1. Introduction

Previously, 70% of sewage sludge in South Korea was disposed using the sea dumping method; however, sea dumping of sewage sludge has been completely prohibited since 2011 pursuant to the London Dumping Convention amended in 1996 [

1]. Generally, the operating cost associated with the sludge handling was often reported to be a significant part of the overall operating cost in the wastewater treatment plant [

2]. Also, sewage sludge management is a growing problem, especially in highly populated areas [

3]. Consequently, incineration, with its advantages of large sewage sludge weight reduction effects, excellent stability, and transformation of sewage sludge into solid fuel, has come to the fore as an alternative for sewage sludge disposal. Due to these advantages, incineration has become the main method of sewage sludge disposal in many countries, including Germany and Japan [

4,

5,

6].

According to the IPCC (Intergovernmental Panel on Climate Change) guidelines, CO

2 emissions from biomass fractions should be excluded from the entire amount of CO

2 emissions when calculating CO

2 emissions and should be separately reported due to their “carbon neutrality”. Sewage sludge is one of the representative biomass fuels. It is mixed with fossil fuels to achieve greenhouse gas reduction or is used by itself as a fuel to replace fossil fuels [

7,

8,

9].

Municipal waste and industrial waste incineration facilities are excluded from biomass fractions when they calculate CO

2 emissions. Sewage sludge incinerators do not estimate CO

2 emissions when estimating GHG (Greenhouse Gases) emissions as CO

2 emissions were considered as 100% biomass fractions. Therefore, GHG emissions from sewage sludge incineration facilities are calculated only for Non-CO

2 emissions [

10,

11,

12].

However, some studies reported that the biomass fraction of sewage sludge might not be 100% [

13,

14,

15]. If, as reported in some studies, the biomass fraction of sewage sludge is not 100%, CO

2 emissions should be considered when greenhouse gas emissions are calculated. Therefore, it is necessary to accurately estimate and reflect the biomass fraction of sewage sludge in order to improve the reliability of greenhouse gas emissions from sewage sludge incineration facilities.

The present study aims to figure out how biomass fraction should be applied when greenhouse gas emissions in sewage sludge incineration facilities are calculated.

2. Methods

The present study seeks to figure out how biomass fraction should be applied in the calculation of greenhouse gas emissions in sewage sludge incineration facilities. To this end, we planned to analyze the biomass fraction of sewage sludge inputted into sewage sludge incineration facilities and the biomass fraction of gases collected from final incineration and to compare the resultant values to figure out the biomass fraction of sewage sludge incineration facilities.

2.1. Selection of Objective Facilities

The sewage sludge incineration facility located in Gyeonggi-do was selected for the reason that, on average, at least 150 tons of sewage sludge are generated from it per day. The selected sewage sludge incineration facility uses the fluidized bed incineration (which is predominantly used in sewage sludge incineration facilities in South Korea); the prevention facilities installed in the sewage sludge incineration facility are a Selective Non-Catalytic Reduction (SNCR) facility, a nitrogen oxide removing facility, a Bag Filter, a dust removing facility, a semi-dry reaction tower, and a wet wash tower. Sewage sludge samples and sewage sludge incineration exhaust gas samples were collected in January–March 2015. The current conditions of the subject facility are shown in

Table 1.

2.2. Sampling of Waste Incinerator Facility

In many EU countries, as well as in the USA, Japan, and Australia, continuous measurement methods are presented and recommended for greenhouse gas measurement in waste incineration facilities in order to enhance reliability [

16,

17,

18].

