1. Introduction

The global concerns on energy and environmental challenges are becoming ever more important. Growing demand for energy, depletion of natural resources and global warming are leading problems in this respect [

1,

2]. Global warming and climate change are leading to wide-ranging challenges including sea level rise, seasonal disorder and natural catastrophes [

3,

4]. The building sector has an important role in the international energy and environmental scenarios as it consumes almost 40% of energy and results in over a third of greenhouse gas (GHG) emissions [

5]. The building sector is experiencing a rapid growth in countries across the world due to factors like population growth, infrastructure development, modernization and urbanization. To tackle the facing of energy and environmental problems, the world is aiming to promote sustainable development as is reflected by the recent global agreement on climate change, COP21 [

6]. The building sector has a crucial contribution to make towards improving sustainability standards and addressing the energy and environmental challenges. In the backdrop of the global drive for sustainability, buildings are facing significant improvement in their energy efficiency standards especially in the developed countries. Efforts are being made both on the policy and technological fronts. While buildings performance regulations and standards are being made stringent through robust policy frameworks, technological advancements are improvising effective solutions to help the cause.

Saudi Arabia is one of the largest countries in the Middle East in terms of geographic area, economy and infrastructural development. Owing to factors like increasing population, modernization and economic development, the energy demand in the country is rapidly surging. Estimates suggest that between 2000 and 2014, the primary energy demand increased by over 100%. Buildings account for almost 80% of the total electricity consumption in the country. The residential buildings alone consume almost 50% of the total national power generation [

1]. Owing to its rich oil and gas reserves, it has traditionally cherished heavily-subsidized energy tariffs. The situation however is fast changing. As of the recently announced strategic policy framework, Vision 2030, there are targets to remove 200 billion Saudi Riyals of energy subsidies by 2020 [

7,

8]. The situation is bound to bring a paradigm shift in the energy consumption patterns. The role of energy conservation strategies and energy efficiency measures is set to become critical. Green roofs can be applied as an energy saving options in Saudi Arabia.

Green roofs are a passive strategy that can be a useful solution in different climates to reduce energy consumption in buildings. It offers energy saving and reduction in GHG emissions while enhancing the aesthetic qualities and architectural presentation of buildings [

9]. It is being used as an energy saving measure in countries around the world [

10,

11]. Although it can reduce the energy demand in different climatic conditions, its performance mainly depends on climatic conditions, building function, insulation of the building envelope and the type of green roof [

12]. Green roofs not only protect the roof from solar radiations and extensive heat fluctuations, but also maintain the indoor temperature by working as insulation. In summer, it reduces the indoor air temperature of the building by providing shading, insulation and evapotranspiration against the solar radiation, while in winter, it works as a wind shield to reduce the heating loads, but the winter effect is less than the summer effect.

The present work aims to investigate the prospects of the green roof, a passive energy saving option, in hot climates by focusing on the climatic conditions of Saudi Arabia. Its main objectives are as follows:

To examine the effectiveness of the green roof in hot climates in terms of energy saving.

To determine the impact of building materials in improving energy performance of buildings.

To study the influence of the orientation on the energy performance of buildings.

The above parameters have been investigated for modern residential villas situated in the city of Dhahran. It is also important to mention that we are considering the same building in the Riyadh climate, as well. Basically, Saudi Arabia has three main population bases, Dhahran/Dammam, Riyadh and Jeddah. The twin cities of Dhahran and Dammam are situated on the east coast of the country, while Jeddah is on the west coast. Both of these locations have quite similar climates, hot and humid. The study has therefore chosen one of these locations, Dhahran, as the representative of the hot and humid climate. Riyadh, on the other hand, has a predominant hot and dry climate. ECOTECT software has been used to model the energy performance of these villas with wide ranging features.

2. Project Brief

The King Fahd University of Petroleum and Minerals situated in the city of Dhahran in Saudi Arabia is one of the largest universities in the Middle East region. Owing to its on-campus huge infrastructure consisting of academic and administration blocks, faculty and student residential buildings, community centers, schools, workshops and warehouses, it presents an urban scale environment. Already having over 1000 residential units for faculty and staff, it has constructed 200 new villas for faculty. Most of these new villas are positioned north-south while some are oriented northeast-southwest. A small proportion of villas also face northwest, as shown in

Figure 1.

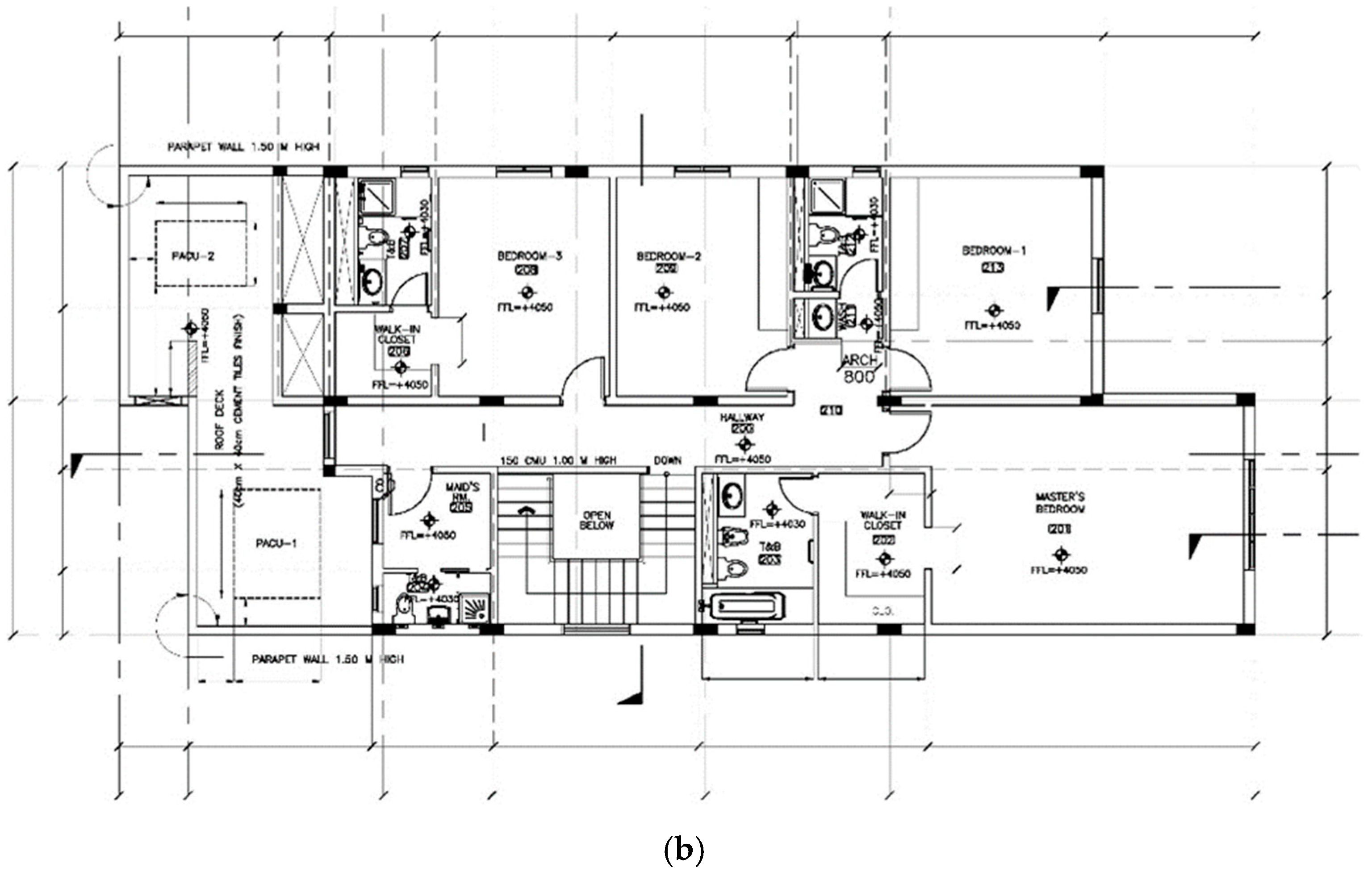

Each villa consists of two stories with almost 450 m

2 of built-up area. The clearance height of each story is 3 m. Main facilities provided on the ground floor are guest room, kitchen, dining, family dining, laundry, toilets, store and service area, as shown in

Figure 2a, while on first floor, four bedrooms are provided with two attached baths and one shared toilet, as shown in

Figure 2b. The window-wall ratio (WWR) is almost 10%. The structural members on the external facade are concrete masonry units (CMU), hollow blocks, while the roof is constructed with reinforced cement concrete (RCC) slab and some other composite materials. Windows are double glazed with aluminum frame. The HVAC system used in these residential buildings is a constant-volume DX unit, while two separate units are installed on the rooftop, one for each floor. The capacity of the HAVC system at the ground floor is 11.9 tons, and the supply of air flow is approximately 11.3 ACH. The capacity of the HVAC system on the first floor is 9.4 tons, and the supply airflow is 9.4 ACH. The lighting power density at the ground floor and first floor is respectively 21 W/m

2 and 13 W/m

2.

