1. Introduction

Anthropogenic climate disruption has become a pivotal constraining factor of socioeconomic development in the twenty-first century [

1,

2]. Traditional industries have created wealth and contribute to the progress of civilization, but have generated calamities for humans, such as the depletion of resources, environmental pollution, and ecological imbalances. Thus, preventive approaches need to be adopted in order to protect environmental damages. Environmental concerns from consumers, governments, and academics have encouraged businesses to introduce environmentally friendly practices that are able to mitigate negative impacts on the environment, (e.g., green management, green marketing, green production, green innovation [

3]). In fact, firms have long recognized that being competitive depends on their internal operations as well as the entire supply chain [

4,

5]. Thus, the management of supply chain is the key to business sustainability.

Green Supply Chain Management (GSCM) is a modern approach that balances environmental impact and resource efficiency and transcends firms’ boundaries [

6]. The theoretical foundation of GSCM is based on the theory of green design, manufacturing, and supply chain management technology. The aims of GSCM are to minimize negative environmental impact and to maximize resource efficiency throughout the manufacturing process, which consists of acquisitions of raw materials, processing, packing, transportation, and waste disposal alternatives (e.g., recycling). The GSCM process has become a role model in developing eco-friendly enterprises and serves as a cornerstone of guiding businesses to meet tighter environmental regulations [

7].

Adopting GSCM approaches has several advantages for businesses. Developing new markets, minimizing production waste, increasing productivity, enhancing corporate reputation, improving long-term profitability, and raising corporate competitiveness in line with the trend of environmental consciousness are all possible benefits of employing GSCM [

8]. Environmental management is considered an ideal strategy for a firm to position itself as an environmentally friendly business under the rising trend of tougher environmental regulations such as the Restriction of Hazardous Substances and Waste Electronics and Electrical Equipment [

4].

The concept of the green supply chain was first proposed by the Manufacturing Research Association at Michigan State University in 1996 [

9]. Recently, the green supply chain has drawn academics’ interests. Many studies have been conducted and the foci of the GSCM were on the concept and connotations of the green supply chain, the design and structure of GSCM [

10], the environment assessment of supply chain management [

11], the metrics or identification criteria for GSCM implementation [

6,

12], GSCM implementation strategies [

13], green purchasing/supply chain decision-making dilemma, theoretical research on the green supply chain, as well as GSCM business performance [

13,

14,

15]. Each GSCM related study or technique employed has addressed different insights, but a lack of holistic perspectives becomes an issue since green capabilities and assessments possessed by firms should be closely linked to GSCM drivers and green providers [

14,

16,

17]. Therefore, a broader perspective is needed to examine the development of eco-friendly enterprises.

The purpose of eco-friendly development planning is to efficiently use limited resources with the aim of creating business value and maintaining sustainability. Researchers [

18,

19] indicate that a firm’s value can be maximized and treats can be minimized if sound strategies are well planned and executed (e.g., meeting new-market requirements) while a firm is not over-dependent on isolated organizational strategies [

20]. Thus, for achieving the goal of being an eco-friendly enterprise, firms have to develop step-by-step procedures to ensure that green providers can satisfy the requirements of green capability, to integrate with GSCM drivers, and, thereby, to ultimately transform needed attributes to sustainable advantages [

16,

17]. To develop an eco-friendly enterprise, the deployment and alignment among GSCM drivers, green capabilities, and providers is vital. Previous studies [

11,

16,

21] have paid attention to how to establish an eco-friendly enterprise. However, the details of how GSCM objectives can be translated into action plans are insufficient. In fact, prior approaches do not directly address the relationships among GSCM drivers, green capabilities, and the qualifications of green providers.

The house of quality (HOQ) in the quality function deployment method is a useful tool to connect components in terms of theoretical rationales and processes [

22]. However, due to broad definitions of green attributes, the results of evaluation are compromised with uncertainties. In addition, fuzzy logic is employed in this study since it is a useful tool to identify the ambiguities and multiplicity of linguistic judgment meanings that are required for the expressions of green attributes [

7]. For the purpose of helping managers to achieve the goal of building eco-friendly enterprises, the study proposed a method that was based on fuzzy logic and the relationship matrix in the QFD to assess supply chain members from GSCM drivers in business environments. A fuzzy green integrated capability index (FGICI) was developed to measure an enterprise’s eco-friendliness level (EFL). Green capability merit ratings and individual average relation weight with green drivers were generated to assess those targeting enterprises. To identify the principal obstacles in the eco-friendliness level, a fuzzy importance enhancement index (FIEI) is also defined in this study. The FIEI comprises the green provider merit rating and its average relation weight with its capabilities. This study also reports how this robust approach was applied for a Taiwanese electronics-based firm. The results of the study revealed that the proposed framework and procedures can be applied for enhancing the eco-friendliness of an enterprise as well as to secure a competitive advantage.

