Seeing the Immaterial: A New Instrument for Evaluating Integrated Management Systems’ Maturity

Abstract

:1. Introduction

2. The Review of the Scientific Literature

3. Research Methodology

- identification and quantification of an IMS property, which we propose to call, by similarity with other concepts in the field of standardized systems, integration maturity or the integration level;

- easy communication of the results of an IMS integration maturity assessment in order to provide valuable information for organizational decisions related to performance and the allocation of resources;

- establishment and validation of a procedure for an IMS management tool based on the above approach, with possible IT automation support.

- (1)

- The identification and documentation of all business processes within the IMS;

- (2)

- The correlation of a list of processes with the requirements of each standard used by the systems included in the IMS (the process–requirement matrix);

- (3)

- The determination of the level of maturity [mij] for each intersection of the process [i] and requirement [j] (defined as the overall operational effectiveness minus the impact of the possible redundancies and conflicts) by performing process audits using a percentage-based scale, which is then numerically converted to color gradients of the three fundamental colors;

- (4)

- The repetition of the previous step for all three components of the IMS, using processes within the firm for rows and the ISO correlation tables for columns (we note that this analysis may include those requirements for which the correspondence is, or can be, clarified based on the standards;

- (5)

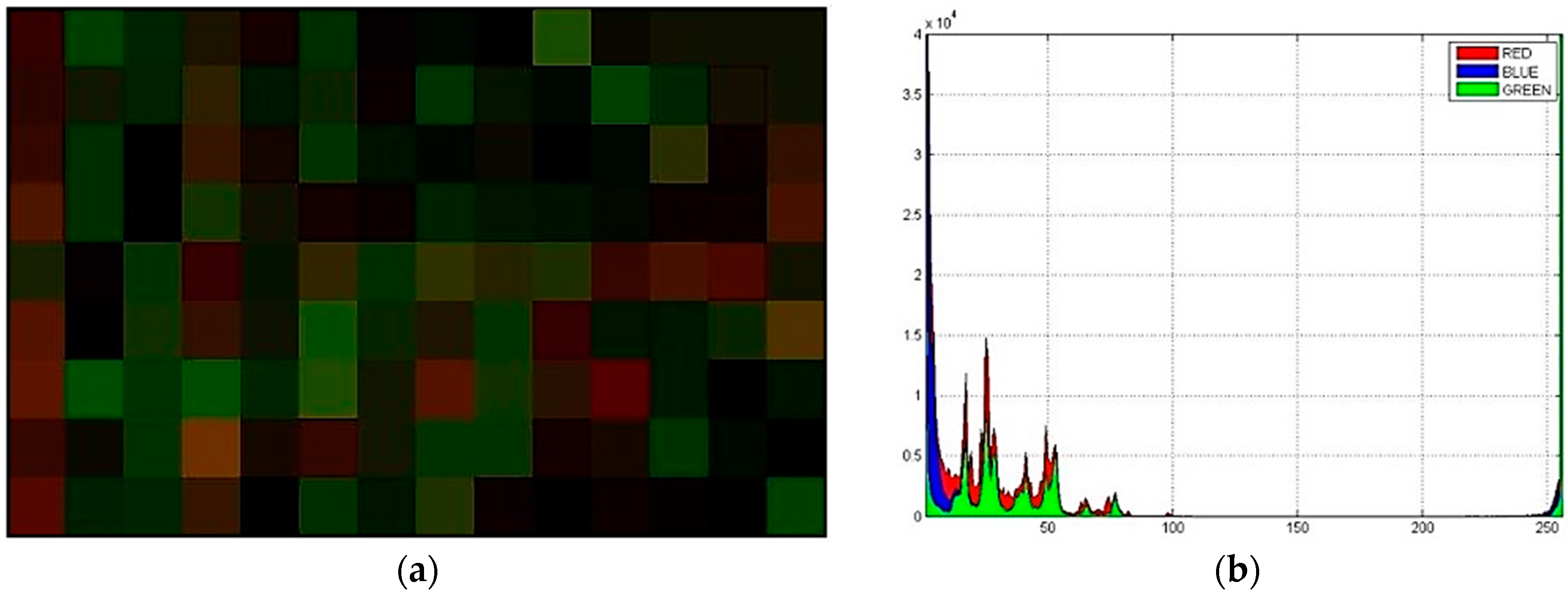

- The performance of three layers of analysis observing the following correspondence:

- a quality management system—QMS—where the maturity degree is associated with intensity levels of the fundamental color red (R);

- environmental management systems—EMS—where the maturity degree is associated with intensity levels of the fundamental color green (G);

- an occupational health and safety management system—OHSMS—where the maturity degree is associated with intensity levels of the fundamental color blue (B).