3. Literature Review on the Green Roof

Green roofs are one of the passive strategies used to reduce the heat transfer and improve the thermal comfort of a building or space by application of vegetation on the roof. It not only reduces the direct and diffuse radiation incidences on the roof [

13], but also improves the life span of the roof by modifying the temperature fluctuations experienced by its different layers, as it reduces the thermal stresses and heat aging of roof components [

14]. Green roofs are basically composite structures in which plants are provided above a soil layer. Below the soil layer, a filter is provided to stop the soil from washing. Rain water storage, which is plastic profile elements, substituting draining gravel, is provided to store water for plants for the dry season. It also takes surplus water to the roof gutter. A root barrier is provided underneath the drainage layer to protect the water-proofing membrane [

15]. Alternatively, offsite prefabricated growing medium in the form of blocks can also be used with plants already sprouted. In this case, the block can be easily removed for maintenance purposes [

16]. There are three types of green roofs, extensive, semi-intensive and intensive green roofs. The intensive green roof is relatively heavy weight construction, provided on thick growing media (soil), and it requires more maintenance because of the types of plants used, as it creates a garden-like environment [

17]. On the other hand, the extensive roof is light weight construction, which requires less maintenance and little human intervention because of less variety of plant types.

Studies show that the green roof is more effective in a hotter and drier climate as urban heat temperature can be reduced more effectively [

18]. Green roofs are more effective at reducing the heat gain than heat loss, as according to a study, 70–90% of the heat gain was reduced in summer, while 10–30% of heat loss in winter [

19]. From one of the studies made on a residential building in Cairo, it was found that the cost saving of the green roof as compared to the conventional roof is between 15 and 32% [

20]. From another study, made in Jordan, it is concluded that 17% of the HVAC energy demand can be reduced by using the green roof [

21]. In another research done in a Mediterranean climate, a 6–49% reduction in energy demand was noticed because of the green roof [

22]. Green roofs can also reduce storm water management by 40%, as according to a research undertaken in Singapore, the green roof can reduce the peak flow by 65% and retain overall runoff by 11.6% for a maximum 1-mm/min rainfall intensity [

23]. A surface temperature difference between the green roof and the conventional roof was noted as an average of 20 °C [

14]. In a research conducted on porous tiles in Guangzhou China, it is noted that the thermal performance of the roof is influenced by moisture content in the porous tiles. The surface temperature of the roof can be decreased up to 11.3 °C if porous tiles contain a sufficient amount of water [

24]. In the case of the green roof, there is not only a soil layer containing moisture content, but also plants provide shading above the whole roof surface.

There are many factors affecting green roof design, like thermal conductivity, specifics heat, density, thermal absorptance, solar absorptance, height of plants, leaf area index, etc. A 150 mm–1200 mm soil depth is required for the intensive green roof to support large plants, while growing media required for the extensive roof can be 50–150-mm thick [

19]. Moreover, the typical weight of the intensive green roof is almost 290 kg/m

2–968 kg/m

2, while for the extensive green roof, it is from 20 to 169 kg/m

2 [

25]. The purpose of the thick soil layer is to create thermal mass, which not only increases the time lag, but also reduces thermal transmittance. Furthermore, soil depth, organic matter and water balance in the soil layer affect the soil thermal performance [

26]. According to a study, a 10 cm-thick soil layer is enough to control the heat penetration [

19]. Another research work done in Singapore reveals that the thermal resistance of roof can be increased by 0.4 KW for every 10-cm increase in the thickness of the substrate layer with clay [

27]. Water content the in soil layer also changes the thermal properties of it, as more water content can increase the thermal conductivity of the layer [

28]. Organic matter in soil also maintains good soil structure [

29]. Required benefits from plants can be achieved by providing proper irrigation [

30].

The vegetation layer not only creates good aesthetics, but is also good for the environment [

31]. A change in the physical characteristics of plants changes the impact on the environment. In a harsh climate, only limited species of plants can survive. Plants’ survivability in a hot climate also depends on the availability of irrigation [

32]. In a research work, after studying twelve different species (forbs, sedum and grasses) commonly used for extensive green roofs, in three different combinations of plants and three different water regimes (wet, moderate and dry), it is concluded that under dry conditions, a diverse plant mix has greater survivability than a monoculture [

33]. Moreover, sedums have better drought tolerance than forbs and grasses. According to another study, the survival of plants depends on plant water use, leaf succulence and substrate properties. Plants with high water holding capacity and high succulence leaves survive longer [

32]. Moreover, the mean thermal conductivity value for leaves varies from 0.268 to 0.58 W/m

2K [

17].

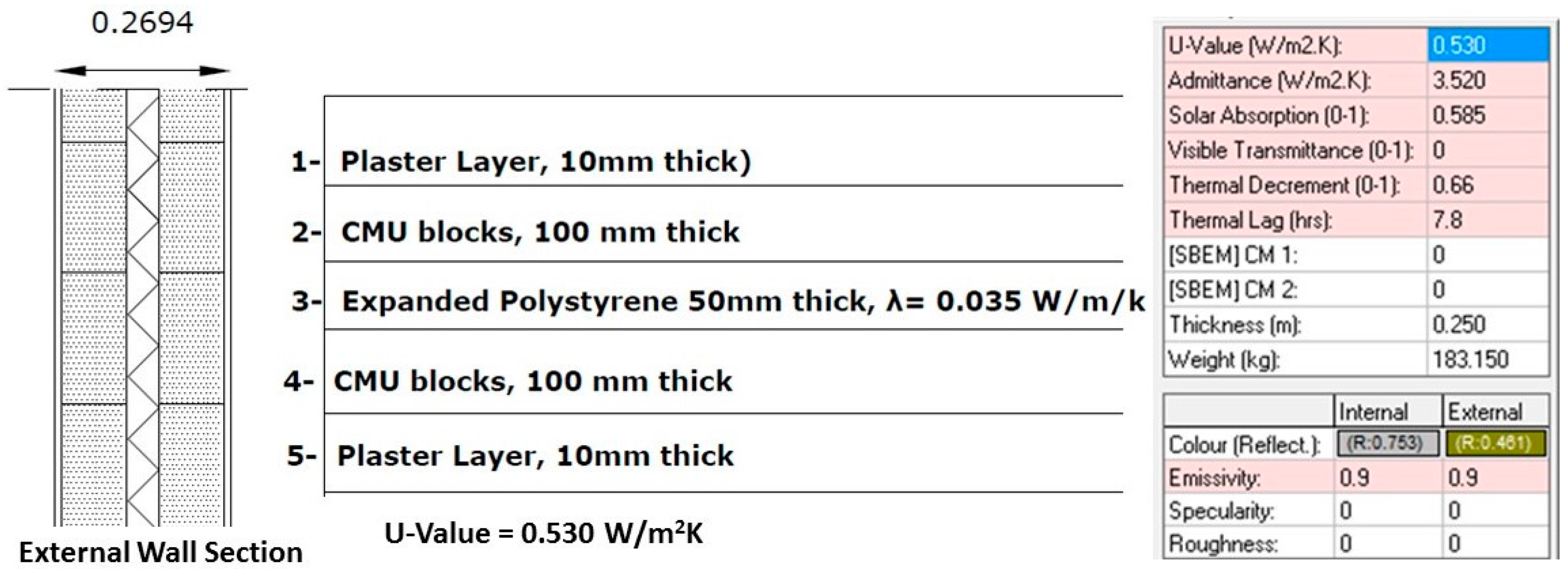

5. Material Used

In this section, we will discuss the material used in this faculty housing project and our proposal for the green roof section. In the external wall section, 100 mm-thick CMU blocks are used on the inner and outer side of the wall with a 50 mm-thick polystyrene layer in the middle. The thermal conductivity value for the whole section is calculated as 0.530 W/m

2K, which is bit higher, so a further increase in the insulation thickness can reduce the thermal conductivity value of the section.

