Analysis of Low-Carbon Economy Efficiency of Chinese Industrial Sectors Based on a RAM Model with Undesirable Outputs

Abstract

:1. Introduction

2. Materials and Methods

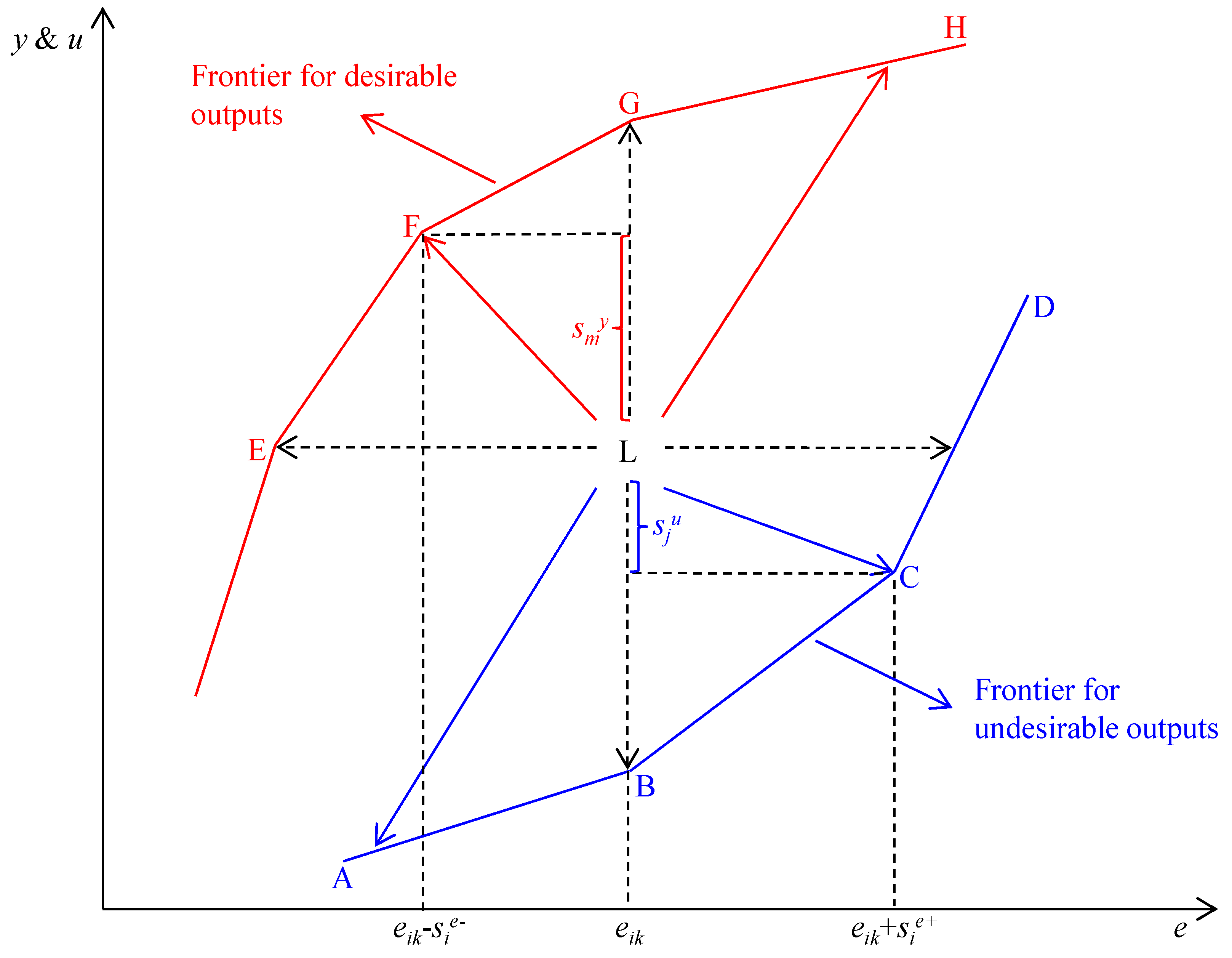

2.1. LCE-RAM Model

2.2. Assignment Model of the CO2 Emission Intensity Mitigation Target

2.2.1. Industrial Output and CO2 Emission Potential Measurement

2.2.2. Assignment of CO2 Emission Intensity Mitigation Target

2.3. Data and Variables

3. Results

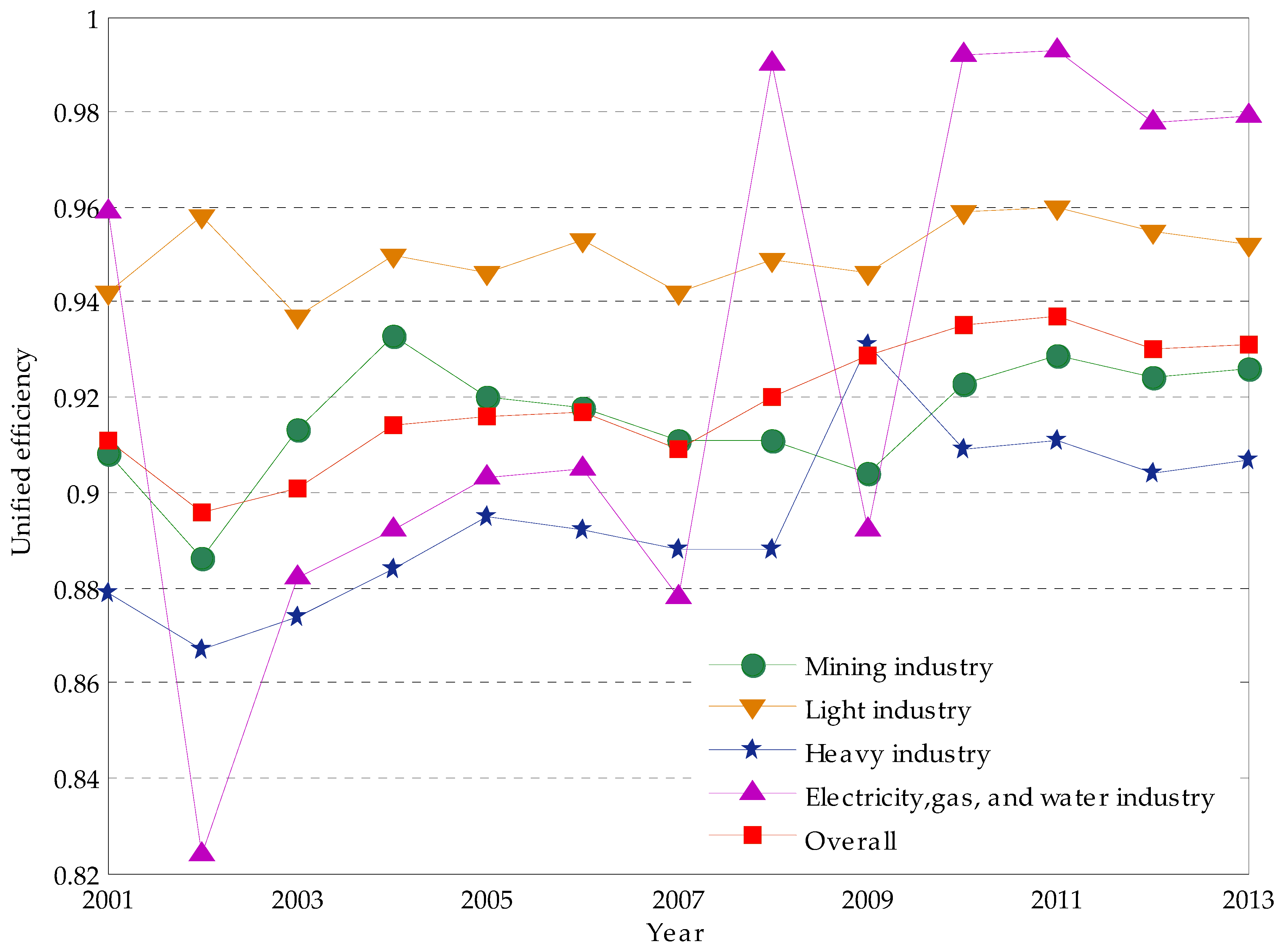

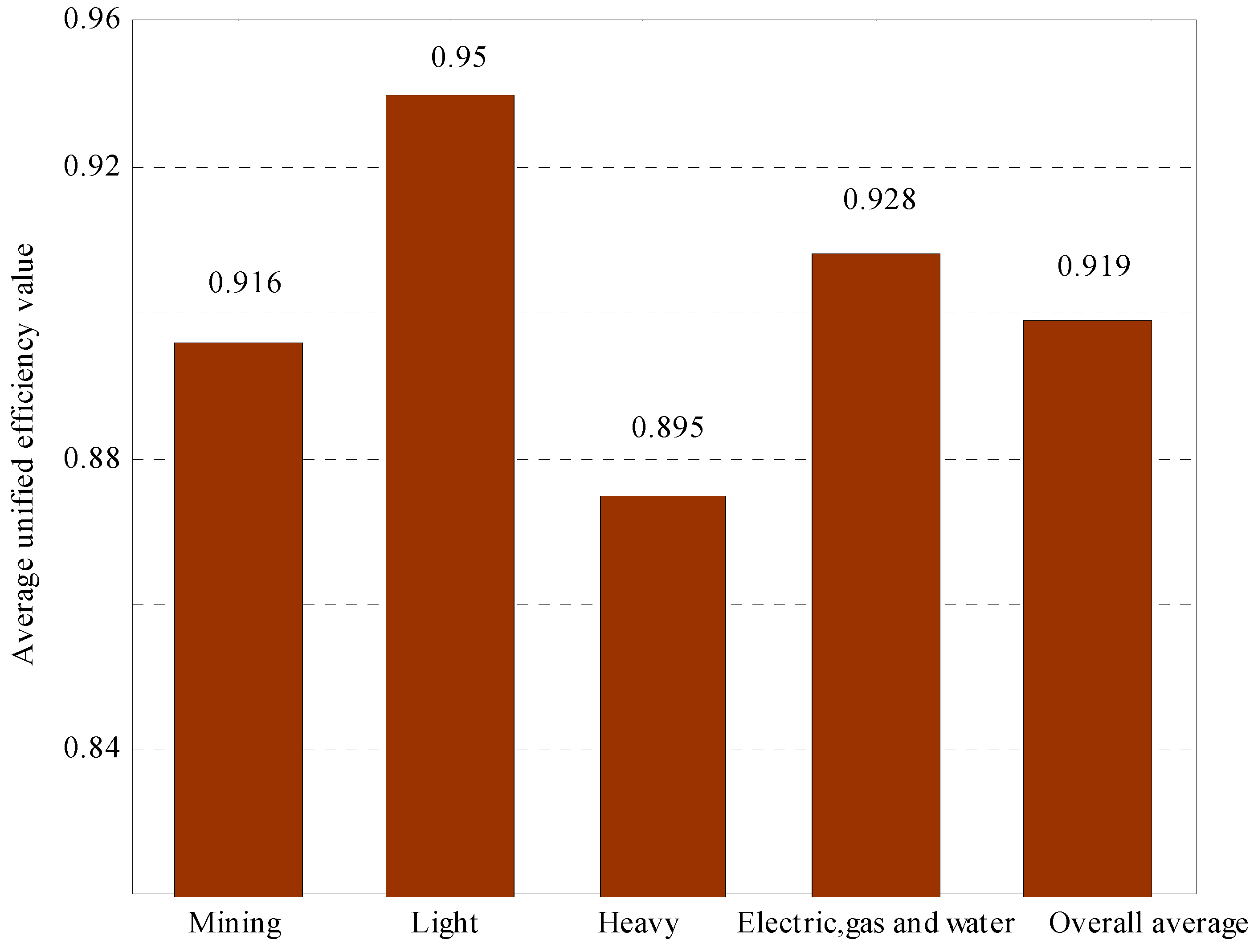

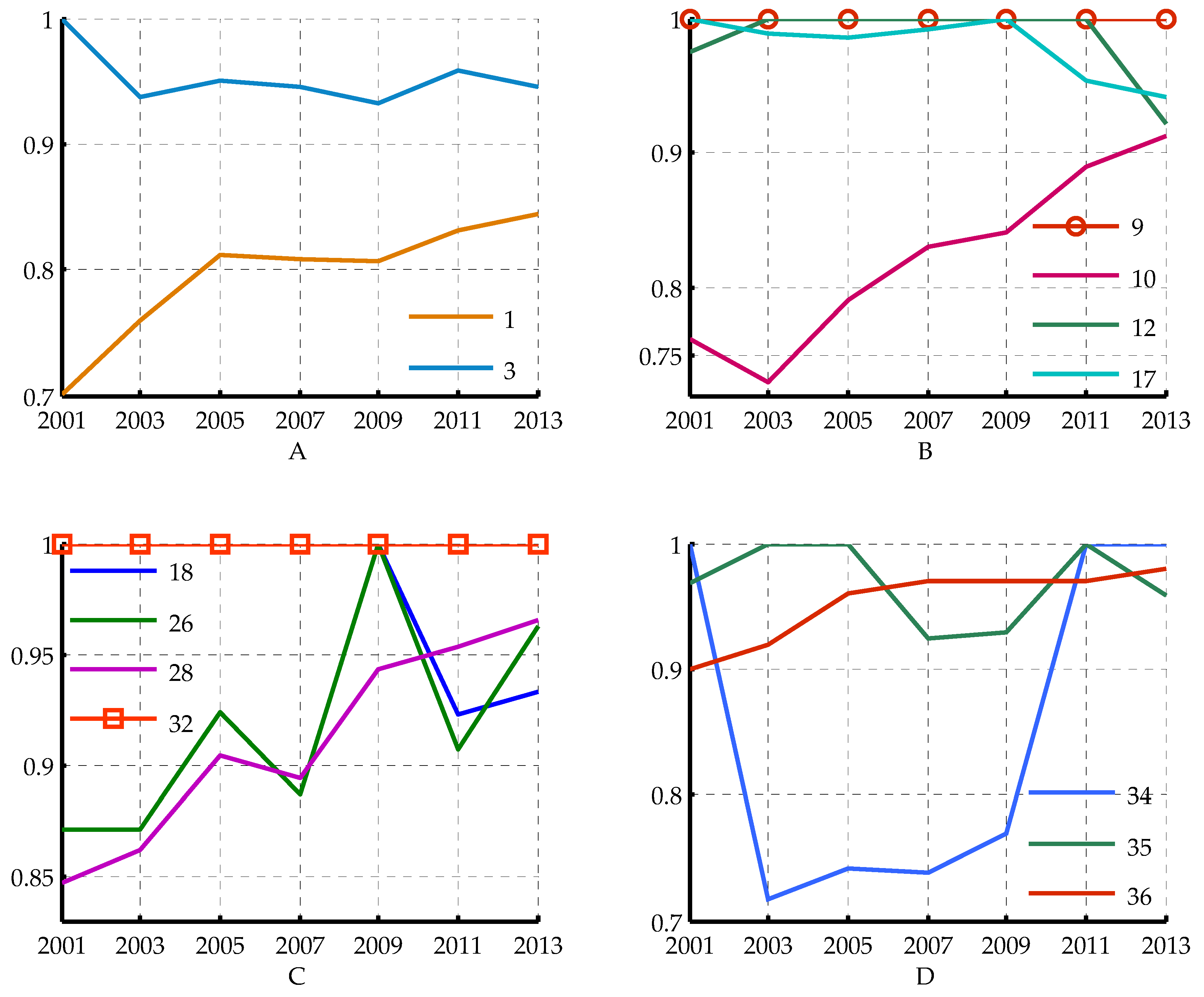

3.1. Low-Carbon Economy Efficiencies of the Four Major Industrial Categories and Their Trends

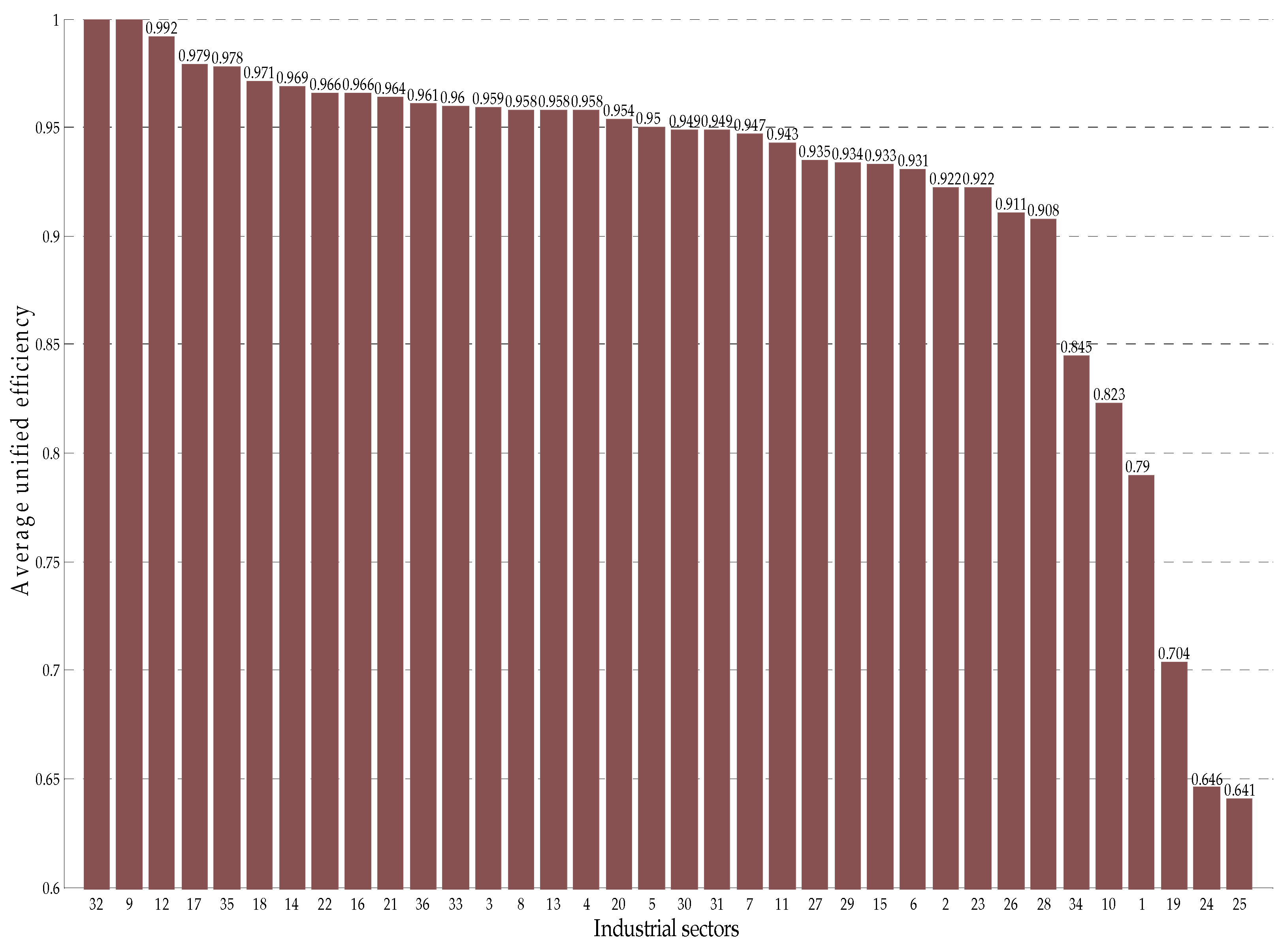

3.2. Efficiency Characteristics of Industrial Sectors

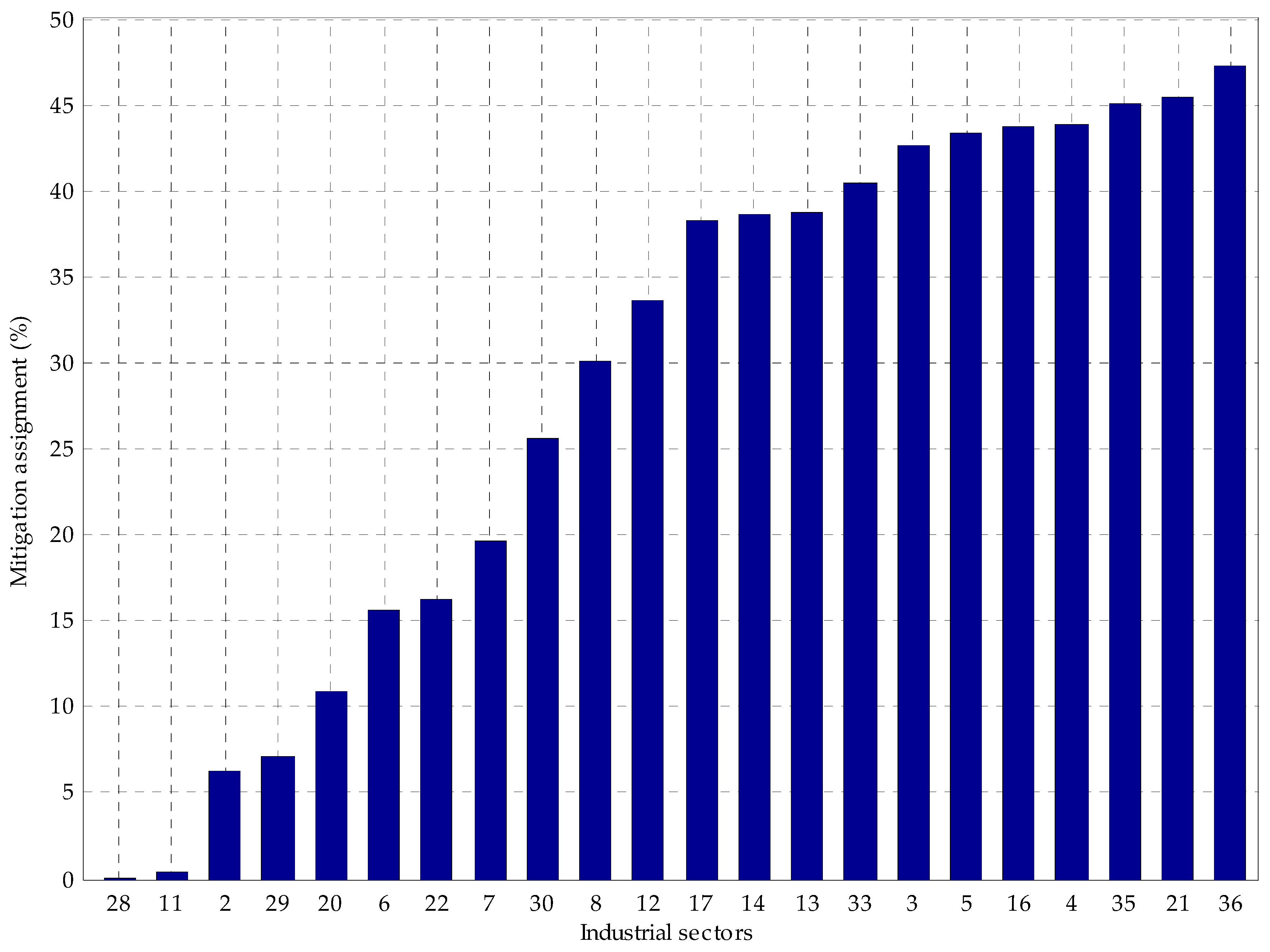

3.3. Assignment of CO2 Emission Intensity Mitigation Target

4. Discussion

