A Flexible Architecture for Extracting Metro Tunnel Cross Sections from Terrestrial Laser Scanning Point Clouds

Abstract

:1. Introduction

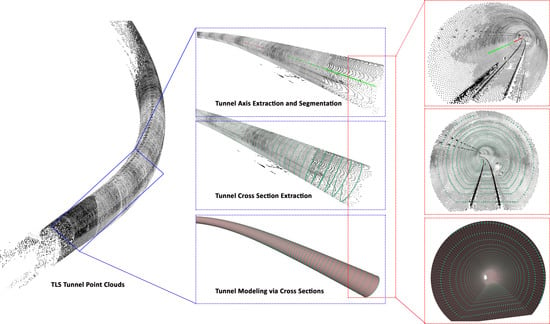

- Tunnel Central Axis Extraction: we present an algorithm for tracking the tunnel central axis in topologically-ware and geometrically-aware manners. That is, we first propose a slice-based algorithm for tracking the initial central axis, which is further refined by integrating a Minimum Spanning Tree (MST) and Savitzky–Golay smoothing.

- Tunnel Central Axis Segmentation: we propose an enhancement to the traditional Random Sample Consensus (RANSAC) algorithm. The enhanced algorithm translates the problem of hybrid linear and nonlinear segment extraction into a sole segmentation of linear elements defined at the tangent space rather than raw data space, significantly simplifying segmentation problem.

- Tunnel Profile Determination: we introduce a high-accuracy interpolation and filtering algorithm for extracting continuous tunnel profiles over the entire tunnel. The generated profile points are determined by using interpolation, and further densified via solving a constrained nonlinear least squares formulation.

2. Methodology

2.1. Tunnel Axis Extraction via the Slice-based Method

2.2. Tunnel Axis Segmentation

2.2.1. Constructing MST of Point Clouds along the Tunnel Axis

2.2.2. Smoothing Central Axis of a Tunnel

2.2.3. Segmentation of the Tunnel Axis

- (a)

- The central axis point clouds are transformed into tangent space (d, ).

- (b)

- An optimal linear segment is first detected from (d, ) space, and then the axis point clouds are divided into inliers and outliers.

- (c)

- We determine the extent of inliers in tangent space. If any point from outliers is inside the extent of the inliers, the corresponding point is removed from the outliers.

- (d)

- The point clouds from the remaining outliers are provided as input. The steps from (b) to (c) are executed repeatedly until all of the remaining outliers have been processed.

- (e)

- The sequence of linear elements extracted in tangent space is restored according to the sequence of their middle points. Hence, we obtain anchor points by circulating around pairwise neighboring linear segments. More precisely, if a linear segment is a neighbor with a linear primitive , there is an anchor point whose position is exactly at the intersection of and .

- (f)

- Using these anchor points, the linear and circular segments in data space are simultaneously determined, since the axis points have a one-to-one mapping relationship between data and tangent spaces.

2.3. Tunnel Cross Section Extraction

2.3.1. Determination of the Cross-Sectional Plane

2.3.2. Determination of a Straight Line Equation

2.3.3. Determination of Cross-Sectional Points

2.3.4. Continuous Extraction of Tunnel Cross Sections

3. Performance Evaluation and Discussion

3.1. Dataset Specifications

3.2. Geometric Error Evaluation

3.3. Topology Evaluation and LoD Representation

3.4. Comparison

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kang, Z.; Zhang, L.; Tuo, L.; Wang, B.; Chen, J. Continuous extraction of subway tunnel cross sections based on terrestrial point clouds. Remote Sens. 2014, 6, 857–879. [Google Scholar] [CrossRef]

- Xie, X.; Lu, X. Development of a 3D modeling algorithm for tunnel deformation monitoring based on terrestrial laser scanning. Undergr. Space 2017, 2, 16–29. [Google Scholar] [CrossRef]

- Qiu, W.; Cheng, Y.J. High-resolution DEM generation of railway tunnel surface using terrestrial laser scanning data for clearance inspection. J. Comput. Civ. Eng. 2016, 31, 04016045. [Google Scholar] [CrossRef]

- Kolymbas, D. Tunnelling and Tunnel Mechanics: A Rational Approach to Tunnelling; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Wang, T.T.; Jaw, J.J.; Chang, Y.H.; Jeng, F.S. Application and validation of profile–image method for measuring deformation of tunnel wall. Tunn. Undergr. Space Technol. 2009, 24, 136–147. [Google Scholar] [CrossRef]