- (6)

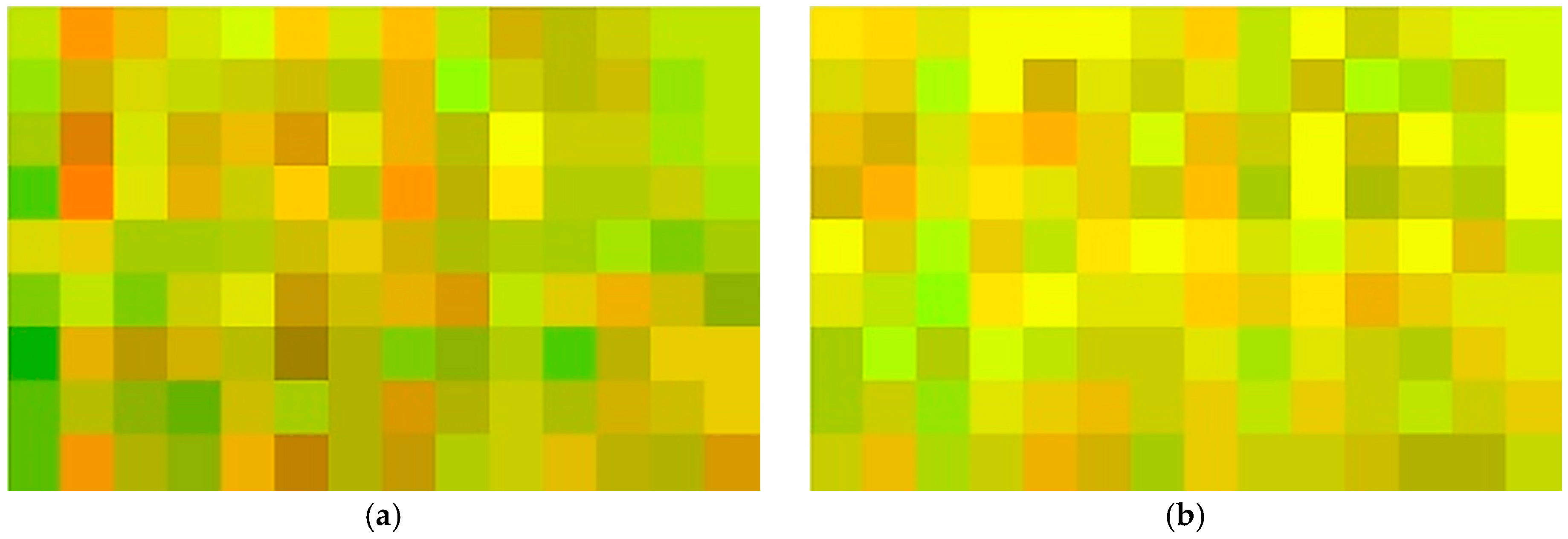

- The color map for the IMS is obtained, each process–requirement intersection being represented by a colored square-shaped element. The integration maturity level is thus represented in the RGB color space, with the white color representing the maximum maturity and black representing the minimum maturity. The combination is performed to obtain an overall image with two-way correspondence regarding IMS maturity, both from a managerial and a chromatic point of view, assuming a similar behavior of color mixing and MS mixing, due to their complexity and homogeneity.

- (7)