4.1. General Analysis of the Low-Carbon Economy Efficiency

4.2. Analysis of the Low-Carbon Economy Efficiency of the Sectors

4.3. Assignment Analysis of the CO2 Emission Intensity Mitigation Targets

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Enegy Agency. Statistic, Statistic Search. Available online: http://www.iea.org/statistics/statisticssearch/ (accessed on 23 October 2016).

- World Bank. Data. Available online: http://data.worldbank.org/indicator/NY.GDP.MKTP.CD?locations=CN (accessed on 23 October 2016).

- Xie, B.C.; Shang, L.F.; Yang, S.B.; Yi, B.-W. Dynamic environmental efficiency evaluation of electric power industries: Evidence from OECD (Organization for Economic Cooperation and Development) and BRIC (Brazil, Russia, India and China) countries. Energy 2014, 74, 147–157. [Google Scholar] [CrossRef]

- Cherniwchan, J. Economic growth, industrialization, and the environment. Resour. Energy Econ. 2012, 34, 442–467. [Google Scholar] [CrossRef]

- Yang, Q.; Wan, X.; Ma, H. Assessing green development efficiency of municipalities and provinces in China integrating models of super-efficiency DEA and malmquist index. Sustainability 2015, 7, 4492–4510. [Google Scholar] [CrossRef]

- Wang, K.; Yu, S.; Zhang, W. China’s regional energy and environmental efficiency: A DEA window analysis based dynamic evaluation. Math. Comput. Model. 2011, 58, 1117–1127. [Google Scholar] [CrossRef]

- Bian, Y.; He, P.; Xu, H. Estimation of potential energy saving and carbon dioxide emission reduction in China based on an extended non-radial DEA approach. Energy Policy 2013, 63, 962–971. [Google Scholar] [CrossRef]

- National Bureau of Statistics of the People’s Republic of China. China Statistical Yearbook. Available online: http://www.stats.gov.cn/tjsj/ndsj/ (accessed on 23 October 2016). (In Chinese)

