A Virtual Restoration Approach for Ancient Plank Road Using Mechanical Analysis with Precision 3D Data of Heritage Site

Abstract

:1. Introduction

2. Background

2.1. Study Area: Chiya Plank Road

2.2. Objectives and Research Questions

3. Methodology

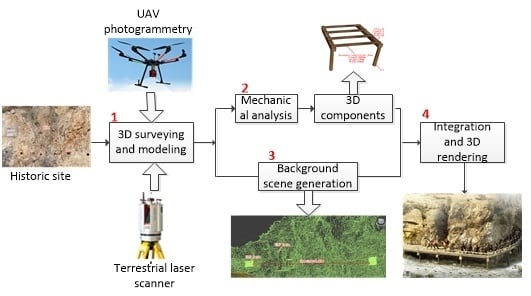

3.1. Technique Flowchart of 3D Restoration Based on Mechanical Analysis

3.2. Precision 3D Surveying Using UAV Photogrammetry and TLS Integration

3.2.1. Mountain and River Data Acquisition Using UAV Photogrammetry

3.2.2. Data Acquisition for Holes and Stone Beams of the Plank Road Using TLS (Terrestrial laser Scanning)

3.2.3. Data Fusion

3.2.4. Triangulated Irregular Network Model Generation and Texture Mapping

3.3. 3D Restoration Based on Mechanical Analysis

3.3.1. The 3D Model Analysis to Determine the Building form of the Ancient Plank Road

