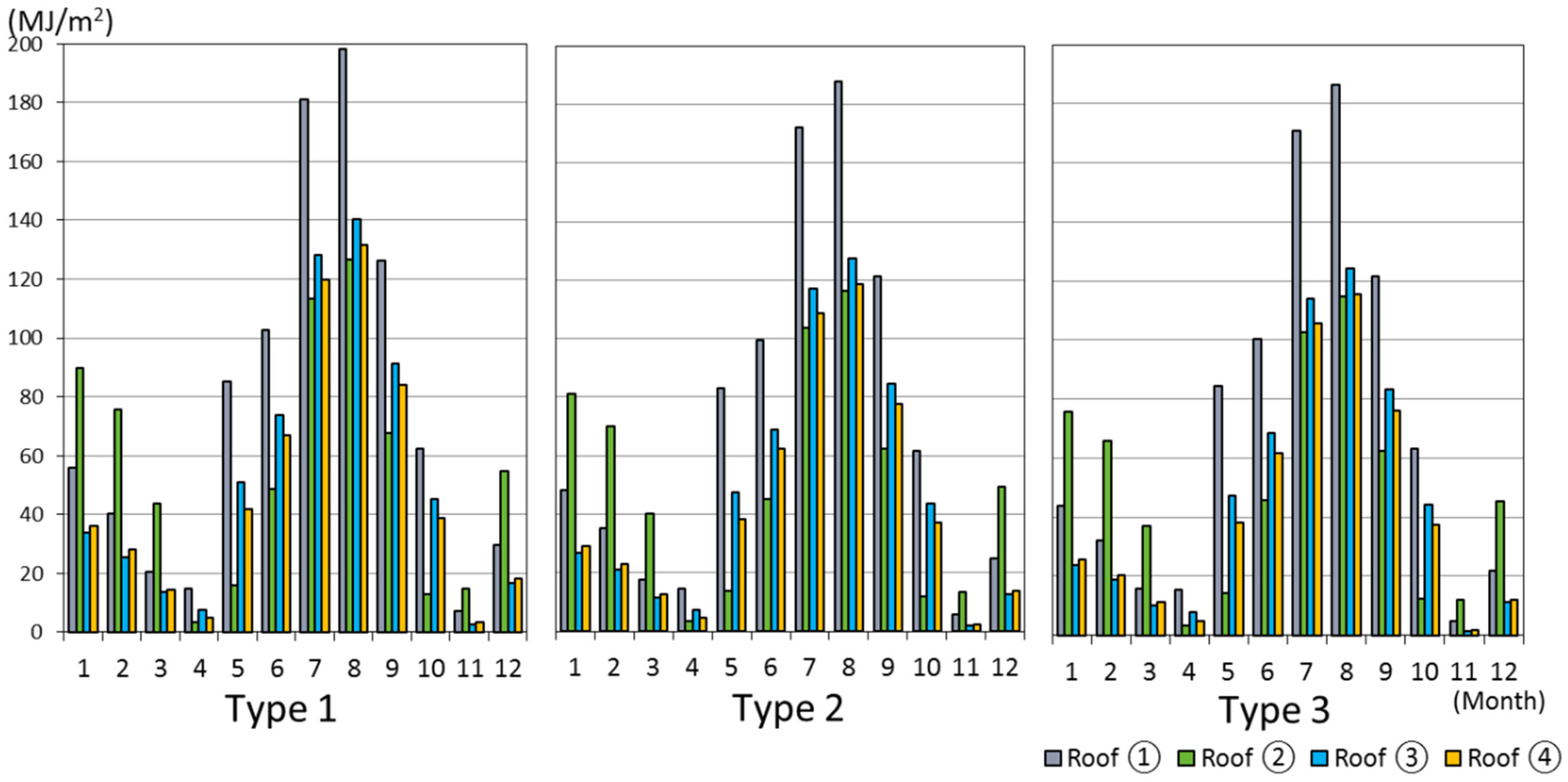

3.1. Annual AC Load of Normal Prefabricated Office

3.2. The Effect of Roof Insulation

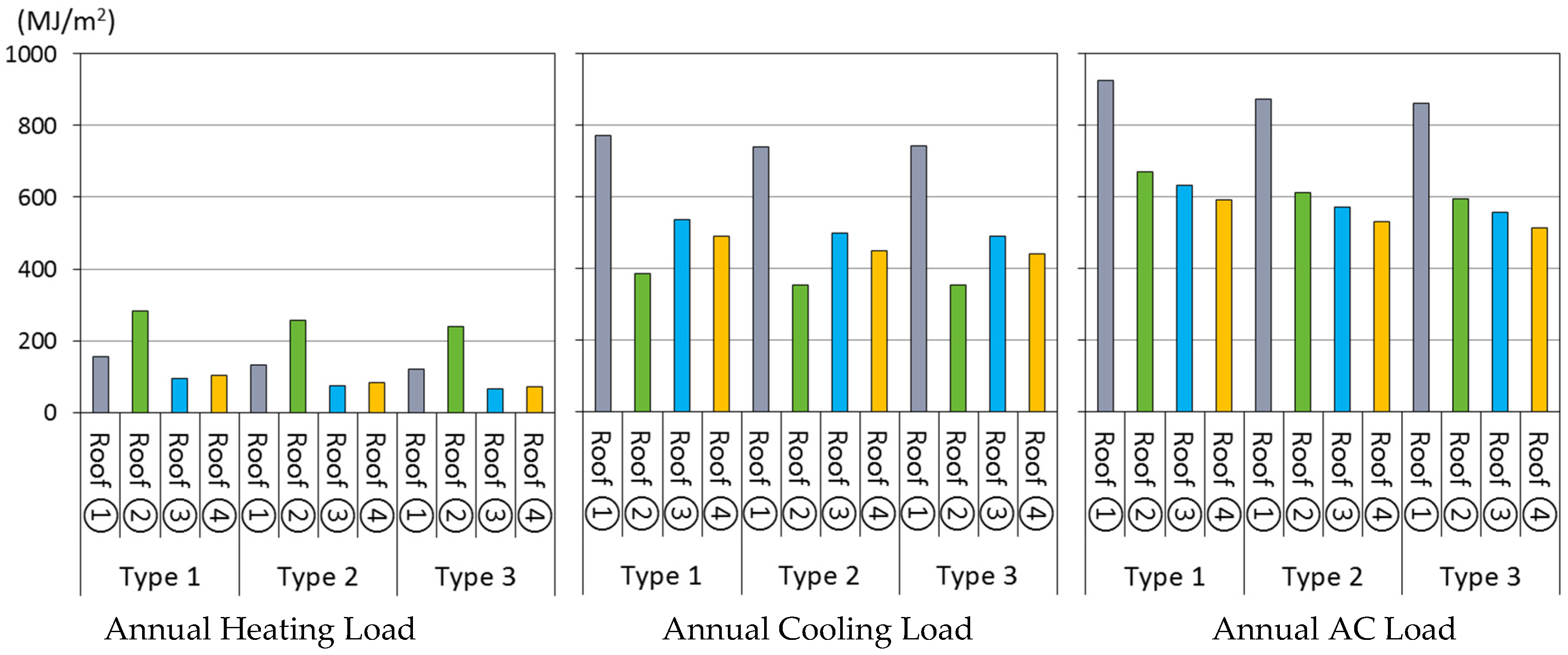

3.2.1. About the AC Load Reduction

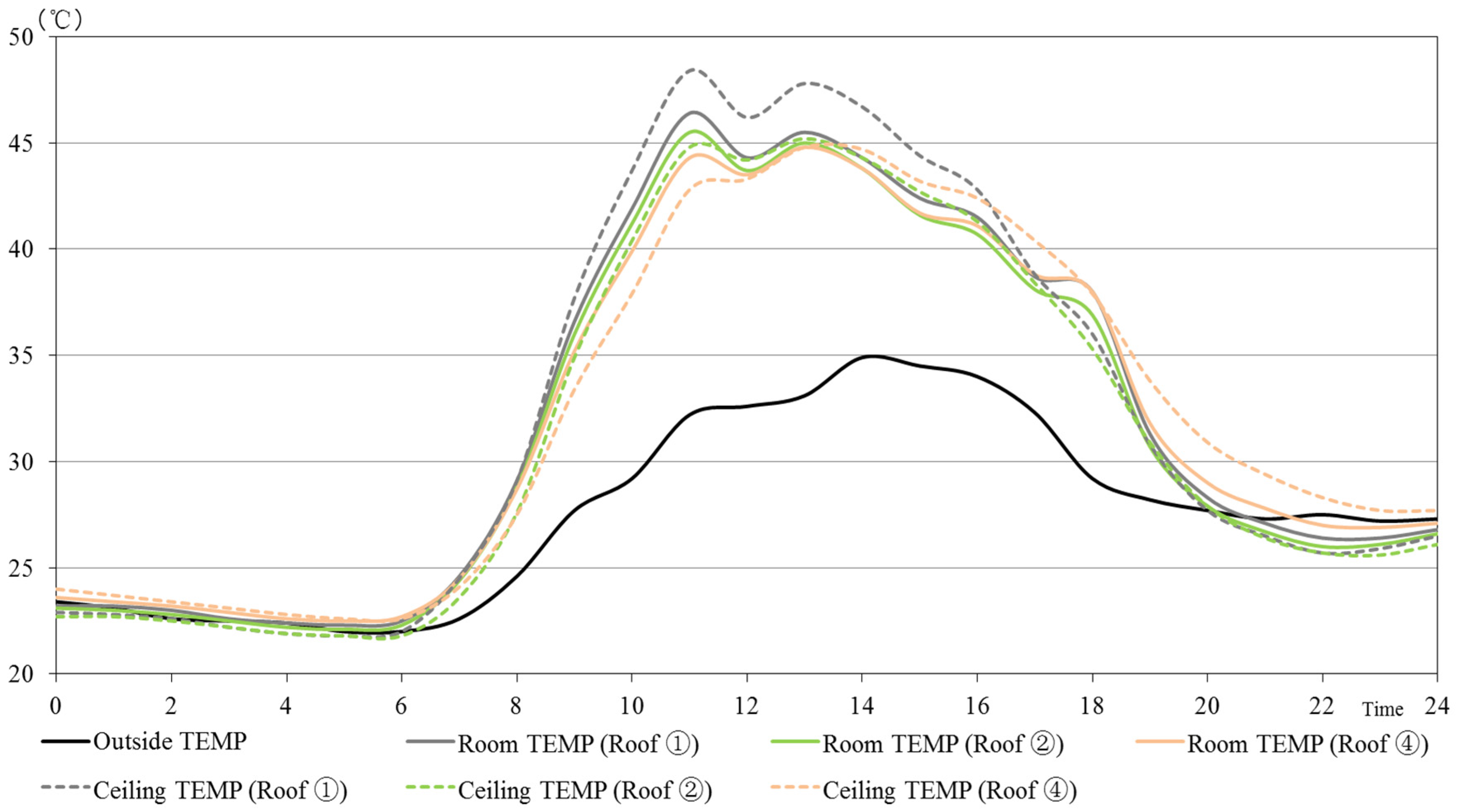

3.2.2. About the Thermal Comfort

4. Results of Actual Measurement

5. Conclusions

- (1)

- In prefabricated offices with reflective-coated roofs (roof ②), the solar energy absorption was significantly reduced. During the summer, the diurnal indoor air temperature increase was mitigated. Because of the small heat capacity without insulation, the indoor heat could be readily cooled down. Conversely, in winter, because of the significant impacts from the outdoor air and low solar energy absorption, it took more time and energy to heat up the whole office.

- (2)

- In prefabricated offices with insulated roofs (roof ③), temperature differences between the indoor air and the interior roof surface were smaller than those of the steel sheet roof prefabricated offices, resulting in an extreme annual AC load reduction of 84.8 kWh/m2 (roof ③).