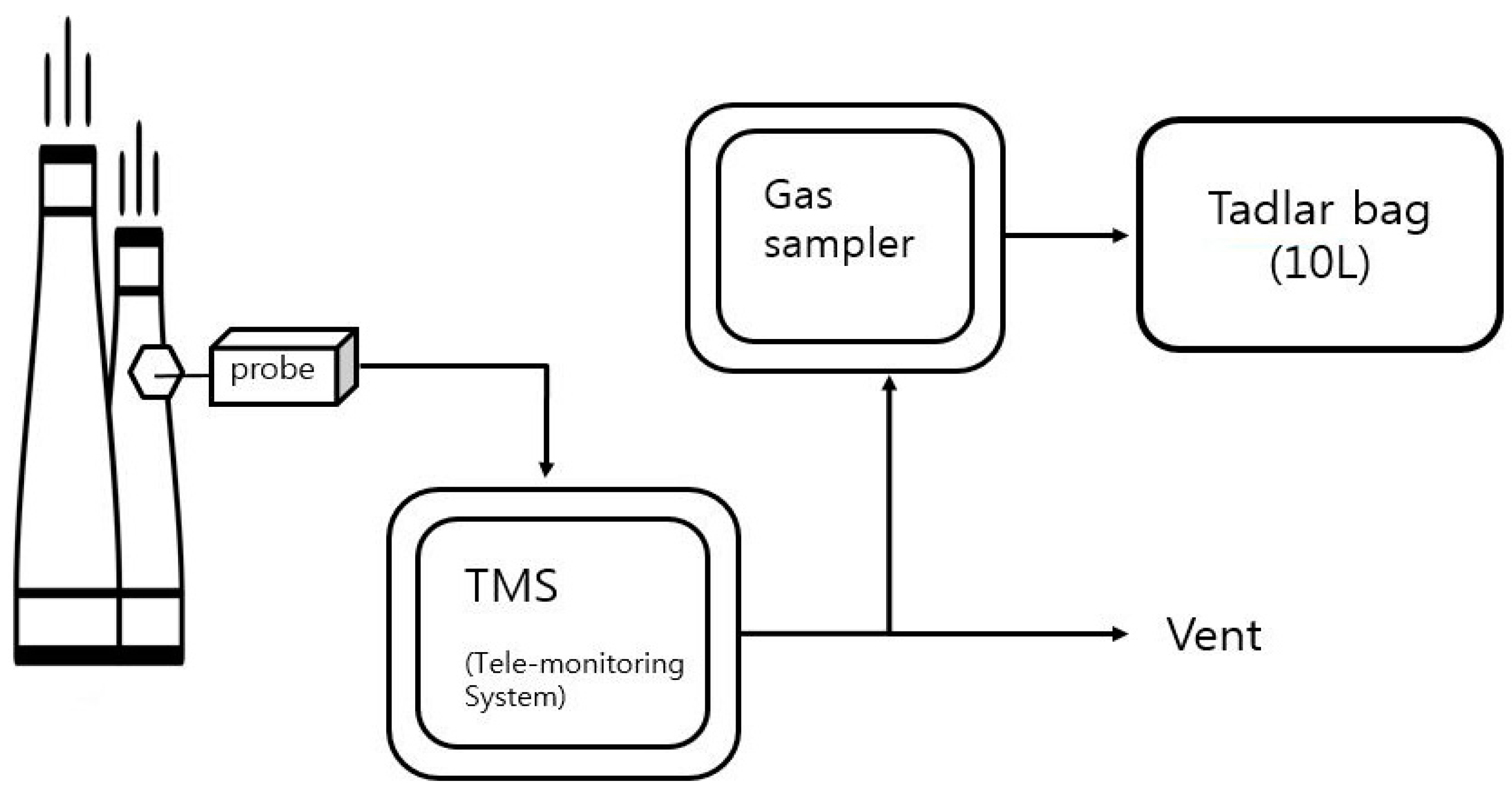

The Mandatory Reporting Rule (MRR) in the USA for greenhouse gases presents the standards for incineration exhaust gas samples for the analysis of biomass fraction of incineration facilities. To meet the standards for samples of the MRR, incineration exhaust gases should be continuously collected for 24 h until the level of ASTM D 6866-08 can be satisfied. In the present study, pursuant to the U.S. mandatory greenhouse gas reporting rule, greenhouse gas samples were continuously collected for 24 h. In South Korea, air pollutants are analyzed and monitored in real-time using automatic remote chimney monitoring systems. Incineration exhaust gases were collected at the rear end of a TMS (Tele-Monitoring System), which is a real-time air pollutant analysis device, using an incineration exhaust gas collecting device made by the present authors. The incineration exhaust gas collecting system is shown in

Figure 1. The incineration exhaust gas collecting device consisted of a device to cool down high-temperature gases to 3 °C to facilitate incineration exhaust gas collection for 24 h (Alpha, Hwaseong-si, Korea), a drain pump for the discharge of cooled moisture (Alpha, Hwaseong-si, Korea), an electronic mass flow meter for the collection of incineration exhaust gases at a constant flow rate (Alicat Scientific, Tucson, AZ, USA), and a pump (KNJ, Seoul, Korea). Samples of sewage sludge for further analysis were sampled in the sewage sludge reservoir.