- BP. Energy Economics. Available online: http://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy/co2-emissions.html (accessed on 23 October 2016).

- Zhou, D.; Zhao, X. Industrial performance of the renewable resources industry in China. Sustainability 2015, 7, 11777–11798. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, P.; Zhao, Z.; Shen, N. Energy efficiency and energy saving potential in China: A directional meta-frontier DEA approach. Sustainability 2014, 6, 5476–5492. [Google Scholar] [CrossRef]

- Dyckhoff, H.; Allen, K. Measuring1 ecological efficiency with data envelopment analysis (DEA). Eur. J. Oper. Res. 2001, 132, 312–325. [Google Scholar] [CrossRef]

- Li, G.; Huang, D.; Li, Y. China’s input-output efficiency of water-energy-food nexus based on the Data Envelopment Analysis (DEA) model. Sustainability 2016, 8, 927. [Google Scholar] [CrossRef]

- Yan, Q.Y.; Jie, T. Biomass power generation industry efficiency evaluation, in China. Sustainability 2014, 6, 8720–8735. [Google Scholar] [CrossRef]

- Liu, J.S.; Lu, L.Y.; Lu, W.M.; Lin, B.J.Y. Data envelopment analysis 1978–2010: A citation-based literature survey. Omega 2013, 41, 3–15. [Google Scholar] [CrossRef]

- Lin, W.; Chen, B.; Xie, L.; Pan, H. Estimating energy consumption of transport modes in China using DEA. Sustainability 2015, 7, 4225–4239. [Google Scholar] [CrossRef]

- Wu, J.; An, Q.; Yao, X.; Wang, B. Environmental efficiency evaluation of industry in China based on a new fixed sum undesirable output data envelopment analysis. J. Clean. Prod. 2014, 74, 96–104. [Google Scholar] [CrossRef]

- Zhou, G.; Chung, W.; Zhang, Y. Measuring energy efficiency performance of China’s transport sector: A data envelopment analysis approach. Expert. Syst. Appl. 2014, 41, 709–722. [Google Scholar] [CrossRef]