3.3.2. Mechanical Analysis to Estimate Geometric Size of the Component

Mechanical Analysis Model for Cross Beams Restoration

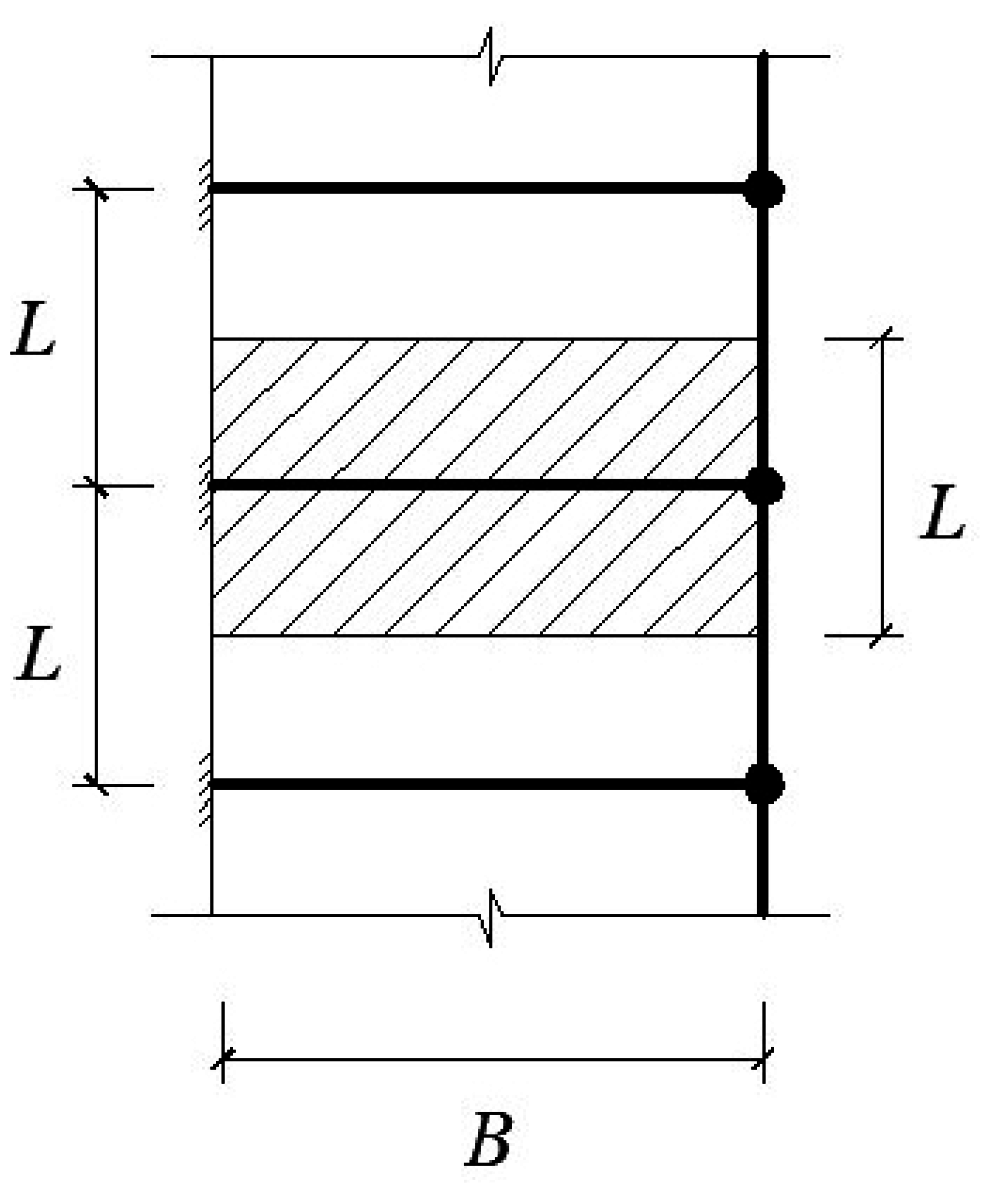

Mechanical Analysis Model for the Longitudinal Beams

3.3.3. Components Restoration

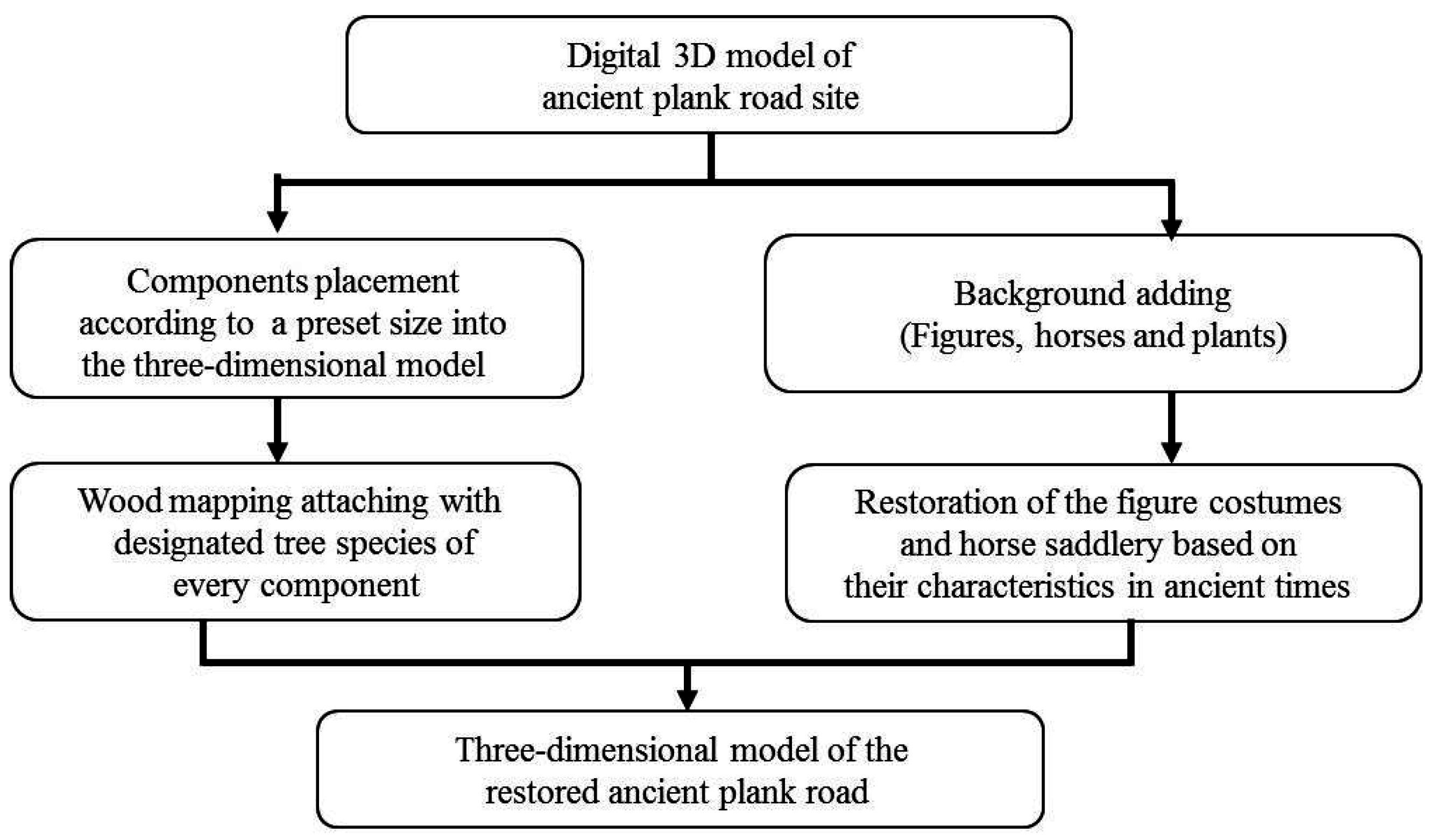

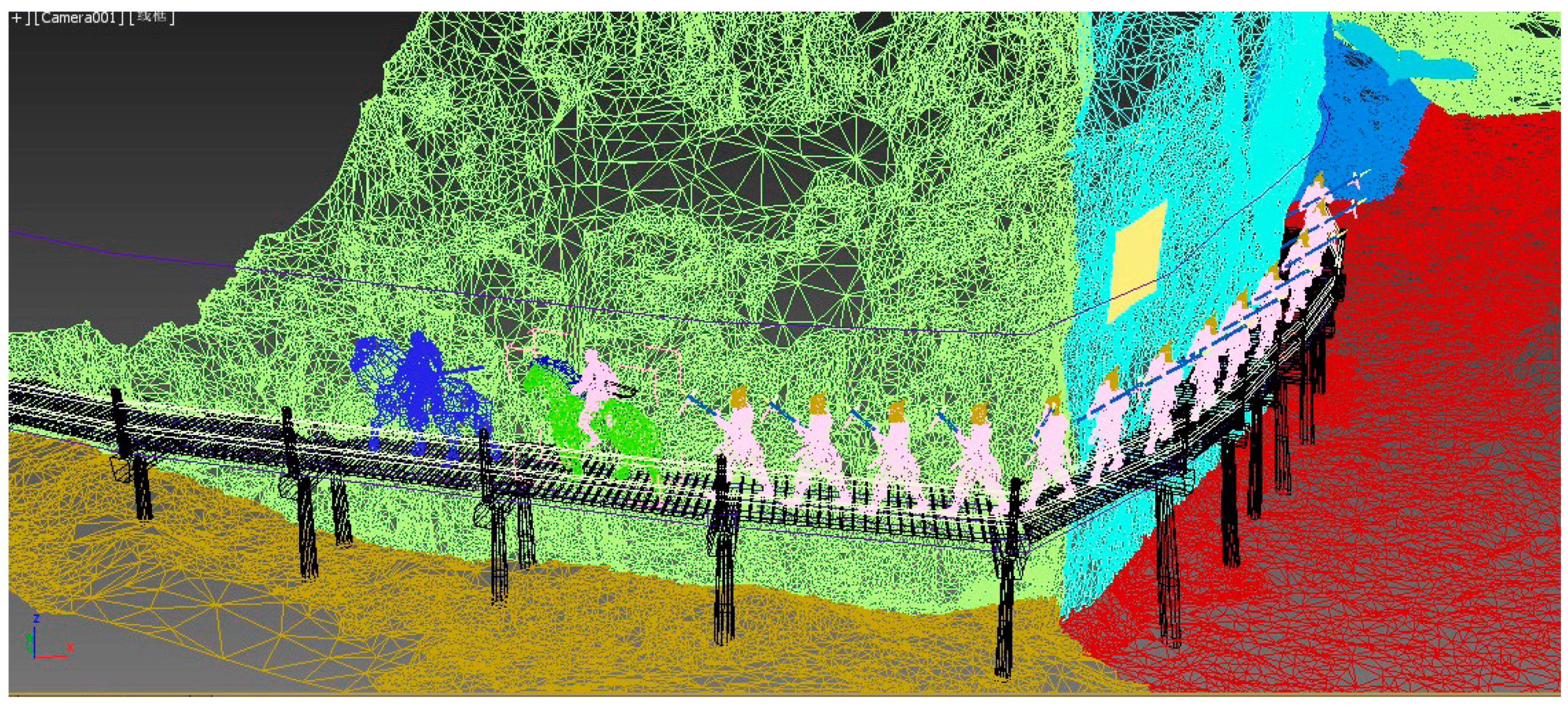

3.3.4. Integration of the Components and Background Scenes for the 3D Model of Chiya Plank Road

4. Results and Discussions

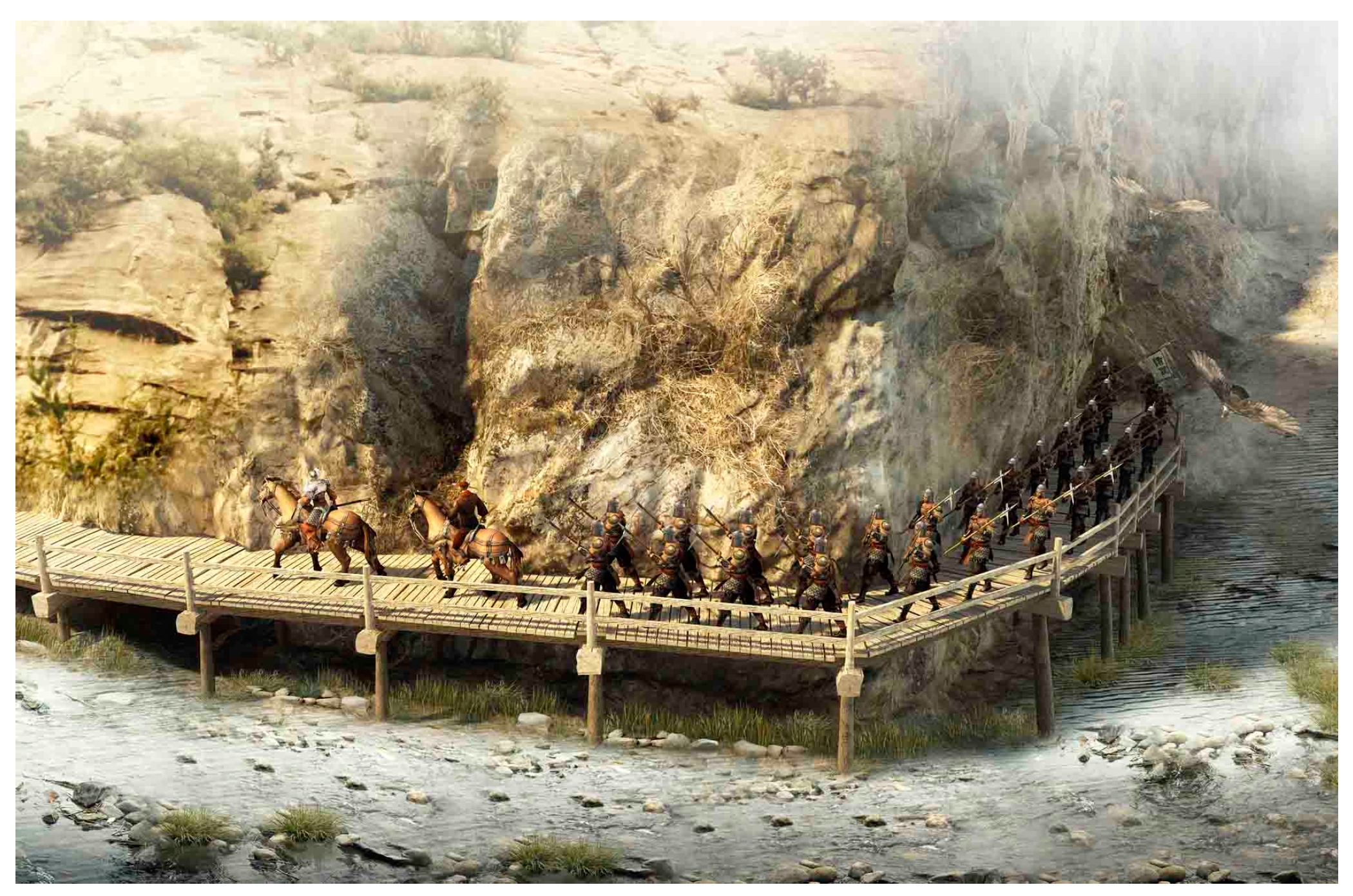

4.1. Restoration Result of the Chiya Plank Road

4.2. Discussions

4.2.1. Restoration Calculus Checking

4.2.2. Added Value of Method

4.2.3. Defects and Uncertainties

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liu, W.A.; Ren, G. The New Study of the Ruin of Ninghe Ancient Plank Road. Salt Ind. 2003, 2013–2015, 9–24. (In Chinese) [Google Scholar]