Figure 3 shows the x-section of the external wall and its thermal properties. Moreover, in partition walls, again, 150-mm CMU blocks are used with plaster on both sides.

In the existing roof section, a 300 mm-thick ribbed concrete slab is used as the structural member, and above it, cement screed is provided for sloping purposes. The bitumen layer is there above the concrete layer for water proofing. Fifty millimeter-thick polystyrene is used as insulation, which might be less, as 70% of the heat is absorbed by the roof, so this may be the most critical area that needs more attention. Above the insulation layer, again, the water-proofing membrane is provided with the cement tile on top. The thermal conductivity value, calculated for the whole section, is 0.490 W/m

2K, which is again high.

Figure 4 shows the roof x-section and its thermal properties.

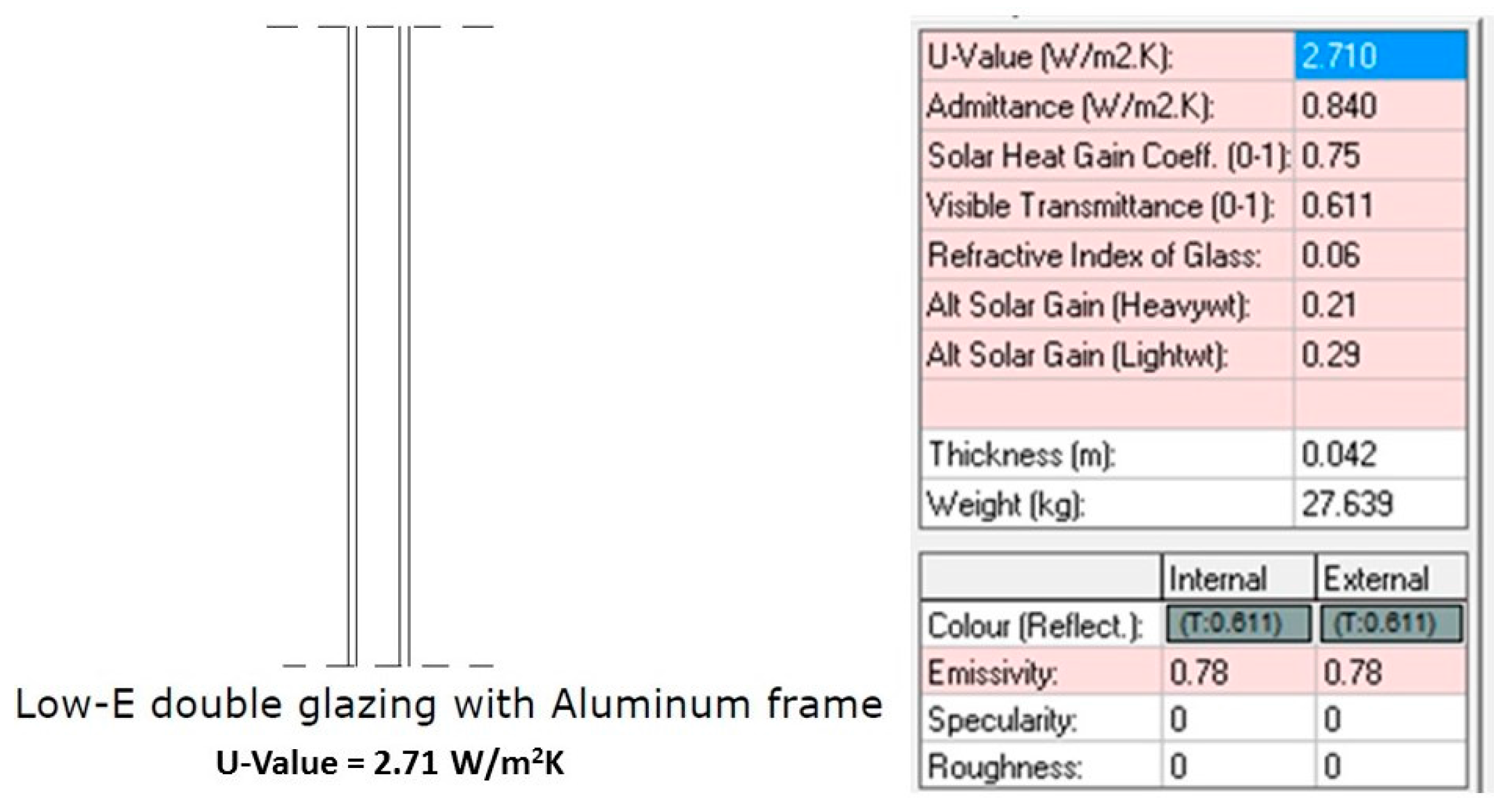

In windows, low-e double glazing is used with an aluminum frame, which has a U-value of 2.71 W/m

2K.

Figure 5 shows the window glass section and its thermal properties.

Since ceiling section does not influence thermal calculations, no thermal insulation layer is provided in the ceiling section. Gypsum board is placed as a false ceiling with a 600-mm air gap to provide air-conditioning ducts.

Figure 6 shows the ceiling section and its properties.

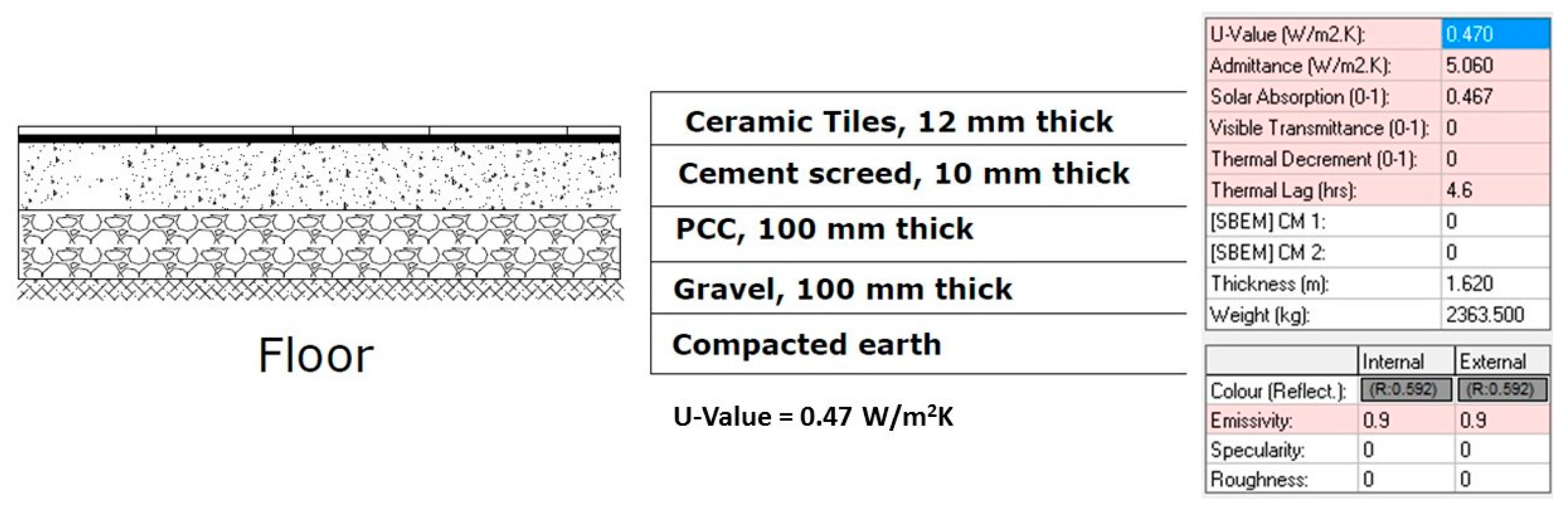

In the floor section, a plain cement concrete (PCC) layer is provided with ceramic tiles on the top. PCC is placed on a layer of gravel, while below the gravel, compacted earth is provided. The U-value of the section is 0.47 W/m

2K.

Figure 7 shows the floor x-section and its thermal properties.