2.3. Analysis of the Biomass Fraction

Official test methods related to biomass fraction analysis include ASTM D 6866, DS/CEN/TS 15440, and CEN/TR 15591. The official test methods include

14C methods, Selective Dissolution Methods, and Balance Methods. In addition, many related studies use other relevant methodologies to analyze biomass fractions [

19,

20,

21,

22,

23,

24].

In the present study, the

14C method was used to calculate the biomass fractions of sewage sludge and sewage sludge incineration exhaust gases. According to the official test methods,

14C methods include LSC (Liquid Scintillation Counter), AMS (Accelerator Mass Spectrometer), and IRMS (Isotope Ratio Mass Spectrometer). In the present study, the application of ASTM-D6866 and AMS analysis method was used. The AMS method enables the analysis of tiny quantities (1 g) and has a precision that is 105 times higher than the general mass analysis devices [

25].

The AMS analysis is suitable for the carbon dating of small samples as it allows the number of atoms of different isotopes of carbon to be counted directly, instead of their ratio having to be inferred from the (very low) level of radioactivity of the sample.

The application of ASTM-D6866 to derive a “Biogenic carbon content (biomass fraction)” is built on the same concepts as radiocarbon dating, but without use of the age equations. It is done by deriving a ratio of the amount of radiocarbon (14C) in an unknown sample to that of a modern reference standard. The modern reference standard used in radiocarbon dating is a NIST (National Institute of Standards and Technology) standard with a known radiocarbon content equivalent approximately to the year AD 1950. AD 1950 was chosen since it represented a time prior to thermo-nuclear weapons testing which introduced large amounts of excess radiocarbon into the atmosphere with each explosion (termed “bomb carbon”). This was a logical point in time to use as a reference for archaeologists and geologists. Therefore, 1950 is used as the reference year in accordance with “fractions of modern carbon (FM)” as below and biomass fractions are calculated by comparing the ratios of radioactive carbon isotopes 14C/12C existing in the standard sample and the analysis sample.

fM,Sample is the promptly measured parameter; however, the fraction of biogenic or fossil carbon (%Bio C (biomass fraction), %Fos C (fossil carbon fraction)) has more substantive relevance.

Since 14C in fossil matter is completely decayed, the content of biogenic carbon (%Bio C) is directly proportional to the 14C fraction in the emitted CO2.