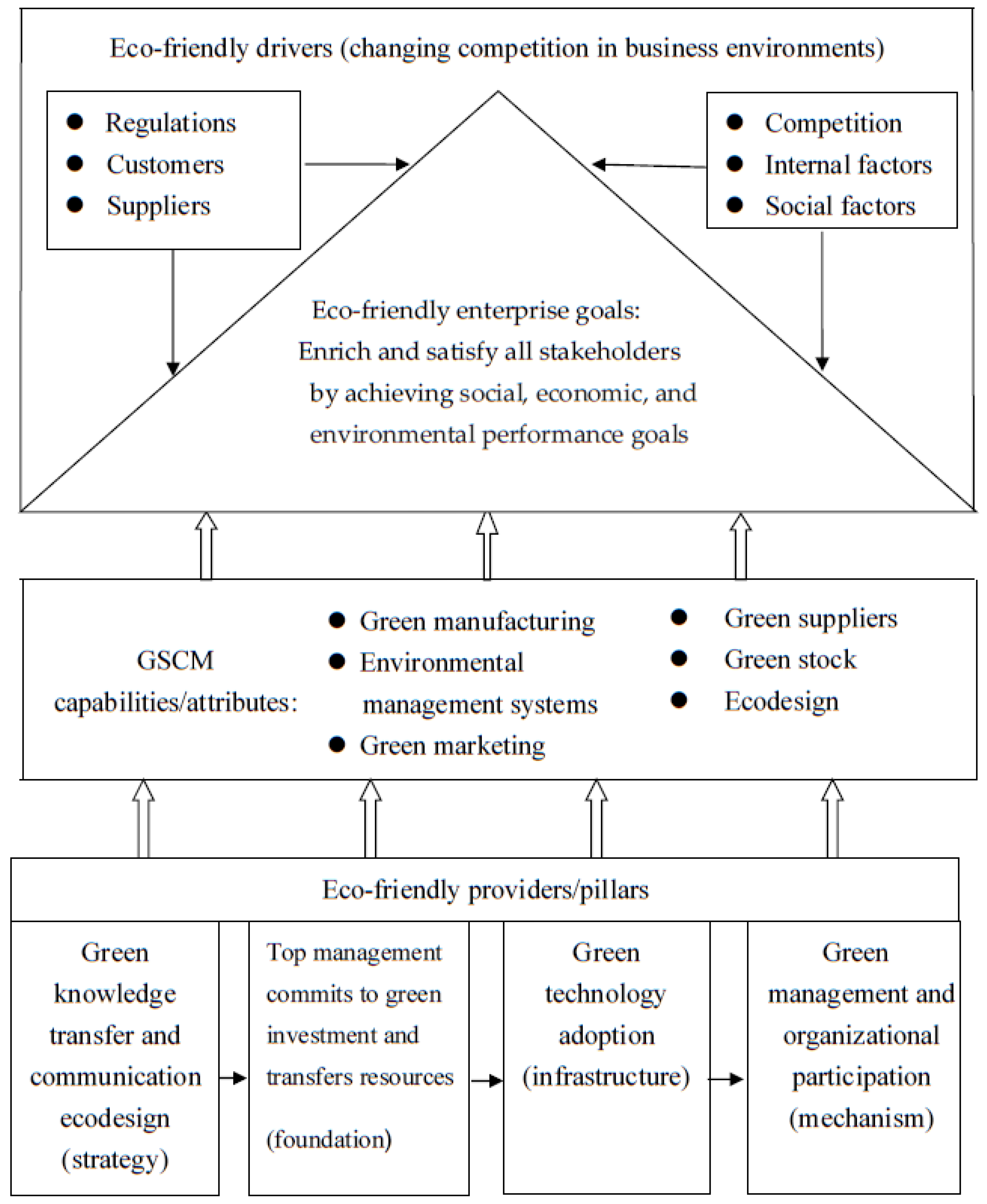

2. Eco-Friendly Enterprise Conceptual Model

The goal of an eco-friendly enterprise is to have its employees, customers, and stakeholders to agree with its environmental concerns. The tougher international environmental regulations and consumers’ growing environmental consciousness become crucial factors for businesses worldwide [

4,

23]. Therefore, proper environmental management plays a critical role for modern enterprises. To enhance the notion of environmental stewardship, the concepts of environmental management (e.g., green management, green marketing, green production, and green innovation) are currently being pursued. Being eco-friendly, an enterprise should have several distinguishing green attributes. Based on the literature [

1,

19,

23,

24,

25,

26,

27,

28,

29], we developed an eco-friendly enterprise conceptual model, as shown in

Figure 1, to provide insights into what constitutes eco-friendly attributes and the providers of an eco-friendly enterprise.

Gaining competitive advantages and economic performance are essential to businesses of all kinds. Eco-friendly enterprises are no exception [

13,

30]. Each enterprise needs to know its internal and external environments and to exploit possible opportunities that enable the enterprise to succeed. Mitigating negative environmental impacts is not a novel concept. In fact, environmental degradation is currently taking place at a substantial scale and at a faster rate than ever before. Certain phenomena (e.g., global warming) have been observed. With tighter international environmental regulations and the increase in consumers’ environmental consciousness, businesses face more challenges. Different enterprises and industrial profiles would have different environmental problems needed to be solved, but certain common traits in terms of GSCM drivers [

1,

12,

23,

24,

28,

31] in a business environment can be categorized as follows: (a) organization related; (b) government regulation and legislation; (c) customer demand; (d) external competitors; (e) society or non-organizational stakeholder groups; and (f) pressure from supply chain partners. These GSCM drivers continue to exercise their functions and are the driving forces to ensure that governments and businesses take more responsibilities to protect environments.

Eco-friendly enterprises are distinguished in certain areas. Researchers have made efforts to identify green capabilities from which enterprise leaders consider the most important issues based on their own visions, goals, and strategies for GSCM [

14,

26,

32,

33]. Shang et al. [

32] examined GSCM capabilities among electronics-related manufacturing firms in Taiwan and grouped a set of 37 green capabilities into six principal categories: (a) green manufacturing and packaging; (b) ecodesign; (c) environmental participation; (d) environmentally friendly purchasing; (e) green marketing; and (f) green stocks. These attributes, representing most aspects of eco-friendliness, can be used to manage all GSCM drivers in an enterprise. In addition, Olugu et al. [

26] identified and developed 10 measures with 49 metrics and six measures with 23 metrics for forward and backward chains, respectively. Regarding the selection of a suitable green supplier, Tseng [

33] identified 16 GSCM criteria for the development of manufacturing firms, as follows: (a) delivery reliability; (b) supplier profitability; (c) relationship with the supplier; (d) green technology capabilities; (e) conformance quality; (f) supplier flexibility; (g) service quality; (h) green-purchasing capabilities; (i) life cycle assessment; (j) green design; (k) green certification; (l) internal green production plans; (m) management support; (n) green production; (o) the reduction of hazardous materials in the production process; and (p) environmental management systems.