- Wu, F.; Fan, L.W.; Zhou, P.; Zhou, D.Q. Industrial energy efficiency with CO2 emissions in China: A nonparametric analysis. Energy Policy 2012, 49, 164–172. [Google Scholar] [CrossRef]

- Wang, K.; Wei, Y.M. China’s regional industrial energy efficiency and carbon emissions abatement costs. Appl. Energy 2014, 130, 617–631. [Google Scholar] [CrossRef]

- Li, H.; Shi, J.F. Energy efficiency analysis on Chinese industrial sectors: An improved Super-SBM model with undesirable outputs. J. Clean. Prod. 2014, 65, 97–107. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Hao, J.F.; Song, J. The CO2, emission efficiency, reduction potential and spatial clustering in China’s industry: Evidence from the regional level. Appl. Energy 2016, 174, 213–223. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. DEA approach for unified efficiency measurement: Assessment of Japanese fossil fuel power generation. Energy Econ. 2011, 33, 292–303. [Google Scholar] [CrossRef]

- Baležentis, T.; Li, T.; Streimikiene, D.; Baležentis, A. Is the Lithuanian economy approaching the goals of sustainable energy and climate change mitigation? Evidence from DEA-based environmental performance index. J. Clean. Prod. 2016, 116, 23–31. [Google Scholar] [CrossRef]

- Zhang, J.; Zeng, W.; Wang, J.; Yang, F.; Jiang, H. Regional low-carbon economy efficiency in China: Analysis based on the Super-SBM model with CO2, emissions. J. Clean. Prod. 2015, in press. [Google Scholar] [CrossRef]

- Haynes, K.; Ratick, S.; Cumming, S.J. Pollution Prevention Frontiers: A Data Envelopment Simulation; University of Illinois Press: Champaign, IL, USA, 1997. [Google Scholar]

- Reinhard, S.; Lovell, C.A.K.; Thijssen, G.J. Environmental efficiency with multiple environmentally detrimental variables: Estimated with SFA and DEA. Eur. J. Oper. Res. 2000, 121, 287–303. [Google Scholar] [CrossRef]

- Hailu, A.; Veeman, T.S. Nonparametric productivity analysis with undesirable outputs: An application to the Canadian pulp and paper Industry. Am. J. Agr. Econ. 2001, 83, 605–616. [Google Scholar] [CrossRef]

- Scheel, H. Undesirable outputs in efficiency valuations. Eur. J. Oper. Res. 2001, 132, 400–410. [Google Scholar] [CrossRef]

- Maleyeff, J. Quantitative Models for Performance Evaluation and Benchmarking: DEA with Spreadsheets and DEA Excel Solver; Springer: Berlin, Germany, 2005. [Google Scholar]

- Zhou, Y.; Liang, D.; Xing, X. Environmental efficiency of industrial sectors in China: An improved weighted SBM model. Math. Comput. Model. 2013, 58, 990–999. [Google Scholar] [CrossRef]

- Seiford, L.M.; Zhu, J. Modeling undesirable factors in efficiency evaluation. Eur. J. Oper. Res. 2002, 142, 16–20. [Google Scholar] [CrossRef]

- Chung, Y.H.; Färe, R.; Grosskopf, S. Productivity and undesirable outputs: A directional distance function approach. J. Environ. Manag. 1997, 51, 229–240. [Google Scholar]

- Färe, R.; Grosskopf, S.; Pasurka, C.A. Environmental Production Functions and Environmental Directional Distance Functions: A Joint Production Comparison. Soc. Sci. Electron. Publ. 2004. [Google Scholar] [CrossRef]

- Boyd, G.A.; Tolley, G.; Pang, J. Plant Level Productivity, Efficiency, and Environmental Performance of the Container Glass Industry. Environ. Res. Econ. 2002, 23, 29–43. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Weber, W.L. Shadow prices and pollution costs in U.S. agriculture. Ecol. Econ. 2006, 56, 89–103. [Google Scholar] [CrossRef]

- Watanabe, M.; Tanaka, K. Efficiency analysis of Chinese industry: A directional distance function approach. Energy Policy 2007, 35, 6323–6331. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Chang, Y.T.; Zhang, N.; Danao, D.; Zhang, N. Environmental efficiency analysis of transportation system in China: A non-radial DEA approach. Energy Policy 2013, 58, 277–283. [Google Scholar] [CrossRef]

- Li, T.; Baležentis, T.; Makutėnienė, D.; Streimikiene, D.; Kriščiukaitienė, I. Energy-related CO2, emission in European Union agriculture: Driving forces and possibilities for reduction. Appl. Energy 2016, 180, 682–694. [Google Scholar] [CrossRef]

- Cooper, W.W.; Park, K.S.; Pastor, J.T. RAM: A Range Adjusted Measure of Inefficiency for Use with Additive Models, and Relations to Other Models and Measures in DEA. J. Prod. Anal. 1999, 11, 5–42. [Google Scholar] [CrossRef]

- Renshaw, E.F. Energy efficiency and the slump in labor productivity in the USA. Energy Econ. 1981, 3, 36–42. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W. Linear programming models for measuring economy-wide energy efficiency performance. Energy Policy 2008, 36, 291l–2916. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, P.; Zhou, D. Efficiency measurement with carbon dioxide emissions: The case of China. Appl. Energy 2012, 90, 161–166. [Google Scholar] [CrossRef]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Kanagawa, Japan, 2006. [Google Scholar]

- National Bureau of statistics Energy Statistics Division National Energy Bureau. China Energy Statistical Yearbook; China Statistical Publishing House: Beijing, China, 2014.