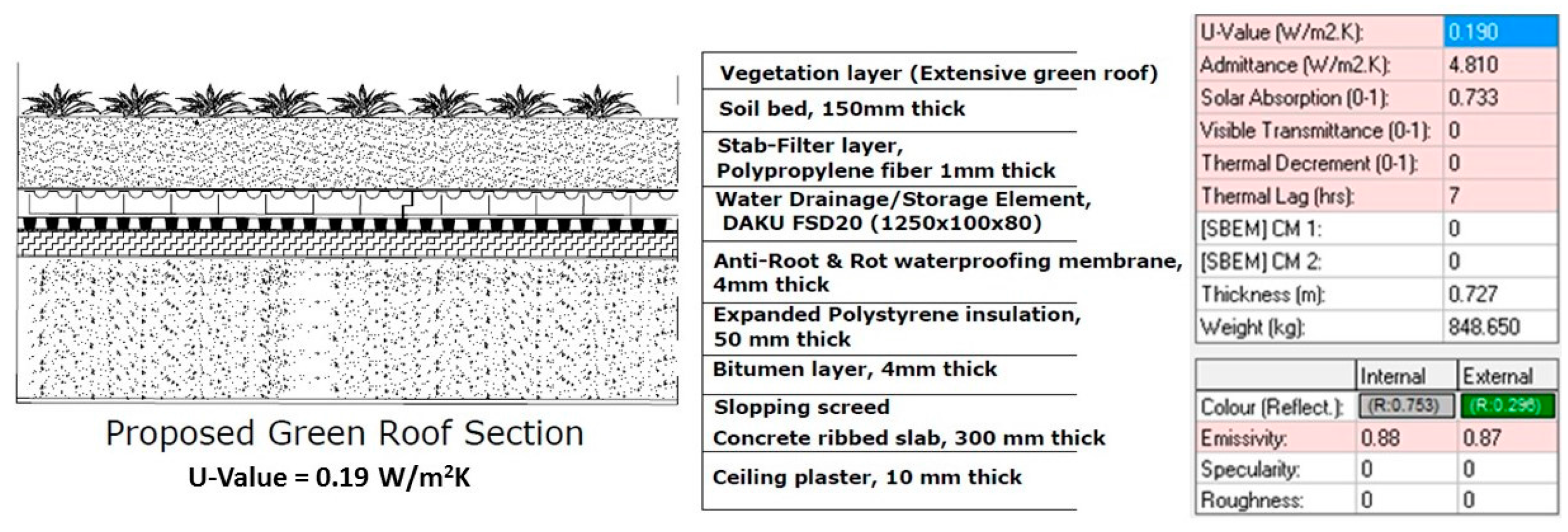

In the proposed green roof section, we are assuming to provide the extensive green roof not only taking into consideration the load-bearing capacity of the existing structure, but also due to the maintenance factor of the green roof. It is also important to mention that a shallow soil depth may result in plants’ root damage from heat and temperature fluctuation, and 2 3/4” soil substrate is suggested by some of the green roof companies for the extensive green roof; but, still it is recommended to provide minimum a 3” deep soil layer. For green roof provision, we are considering green roof layers on existing conventional roofs, where reinforced cement concrete (RCC slab) is used as the main structural member and above which bitumen is provided as the water-proofing membrane. The same 50 mm-thick insulation “extruded polystyrene” layer is considered above the bitumen, which is provided in the existing roof structure, so the true effect of the green roof could be observed. The root barrier with the water proofing membrane is provided above the insulation layer to protect the insulation and the other structure from any damage. The water drainage system, which not only stores rainwater, but also takes excessive water to the gutter, is provided above the root barrier layer. The drainage system is basically recycled plastic modular elements, normally having a 6-cm height. Above the drainage layer, a 150 mm-thick soil bed is placed, and we are considering 150 mm as the plant height above the soil layer. While creating the green roof section on the software ECOTECT, we are considering a 300 mm-thick layer for soil and plants, as plants are not available as material on the software, and the green roof main section (soil layer and plants) works as thermal mass or as shading on the existing roof structure, so considering one thick layer can resolve the problem. The thermal conductivity value calculated for this green roof section is 0.190 W/m

2K since we did not change the thickness of the insulation, as used in the conventional roof section. The thermal conductivity value of the green roof section can be further improved by changing the specification and thicknesses of insulation, soil layer and plants.

Figure 8 shows the x-section of the proposed green roof and its properties. Since we are considering the extensive green roof on the existing structure, we planned to use a combination of forbs, sedum and grasses, which has better survivability in a hot climate, like Saudi Arabia, as discussed in the literature review [

33].

6. Thermal Analysis

All analyses are made on the software ECOTECT. ECOTECT by Autodesk is a unique building performance analysis software that performs a variety of analyses with simple and intuitive 3D modeling. It is user-friendly interface, and compatibility with other software like AutoCAD, REVIT, etc., makes it popular among designers to use from the conceptual to the design stage. It can perform analysis like solar stereographic shadows, overshadowing and solar reflection, sun penetration and shading, analysis of artificial lighting, solar access and photovoltaic/heat collection, acoustic reflections and reverberation times and hourly thermal comfort and monthly space loads with a weather tool option for a specific location [

37]. Especially, “solar access analysis” to calculate the incident solar radiation and the “shading design wizard” to design the proper shading make it prominent among other software. Difficulty in creating complex geometry and lacking study of the fluid dynamics are some limitations that this software has.

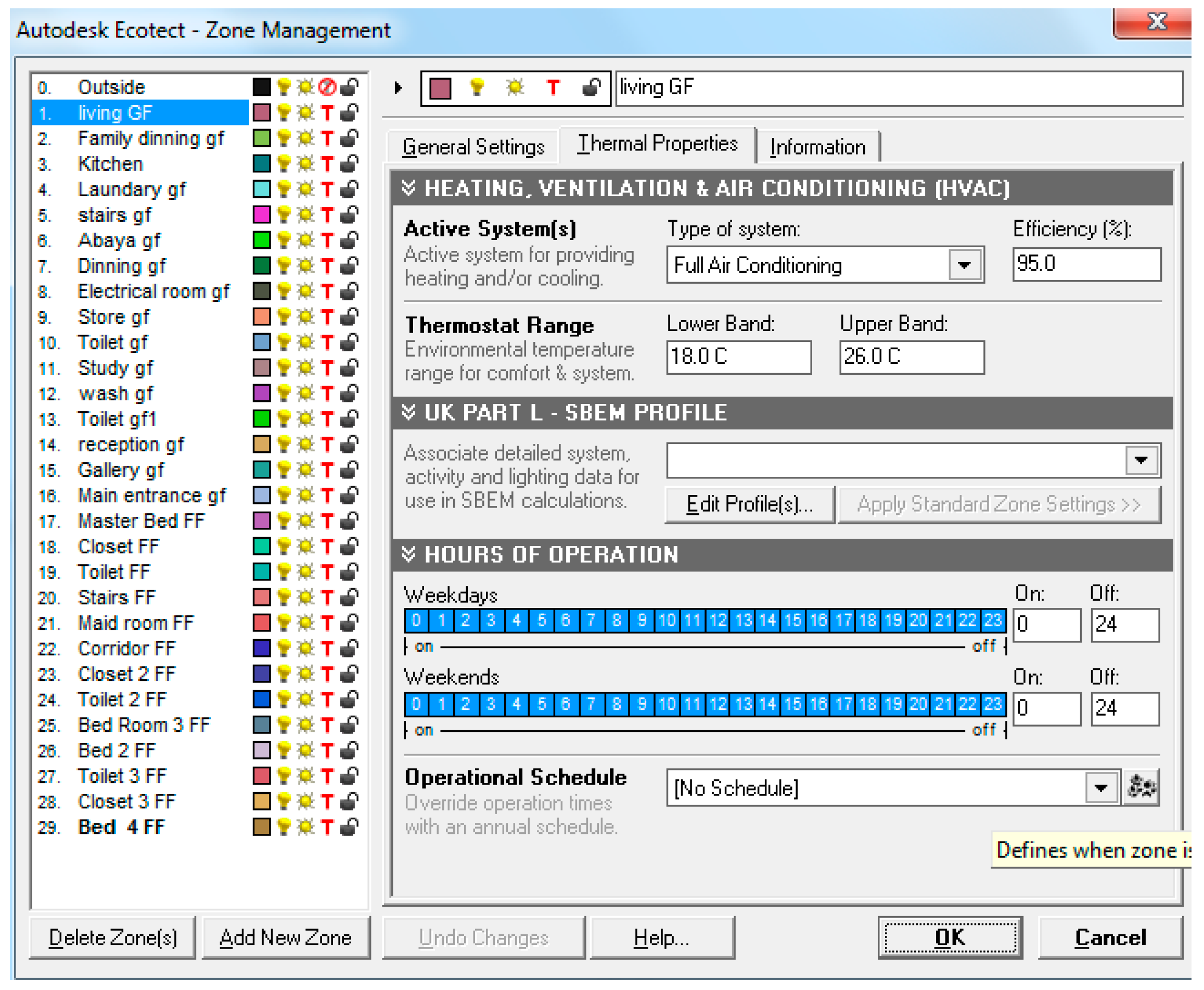

Heating and cooling loads are a measure of energy needs to be added or removed from a space by either mechanical or natural systems to provide the desired level of comfort within a space [