An eco-friendly enterprise requires being responsive to green management practices. Green providers also need to perform identified green characteristics. Supply chain strategies, structures, core competencies, supply chain processes, and information systems are key to determining qualified green providers [

12,

13,

19,

24,

25,

34]. From the viewpoint of green supplier development practices, Bai and Sarkis [

25] grouped a set of 30 green provider characteristics into three major categories: (a) green knowledge transfer and communication; (b) investment and resource transfer; and (c) management and organizational practices. Azevedo et al. [

19] identified 10 criteria that are the most critical green practices as indicated by the managers of a Portuguese automotive supply chain. These criteria are as follows: (a) developing environmentally friendly products; (b) implementing environmentally friendly internal operations; (c) gaining recognition for environmentally positive behaviors; (d) environmentally friendly purchasing; (e) environmental collaboration with customers; (f) encouraging suppliers to adopt more environmentally friendly behaviors; (g) interacting with customers to change product specifications; (h) reverse logistics; (i) ISO 14001 certification; and (j) waste minimization. A GSCM development literature review conducted by Dubey et al. [

34] reported five principal components encompassing 26 GSCM providers. These providers were: (a) top-management commitment; (b) institutional pressure; (c) supplier relationship management; (d) total quality management; and (e) green technology adoption. In summary, researchers have made efforts to identify diverse aspects of GSCM drivers, green capabilities, and providers. However, no single set of GSCM drivers, green capabilities, and providers reflects a full spectrum of possible practices.

In the literature, researchers [

14,

25,

35] have proposed a conceptual model for eco-friendly practices. The goal of eco-friendly development planning is to effectively connect the resources possessed by enterprises so that negative environmental issues can be prevented or even eliminated. Study results [

16,

17,

36] have shown that the GSCM priority is to understand the relationships among GSCM drivers as well as green capabilities and providers. Thus, both capabilities and providers can be synthesized with GSCM drivers and to turn them into a competitive advantage. However, a paucity of holistic methods exists concerning organizational deployment and integration among GSCM drivers in the business environment, green capabilities and providers [

14,

16,

17].

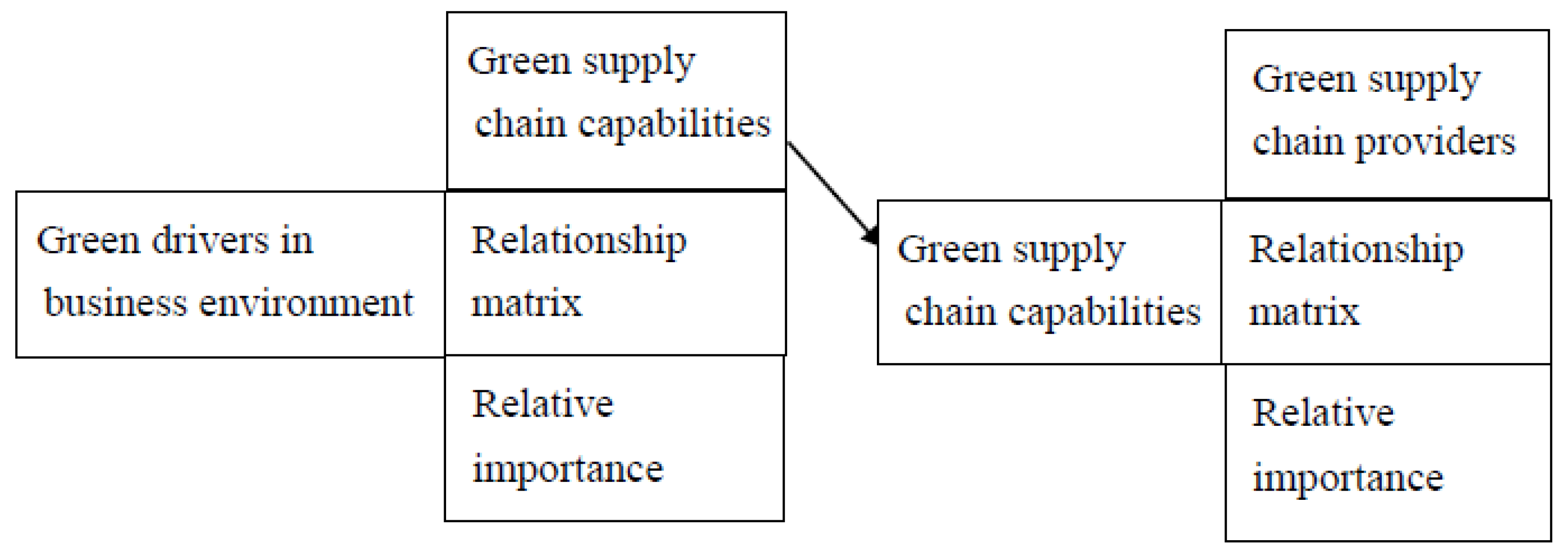

The aim of the Quality Function Deployment (QFD) method focuses on detailed pre-planning process in order to deploy customer needs and the specification of a new product [

37]. It uses several house of quality (HOQ) charts to describe the relationship to each other all through the new product project: product engineering, parts deployment, process planning, and product. There are seven major aspects in the basic HOQ format: (a) customer needs (CNs); (b) the importance of CNs; (c) design requirements (DRs); (d) a relationship matrix for CNs and DRs; (e) correlation among DRs; (f) competitor analysis; and (g) the prioritization of DRs. A simplified HOQ matrix is called a relationship matrix, in which the competitor analysis and correlation analyses among DRs are removed. In this study, a simplified HOQ matrix was used to analyze and deploy the relationships among GSCM drivers in the business environment, green capabilities, and select suitable green providers.

Although QFD has been proposed as a customer-driven product development and delivery methodology, an enterprise can use a QFD approach to achieve various strategic goals [

22,

38,

39,

40]. To help managers measure eco-friendliness more efficiently, the eco-friendly enterprise conceptual model and the relationship matrix in the QFD method were applied in this study. In addition, this study proposes a novel systematic model for alignment and integration. By doing so, green providers can assess their green capabilities and cope with green drivers (

Figure 2). This model is described as follows:

Deploying a green strategy: identifying green capabilities that can provide the strength required for responding to problems associated with environmental impacts and searching for a competitive advantage by relying on close connections and the coordination of GSCM drivers and green capabilities.

Aligning green ingredients: finding green providers constituting the means by which the needs of an enterprise related to green capabilities can be met by relying on close connections and the coordination of green capabilities and providers.