| Industry Classification | Industry Code | Industry Name |

|---|---|---|

| Mining industry | 1 | Coal mining and washing |

| 2 | Oil and natural gas mining | |

| 3 | Ferrous metal mining | |

| 4 | Non-ferrous metal mining | |

| 5 | Non-metal mining | |

| Light industry | 6 | Agricultural product processing |

| 7 | Food manufacturing | |

| 8 | Beverage manufacturing | |

| 9 | Tobacco manufacturing | |

| 10 | Textile industry | |

| 11 | Textile clothes, shoes, hats manufacturing | |

| 12 | Leather, fur, feather manufacturing | |

| 13 | Wood processing, wood, bamboo, cane, palm, and straw manufacturing | |

| 14 | Furniture manufacturing | |

| 15 | Papermaking and paper products | |

| 16 | Press and intermediary replication | |

| 17 | Cultural, educational, and sport goods manufacturing | |

| Heavy industry | 18 | Oil processing, coking, and nuclear fuels processing |

| 19 | Manufacturing of chemical | |

| 20 | Manufacturing of medicines | |

| 21 | Manufacturing of chemical fiber | |

| 22 | Manufacturing of rubber | |

| 23 | Manufacturing of plastics | |

| 24 | Manufacturing of non-metal products | |

| 25 | Smelting and rolling process of non-ferrous metal | |

| 26 | Smelting and rolling process of Ferrous metal | |

| 27 | Manufacturing of metal products | |

| 28 | Manufacturing of ordinary machinery | |

| 29 | Manufacturing of special equipment | |

| 30 | Manufacturing of transportation and equipment | |

| 31 | Manufacturing of electric machines | |

| 32 | Manufacturing of communication device, computers and other electronic | |

| 33 | Manufacturing of instruments, cultural and official mechanics | |

| Electricity, gas and water industry | 34 | Production and supply of electricity, power |

| 35 | Gas production and supply | |

| 36 | Water production and supply |

| Indicators | Non-Energy Inputs | Energy Input | Desirable Output | Undesirable Output | |

|---|---|---|---|---|---|

| Variables | Labor (x1) | Capital (x2) | Energy (e) | Industrial output (y) | CO2 emission (u) |

| Unit | 104 person | 109 Yuan | 104 TCE | 109 Yuan | 104 Tons |

| Min | 14 | 30,505.56 | 59,887.77 | 4.37 | 211.07 |

| Max | 945.34 | 7.16 | 39.12 | 99,652.67 | 213,291 |

| 945.34 | |||||

| Media | 134.9 | 968.53 | 1069.77 | 4513.88 | 14,397.85 |

| Mean | 206.83 | 2153.89 | 3971.3 | 9452.20 | 4537.48 |

| Industry Classification | 2001 | 2003 | 2005 | 2007 | 2009 | 2011 | 2013 | Mean | |

|---|---|---|---|---|---|---|---|---|---|

| Mining industry | 1 | 0.701 | 0.760 | 0.811 | 0.809 | 0.807 | 0.831 | 0.844 | 0.795 |

| 2 | 0.909 | 0.917 | 0.937 | 0.938 | 0.926 | 0.934 | 0.932 | 0.928 | |

| 3 | 1.000 | 0.938 | 0.950 | 0.945 | 0.932 | 0.959 | 0.946 | 0.953 | |

| 4 | 0.972 | 0.984 | 0.951 | 0.939 | 0.932 | 0.959 | 0.952 | 0.956 | |

| 5 | 0.957 | 0.967 | 0.951 | 0.926 | 0.924 | 0.960 | 0.955 | 0.949 | |

| Light industry | 6 | 0.913 | 0.907 | 0.939 | 0.903 | 0.912 | 0.949 | 0.945 | 0.924 |

| 7 | 0.948 | 0.951 | 0.958 | 0.906 | 0.934 | 0.953 | 0.945 | 0.942 | |

| 8 | 0.928 | 0.936 | 0.963 | 0.976 | 0.967 | 0.973 | 0.965 | 0.958 | |

| 9 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | |

| 10 | 0.762 | 0.730 | 0.790 | 0.831 | 0.841 | 0.889 | 0.913 | 0.822 | |

| 11 | 0.930 | 0.893 | 0.914 | 1.000 | 0.943 | 0.970 | 0.966 | 0.945 | |

| 12 | 0.975 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.922 | 0.985 | |

| 13 | 0.977 | 0.975 | 0.949 | 0.930 | 0.921 | 0.958 | 0.951 | 0.952 | |

| 14 | 1.000 | 1.000 | 0.949 | 0.928 | 0.917 | 0.956 | 0.951 | 0.957 | |

| 15 | 0.902 | 0.892 | 0.928 | 0.917 | 0.946 | 0.958 | 0.969 | 0.930 | |

| 16 | 0.964 | 0.974 | 0.976 | 0.928 | 0.976 | 0.963 | 0.954 | 0.962 | |

| 17 | 1.000 | 0.988 | 0.985 | 0.991 | 1.000 | 0.953 | 0.942 | 0.980 | |

| Heavy industry | 18 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.923 | 0.933 | 0.979 |