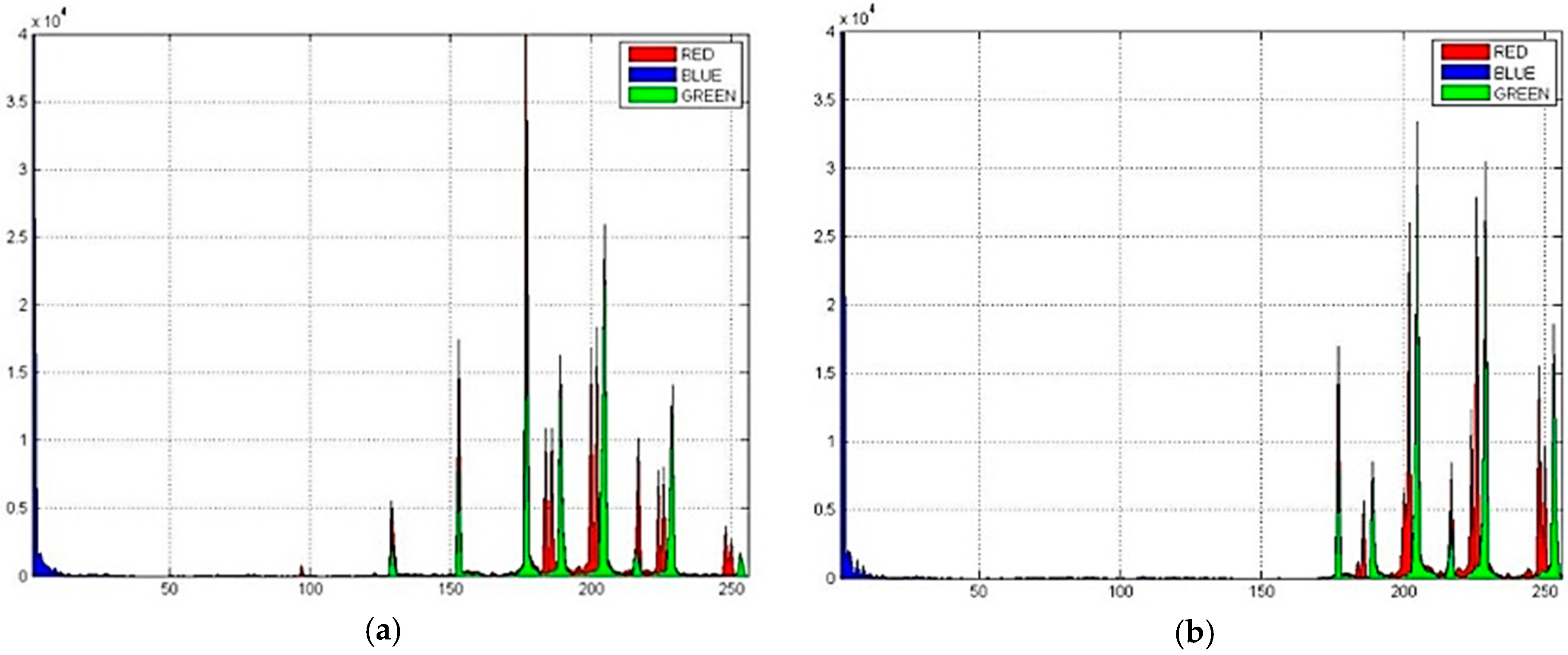

- The color map is analyzed with specific image processing tools, such as Fourier Fast Transformation (FFT) or the RGB histogram, by transferring colors in the frequency analysis domain.

- (8)

- The results of the color map processing are interpreted from a managerial perspective and scenarios for improving the IMS or its components are elaborated.

4. Results and Discussion

- Both channel histograms move to the right of the horizontal scale, indicating the maturation of the individual components (i.e., they are more effective and impactful in performing the function ascribed to them by the reference standards’ requirements), as the number of points of greater color intensity is increasing.

- Moreover, the growth in the second diagram is more strongly correlated between the two basic colors (red and green), indicating that the two systems begin to develop in common (i.e., they support each other in achieving objectives and operating effectively).

- The shape of the histogram is improved, more closely approaching a normal distribution (the color combinations are found within a narrower interval, indicating greater internal cohesion and a better balance within the integrated system).

- The histogram for the green color presents increases and movements more significant than the one for red, specific for a management system at the beginning of its improvement cycle (in this case the EMS), when variations are larger and more random.

- It can be easily observed that the histogram contains a series of close shades, which seems to support the idea that the number of appreciation levels for maturity should be reduced, although in the second picture we can already see a better grouping of the categories.

- It should not be forgotten, however, the importance of processes in the whole system, based on their delivered added value, e.g., the managerial process “Development” influences investments and new projects and can be considered more important than the support process “Storage”, which only aids in the temporary placement of materials/products, and evolves faster towards improved levels of integration.

- Intervention decisions should take into account the need to advance the overall integration maturity while at the same time increasing inner cohesion (i.e., process performance aligned to similar levels).

5. Conclusions

- Unlike existing models, focusing more on a qualitative-subjective approach that divides maturity into classes, levels or categories, this solution enables an improved quantification and a fine discretization of the integration maturity assessment.

- The proposed algorithm uses existing procedures and processes from the implemented systems (process audits, correspondence of requirements) and requires no extra effort that might discourage or drive away companies or their employees from collecting and processing the necessary data.

- The instrument has a mathematical apparatus and computer support, which is transparent to the users, that at the same time ensures scientific consistency, ease of use, and stimulating problem solving, and the identification of opportunities for improvement; this is accentuated by the peoples’ positive understanding of chromaticity, which allows for an intuitive form of visualization that, once assimilated by the user, facilitates the rapid identification of the integration level.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Organization for Standardization. ISO 9000:2005—Quality Management Systems—Fundamentals and Vocabulary; International Organization for Standardization: Geneva, Switzerland, 2005. [Google Scholar]

- International Organization for Standardization. ISO 14001:2004—Environmental Management Systems—Requirements with Guidance for Use; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- British Standards Institution. BS OHSAS 18001:2007—Occupational Health and Safety Management Systems—Requirements; British Standards Institution: London, UK, 2007. [Google Scholar]

- International Organization for Standardization. Economic Benefits of Standards; International Organization for Standardization: Geneva, Switzerland, 2014; Available online: http://www.iso.org/iso/ebs_case_studies_factsheets.pdf (accessed on 12 November 2016).