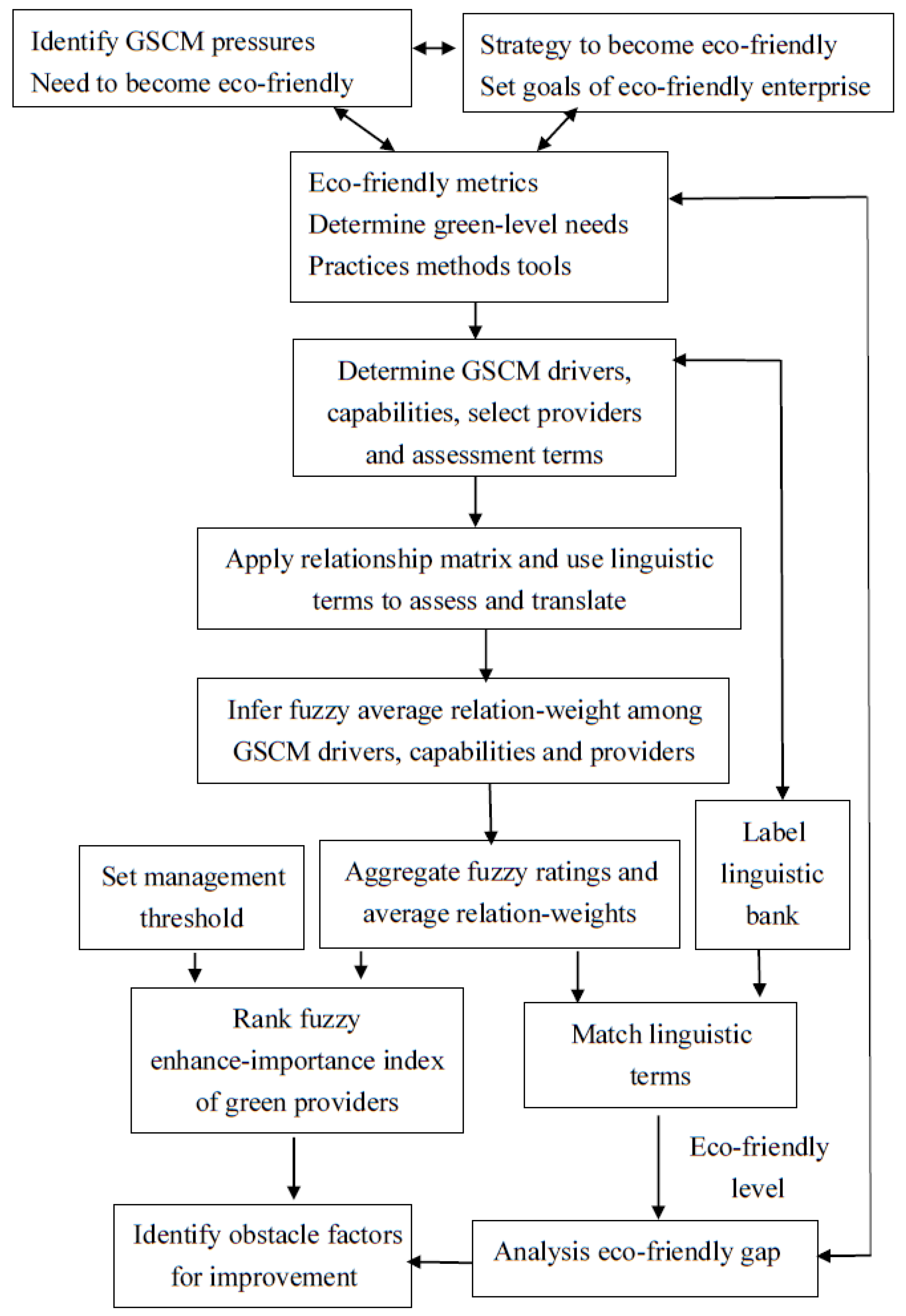

4. Fuzzy QFD-Based Model for Eco-Friendly Enterprise Development and Evaluation

To achieve eco-friendly enterprise, the plan for deploying and aligning of GSCM drivers, green capabilities, and providers and transforming them into a competitive edge are critical. This is because only the green providers consistently fit green capabilities and transform into a competitive advantage, and then the green capabilities can cope with GSCM drivers and eco-friendliness can achieve. Due to an either “imprecise” or “vague” definition of green attributes and their relationships, the aligning and deploying evaluation process is associated with uncertainties and ambiguity. Managers must make decisions by considering a group of non-numerical values green attributes and relationships. Although none of attributes may meet the need of a particular enterprise, managers still must be considered in the evaluation process. Thus, the tradition evaluation approaches, such as analytical hierarchical process (AHP) or multiple attribute decision making (MADM), cannot conduct such evaluations effectively. In company, the strategic planning evaluation is always made primarily based on the opinions of experts because they have the ability to understand and analyze obscure or imprecise events that are not easily incorporated into existing analytical methods. According to Karwowski and Mital [

51], in circumstances where evaluators cannot conduct substantive assessments, linguistic expressions are used to estimate ambiguous events. Linguistic terms typically have vague meanings. One approach to capturing the meanings of linguistic terms is the fuzzy logic approach to associate each term with a possibility distribution [

52].

According to the eco-friendliness development plan conducted by researchers [

14,

16,

17], the green capabilities and assessments should be closely linked and coordinated with GSCM drivers and green providers. However, the theme of enterprise eco-friendliness has failed to be sufficiently addressed in the literature concerning. In addition, the relevant perspectives and the relationship matrix in the quality function deployment (QFD) method provide an excellent tool for solving the linking processes problems. To assist managers in enhancing firms’ eco-friendliness, by using the QFD relationship matrix and fuzzy logic, a fuzzy logic–QFD eco-friendliness-enhancing model (FLQFDEFEM) composed of four major components (

Figure 3) was developed for eco-friendly enterprise development and evaluation. GSCM drivers were first identified through a business environment survey. Afterward, the goals of eco-friendliness were set up, and the attributes of green capabilities for assessment were identified. The required green providers for measurement were then selected. Second, apply the relationship matrix to align the drivers, capabilities, and providers, and to further analyze the fuzzy average relation weight. Third, synthesize the fuzzy ratings and average relation weights of the capabilities to obtain the fuzzy green integrated capability index (FGICI) of the enterprise and to match the FGICI with an appropriate linguistic term of eco-friendly label. Finally, synthesize the fuzzy ratings and average relation-weights of the providers to obtain the FIEI. They were further rank-ordered to identify the major obstacles and enabled researchers to conduct the proactive implementation of the appropriate ameliorative measures.