- Wang, T.T.; Jaw, J.J.; Hsu, C.H.; Jeng, F.S. Profile-image method for measuring tunnel profile–Improvements and procedures. Tunn. Undergr. Space Technol. 2010, 25, 78–90. [Google Scholar] [CrossRef]

- Attard, L.; Debono, C.J.; Valentino, G.; Di Castro, M. Tunnel inspection using photogrammetric techniques and image processing: A review. ISPRS J. Photogramm. Remote Sens. 2018, 144, 180–188. [Google Scholar] [CrossRef]

- Yoon, J.S.; Sagong, M.; Lee, J.; Lee, K.S. Feature extraction of a concrete tunnel liner from 3D laser scanning data. Ndt & E Int. 2009, 42, 97–105. [Google Scholar]

- Fekete, S.; Diederichs, M.; Lato, M. Geotechnical and operational applications for 3-dimensional laser scanning in drill and blast tunnels. Tunn. Undergr. Space Technol. 2010, 25, 614–628. [Google Scholar] [CrossRef]

- Charbonnier, P.; Chavant, P.; Foucher, P.; Muzet, V.; Prybyla, D.; Perrin, T.; Grussenmeyer, P.; Guillemin, S. Accuracy assessment of a canal-tunnel 3d model by comparing photogrammetry and laserscanning recording techniques. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2013, 40, 171–176. [Google Scholar] [CrossRef]

- Walton, G.; Delaloye, D.; Diederichs, M.S. Development of an elliptical fitting algorithm to improve change detection capabilities with applications for deformation monitoring in circular tunnels and shafts. Tunn. Undergr. Space Technol. 2014, 43, 336–349. [Google Scholar] [CrossRef]

- Nuttens, T.; Stal, C.; De Backer, H.; Schotte, K.; Van Bogaert, P.; De Wulf, A. Methodology for the ovalization monitoring of newly built circular train tunnels based on laser scanning: Liefkenshoek Rail Link (Belgium). Automat. Constr. 2014, 43, 1–9. [Google Scholar] [CrossRef]

- Han, S.; Cho, H.; Kim, S.; Jung, J.; Heo, J. Automated and efficient method for extraction of tunnel cross sections using terrestrial laser scanned data. J. Comput. Civ. Eng. 2012, 27, 274–281. [Google Scholar] [CrossRef]

- Cheng, Y.J.; Qiu, W.; Lei, J. Automatic extraction of tunnel lining cross-sections from terrestrial laser scanning point clouds. Sensors 2016, 16, 1648. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Yang, H.; Neumann, I. A feature extraction method for deformation analysis of large-scale composite structures based on TLS measurement. Compos. Struct. 2018, 184, 591–596. [Google Scholar] [CrossRef]

- Tan, K.; Cheng, X.; Ju, Q. Combining mobile terrestrial laser scanning geometric and radiometric data to eliminate accessories in circular metro tunnels. J. Appl. Remote Sens. 2016, 10, 030503. [Google Scholar] [CrossRef]

- Tan, K.; Cheng, X.; Ding, X.; Zhang, Q. Intensity data correction for the distance effect in terrestrial laser scanners. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2016, 9, 304–312. [Google Scholar] [CrossRef]

- Dimitrov, A.; Golparvar-Fard, M. Robust NURBS surface fitting from unorganized 3D point clouds for infrastructure as-built modeling. In Proceedings of the Computing in Civil and Building Engineering, Orlando, FL, USA, 23–25 June 2014; pp. 81–88. [Google Scholar]

- Nahangi, M.; Haas, C.T. Skeleton-based discrepancy feedback for automated realignment of industrial assemblies. Autom. Constr. 2016, 61, 147–161. [Google Scholar] [CrossRef]

- Gosliga, R.V.; Lindenbergh, R.; Pfeifer, N. Deformation Analysis of a Bored Tunnel by Means of Terrestrial Laser Scanning. 2006. Available online: https://s3.amazonaws.com/academia.edu.documents/38455846/deformation_analysis_of_a_bored_tunnel_by_means_of_terrestrial_laser_scanning.pdf?AWSAccessKeyId=AKIAIWOWYYGZ2Y53UL3A&Expires=1549004618&Signature=k9CvopqMh2yKDQq15nBgyf2Xbbc%3D&response-content-disposition=inline%3B%20filename%3DDEFORMATION_ANALYSIS_OF_A_BORED_TUNNEL_B.pdf (accessed on 1 February 2019).