- International Organization for Standardization. The ISO Survey of Management System Standard Certifications 2015; International Organization for Standardization: Geneva, Switzerland, 2016; Available online: http://www.iso.org/iso/the_iso_survey_of_management_system_standard_certifications_2015.pdf (accessed on 13 November 2016).

- International Organization for Standardization/International Electrotechnical Commission. ISO/IEC 27001:2013—Information Technology—Security Techniques—Information Security Management Systems—Requirements; International Organization for Standardization/International Electrotechnical Commission: Geneva, Switzerland, 2013. [Google Scholar]

- International Organization for Standardization. ISO 26000:2010—Guidance on Social Responsibility—Principles of Social Responsibility; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- International Organization for Standardization. ISO/TS 16949:2009—Quality Management Systems—Particular Requirements for the Application of ISO 9001:2008 for Automotive Production and Relevant Service Part Organizations; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- International Organization for Standardization. ISO 22000:2005—Food Safety Management Systems—Requirements for Any Organization in the Food Chain; International Organization for Standardization: Geneva, Switzerland, 2005. [Google Scholar]

- International Organization for Standardization. ISO 9001:2008—Quality Management Systems—Requirements; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- International Organization for Standardization. ISO Management System Standards; International Organization for Standardization: Geneva, Switzerland, 2016; Available online: http://www.iso.org/iso/home/standards/management-standards/mss-list.htm. (accessed on 12 November 2016).

- Domingues, P.; Sampaio, P.; Arezes, P. Analysis of integrated management systems from various perspectives. Total Qual. Manag. Bus. Excell. 2015, 26, 1311–1334. [Google Scholar] [CrossRef]

- Kauppila, O.; Härkönen, J.; Väyrynen, S. Integrated HSEQ management systems: Developments and trends. Int. J. Qual. Res. 2015, 9, 231–242. [Google Scholar]

- Kymal, C.; Gruska, G.; Reid, R.D. Integrated Management Systems; American Society for Quality: Milwaukee, WI, USA, 2015. [Google Scholar]

- Nunhes, T.V.; Ferreira Motta, L.C.; de Oliveira, O.J. Evolution of integrated management systems research on the Journal of Cleaner Production: Identification of contributions and gaps in the literature. J. Clean. Prod. 2016, 139, 1234–1244. [Google Scholar] [CrossRef]

- Bititci, U.S.; Garengo, P.; Ates, A.; Nudurupati, S.S. Value of maturity models in performance measurement. Int. J. Prod. Res. 2015, 53, 3062–3085. [Google Scholar] [CrossRef] [Green Version]

- Tarhan, A.; Turetken, O.; Reijers, H.A. Business process maturity models: A systematic literature review. Inf. Softw. Technol. 2016, 75, 122–134. [Google Scholar] [CrossRef]

- Domingues, P.; Sampaio, P.; Arezes, P.M. Integrated management systems assessment: A maturity model proposal. J. Clean. Prod. 2016, 124, 164–174. [Google Scholar] [CrossRef]

- British Standard Institution (BSI). PAS 99 Specification of Common Management System Requirements as a Framework for Integration; BSI: London, UK, 2012. [Google Scholar]

- Tangen, S.; Warris, A. New Format for Future ISO Management system Standards. 2012. Available online: https://www.iso.org/news/2012/07/Ref1621.html (accessed on 30 July 2017).

- Bernardo, M.; Simon, A.; Tarí, J.J.; Molina-Azorín, J.F. Benefits of management systems integration: A literature review. J. Clean. Prod. 2015, 94, 260–267. [Google Scholar] [CrossRef]

- Olaru, M.; Maier, D.; Nicoara, D.; Maier, A. Establishing the basis for development of an organization by adopting the integrated management systems: Comparative study of various models and concepts of integration. Procedia 2014, 109, 693–697. [Google Scholar] [CrossRef]

- Asif, M.; Fisscher, O.A.; de Bruijn, E.J.; Pagell, M. Integration of management systems: A methodology for operational excellence and strategic flexibility. Oper. Manag. Res. 2010, 3, 146–160. [Google Scholar] [CrossRef]

- Asif, M.; de Bruijn, E.J.; Fisscher, O.A.; Searcy, C. Meta-management of integration of management systems. TQM J. 2010, 22, 570–582. [Google Scholar] [CrossRef]

- Bernardo, M.; Casadesus, M.; Karapetrovic, S.; Heras, I. An empirical study on the integration of management system audits. J. Clean. Prod. 2010, 18, 486–495. [Google Scholar] [CrossRef]

- Simon, A.; Bernardo, M.; Karapetrovic, S.; Casadesús, M. Integration of standardized environmental and quality management systems audits. J. Clean. Prod. 2011, 19, 2057–2065. [Google Scholar] [CrossRef]

- Bernardo, M.; Casadesus, M.; Karapetrovic, S.; Heras, I. How integrated are environmental, quality and other standardized management systems? An empirical study. J. Clean. Prod. 2009, 17, 742–750. [Google Scholar] [CrossRef]