- Miller, F.P.; Vandome, A.F.; Mcbrewster, J. Ancient Chinese Wooden Architecture; Alphascript Publishing: Beau Bassin, Mauritius, 2010. [Google Scholar]

- Surhone, L.M.; Timpledon, M.T.; Marseken, S.F. Plank Road; Betascript Publishing: Beau Bassin, Mauritius, 2010. [Google Scholar]

- Wang, C.; Li, X. Design and Actualization of Urban Planning Information System Combining 2D GIS and 3D Simulation. Urban Geotech. Investig. Surv. 2008, 3, 10–13. [Google Scholar]

- Zhang, N. Research and Realization of 2D Geological Modeling Based on GIS; China University of Petroleum: Beijing, China, 2007. [Google Scholar]

- Cheng, B.; Xiao, H. 3D Object-oriented Scene Creation and GIS Data Management. Geomat. World 2004, 3, 25–28. [Google Scholar]

- Zhu, Q. 3D GIS and Its Application in Smart City. J. Geo-Inf. Sci. 2014, 2, 151–157. [Google Scholar]

- Wang, S. Application and Analysis of Surveying Technology of low altitude UAV Aero-photography and Remote Sensing in Surveying Field. Heilongjiang Sci. Technol. Inf. 2016, 8, 60. (In Chinese) [Google Scholar]

- Jun, Y.; Shaohua, W.; Jiayuan, L. Research on Fine Management and Visualization of Ancient Architectures Based on Integration of 2D and 3D GIS Technology. IOP Publ. 2014, 17, 012168. [Google Scholar] [CrossRef]

- Zheng, D.; Yang, L. Collecting System of Building Surface Data with Three-D Laser Scanning Survey Aided with Digital Photogrammetry. Build. Sci. 2004, 4, 75–79. [Google Scholar]

- Hong, O. Research on 3D Digital Modeling Method of Ancient Architecture in the Palace Museum. J. Beijing Union Univ. Nat. Sci. 2015, 3, 10–14. (In Chinese) [Google Scholar]

- Wang, F.; Song, Y.; Gao, Z.; Zeng, F. Application of UAV Aerial Surveying and TLS Technology to Surveying and Modeling in Historic site of Guangzhou Steel Works. Bull. Surv. Mapp. 2016, 4, 72–74. [Google Scholar]

- Domingo, I.; Villaverde, V.; López-Montalvo, E. Latest developments in rock art recording: Towards an integral documentation of Levantine rock art sites combining 2D and 3D recording techniques. J. Archaeol. Sci. 2013, 40, 1879–1889. [Google Scholar] [CrossRef]

- Hinzen, K.G.; Schreiber, S.; Rosellen, S. A high resolution laser scanning model of the Roman theater in Pinara, Turkey—Comparison to previous measurements and search for the causes of damage. J. Cult. Herit. 2013, 14, 424–430. [Google Scholar] [CrossRef]