3. Result and Discussion

3.1. Biomass Fraction of Sewage Sludge

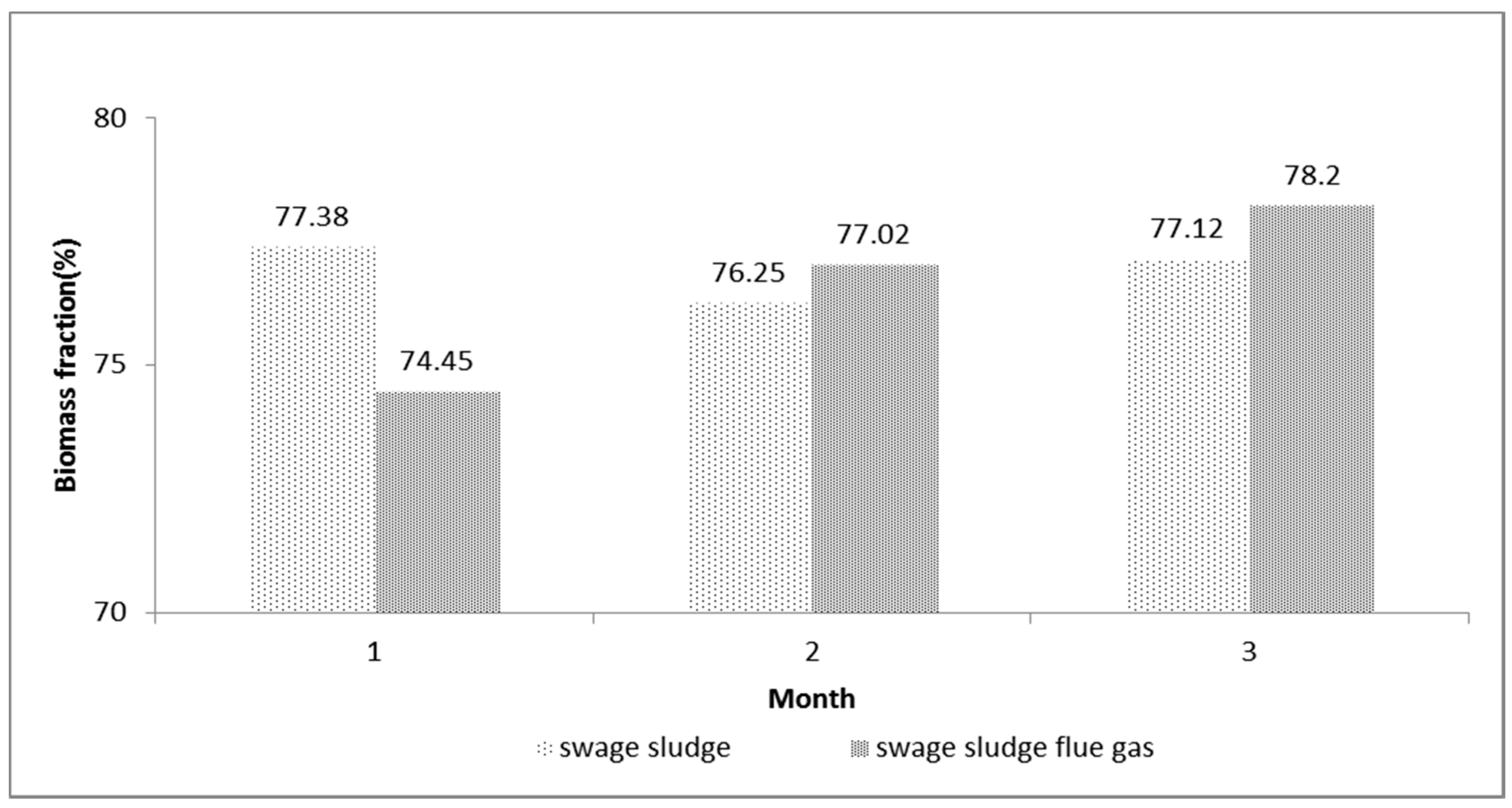

To calculate the biomass fractions of sewage sludge and sewage sludge incineration exhaust gases, the sewage sludge and sewage sludge incineration exhaust gas samples were collected three times in total, once per month from January to March; furthermore, the biomass fractions were analyzed using the AMS method.

According to the results of the biomass fractions of sewage sludge sample analysis, the average biomass fraction was 76.92% and the range of biomass contents was 76.25%–77.38% depending on the time of the sample collection. The standard deviation of the biomass fractions of sewage sludge samples was 0.59, suggesting that the biomass fractions were not very different across different time periods (see

Table 2 below).

3.2. Biomass Fraction of Sewage Sludge Flue Gas

The average biomass fraction of incineration exhaust gases from the sewage sludge incineration facility amounted to 76.56%. The biomass fractions of the incineration exhaust gases were in the range of 74.45–78.20% across different times of samples and the standard deviation was 1.92, indicating that the biomass fractions were not very different across different periods of time (see

Table 3 below).

3.3. Comparison of Biomass Fraction in Objective Sewage Sludge Incinerator

Sewage sludge and sewage sludge incineration exhaust gas samples were simultaneously collected from the sewage sludge incineration facility and the biomass fractions were compared. The differences in the biomass fractions were smaller than approximately 3%, indicating that the biomass contents of sewage sludge and sewage sludge incineration exhaust gases were not very different. The biomass fractions of the samples collected for the first time showed a difference of approximately 3%, while those of the samples collected for the second and third time showed differences below 1%.

The biomass fractions of sewage sludge, that is the subject of incineration by the sewage sludge incineration facility and those of sewage sludge incineration exhaust gases that are finally emitted after incineration, were in the range of 74.45–78.2%; none of the two results showed a biomass fraction of 100%. Therefore, when calculating greenhouse gas emissions, sewage sludge incineration facilities should consider fossil carbon fractions excluding biomass fractions (see

Figure 2 below).