- Bernardo, M.; Marti, S.; Karapetrovic, S.; Inaki, H. Do integration difficulties influence management system integration levels? J. Clean. Prod. 2012, 21, 23–33. [Google Scholar] [CrossRef]

- Bernardo, M.; Casadesus, M.; Karapetrovic, S.; Heras, I. Integration of standardized management systems: Does the implementation order matter? Int. J. Oper. Prod. Manag. 2012, 32, 291–307. [Google Scholar] [CrossRef]

- Sampaio, P.; Saraiva, P.; Domingues, P. Management systems: Integration or addition? Int. J. Qual. Reliab. Manag. 2012, 29, 402–424. [Google Scholar] [CrossRef] [Green Version]

- Abad, J.; Dalmau, I.; Vilajosana, J. Taxonomic proposal for integration levels of management systems based on empirical evidence and derived corporate benefits. J. Clean. Prod. 2014, 78, 164–173. [Google Scholar] [CrossRef]

- Merriam-Webster Dictionary, Mature. Available online: https://www.merriam-webster.com/dictionary/mature (accessed on 7 August 2017).

- Bersin by Deloitte, Bersin Lexicon—Organizational Maturity. Available online: http://www.bersin.com/Lexicon/Details.aspx?id=14272 (accessed on 11 August 2017).

- Mettler, T. Maturity assessment models: A design science research approach. Int. J. Soc. Syst. Sci. 2011, 3, 81–98. [Google Scholar] [CrossRef]

- Van Looy, A. Business Process Maturity; Springer: Cham/Heidelberg, Germany; New York, NY, USA; Dordrecht, The Netherlands; London, UK, 2014. [Google Scholar]

- Röglinger, M.; Pöppelbuß, J.; Becker, J. Maturity models in business process management. Bus. Process Manag. J. 2012, 18, 328–346. [Google Scholar] [CrossRef]

- Rose, J. Selecting, Using and Creating Maturity Models; A Tool for Assurance and Consulting Engagements (Practice Guide); The Institute of Internal Auditors: Lake Mary, FL, USA, 2013. [Google Scholar]

- Becker, J.; Knackstedt, R.; Pöppelbuß, J. Developing maturity models for IT management—A procedure model and its application. Bus. Inf. Syst. Eng. 2009, 1, 213–222. [Google Scholar] [CrossRef]

- Software Engineering Institute. Standard CMMI® Appraisal Method for Process Improvement (SCAMPI SM) A, 1st ed.; Method Definition Document; Carnegie Mellon University: Pittsburgh, PA, USA, 2011. [Google Scholar]

- EFQM. Assessment. Available online: http://www.efqm.org/what-we-do/assessment (accessed on 11 August 2017).

- Software Engineering Institute. CMMI for Development, version 1.3; Carnegie Mellon University: Pittsburgh, PA, USA, 2010. [Google Scholar]

- Abrahamsson, S.; Hansson, J.; Isaksson, R. Integrated Management Systems—Advantages, problems. In Proceedings of the 13th Toulon-Verona Conference Organisational Excellence in Services, Coimbra, Portugal, 2–4 September 2010. [Google Scholar]

- Domingues, P.; Sampaio, P.; Arezes, P. Integrated management systems as complex adaptive systems. In Proceedings of the 8th International Conference Working on Safety, Porto, Portugal, 23–25 September 2015. [Google Scholar]

- Dragomir, M.; Popescu, S. Contributions regarding the design, development, implementation and continuous improvement of integrated management systems. In Proceedings of the 6th International Conference Management of Technological Changes, Alexandroupolis, Greece, 3–5 September 2009. [Google Scholar]

- Pascale, D. A Review of RGB Color Spaces … from xyY to R’G’B’; BabelColor Company: Montreal, QC, Canada, 2003. [Google Scholar]

- Excel Tips. Square Cells in Excel, 8 December 2004. Available online: http://excel-tips.blogspot.ro/2004/12/square-cells-in-excel.html (accessed on 29 November 2016).

- Jayaraman, S.; Esakkirajan, S.; Veerakumar, T. Digital Image Processing, 3rd ed.; Tata McGraw Hill Education: New Delhi, India, 2010. [Google Scholar]