5. Case Study: Eco-Friendly Enterprise Development and Evaluation of a Taiwanese Electronics Company

This section presents an eco-friendly development project at EA Optronics company in Hsinchu, Taiwan (company names were anonymous to encourage participants’ participation) to detail the FLQFDEFEM and show how it can be used in an eco-friendly development. Every enterprise is typically recognized to have its own operational business objectives and strategy. Thus, applied in a specific situation or enterprise, this should be modified or extended to meet their requirement.

5.1. Subject of Case Study

EA Optronics is an internationally famous electronics-related manufacturing firm, particularly noted for its TFT (Thin-Film Transistor)-LCD panels and green energy industry. Its annual revenue was approximately US$13 billion in 2014. EA Optronics engages marketing and service operations all over the world, focusing on the Asia-Pacific region, Europe, and America. The supporting dealers and distributors are located in more than 50 countries. In the twenty-first century, the market for IT products has matured. Low-cost production in developing nations has proliferated. Thus, EA Optronics has been forced to be more locally oriented in response to an uncertain business environment. Such changes have profoundly challenged EA Optronics. To maximize social, economic, and environmental performance, EA Optronics has strived to become a major global supplier to reduce environmental consequences for the purpose of satisfying its stakeholders, achieving time-to-market reductions, lowering the total cost of ownership, and enhancing overall competitiveness.

The IT product supply chain is characterized by dynamics and volatile product demand. EA Optronics has recognized environmental management to be a key strategic issue, with the potential to have a lasting impact on the company’s reputation, competitiveness, and performance. The executive team at EA Optronics continues to face challenges in terms of how to manage GSCM practices in an efficient fashion. The firm is considering to develop green factors as a means to promote the company and its products. Since the eco-friendly enterprise has been advocated as the twenty-first-century business paradigm and is perceived as the ideal strategy for companies seeking to enhance their environmental performance, to attain competitive advantages, and to secure their position as international leaders, and the management team at EA Optronics sets a goal of being an eco-friendly enterprise through continuous improvements. An analysis and evaluation committee (composed of one professor, three company managers, and two GSCM professionals with extensive consulting experience) led by the executive vice president was organized. This committee was selected from the most knowledgeable persons who were mastered in GSCM principles and whose responsibilities included investigating and rectifying problems. Each member presented his/her concerns to the evaluation, which had to be reconciled by reaching a consensus. This was a necessary procedure because the success of the project requires the participation and contribution of all departments in company.

5.2 Applying the FLQFDEFEM to the Eco-Friendly Enterprise Development Project at EA Optronics

When EA Optronics set the goal of achieving an excellent eco-friendly enterprise based on social, economic, and environmental performance through GSCM implementation, the committee had several questions such as “Precisely what is eco-friendliness, and how can it be measured?”; “How can both analytical and intuitive understandings of eco-friendliness be developed in a particular business environment?”; and “How can GSCM be enhanced at EA Optronics?” Answering such questions necessitates knowledge on what to measure, how to measure it, how to evaluate the results, and how to conduct improvements based on the findings. Moreover, how to link GSCM drivers, green capabilities, and providers to ensure that providers can enhance the capabilities and that the capabilities can cope with GSCM drivers, as well as how to translate them into a competitive advantage, must be considered if a company is to become eco-friendly. Although critical concepts and steps for development have previously been identified, no systematic tool is available for aligning these concepts. Moreover, because the ill-defined and ambiguous elements concerning exists in green attributes and their interrelationships, it is difficult to determine whether a value (e.g., 0.2) is low or another value (e.g., 0.3) is also low, and experts can only differentiate easily among low, medium, and high relationships. Therefore, they decided to use linguistic terms for measuring the ambiguous green attributes. Furthermore, the CEO expressed a desire to pursue a method that takes the uncertainties of each attribute into consideration, yet maintains the multiple properties to provide a helical assessment of the eco-friendly performance for the GSCM. Fuzzy logic can be a useful tool for applying in this context, instead of as a single value as in traditional methods, since linguistic variables contain ambiguities and multiple meanings, and the information obtained can be expressed as a range in a fuzzy set. On the basis of the procedures of the FLQFDEFEM model, the eco-friendly enterprise development plan was implemented and achieved the goal. The initiate eco-friendly enterprise development project is summarized as follows:

5.2.1. Identify GSCM Drivers, Green Capabilities and Providers for the Assessment

To enhance and achieve eco-friendliness, the deployment and linkage of GSCM drivers, green capabilities, and providers, as well as their transformation into a competitive advantage are critical. Because each company is different and faces different challenges, a full spectrum of questions can hardly be presented completely. To elicit assessment criteria reflecting the nature and entire set of GSCM attributes, the experts reviewed and discussed a series of global environmental regulations, government regulations and legislation, changes in the business environment, as well as environmental impacts. A survey was conducted. To facilitate members’ holistic understandings of the current conditions, a meeting was held. The major contents were as follows:

The organization’s environmental goals and strategies: the overall objective in addressing environmental issues to achieve an excellent eco-friendly enterprise according to social, economic, and environmental performance; the general attitude toward environmental legislation and impacts; internal environmental management; and recovery investment.

Supply chain policy and characteristics: supply chain priorities (social, economic, and environmental performance), the supply chain process, supplier selection, perceived environmental issues, drivers, core business and competencies, and specific supply chain management problems.

Business structure: organization, process, IT, product design, and purchasing management, and providing the capabilities for GSCM enhancement, including GSCM project descriptions and support by management as well as other departments.

GSCM practices: those performed in response to environmental issues, such as corporate social responsibility reports, annual environmental and financial reports, supplier evaluation questionnaires, internal newsletters, collaborating with customers and suppliers, GSCM projects, main project drivers, inhibitors, and techniques for overcoming them, approaches to measuring the impact of the GSCM project, lessons learned, and the project as piloted within a particular area of the organization or introduced throughout the entire organization from the start.