According to Giger (1984) and McEvoy (1985) [

14,

15], in the analysis of sewage sludge, Linear Alkylbenzene Sulphonate (LAS) and 4-Nonylphenol components contained in surfactants, such as dishwashing detergents, liquids and shampoos, that were not completely treated during sewage treatment remained in the sewage sludge. This is the reason why we included fossil fuel-based carbon in sewage sludge in the present study.

4. Conclusions

In the present study, attempts were made to examine how to apply biomass contents to the calculation of greenhouse gas emissions from sewage sludge incineration facilities. To this end, the biomass fractions of sewage sludge inputted into the subject incineration facility and those of sewage sludge incineration exhaust gases finally emitted were analyzed using the 14C Method.

Sewage sludge and sewage sludge incineration exhaust gas samples were simultaneously collected three times between January and March 2015.

According to the results of the analysis of biomass fractions, the average biomass fraction of the sewage sludge samples was 76.92% and that of the incineration exhaust gases from the sewage sludge incineration facility was 76.56%, suggesting no big difference on average. The biomass contents of both the sewage sludge and the sewage sludge incineration exhaust gases did not amount to 100%. The reason behind this finding could be the fact that Linear Alkylbenzene Sulphonate (LAS) and 4-Nonylphenol components that are contained in surfactants, such as dishwashing detergents, liquids, and shampoos, were not completely treated during sewage treatment and remained in the sewage sludge (see Giger (1984) and McEvoy (1985) [

14,

15]).

At present, in many countries such as South Korea, Japan, and Germany, when calculating greenhouse gas emissions from sewage sludge incineration facilities, all CO2 emissions from sewage sludge are judged to be biomass and only the greenhouse gas emissions that correspond to non-CO2 gases are calculated as greenhouse gas emissions. However, since, according our results, the fraction of sewage sludge is not 100% biomass, if CO2 emissions are excluded according to the existing greenhouse gas emission calculation method, the amount of emissions may be underestimated.

Therefore, to accurately calculate greenhouse gas emissions from sewage sludge incineration facilities, CO2 emissions should be calculated in consideration of the fossil carbon fractions of sewage sludge. Further studies aiming to figure out the biomass fractions of CO2 emitted from sewage sludge incineration facilities and to compare greenhouse gas emissions according to CO2 emission calculation methods using such biomass fractions will improve the reliability of greenhouse gas inventories of sewage sludge incineration facilities.

Acknowledgments

This work is financially supported by Korea Ministry of Environment (MOE) as “Graduate School specialized in Climate Change”. This subject is supported by the Korea Ministry of Environment as “Climate Change Correspondence R&D Program (2016001300004)”.

Author Contributions

All the authors contributed towards the completion of the paper. Eui-chan Jeon guided the experiments and designed the study. Seongmin Kang wrote the paper and analyzed the data, data interpretation. Seungjin Kim, Jeongwoo Lee, Youngjae Jeon conducted the experiments, analyzed the results, and Ki-Hyun Kim review and modified the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, M.Y.; Kim, J.K.; Lee, H.D.; Kim, S.C. Combustion Characteristics of Sewage sludge-bituminous coal mixture. Appl. Chem. 2009, 13, 93–96. [Google Scholar]

- Teh, C.Y.; Budiman, P.M.; Shak, K.P.Y.; Wu, T.Y. Recent advancement of coagulation-flocculation and its application in wastewater treatment. Ind. Eng. Chem. Res. 2016, 55, 4363–4389. [Google Scholar] [CrossRef]

- Vochozka, M.; Maroušková, A.; Váchal, J.; Straková, J. Appraisal of changes in sewage sludge management. Int. J. Environ. Sci. Technol. 2016, 13, 1607–1614. [Google Scholar] [CrossRef]

- Fytili, D.; Zabaniotoua, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Werther, J.; Ogada, T. Sewage sludge combustion. Prog. Energy Combust. Sci. 1999, 25, 55–116. [Google Scholar] [CrossRef]

- Takahiro, M.; Yoshizo, S.; Hidekazu, N.; Takafumi, Y.; Takami, K.; Hitoshi, H.; Seiichiro, O. Combustion characteristics of sewage sludge in an incineration plant for energy recovery. Fuel Process. Technol. 2009, 90, 778–783. [Google Scholar]