- International Organization for Standardization. ISO 9004:2009—Managing for the Sustained Success of an Organization—A Quality Management Approach; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

| Section A. A Conceptual Framework for Integrated Management Systems (IMSs) |

| IMS Definition and the Usual Components |

| An IMS is a management system that integrates all systems and processes of an organization into one complete framework [19], enabling it to work as a single unit with unified objectives. Usually (i.e., most often found in practice), an IMS integrates the standardized management systems dedicated to Quality (QMS) (ISO 9001), Environment (EMS) (ISO 14001), and Occupational Health and Safety (OHSMS) (OHSAS 18001, replaced by ISO 45001). The integration refers [14] to risks, processes, documents, and auditing, including the way the structure of the new versions of these standards facilitate their requirements’ integration by a common High-Level Structure (HLS) [20]. As a normative reference, PAS99 [19], delivering guidance for IMS realization could be also mentioned. |

| Organizational Benefits from Adopting IMS |

| Reference [21], which analyzes about 120 publications about the benefits of standardized management systems in general and of IMSs in particular, groups the benefits of companies for adopting IMSs into internal benefits (overall organization, and specific to human resources, performance management, and system audits) and external benefits (market stakeholders and auditing/certification). Reference [12], analyzing specific literature, reports, as the most common drawbacks identified related to non-integrated systems, effort duplication and increasing bureaucracy. |

| IMS Implementation Strategies and Models |

| For IMS implementation, Olaru, M. et al [22] identifies and analyzes different models of integration realizing a comparative study of those applying the quality–environment–health triad and safety management standards. Reference [23] describes the start of integration, its moments, and the functional and structural changes and their impact on the level of processes, documentation, staff behavior, reducing needed resources and losses, and improving company performance, and declares integration as a tool to reform company bureaucracy. Reference [24] identifies methodologies and approaches for managerial system integration: sequential, systemic, hierarchical, TQM, integrating augmented standards, and incorporation in processes. It also defines the levels of control for integration in the system approach case (meta level–object level–intervention level) as well as its characteristics. |

| IMS Audit/Assessment |

| Reference [14] mentions that minimal integration for audits means one audit process, an integrated audit schedule, integrated forms including checklists, and a team capable of conducting an integrated audit. Reference [25], exploring the audit process integration, reviews specific issues such as team, simultaneity, implementation, and planning/reporting IMS audits, and identifies three levels of integration: not integrated, partially integrated, and fully integrated. Reference [26] notes a higher degree of integration of specific components in internal audits compared with external audits. |

| IMS Levels/Degrees of Integration |

| There is no consensus concerning this subject even between papers with common authors. The authors of [27] recorded the levels of integration of IMSs identified by other authors—addition–merger integration; individual–combination integration; separated–aligned integration; harmonization–cooperation–amalgamation—framing them into four distinct levels. They evaluate the degree of individual integration on processes, focusing the investigation on human resources and on documentation. At the same time, Bernardo, M. et.al. [25] identifies three levels of integration: not integrated, partially integrated, and fully integrated, while the authors of References [28,29] studied whether the degree of integration is influenced by the difficulties of implementation (from standards, organization, resources, consultants, certification bodies) or by the implementation order of the component standards. The authors of [30] mention the integration steps proposed by British Standards Institution—BSI (Combined–Integratable–Integrating–Integrated) and refer in the empirical study to five levels of integration. The authors of Reference [31] support the three levels of integration, places integration at the level of managerial processes, and notes that obtaining a higher degree of integration is more difficult for large companies. |

| Section B. A Conceptual Framework for a Maturity Approach to Managerial Systems |

| Maturity as Concept and the Organizational Entities to Which It can be Associated |

| Based on Reference [32], maturity could be defined as the “quality” or “state” gained by an entity during its “natural” or “intended” process of “change, growth and development” towards “a final or desired state.” In Reference [33], organization maturity is defined as the level of readiness and experience in relation to people, processes, technologies, and consistent measurement practices. It implies [34] an evolutionary progress in the demonstration of a specific ability or a maturity factor, such as people/culture, processes/structures, and objects/technology. |

| Maturity Models (MMs), Types and Usage Purposes in Organizations |

| MMs represent tools for systematically assessing and improving capabilities or critical factors for reaching goals [35]. An MM includes a sequence of levels that form an anticipated, desired, or logical path from an initial state to maturity. The main classifications of MMs are in terms of how they should be used; in this sense, three types of MMs can be mentioned [36]: descriptive (internal diagnostic tool or base for external reports); prescriptive (indicating desirable levels and providing improvement guidance), and comparative (for internal or external benchmarking). From their beginnings in the 1970s [34], passing through software Capability Maturity Model Integration—CMMI (early 1990s) and ISO/IEC 15504, a wide range of MMs have been developed by practitioners and academics, mainly as a basis of informed approaches for continuous improvement or means of self- or third-party assessment. |

| MM Design and Usage |

| After [36,37] MM development associates its design and use in a common sequential process with the following design stages: establish purpose and components, determine scale, and set expectations for component levels, to which the utilization phase adds the following: set targets for each component, assess the level of maturity by component, and consider possible improvements. MMs are usually subject to a validation and improvement phase that includes the following as additional stages: check suitability for purpose, consider possible missing elements, and revise and improve the model [37]. Reference [38] proposes a set of nine requirements and a procedure for designing MMs and provides a synopsis of design processes, and Reference [36] provides three sets of design principles for MMs: basic, specific to descriptive, and specific to prescriptive use. |