- (3)

- With the new roof style that we provided (roof ④), the heating load in winter was slightly higher than it was in the insulated roof (roof ③) prefabricated offices and the cooling load in the summer was obviously low. The annual AC load reduction was 10.9% (roof ③) compared to the reflective-coated roof (roof ②) which was 7.8% (roof ③) lower than that of the insulated roof (roof ③) prefabricated offices.

Author Contributions

Conflicts of Interest

References

- Senaratne, S.; Gerace, D.; Mirza, O.; Tam, V.W.Y. The costs and benefits of combining recycled aggregate with steel fibres as a sustainable, structural material. J. Cleaner Prod. 2016, 112, 2318–2327. [Google Scholar] [CrossRef]

- Institute for Building Environment and Energy Conservation. Explanation of the Energy-Saving Standards for Houses 2002; Institute for Building Environment and Energy Conservation: Tokyo, Japan, 2002. [Google Scholar]

- Mousa, M.S.; Akash, B.A. Some prospects of energy saving in buildings. Energ. Convers. Manag. 2001, 42, 1307–1315. [Google Scholar]

- Salmaan, C.; David, H.; Cripps, A.; Knott, D. BioTRIZ suggests radiative cooling of buildings can be done passively by changing the structure of roof insulation to let longwave infrared pass. J. Biol. Educ. 2008, 5, 55–66. [Google Scholar]

- Ramamurthy, P.; Sun, T.; Rule, K.; Bou-Zeid, E. The joint influence of albedo and insulation on roof performance: An observational study. Energ. Build. 2015, 93, 249–258. [Google Scholar] [CrossRef]

- Shaik, S.; Talanki, A.B.P.S. Optimizing the position of insulating materials in flat roofs exposed to sunshine to gain minimum heat into buildings under periodic heat transfer conditions. Environ. Sci. Pollut. Res. 2015, 23, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Al-Sallal, K.A. Comparison between polystyrene and fiberglass roof insulation in warm and cold climates. Renew. Energ. 2003, 28, 603–611. [Google Scholar] [CrossRef]

- Akbari, H.; Levinson, R.; Miller, W.; Berdahl, P. Cool Colored Roofs to Save Energy and Improve Air Quality; Ernest Orlando Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2005.

- Akbari, H.; Cartalis, C.; Kolokotsa, D.; Muscio, A.; Pisello, A.L.; Rossi, F.; Santamouris, M.; Synnefa, A.; Wong, N.H.; Zinzi, M. Local climate change and urban heat island mitigation techniques—the state of the art. J. Civ. Eng. Manag. 2016, 22, 1–16. [Google Scholar] [CrossRef]

- Dabaieh, M.; Wanas, O.; Hegazy, M.A.; Johansson, E. Reducing cooling demands in a hot dry climate: A simulation study for non-insulated passive cool roof thermal performance in residential buildings. Energ. Build. 2015, 89, 142–152. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Labrincha, J.; Cabeza, L.; Granqvist, C.G. (Eds.) Eco-efficient Materials for Mitigating Building Cooling Needs: Design, Properties and Applications, 1st ed.; Woodhead Publishing: Cambridge, UK; Waltham, MA, USA; Kidlington, UK, 2015.

- Joseph, P.; Tretsiakova-McNally, S. Sustainable Non-Metallic Building Materials. Sustainability 2010, 2, 400–427. [Google Scholar] [CrossRef]

- Kuma, Y.; Fukuda, H.; Ozaki, A. Performance evaluation of residences by dynamic simulation: heat load based on changing the location, plan and specification of residences. J. Asian. Architect. Build. Eng. 2007, 6, 183–188. [Google Scholar] [CrossRef]

- Ozaki, A.; Watanabe, T.; Hayashi, T.; Ryu, Y. Systematic analysis on combined heat and water transfer through porous materials based on thermodynamic energy. Energ. Build. 2001, 33, 341–350. [Google Scholar] [CrossRef]

- Ozaki, A.; Tsujimaru, T. Prediction of hygrothermal environment of buildings based upon combined simulation of heat and moisture transfer and airflow. In Proceedings of the Ninth International IBPSA Conference, Montréal, AL, Canada, 15–18 August 2005.