Based on the results of the discussion, the committee referred to factors proposed in previous studies [

1,

19,

23,

24,

25,

26,

27,

28,

29]. To facilitate reaching a consensus in terms of criteria determinations and relative importance to the enterprise, the Delphi iterative procedures were employed in this stage. After three iterative procedures were ran, the GSCM drivers were identified, and the green capabilities were set and green providers for the assessment were selected, as shown in

Table 2 (this table presents merely what the author assessed to be the most prevalent and meaningful factors for this project).

5.2.2. Determine the Preferred Measurement Scale

The ad hoc usage of linguistic terms and their corresponding membership functions is the characteristic of fuzzy logic. Widely used linguistic terms and their corresponding membership functions have been proposed for linguistic assessments. Instead of eliciting linguistic variables and associating fuzzy numbers from the experts, for the sake of convenience, they could be obtained directly from previous studies or basic models and modified it to incorporate individual situations and the requirements of different users. Since individuals only have a limited memory span, nine linguistic levels is the maximum number recommended [

53].

The experts reviewed green supply chain features, goals, policies, strategies, structures, capabilities, phases of competition, and GSCM-related practice original data and information before the assessment proceeded. Initially, the members could not reach a consensus on linguistic terms and their fuzzy numbers. The linguistic terms and their corresponding fuzzy numbers in literature were adopted for minimizing argument, and they further modified it to incorporate the specific characteristics of EA Optronics. To validate these linguistic terms and their corresponding fuzzy numbers were appropriate and to ease communications within the committee, we asked them to describe the fuzzy numbers when we gave them a linguistic term. This continued until their answers reached consensus. After the ongoing discussion process, the committee selected the linguistic terms and its associated fuzzy numbers for measuring as listed in

Table 1, based on their long-standing recognition of the meaning of linguistic values.

5.2.3. Apply the Relationship Matrix and Use the Linguistic Terms to Assess the GSCM Attributes and Relationship Levels

For defining the relationships among the variables, a series of brainstorming sessions were further held. The experts were queried regarding the mutual relationships among variables, such as how and how much a particular feature facilitates can enhance the others. Based on their experience, knowledge, and judgment and the conclusions of the review meetings and brainstorming sessions, the experts used the relationship matrix (

Table 3) and the level scale W = {Extremely Low (EL), Very Low (VL), Low (L), Fair (F), High (H), Very High (VH), Extremely High (EH)} and its associated fuzzy number as shown in

Table 1, in order to measure the level of importance of the GSCM drivers. The weighting scale RS = {Very Low (VL), Low (L), Fair (F), High (H), Very High (VH)} and its associated fuzzy number, as shown in

Table 1, was used to evaluate the degree of relationships between the green capabilities and GSCM drivers, as well as the relationship levels between green providers and green capabilities. The rating scale R = {Worst (W), Very Poor (VP), Poor (P), Fair (F), Good (G), Very Good (VG), Excellent (E)} and its associated fuzzy number, as shown in

Table 1, was also used to assess the performance of the green capabilities and green providers.

Table 3 and

Table 4 are a sample of the results of the assessment. Then, based on the associated relationships listed in

Table 1, linguistic variables and their corresponding fuzzy numbers, the results of the assessment were translated into fuzzy numbers.

5.2.4. Analyze the Fuzzy Average Relation Weight in the Relationship Matrix

It is important to aggregate the different experts’ opinions in group decision-making. Many methods can be used to aggregate the experts’ opinions, such as median, mean, and mixed operators. Since the median operation is more robust in a small sample, this method was chosen to pool the experts’ assessments.

After the consideration of different expert assessments, based on the HOQ and the definition of fuzzy weighted average [

8], the total fuzzy average relation weight between a particular column item and the entire list of row items was defined as

where

FARWGCDj denotes the fuzzy average relation weight of the

jth green capability for all GSCM drivers;

FLIGDi denotes the fuzzy level in the importance of the

ith GSCM drivers; and

FRLGDCij denotes the fuzzy relationship level between

GSCM driver

i and capability

j:

where

FARWGPCk denotes the fuzzy average relation weight of the

kth providers for all green capabilities;

FARWGCDj denotes the fuzzy average relation weight of the

jth green capability derived from Equation (8); and

FRLGCPjk denotes the fuzzy relation level between green capability

j and provider

k.

The fuzzy average relation weights of green capabilities and green providers can be obtained, as listed in

Table 5, by using Equations (2a), (2b), (8), and (9).

5.2.5. Aggregate the Fuzzy Ratings and Fuzzy Average Relation Weights of Green Capabilities into an FGICI

The FGICI represents the green performance of an enterprise that will influence or impact making appropriate responses to environmental impacts on the GSCM environment. A higher FGICI regarding a GSCM indicates higher eco-friendliness.

According to the definition of the fuzzy weighted average operation [

8], the FGICI is defined as

where FMGC

j denotes the fuzzy merit of the

jth green capability, and

FARWGCDj denotes the fuzzy average relation weight of the

jth green capability derived from Equation (8).

By performing the fuzzy weighted average operation, the FGICI for EA Optronics was found to be

5.2.6. Match the FGICI with an Appropriate Linguistic Level

Once the FGICI was obtained, to identify the eco-friendliness level (EFL), the committee approximated a linguistic label, the meaning of which was identical (or the closest to) that of the FGICI meaning from the natural-language EFL set.

Several methods have been proposed to translate the fuzzy number back to linguistics. There are three basically techniques: (a) the Euclidean distance, (b) successive approximation, and (c) piecewise decomposition. It is recommended that the Euclidean distance method be utilized because it is the simplest to implement and the most intuitive form of human perception of closeness of proximity [

54].