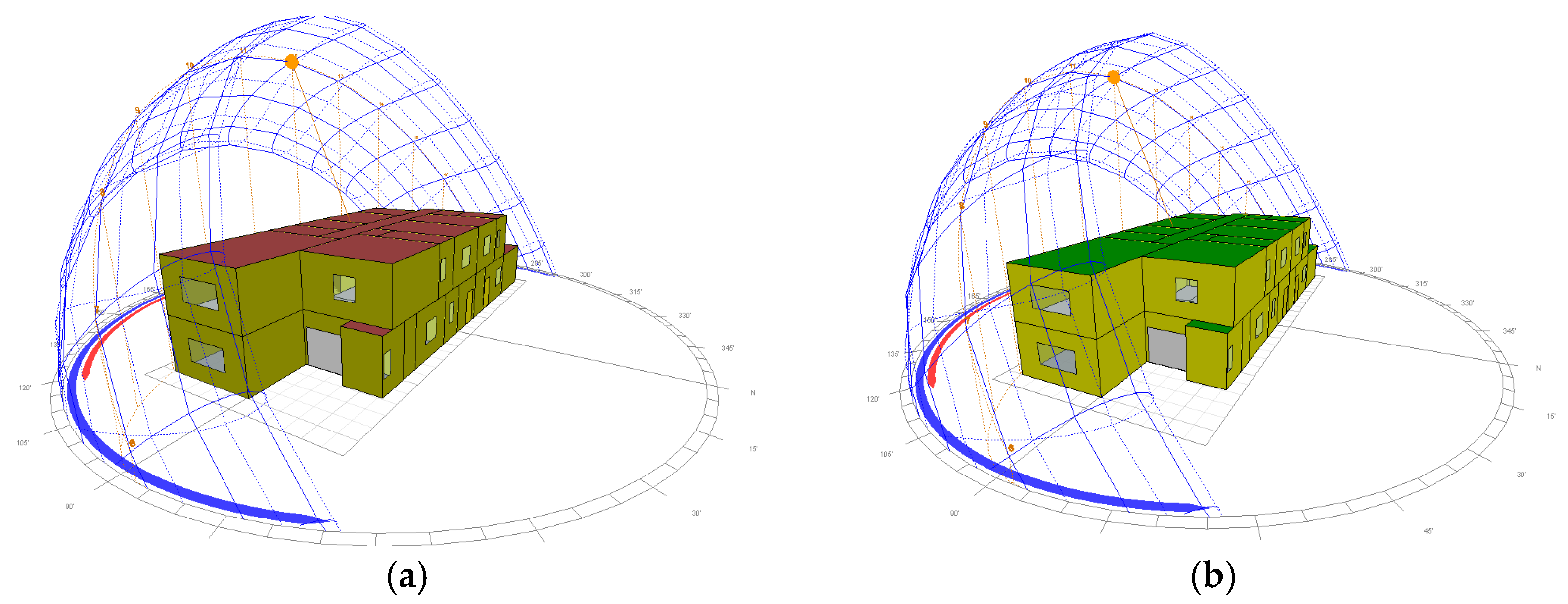

38]. Heating and cooling loads help in choosing the type of system and its capacity. This also helps in choosing duct sizes and its type. These loads have a direct impact on the construction and operational cost, occupant comfort and building durability. To do these analyses, we prepared two separate models with the same materials on the walls, floors, ceiling, windows and doors, as shown in

Figure 9. On one model, the conventional roof material was applied, while on the other, the green roof was considered. Monthly load discomfort analysis was run after making the zone settings. The weather data file for Dhahran’s climate is not available in ECOTECT, so we are considering the Kuwait coastal area climate for analysis, since many other software products do the same by default.

The main considerations while making the analysis, as also shown in

Figure 10, were:

Design for the full air-conditioning system due to the hot weather of Saudi Arabia, where air-conditioning is required twenty four hours a day for 12 months.

Thermostat range: 18–26 °C.

Operating hours: 24 h/day.

Air speed: 0.50 m/s.

Clothing factor: 1.0.

Air change rate: 0.50.

Wind sensitivity: 0.25.