- Savitzky, A.; Golay, M.J.E. Smoothing and Differentiation of Data by Simplified Least Squares Procedures. Anal. Chem. 1964, 36, 1627–1639. [Google Scholar] [CrossRef]

- Fischler, M.A.; Bolles, R.C. Random sample consensus: A paradigm for model fitting with applications to image analysis and automated cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Lu, T. Research on the Total Least Squares and Its Application in Surveying Data Processing. Ph.D. Thesis, School of Geodesy and Geomatics, Wuhan University, Wuhan, China, 2010. [Google Scholar]

- Golub, G.H.; Van Loan, C.F. An analysis of the total least squares problem. SIAM J. Numer. Anal. 1980, 17, 883–893. [Google Scholar] [CrossRef]

- Kamintzis, J.E.; Jones, J.; Irvine-Fynn, T.; Holt, T.; Bunting, P.; Jennings, S.J.A.; Porter, P.R.; Hubbard, B. Assessing the applicability of terrestrial laser scanning for mapping englacial conduits. J. Glaciol. 2018, 64, 37–48. [Google Scholar] [CrossRef]

- Shapiro, A. Monte Carlo sampling methods. Handb. Oper. Res. Manag. Sci. 2003, 10, 353–425. [Google Scholar]

- Kazhdan, M.; Hoppe, H. Screened poisson surface reconstruction. ACM Trans. Graph. 2013, 32, 29. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, L.; Fang, T.; Mathiopoulos, P.T.; Tong, X.; Qu, H.; Xiao, Z.; Li, F.; Chen, D. A multiscale and hierarchical feature extraction method for terrestrial laser scanning point cloud classification. IEEE Trans. Geosci. Remote Sens. 2015, 53, 2409–2425. [Google Scholar] [CrossRef]

| Central Angles | Mean | RMSE | ||||

|---|---|---|---|---|---|---|

| 30 | 1.4189 m | 1.4261 m | 1.4231 m | 1.4235 m | 0.0008 m | 0.0009 m |

| 60 | 2.7414 m | 2.7544 m | 2.7492 m | 2.7500 m | 0.0015 m | 0.0017 m |

| 90 | 3.8762 m | 3.8948 m | 3.8880 m | 3.8891 m | 0.0020 m | 0.0023 m |

| 180 | 5.4817 m | 5.5075 m | 5.4984 m | 5.5000 m | 0.0028 m | 0.0032 m |

| Scanner | Scan Angular Resolution | #Pts | Range Accuracy |

|---|---|---|---|

| RIEGL VZ-400 | 0.046 | 2,686,866 | ± 5 mm |

| #Profile | Max | Min | Mean | RMSE | |

|---|---|---|---|---|---|

| 260 | 2.7632 m | 2.7481 m | 2.7538 m | 0.0026 m | 0.0046 m |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Z.; Chen, D.; Shi, Y.; Zhang, Z.; Jin, F.; Yun, T.; Xu, S.; Kang, Z.; Zhang, L. A Flexible Architecture for Extracting Metro Tunnel Cross Sections from Terrestrial Laser Scanning Point Clouds. Remote Sens. 2019, 11, 297. https://doi.org/10.3390/rs11030297

Cao Z, Chen D, Shi Y, Zhang Z, Jin F, Yun T, Xu S, Kang Z, Zhang L. A Flexible Architecture for Extracting Metro Tunnel Cross Sections from Terrestrial Laser Scanning Point Clouds. Remote Sensing. 2019; 11(3):297. https://doi.org/10.3390/rs11030297

Chicago/Turabian StyleCao, Zhen, Dong Chen, Yufeng Shi, Zhenxin Zhang, Fengxiang Jin, Ting Yun, Sheng Xu, Zhizhong Kang, and Liqiang Zhang. 2019. "A Flexible Architecture for Extracting Metro Tunnel Cross Sections from Terrestrial Laser Scanning Point Clouds" Remote Sensing 11, no. 3: 297. https://doi.org/10.3390/rs11030297