| Maturity Assessment and The Presentation of Their Results |

| Maturity assessment is based on self-assessment (audits) or external evaluation processes, following consecrated procedures such as SCAMPI (Standard CMMI Appraisal Method for Process Improvement) for CMMI [39], and the EFQM Assessment applied in the well-known excellence model [40], or developed for the specific purpose of the MM. A typical assessment process has the following phases: plan the assessment, collect and analyze data, report findings, deduce recommendations, implement recommendations, and track the improvements. The nature of the assessed variables and results depend on the MM design and could be qualitative or quantitative, sometimes both being present. Keeping the same examples, CMMI uses [41] qualitative approaches for both assessed variables and results, and five levels of maturity are available: Initial, Managed, Defined, Quantitatively Managed, and Optimizing. For the EFQM model [40], the 9 assessment criteria and their sub-criteria are qualitative, but their evaluation is made quantitatively. There have not been any identified references for MMs using color to present assessment results. |

| Other References Approaching the IMS Maturity |

| Few web references were explicitly identified as addressing IMS maturity in a consistent way. Some of these [42] place maturity in association with the IMS “integration levels” (which appears to be a relevant approach), while others just mention the IMS impact on an organization and the maturity of processes. Reference [18] and four other publications by the same authors (2012–2017) deliver an exception, focusing on IMS–MM development, which uses a tri-dimensional approach having the following as axes: key process agents, externalities (external features that impact on the IMS maturity), and excellence management pillars (based on the quality management principles). The maturity assessment combines a CMMI approach with statistics and leads to six maturity levels. |

| Certification | Quality Management System | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Process | 5.3 | 5.2 | 7.2.1 | 5.4.1 | 5.5, 6.1 | 6.2 | 4.2.1–3 | 7 | 8.1 | 8.2, 8.4 | 8.3 | 4.2.4 | 8.2.2 | 5.6 |

| Management | 204 | 255 | 230 | 217 | 230 | 255 | 217 | 255 | 204 | 204 | 191 | 204 | 204 | 204 |

| Development | 179 | 204 | 217 | 204 | 204 | 204 | 191 | 230 | 191 | 204 | 191 | 204 | 179 | 204 |

| Analysis | 179 | 204 | 217 | 204 | 230 | 204 | 230 | 230 | 191 | 255 | 204 | 204 | 191 | 204 |

| Sales | 128 | 255 | 230 | 217 | 204 | 255 | 191 | 255 | 191 | 255 | 191 | 191 | 204 | 191 |

| Design | 217 | 230 | 179 | 179 | 191 | 204 | 230 | 204 | 179 | 191 | 179 | 191 | 153 | 179 |

| Purchasing | 153 | 204 | 153 | 204 | 230 | 191 | 204 | 217 | 204 | 204 | 217 | 230 | 204 | 153 |

| Production | 102 | 217 | 179 | 204 | 191 | 153 | 179 | 153 | 153 | 191 | 128 | 191 | 230 | 230 |

| Storage | 128 | 191 | 153 | 128 | 204 | 179 | 179 | 204 | 179 | 204 | 179 | 204 | 204 | 230 |

| Delivery | 128 | 230 | 179 | 153 | 230 | 179 | 179 | 191 | 191 | 204 | 217 | 191 | 179 | 204 |

| Certification | Environmental Management System | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Process | 4.2 | 4.3.1 | 4.3.2 | 4.3.3 | 4.4.1 | 4.4.2–3 | 4.4.4–5 | 4.4.6 | 4.4.7 | 4.5.1–2 | 4.5.3 | 4.5.4 | 4.5.5 | 4.6 |

| Management | 230 | 153 | 191 | 230 | 255 | 204 | 230 | 191 | 230 | 179 | 191 | 204 | 230 | 230 |

| Development | 230 | 179 | 217 | 217 | 204 | 191 | 204 | 179 | 255 | 204 | 191 | 191 | 230 | 230 |

| Analysis | 204 | 128 | 230 | 179 | 191 | 153 | 230 | 179 | 191 | 255 | 204 | 204 | 230 | 230 |

| Sales | 204 | 128 | 230 | 179 | 204 | 204 | 204 | 153 | 179 | 230 | 204 | 204 | 204 | 230 |

| Design | 217 | 204 | 204 | 204 | 204 | 191 | 204 | 179 | 191 | 204 | 204 | 230 | 204 | 204 |

| Purchasing | 204 | 230 | 204 | 204 | 230 | 153 | 191 | 179 | 153 | 230 | 204 | 179 | 191 | 179 |

| Production | 179 | 179 | 153 | 179 | 191 | 128 | 179 | 204 | 179 | 204 | 204 | 179 | 204 | 204 |

| Storage | 191 | 191 | 179 | 179 | 191 | 204 | 179 | 153 | 179 | 204 | 191 | 179 | 191 | 204 |