7. Results

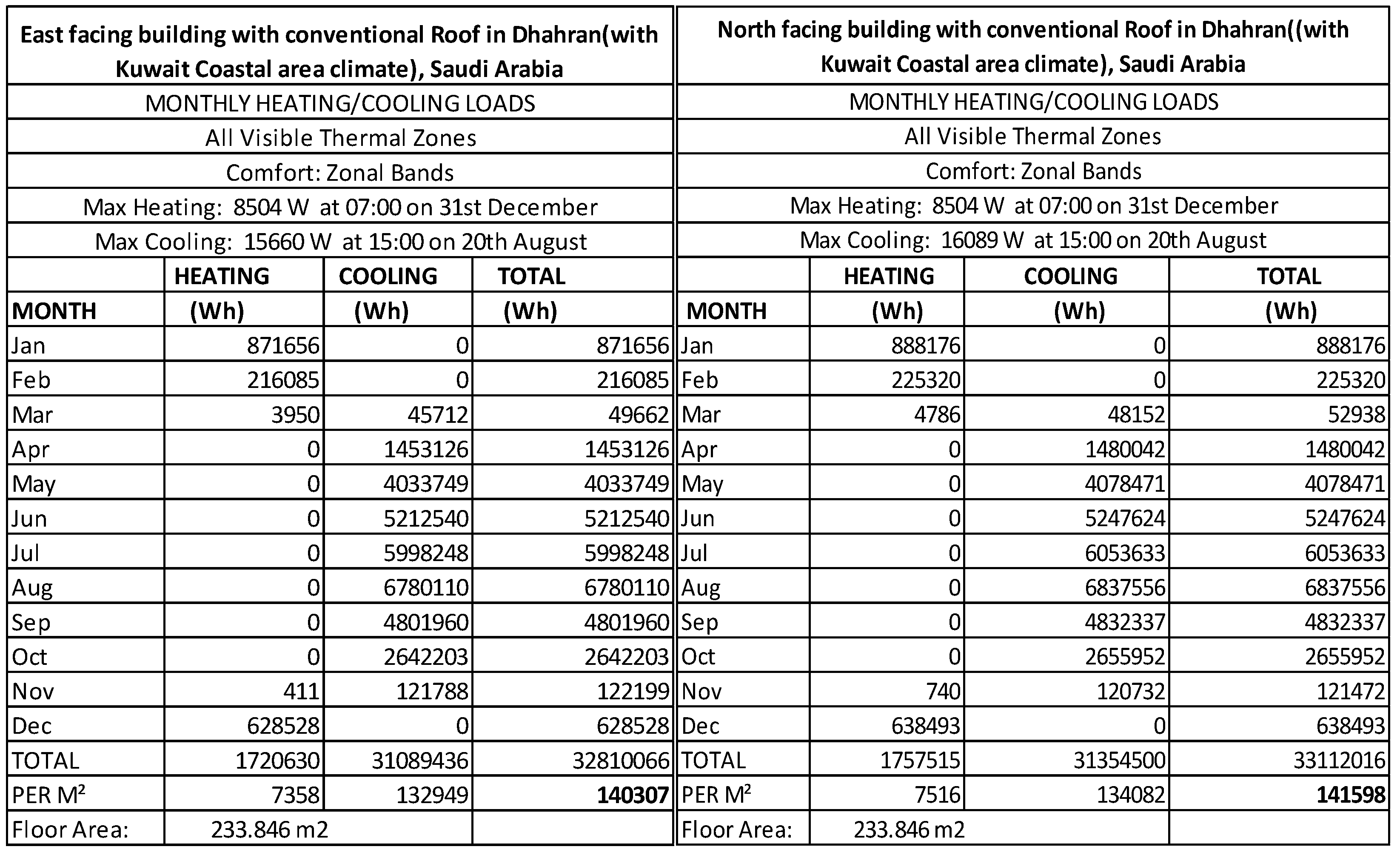

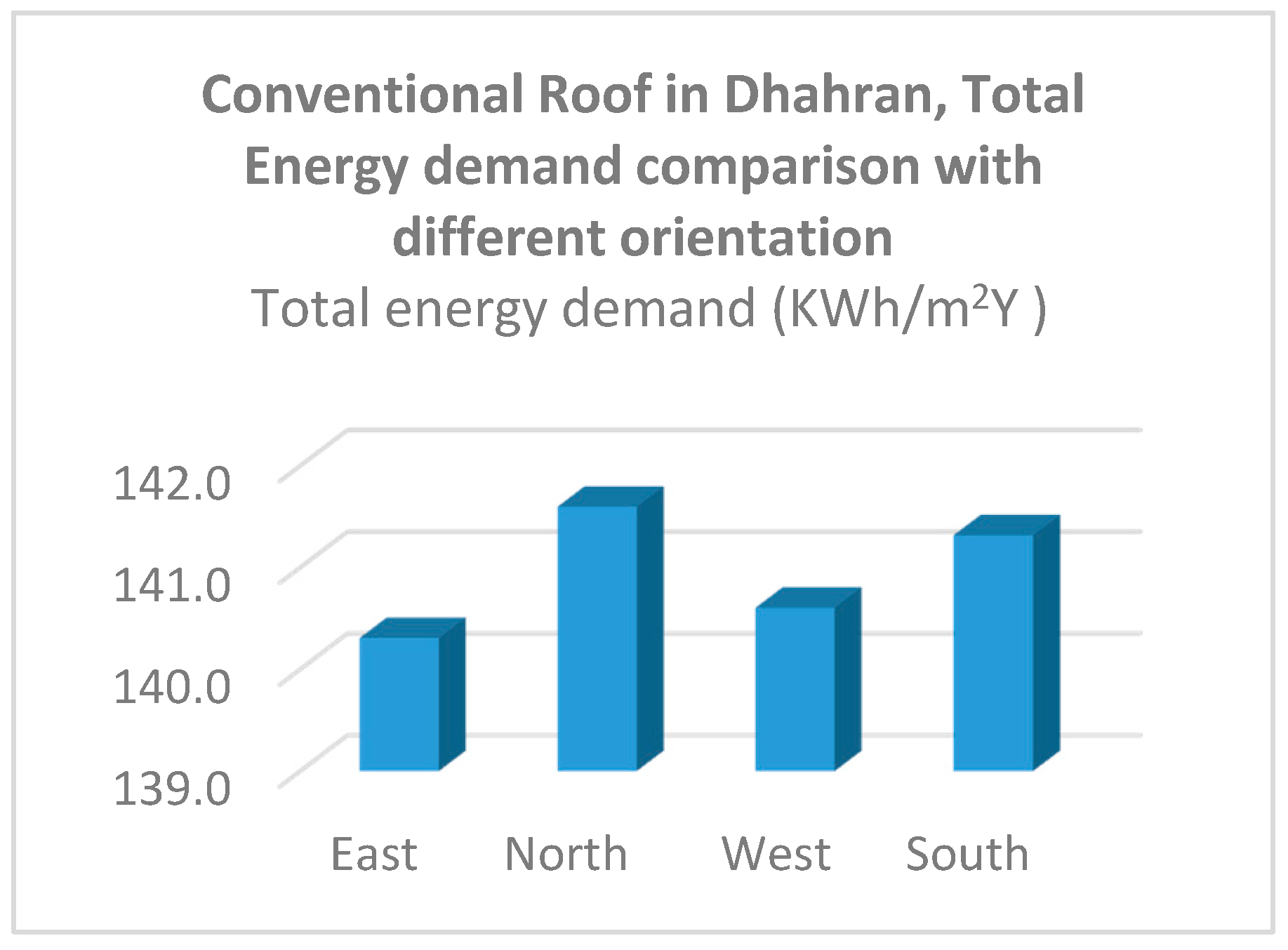

Load discomfort analysis informs us about the total energy demand of the building including heating and cooling loads. Monthly load discomfort analysis is made for Dhahran region while considering the Kuwait coastal area weather data file, as the Dhahran weather data file is not available in ECOTECT. It is also important to mention that we are considering detached housing to understand the reduction in energy demand because of the building orientation; otherwise, these houses are placed in different orientations and the proper urban arrangement, as discussed in the project brief. The selected detached building is analyzed with four different orientations, east facing, west facing, north facing and south facing. Initially, analysis is made with the existing roof structure to understand the orientation, consuming the maximum amount of energy.

Figure 11, shows the results generated by the software with east- and north-facing models and with the conventional (existing) roof. These results are summarized in

Table 1 and

Figure 12.

The difference in energy demand for the four orientations is minor with the east-facing one consuming the minimum, 140.3 KWh/m

2Y as shown in

Table 1. West-facing and north-south-facing orientations respectively consume 140.6 KWh/m

2Y and 141.6 KWh/m

2Y. It can be concluded that the east-west orientation is consuming less compared to the other three because the longitudinal axis of the building is facing north-south, and since the north side is least exposed to sun and the one of a longer elevation is mostly under shade, so mainly the heat transmission is from the south side only. It also depends on the number of windows provided at different elevations. Furthermore, even if we are going to consider the same orientation with the neighborhood, the results would be even better as now, the southern side of the building will also be under shade because of the adjacent building. On the other hand, the building facing south or north is consuming the maximum amount of energy since the longitudinal axis is facing east-west, and this will be exposed to sun either in the morning or in the afternoon; but the front elevation along the south is exposed to sun most of time, as this time north, which is least exposed to sun, is along the shorter axis, so total energy demand is higher.