The Euclidean method was used to calculate the distance from the given fuzzy number to other fuzzy numbers that can be a natural-language expressions set. Assume EFL (eco-friendliness level) is a natural-language set, and U

FGICI is the fuzzy number of the FGICI and

is fuzzy number of the natural-language EFL expression; then, the Euclidean distance between the FGICI fuzzy number and each fuzzy number EFL

i ∈ EFL can be calculated as below:

where

p = {

x0,

x1, …,

xm} ⊂ [0, 1] so that 0 =

x0 <

x1 < …<

xm = 1.0. The Euclidean distance from the FGICI to each member in the EFL can be obtained by simplifying let

p = {0, 0.05, 0.1, 0.15, 0.2, 0.25, 0.3, 0.35, 0.4, 0.45, 0.5, 0.55, 0.6, 0.65, 0.7, 0.75, 0.8, 0.85, 0.9, 0.95, 1}. Afterward, the closest natural expression with the minimum distance can be identified.

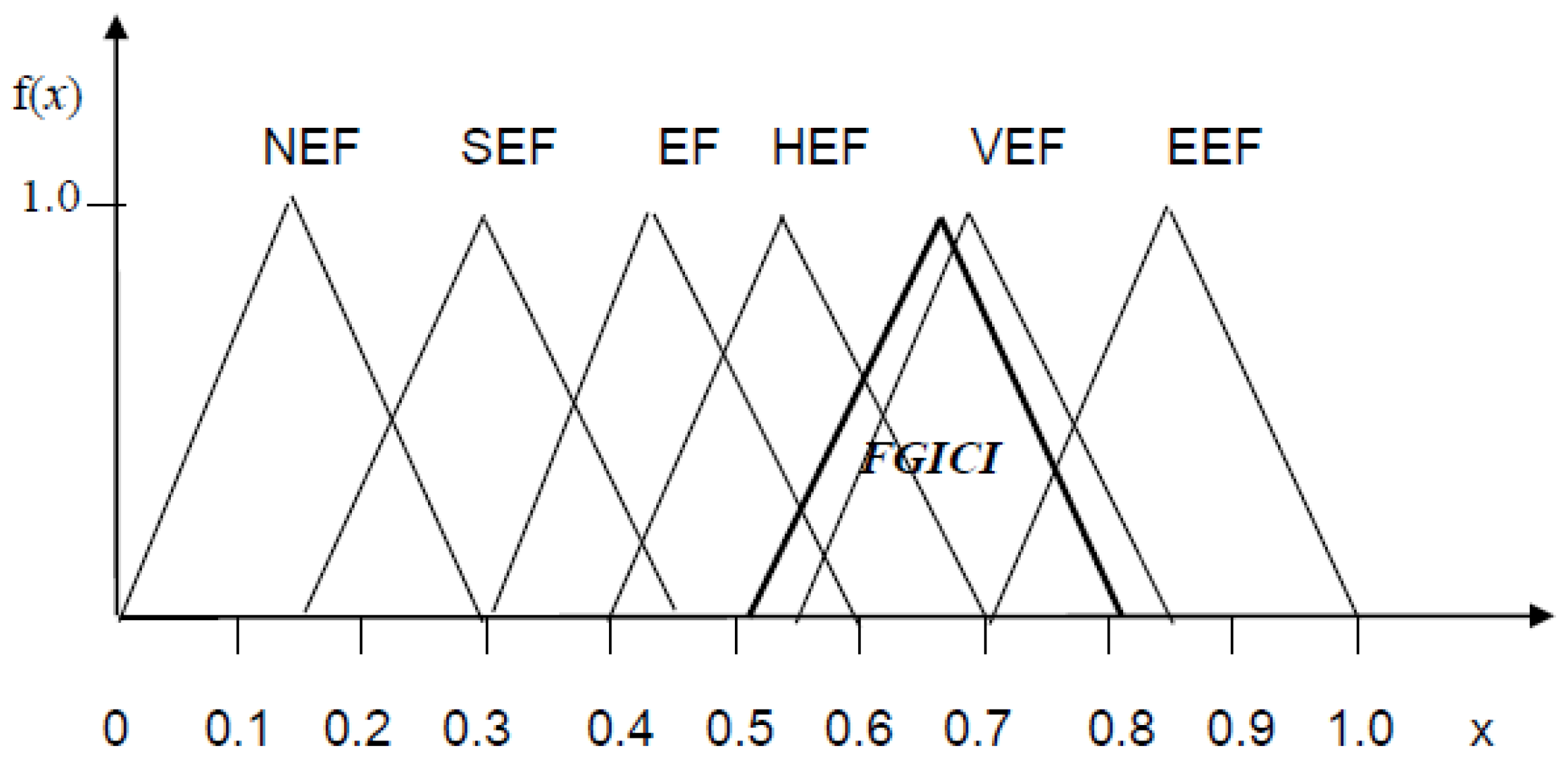

Each company should choose the labels and membership functions according to their goal and strategy for translating the

FGICI back into linguistic terms. In this case, the set EFL = {Extremely Eco-friendly (EEF), Very Eco-friendly (VEF), Highly Eco-friendly (HEF), Eco-friendly (EF), Slightly Eco-friendly (SEF), Non-eco-friendly (NEF)} was used for labeling, and its linguistics and corresponding membership functions are shown in

Figure 4.

Next, by applying the Euclidean distance D from the FGICI to each member in the set, the EFL was calculated as follows:

Since the linguistic label “Very Eco-friendly” with the minimum D, the EFL of GSCM in EA Optronics could be labeled “Very Eco-friendly,” as shown in

Figure 4.

5.2.7. Conduct Analysis and Provide Recommendations

An eco-friendliness assessment not only determines the EFL of an enterprise but also, and most importantly, helps managers assess distinctive competencies and identify the principal adverse factors for possible future implementation of an appropriate plan for enhancing the EFL.

The purpose of green providers is to determine and provide the entire eco-friendly behavior set of an enterprise. For the purpose of identifying principal obstacles and enhancing the EFL, an FIEI, which comprises low merit ratings and the high average relation weight of green providers, represents an effect that contributes to improving the eco-friendliness of a supply chain. A higher FIEI indicates a higher degree of contribution for a particular factor. Thus, the FIEI score of a factor is used for identifying principal adverse factors. Hence, for obtaining the factor with the lowest merit rating and the highest average relation weight for each eco-friendly provider

k, the fuzzy index for

FIEIk is defined as

where

[(1, 1, 1) θ

FMGPk];

FMGPk denotes the fuzzy merit of the

kth green provider; and

FARWGPCk denotes the fuzzy average relation weight of the

kth green providers for all green capabilities.