| Delivery | 191 | 153 | 179 | 179 | 179 | 128 | 179 | 153 | 204 | 204 | 191 | 179 | 179 | 153 |

| Certification | Quality Management System | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Process | 5.3 | 5.2 | 7.2.1 | 5.4.1 | 5.5, 6.1 | 6.2 | 4.2.1–3 | 7 | 8.1 | 8.2, 8.4 | 8.3 | 4.2.4 | 8.2.2 | 5.6 |

| Management | 255 | 255 | 230 | 255 | 255 | 255 | 230 | 255 | 204 | 255 | 204 | 230 | 230 | 230 |

| Development | 217 | 230 | 204 | 255 | 204 | 230 | 204 | 230 | 204 | 204 | 204 | 191 | 204 | 230 |

| Analysis | 230 | 204 | 217 | 255 | 255 | 230 | 230 | 230 | 204 | 255 | 204 | 255 | 204 | 255 |

| Sales | 204 | 255 | 230 | 255 | 230 | 230 | 204 | 255 | 179 | 255 | 179 | 204 | 191 | 255 |

| Design | 255 | 217 | 204 | 230 | 204 | 255 | 255 | 255 | 217 | 230 | 230 | 255 | 217 | 204 |

| Purchasing | 230 | 204 | 191 | 255 | 255 | 230 | 230 | 255 | 230 | 255 | 230 | 230 | 230 | 230 |

| Production | 179 | 204 | 191 | 230 | 204 | 204 | 204 | 230 | 191 | 230 | 204 | 191 | 230 | 230 |

| Storage | 179 | 204 | 179 | 230 | 230 | 230 | 204 | 230 | 204 | 230 | 204 | 204 | 204 | 230 |

| Delivery | 204 | 230 | 191 | 204 | 230 | 204 | 179 | 230 | 204 | 204 | 204 | 179 | 179 | 204 |

| Certification | Environmental Management System | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Process | 4.2 | 4.3.1 | 4.3.2 | 4.3.3 | 4.4.1 | 4.4.2–3 | 4.4.4–5 | 4.4.6 | 4.4.7 | 4.5.1–2 | 4.5.3 | 4.5.4 | 4.5.5 | 4.6 |

| Management | 230 | 217 | 230 | 255 | 255 | 255 | 230 | 204 | 230 | 255 | 204 | 230 | 255 | 255 |

| Development | 217 | 204 | 255 | 255 | 179 | 230 | 204 | 230 | 230 | 191 | 255 | 230 | 204 | 255 |

| Analysis | 191 | 179 | 230 | 204 | 179 | 204 | 255 | 191 | 204 | 255 | 191 | 255 | 230 | 255 |

| Sales | 179 | 179 | 230 | 230 | 230 | 204 | 204 | 191 | 204 | 255 | 191 | 204 | 204 | 255 |

| Design | 255 | 204 | 255 | 204 | 230 | 230 | 255 | 230 | 230 | 255 | 217 | 255 | 191 | 230 |

| Purchasing | 230 | 230 | 255 | 230 | 255 | 230 | 230 | 204 | 204 | 230 | 179 | 204 | 230 | 230 |

| Production | 204 | 255 | 204 | 255 | 230 | 204 | 204 | 230 | 230 | 230 | 204 | 204 | 204 | 230 |

| Storage | 204 | 204 | 230 | 230 | 204 | 191 | 204 | 204 | 230 | 204 | 204 | 230 | 204 | 204 |

| Delivery | 204 | 191 | 217 | 204 | 179 | 179 | 204 | 204 | 204 | 204 | 191 | 179 | 179 | 217 |

| Measure | Certification | Surveillance | Delta |

|---|---|---|---|

| Mean value | 129.916 | 145.272 | 15.357 |

| Standard deviation | 93.352 | 102.999 | 9.647 |

| Entropy | 4.623 | 4.036 | −0.587 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dragomir, M.; Popescu, S.; Neamțu, C.; Dragomir, D.; Bodi, Ș. Seeing the Immaterial: A New Instrument for Evaluating Integrated Management Systems’ Maturity. Sustainability 2017, 9, 1643. https://doi.org/10.3390/su9091643

Dragomir M, Popescu S, Neamțu C, Dragomir D, Bodi Ș. Seeing the Immaterial: A New Instrument for Evaluating Integrated Management Systems’ Maturity. Sustainability. 2017; 9(9):1643. https://doi.org/10.3390/su9091643

Chicago/Turabian StyleDragomir, Mihai, Sorin Popescu, Călin Neamțu, Diana Dragomir, and Ștefan Bodi. 2017. "Seeing the Immaterial: A New Instrument for Evaluating Integrated Management Systems’ Maturity" Sustainability 9, no. 9: 1643. https://doi.org/10.3390/su9091643