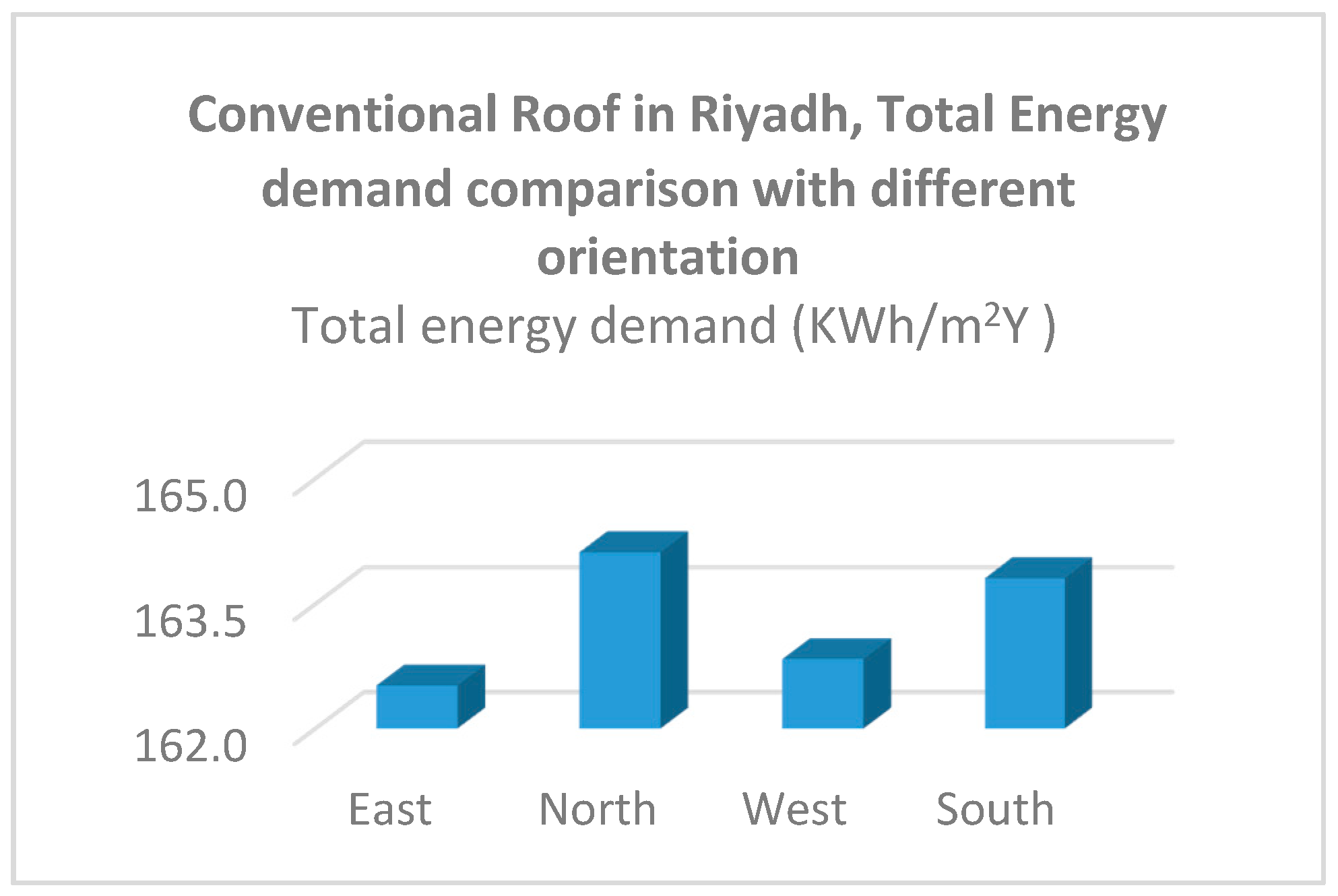

The monthly load discomfort analysis in four different orientations with conventional (existing roof) roofs are repeated in the Riyadh climate, and almost a similar type of trend is observed, as shown in

Table 2 &

Figure 13. The east-west-oriented building is consuming a lesser amount of energy, but the north-facing building has the maximum energy demand. It is also important to mention that in this case study, if the building is north oriented, then the south elevation, which will be the rear in that case, has more windows, which increases the energy demand; that is why the north-facing building has slightly higher energy demand as compared to the south-facing building.

If we are going to compare the total energy demand in two different climates, which are Dhahran and Riyadh, with the existing conventional roof, then the result generated by the software clearly tells that the total energy demand in Riyadh would be almost 14% higher along different orientations, as shown in

Table 3. If we are going to compare heating loads in both climates, it is quite clear that these are high in Dhahran, and this is because of the winter duration, as this is for a greater time period in Dhahran. The longer winter period in Dhahran reduces the cooling loads, and hence, total energy demand in the Dhahran climate is less than Riyadh.

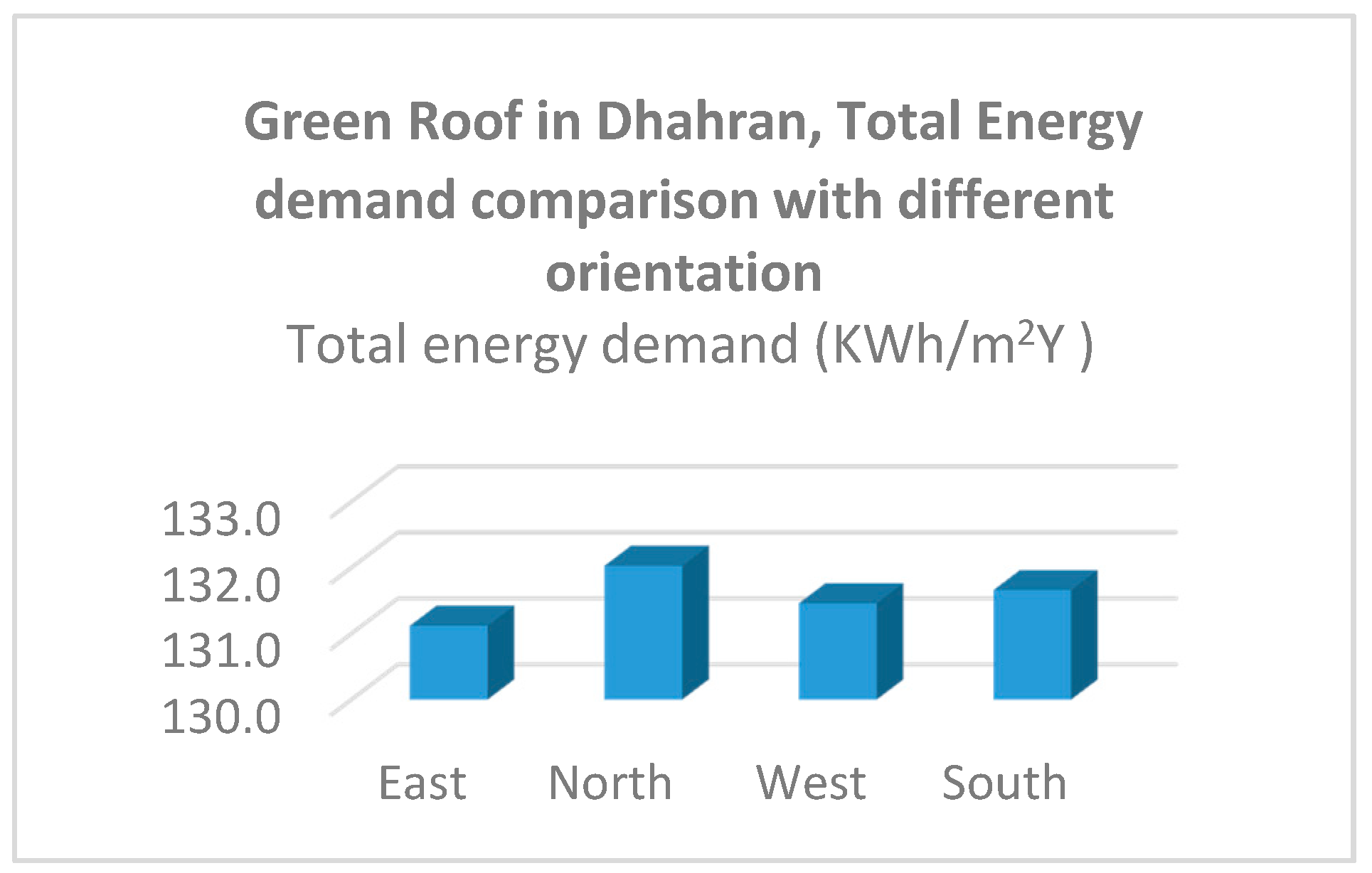

Now, we replaced the conventional roof with the green roof in Dhahran climate.

Table 4 and

Figure 14, show the results generated by the software. In this model, the green roof is placed at the top instead of the conventional roof, while all other specifications (for walls, floors, windows, doors etc.) are the same, and a considerable reduction is noted in the cooling load, as it came down from 132 KWh/m

2Y to 124 KWh/m

2Y, while the reduction in heating demand is less than 1 KWh/m

2Y; which was 7.5 KWh/m

2Y before, but became almost 6.8 KWh/m

2Y.

Comparing the total energy demand between the conventional and green roof in Dhahran, the latter is found to provide 6.5% of savings with respective loads of 140 KWh/m

2Y and 131 KWh/m

2Y, as shown in

Table 5.