- Zabaniotoua, A.; Theofiloub, C. Green energy at cement kiln in Cyprus—Use of sewage sludge as a conventional fuel substitute. Renew. Sustain. Energy Rev. 2008, 12, 531–541. [Google Scholar] [CrossRef]

- David, M.K. Biodiesel Production from Municipal Sewage Sludges. Energy Fuels 2010, 24, 2791–2794. [Google Scholar]

- Shireen, M.K.; Debabrata, D. Biohydrogen as a renewable energy resource—Prospects and potentials. Int. J. Hydrog. Energy 2008, 33, 258–263. [Google Scholar]

- Environment Agency Austria Umweltbundesamt. Austria’s National Inventory Report 2015; Environment Agency Austria Umweltbundesamt: Canberra, Australia, 2015.

- Federal Environment Agency (UBA). National Inventory Report for the German Greenhouse Gas Inventory 1990–2013; Federal Environment Agency (UBA): Dessau, Germany, 2015.

- Greenhouse Gas Inventory Office of Japan (GIO). National Greenhouse Gas Inventory Report of Japan; Greenhouse Gas Inventory Office of Japan (GIO): Tsukuba-shi, Japan, 2015.

- Beta Analytic, USA Sewage Sludge. Available online: http://www.betalabservices.com/renewable-carbon/sewage-sludge.html (accessed on 2 April 2016).

- McEvoy, J.; Giger, W. Accumulation of linear alkylbenzenesulphonate surfactants in sewage sludges. Naturwissenschaften 1985, 72, 429–431. [Google Scholar] [CrossRef]

- Giger, W.; Brunner, P.H.; Schaffner, C. 4-Nonylphenol in sewage sludge: Accumulation of toxic metabolites from non-ionic surfactants. Science 1984, 225, 623–625. [Google Scholar] [CrossRef] [PubMed]

- Department of the Environment (DOE). Technical Guidelines for the Estimation of Greenhouse Gas Emissions by Facilities in Australia; Department of the Environment (DOE): Canberra, Australia, 2012.

- Environmental Protection Agency (EPA). 2011. 40 CFR Part 98 Mandatory Reporting of Greenhouse Gases, Federal Register; Environmental Protection Agency (EPA): Washington, DC, USA, 2011.

- European Commission. Biomass Issues in the EU ETS; MRR Guidance Document; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- ASTM International. 6866: Standard Test Methods for Determining the Bio based Content of Solid, Liquid, and Gaseous Samples Using Radiocarbon Analysis; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Anna, W.L.; Karsten, F.; Niels, H.P.; Johann, F.; Helmut, R.; Thomas, A. Biogenic carbon in combustible waste: Waste composition, variability and measurement uncertainty. Waste Manag. Res. 2013, 31, 56–66. [Google Scholar]

- Mohn, J.; Szidat, S.; Fellner, J.; Rechberger, H.; Quartier, R.; Buchmann, B.; Emmenegger, L. Determination of biogenic and fossil CO2 emitted by waste incineration based on 14CO2 and massbalances. Bioresour. Technol. 2008, 99, 6471–6479. [Google Scholar] [CrossRef] [PubMed]

- Mohn, J.; Szidat, S.; Zeyer, K.; Emmenegger, L. Fossil and biogenic CO2 from waste incineration based on a yearlong radio carbon study. Waste Manag. 2012, 32, 1516–1520. [Google Scholar] [CrossRef] [PubMed]

- Levin, I.; Kromer, B.; Schmidt, M.; Sartorius, H. A novel approach for independent budgeting of fossil fuel CO2 over Europe by 14CO2 observations. Geophys. Res. Lett. 2003, 30, 2194. [Google Scholar] [CrossRef]

- Palstra, S.W.L.; Meijer, H.A.J. Carbon-14 based determination of the biogenic fraction of industrial CO2 emissions. Appl. Valid. Bioresour. Technol. 2010, 101, 3702–3710. [Google Scholar] [CrossRef] [PubMed]

- Matthias, R. Radiocarbon Measurement of Micro-Scale Samples—A Carbon Dioxide Inlet System for AMS; Philosophisch-Naturwissenschaftlichen Fakulttp der Universiter Bern: Bern, Switzerland, 2008. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).