- Architectural Institute of Japan. Expanded AMeDAS Weather Data (1981–2000); Architectural Institute of Japan: Tokyo, Japan, 2005. [Google Scholar]

- Morikita Publishing Co., Ltd. Architectural Environment Engineering 1996; Morikita Publishing Co., Ltd: Tokyo, Japan, 1996. [Google Scholar]

- Japan Federation of Construction Contractors. Survey Report on the Properties of Building Materials; Japan Federation of Construction Contractors: Tokyo, Japan, 2014. [Google Scholar]

- Tsukiyama, Y.; Sunaga, N.; Suzuki, A.; Fukazawa, T.; Chiba, Y. Study on thermal storage characteristics of AAC floor panels using an actual test rooms. Am. J. Environ. Eng. 2010, 75, 149–156. [Google Scholar] [CrossRef]

- Wang, Y.; Fukuda, H.; Kuma, Y.; Ozaki, A. Study of Air-conditioning load: Comparison of steel and RC residence units. J. Asian. Architect. Build. Eng. 2010, 9, 571–576. [Google Scholar] [CrossRef]

- Wang, Y.; Fukuda, H.; Ozaki, A. Simulation study on the effect of insulation on interior structural parts of super high-rise residences. Am. J. Environ. Eng. 2011, 76, 999–1008. [Google Scholar] [CrossRef]

| Room Area | Officer No. | Person Heat | Lights Heat | OA Heat | Inter Heat | |

|---|---|---|---|---|---|---|

| (m2) | (Person) | (W) | (W) | (W) | (W) | |

| Type 1 | 20.88 | 3 | 216 | 522 | 731 | 1469 |

| Type 2 | 40.20 | 5 | 360 | 1005 | 1407 | 2772 |

| Type 3 | 57.63 | 7 | 504 | 1441 | 2017 | 3962 |

| Inner Surface | Outside Surface | ||||

|---|---|---|---|---|---|

| Solar Absorption | Longwave Radiation | Solar Absorption | Longwave Radiation | ||

| Roof ① | Steel Sheet | 0.80 | 0.90 | 0.60 | 0.20 |

| Roof ② | Heat barrier painting | 0.80 | 0.90 | 0.08 | 0.99 |

| Roof ③ | Wooden chips | 0.80 | 0.90 | 0.80 | 0.65 |

| Roof ④ | Packed wooden chips | 0.80 | 0.90 | 0.30 | 0.90 |

| Walls | 0.60 | 0.90 | 0.40 | 0.95 | |

| Flooring | 0.65 | 0.90 | - | - | |

| Components | Materials | Thickness | Thermal Conductivity | Specific of Heat | Specific of Weight | |

|---|---|---|---|---|---|---|

| (mm) | (W/m·K) | (J/kg·K) | (kg/m3) | |||

| Roof | Steel Sheet | Steel Sheet | 0.6 | 45 | 462.4 | 8160 |

| Refractory Investment | 5 | 0.038 | 840 | 1.2 | ||

| Insulated | Wooden Chips | 100 | 0.071 | 800 | 138 | |

| Steel Sheet | 0.6 | 45 | 462.4 | 8160 | ||

| Refractory Investment | 5 | 0.038 | 840 | 1.2 | ||

| Walls | Steel Sheet | 0.5 | 45 | 462.4 | 8160 | |

| Polurethane Foam | 30 | 0.028 | 1470 | 28 | ||

| Plyboard | 10 | 0.22 | 870 | 700 | ||

| Flooring | Concrete | 100 | 1.6 | 840 | 2200 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Fukuda, H. Timber Chips as the Insulation Material for Energy Saving in Prefabricated Offices. Sustainability 2016, 8, 587. https://doi.org/10.3390/su8060587

Wang Y, Fukuda H. Timber Chips as the Insulation Material for Energy Saving in Prefabricated Offices. Sustainability. 2016; 8(6):587. https://doi.org/10.3390/su8060587

Chicago/Turabian StyleWang, Yupeng, and Hiroatsu Fukuda. 2016. "Timber Chips as the Insulation Material for Energy Saving in Prefabricated Offices" Sustainability 8, no. 6: 587. https://doi.org/10.3390/su8060587