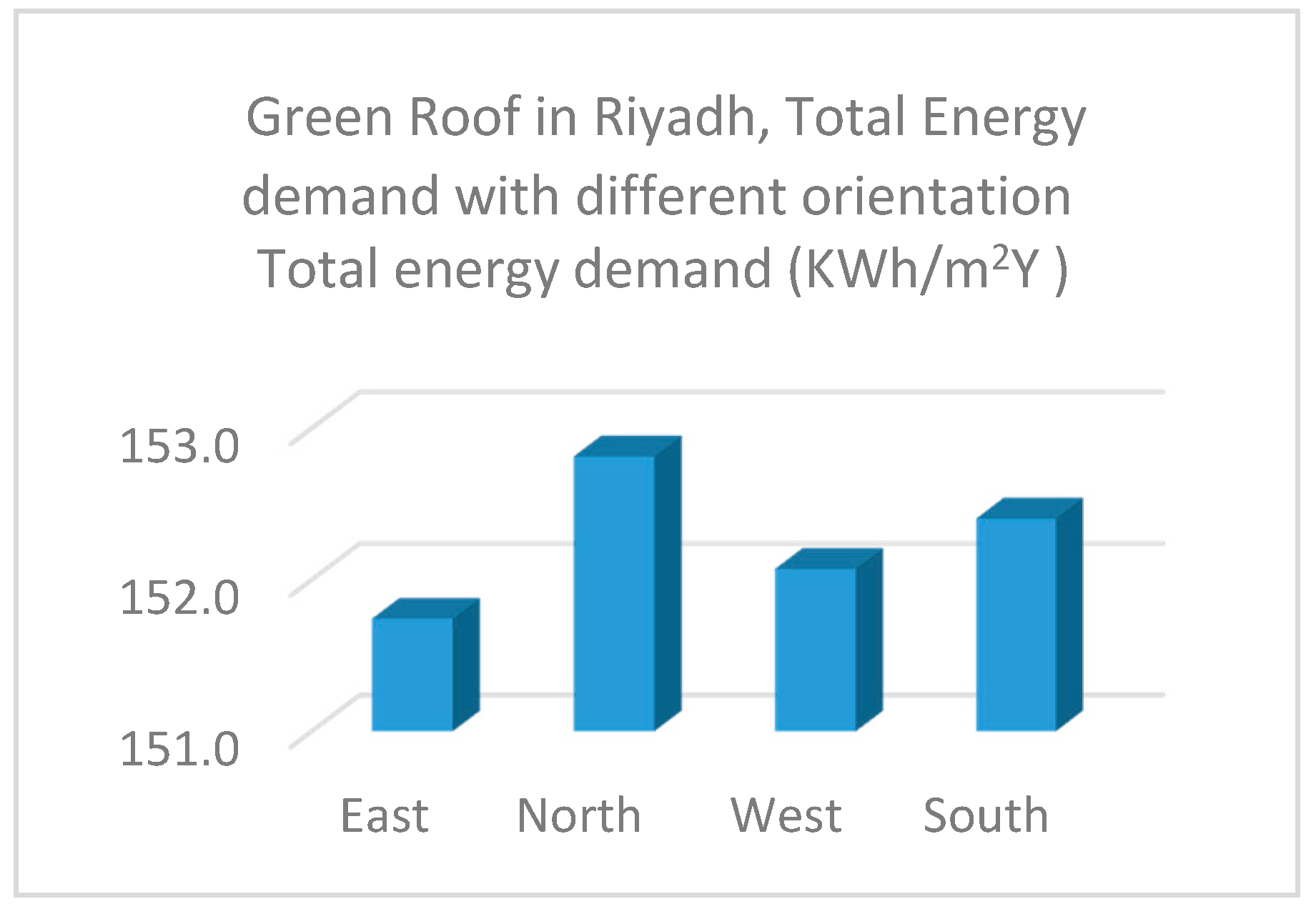

Now, the conventional roof (existing) is replaced with the green roof in Riyadh, and the analyses are made in four different orientations. In terms of orientation, the trend of the energy demand is almost same as the green roof in Riyadh, as east-west is the most suitable orientation with the minimum energy demand, while north-south has the maximum energy demand as shown in

Figure 15. Cooling loads got reduced almost 10 KWh/m

2Y from 158 KWh/m

2Y to 148 KWh/m

2Y, while the reduction in heating loads is almost ignorable, as reduction is from 4.3 KWH/m

2Y to 4.0 KWh/m

2Y as shown in

Table 6.

Now, we compared the results of conventional roof with green roof in Riyadh and found that with the east-facing building, the saving can be 6.63% as compared to the conventional roof in the Riyadh climate, and it reaches almost 7% for the south-facing building, as shown in

Table 7.

Comparing the effectiveness of the green roof in the hot and humid (Dhahran climate) and the hot and dry climate (Riyadh), we found that the reduction in energy demand is slightly higher in Riyadh as compared to Dhahran, as shown in

Table 8, as is also suggested by other studies that the green roof is more effective in a hot and dry climate [

18].

8. Discussion

As part of energy conservation strategies in buildings, a number of systems and materials can be applied to reduce the energy demand. Walls, floors, roofs and windows can be designed in such a way that heat losses in winter and heat gain in summer could be minimized. Green roofs are a passive strategy, which insulate the building rooftop. The vegetation component of the green roof reduces the heat gain by working as an active dynamic air envelope system. It provides exterior shading to control the direct solar radiation, thus leading to considerable energy saving. In this research project, we have considered newly-constructed villas in KFUPM, Dhahran Saudi Arabia, as the case study and modelled green roof layers above the existing roof structure with the same insulation thickness as provided in the conventional roof. We considered the extensive green roof for this purpose because of its low maintenance factor and its structural lightness in terms of weight.

To attain our goals, firstly, we prepared two separate models in the software ECOTECT, one with the conventional and the other with the green roof. We placed the conventional roof model in four different orientations facing east, west, north and south and calculated the total energy demand with the Dhahran climate. Then, we replaced the existing conventional roof with the green roof and observed the energy savings. We considered the same building in the Riyadh climate and repeated all analyses to understand the validity of the green roof in two different Saudi climates. Moreover, to understand the energy savings due to the appropriate orientation, we considered the detached residential building. It is also important to mention that the effectiveness of the green roof also depends on the level of insulation provided for the building envelope and windows along with climatic conditions and building function. We analyzed this building with single and double glazing although single glazing results are not included in this research paper but after providing the efficient glazing and better insulated walls, energy saving because of green rooftop became more significant.

With energy savings, the initial cost, maintenance cost and the system’s payback period also need to be considered. Normally, a green roof costs more than most conventional roofs or cool rooftops. Green roofs cost depends on its type (intensive or extensive) and its components’ specifications, like depth of growing medium, type of roofing system, type of drainage system, type of plants, etc. The cost of the extensive and intensive green roof options has been reported to be

$10/ft

2 and

$25/ft

2, respectively [

39]. Maintenance expenses of the green roof also need to be considered at the time of construction, as it mainly depends on the type of plants provided on it. Most of the maintenance cost emerges in the first year as plants develop, and it can be

$0.75–

$1.50 for every square foot [

40].

Besides energy savings, there are several other benefits that can be attained due to the provision of the green roof. It can also potentially enhance the property value. Although no such data are available showing the increment in property value due to the green roof, according to some statistics, a normal house price can increase by up to 7.1% with close proximity to greenery [

41]. It is also important to mention that the life span of the conventional roof is around 20 years, while for the green rooftop, it is 40–55 years [

42]. The green rooftop also helps with carbon reduction and controlling air contamination. Dust, particulates and nitrates (NO

2) are the measure of the air quality, and different plants have different oxygen-carbon dioxide conversion rates; but, according to a study, 80–85 kg of toxins per hectare per year can be removed by green roofs [

43]. In urban areas, the creation of natural surroundings is not a typical interest, and the green roof can help with creating such an environment by providing plants and soil contributing to the richness of the natural habitat. The green roof also helps with mitigating the urban heat island effect. Urban areas are full of dull surfaces with low albedo, which is basically the reflection capability of any surface [

44]. Dull surfaces and the absence of vegetation increase the urban air temperature amid summer months [

45]. This results in increased building energy demand and consequently more usage of HVAC systems.

The findings of this work reveal that buildings in Saudi Arabia oriented along east-west consume the least amount of energy. It is also reported that the total energy demand of buildings is least when the orientation angle is zero, which means placing the long axis of the building along east-west can be the most suitable option [

46]. Similarly, according to Ghobadian (2006), the most suitable orientation in Iran is also east-west, as the length of the building should be towards the south, so in winter, it could gain the maximum solar energy, and in summer, shading devices can be used to protect it from heat [

47].

9. Conclusions

The presented work has investigated the impact of the orientation and green roof on the energy performance of buildings in the hot-humid and hot-dry climatic conditions of Saudi Arabia. Dhahran and Riyadh have been used as the representative cities for these two climatic conditions, respectively. The findings of the modeling work undertaken with the help of ECOTECT software reveal a nominal difference in the energy performance of the selected building with varying orientations. For example, in the case of Dhahran, the building consumes 140.3, 140.6, 141.6 and 141.3 KWh/m2Y, respectively, for east, west, north and south facing. The total energy demand in the Riyadh climate is however found to be almost 14% higher than in the Dhahran climate, mainly due to the longer and more intense summer in the case of the former. The green roof is observed to be marginally more effective in the hot and dry climate of Riyadh compared to the hot and humid conditions of Dhahran. The results of the analysis indicate that in the climatic conditions of Dhahran and Riyadh, the green roof can reduce the energy consumption by 6.7% and 6.8%, respectively.