Because the GSCM integrated capability index level of EA Optronics was “Very Eco-friendly”, it had an EFL merit of 0.51–0.81, which is far from the “Extremely Eco-friendly” objective, obstacles within the organization affect or hinder EA Optronics from achieving the “Extremely Eco-friendly” rating. For identifying obstacles, 10 FIEIs are obtained (

Table 6) by solving Equation (12).

By applying the left-and-right fuzzy ranking method developed by Chen and Hwang [

49], the 10 FIEIs were defuzzified (

Table 6). These indices represent the effect of each provider contributing to the GSCM integrated capability index level of EA Optronics. To focus their attention on a few critical factors, based on the Pareto principle, the committee set the scale to 0.4 as the management threshold for identifying factors for improvement. As shown in

Table 6, the performance of three providers did not meet the threshold: (a) internal environmental audits; (b) long-term contracts incorporated with environmental dimensions; and (c) the promotion of an environmentally conscious culture. These providers exhibit the greatest potential for enhancing supply chain eco-friendliness. In considering the features of the obstacles within the company, a corrective action plan was suggested by the committee to implement in order to overcome these obstacles and to stimulate and enhance EA Optronics EFL.

Through a series of improvement projects (three years and six cycles), EA Optronics incorporated long-term contracts with environmental dimensions, promoted total environmental consciousness, strictly implemented internal environmental audits, continued to develop low-carbon products by using innovative production methods, and led the supply chain in adopting a sustainable production model based on the concepts of energy conservation and low carbon emissions, thereby raising the supply chain EFL to nearly the “Extremely Eco-friendly” level. Furthermore, EA Optronics was awarded the Oekom Research AG “prime” status, making it the leader of ethical evaluation for companies, ahead of international enterprises such as Hitachi, Kyocera, Nikon, and Samsung. The tangible benefits were average sales increases by 1.0%, 8.8%, and 0.5% in the past three years and an ascent in the global rankings, especially in the market for liquid-crystal panel displays.

6. Discussion and Conclusions

The eco-friendliness is perceived as the dominant competitive vehicle in enterprise. To effectively achieve eco-friendliness, it is crucial for enterprises to deploy and align GSCM drivers in business environment, green capabilities and providers to ensure that green providers can consistently satisfy green capabilities and cope with GSCM drivers and transforming them into strategic competitive advantages. Although the critical concepts and steps for achieving eco-friendliness have been identified, a systematic tool remains ineffective for converting strategies into actions and addressing issues pertaining to the interface among these steps. Many approaches concerning eco-friendly development are constructed in nature. Conventional (crisp) evaluation approaches are ineffective for addressing such ambiguous relationships among GSCM drivers, green capabilities and green providers. To offset the shortcomings of complexities and vagueness concerning addressed relationships, this study proposed a fuzzy QFD-based framework to connect and address issues regarding the interface and coordination among green providers, capabilities, and drivers. The proposed method provides a novel systematic structure to convert GSCM drivers in the business environment into the green capabilities requirement, and green providers (items for actions). Furthermore, for measuring the EFL of an enterprise, an FGICI comprising green capability ratings and its total relation weights with GSCM drivers was developed in this report. An eco-friendliness development project in a Taiwanese electronics enterprise was described in this study to show how the proposed method can be applied. After the development and evaluation stages, the proposed framework and procedures were considered to be capable of enhancing the EFL of an enterprise as well as ensuring an enterprise’s competitive advantage.

The developed method used the FLQFDEFEM for assessment. According to the comments from this case study, compared to the method that was used to resolve certain problems in traditional strategic business planning (including eco-friendly enterprise development) methods, several advantages were found:

The method provides an integrative and systemic procedure for eco-friendly operational strategic planning and is not merely a method for measuring the EFL. The eco-friendly operational strategic planning is a complex decision-making process, not merely as isolated technology islands within the company, requiring careful consideration of various performance criteria. The FLQFDEFEM procedure leading from market requirements to identify the GSCM drivers, according to the characteristic of drivers to select and deploy the capabilities needed, ultimately determines the appropriate providers. Thus, the method can ensure that value can be maximised and competitive threat minimized. The results of the study also indicated that to be truly eco-friendly, an enterprise must logically integrate and deploy a number of distinguishing providers with drivers and good capabilities, being finally transformed into strategic competitive edges.

The method is able to provide more convincing, informative, and reliable results for researchers, compared to traditional multiple criteria decision-making methods. The FGICI is expressed in a range of values (as shown in

Figure 4). Such values enable researchers to make unbiased decisions and to make the organization’s managers buy into such belief.

The method provides a very useful source of information for practitioners that seek to implement GSCM systems. It yields a dynamic reference linking the business strategy to a firm’s environment and provides detailed information for implementation through continuous improvements.

There are some limitations to the fuzzy logic approach, and even the case study has demonstrated the usefulness of the model for defining, aligning, measuring, and improving eco-friendliness in the business strategic planning. The membership function of natural-language expression depends on the managerial perspective of the decision-maker. The decision-maker must be at a strategic level in the company in order to realize the importance and trends of all aspects, such as strategy, marketing, technology, and manufacturing. Furthermore, company features and industrial profiles vary by enterprises (e.g., Samsung (Seoul, Korea) and EA Optronics)—for example, electronics- and motor-related manufacturing firms. Hence, a company must establish unique membership functions that are specific to its own environment and considerations. Moreover, the list and distinction of GSCM drivers, capabilities, and providers are merely presented as they were assessed in this research as the most prevalent and meaningful factors in the case study. Hence, it is still a relatively novel concept that has not been widely discovered in the industry. The computation of a fuzzy weighted average can be complex and is not easily comprehended by managers. However, this calculation approach was computerized to increase its accuracy while reducing both computational time and errors. Furthermore, the strategic intent to become eco-friendly and increase in core competencies for the purpose of gaining a competitive advantage are essential for a company. Every company should understand its circumstances, the threats it receives from the business environment, and the opportunities that would enable the company to succeed.