| 19 | 0.665 | 0.642 | 0.688 | 0.703 | 0.748 | 0.770 | 0.779 | 0.714 | |

| 20 | 0.936 | 0.929 | 0.955 | 0.966 | 0.960 | 0.968 | 0.968 | 0.955 | |

| 21 | 0.930 | 0.955 | 0.976 | 0.956 | 0.960 | 0.966 | 0.959 | 0.957 | |

| 22 | 0.965 | 0.975 | 0.968 | 0.939 | 0.976 | 0.981 | 0.957 | 0.966 | |

| 23 | 0.954 | 0.936 | 0.940 | 0.961 | 0.938 | 0.960 | 0.790 | 0.926 | |

| 24 | 0.615 | 0.582 | 0.648 | 0.699 | 0.716 | 0.732 | 0.555 | 0.650 | |

| 25 | 0.601 | 0.569 | 0.551 | 0.552 | 1.000 | 0.568 | 0.907 | 0.678 | |

| 26 | 0.871 | 0.871 | 0.924 | 0.887 | 1.000 | 0.907 | 0.963 | 0.918 | |

| 27 | 0.925 | 0.916 | 0.931 | 0.941 | 0.918 | 0.944 | 0.945 | 0.931 | |

| 28 | 0.847 | 0.862 | 0.904 | 0.894 | 0.943 | 0.953 | 0.965 | 0.910 | |

| 29 | 0.881 | 0.895 | 0.939 | 0.932 | 0.954 | 0.967 | 0.958 | 0.932 | |

| 30 | 1.000 | 1.000 | 0.937 | 0.925 | 0.950 | 0.971 | 0.964 | 0.964 | |

| 31 | 0.904 | 0.877 | 1.000 | 0.931 | 0.916 | 1.000 | 0.921 | 0.936 | |

| 32 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | |

| 33 | 0.975 | 0.980 | 0.954 | 0.923 | 0.923 | 0.961 | 0.950 | 0.952 | |

| Electricity, gas, and water industry | 34 | 1.000 | 0.717 | 0.741 | 0.739 | 0.770 | 1.000 | 1.000 | 0.852 |

| 35 | 0.969 | 1.000 | 1.000 | 0.925 | 0.929 | 1.000 | 0.958 | 0.969 | |

| 36 | 0.90 | 0.92 | 0.96 | 0.97 | 0.97 | 0.97 | 0.98 | 0.953 | |

| Mean | 0.910 | 0.901 | 0.916 | 0.909 | 0.929 | 0.936 | 0.931 | 0.919 | |

| Sector Code | Sector Code | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.00 | 0.13 | 0.00 | 2800.87 | 19 | 0.00 | 0.40 | 0.00 | 40,267.87 |

| 2 | 0.07 | 0.16 | 288.86 | 1886.88 | 20 | 0.31 | 0.11 | 4569.19 | 603.66 |

| 3 | 0.28 | 0.27 | 1083.36 | 2034.72 | 21 | 0.33 | 0.28 | 1824.84 | 1469.73 |

| 4 | 0.30 | 0.27 | 616.52 | 1294.26 | 22 | 0.19 | 0.08 | 1169.72 | 1151.17 |

| 5 | 0.33 | 0.25 | 871.18 | 998.34 | 23 | 0.00 | 0.38 | 0.00 | 33,847.26 |

| 6 | 0.19 | 0.16 | 5263.33 | 1619.74 | 24 | 0.00 | 0.44 | 0.00 | 93,540.70 |

| 7 | 0.28 | 0.20 | 3132.64 | 927.29 | 25 | 0.09 | 0.35 | 4408.57 | 19,849.17 |

| 8 | 0.32 | 0.11 | 3470.97 | 424.20 | 26 | 0.22 | 0.09 | 4664.17 | 1560.95 |

| 9 | 0.00 | 0.00 | 0.00 | 0.00 | 27 | 0.18 | 0.07 | 3791.77 | 823.33 |

| 10 | 0.00 | 0.19 | 0.00 | 4160.45 | 28 | 0.00 | 0.00 | 0.00 | 1.98 |

| 11 | 0.00 | 0.00 | 0.00 | 13.71 | 29 | 0.21 | 0.07 | 5349.97 | 239.45 |

| 12 | 0.25 | 0.17 | 2044.25 | 377.91 | 30 | 0.33 | 0.26 | 24,686.97 | 2349.50 |

| 13 | 0.28 | 0.22 | 2344.53 | 927.49 | 31 | 0.17 | 0.19 | 8642.17 | 2049.33 |

| 14 | 0.30 | 0.21 | 1441.81 | 163.64 | 32 | 0.00 | 0.00 | 0.00 | 0.00 |

| 15 | 0.00 | 0.26 | 0.00 | 2771.89 | 33 | 0.31 | 0.22 | 2897.15 | 46.44 |

| 16 | 0.35 | 0.24 | 1577.57 | 382.61 | 34 | 0.00 | 0.00 | 0.00 | 0.00 |

| 17 | 0.30 | 0.20 | 930.89 | 230.07 | 35 | 0.34 | 0.26 | 724.82 | 484.42 |

| 18 | 0.00 | 0.39 | 0.00 | 11,328.73 | 36 | 0.57 | 0.18 | 462.46 | 800.32 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, M.; Fu, Y.; Wang, T.; Jing, K. Analysis of Low-Carbon Economy Efficiency of Chinese Industrial Sectors Based on a RAM Model with Undesirable Outputs. Sustainability 2017, 9, 451. https://doi.org/10.3390/su9030451

Meng M, Fu Y, Wang T, Jing K. Analysis of Low-Carbon Economy Efficiency of Chinese Industrial Sectors Based on a RAM Model with Undesirable Outputs. Sustainability. 2017; 9(3):451. https://doi.org/10.3390/su9030451

Chicago/Turabian StyleMeng, Ming, Yanan Fu, Tianyu Wang, and Kaiqiang Jing. 2017. "Analysis of Low-Carbon Economy Efficiency of Chinese Industrial Sectors Based on a RAM Model with Undesirable Outputs" Sustainability 9, no. 3: 451. https://doi.org/10.3390/su9030451