- Guidi, G.; Russo, M.; Angheleddu, D. 3D survey and virtual reconstruction of archeological sites. Digit. Appl. Archaeol. Cult. Herit. 2014, 1, 55–69. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, S.; Fu, C.; Ai, M.; Yu, D.; Wang, W. Fine Surveying and 3D Modeling Approach for Wooden Ancient Architecture via Multiple Laser Scanner Integration. Remote Sens. 2016, 8, 270. [Google Scholar] [CrossRef]

- Pesci, A.; Casula, G.; Boschi, E. Laser scanning the Garisenda and Asinelli towers in Bologna (Italy): Detailed deformation patterns of two ancient leaning buildings. J. Cult. Herit. 2011, 12, 117–127. [Google Scholar] [CrossRef] [Green Version]

- Kuzminsky, S.C.; Gardiner, M.S. Three-dimensional laser scanning: Potential uses for museum conservation and scientific research. J. Archaeol. Sci. 2012, 39, 2744–2751. [Google Scholar] [CrossRef]

- Chellini, G.; Nardini, L.; Pucci, B. Evaluation of seismic vulnerability of Santa Maria del Mar in Barcelona by an integrated approach based on terrestrial laser scanner and finite element modeling. Int. J. Arch. Herit. 2014, 8, 795–819. [Google Scholar] [CrossRef]

- Li, S.; Hou, M.; Wu, Y.; Hu, Y.; Zhang, Y. 3D Information Recording and Application of Rock Relics. Urban Geotech. Investig. Surv. 2013, 2, 85–88. [Google Scholar]

- Kontogianni, G.; Georgopoulos, A.; Saraga, N.; Alexandraki, E.; Tsogka, K. 3D Virtual reconstruction of the middle Stoa in the Athens ancient Agorà. ISPRS Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2013, xl-5/w1, 125–131. [Google Scholar] [CrossRef]

- Dore, C.; Murphy, M.; McCarthy, S.; Brechin, F.; Casidy, C.; Dirix, E. Structural simulations and conservation analysis-Historic building information model (HBIM). Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2015, XL-5/W4, 351–357. [Google Scholar] [CrossRef]

- Oreni, D.; Brumana, R.; Della Torre, S.; Banfi, F.; Previtali, M. Survey turned into HBIM: the restoration and the work involved concerning the Basilica di Collemaggio after the earthquake (L’Aquila). ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2014, II-5, 267–273. [Google Scholar] [CrossRef]

- Sánchez-Aparicio, L.J.; Villarino, A.; García-Gago, J.; González-Aguilera, D. Photogrammetric, Geometrical, and Numerical Strategies to Evaluate Initial and Current Conditions in Historical Constructions: A Test Case in the Church of San Lorenzo (Zamora, Spain). Remote Sens. 2016, 8, 60. [Google Scholar] [CrossRef]

- Tang, H. Science and Civilisation in China, Volume of Bridge; Science Press: Beijing, China, 2000; p. 152. (In Chinese) [Google Scholar]

- Wang, K. History of Ancient Road in Shaanxi Province; China People’s Communications Press: Beijing, China, 1989. (In Chinese) [Google Scholar]

- Wang, P. Shu Road of China; China Travel & Tourism Press: Beijing, China, 2008. (In Chinese) [Google Scholar]

- Gao, C.; Wang, J.; Wang, X.; Hu, F. Roads Converge on Chang’an, the Trip of Cultural Geography of Ancient Roads in Qinling; Northwest University Press: Xi’an, China, 2010. (In Chinese) [Google Scholar]

- Guidi, G.; Remondino, F.; Russo, M. A multi-resolution methodology for the 3D modeling of large and complex archeological areas. Int. J. Arch. Comput. 2009, 7, 39–55. [Google Scholar] [CrossRef]

- Revaud, J.; Weinzaepfel, P.; Harchaoui, Z.; Schmid, C. DeepMatching: Hierarchical Deformable Dense Matching. Int. J. Comput. Vis. 2015, 2, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Haala, N.; Rothermel, M. Dense multiple stereo matching of highly overlapping UAV imagery. ISPRS Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, XXXIX-B1, 387–392. [Google Scholar] [CrossRef]

- Torres-Martínez, J.A.; Seddaiu, M.; Rodríguez-Gonzálvez, P.; Hernández-López, D.; González-Aguilera, D. A Multi-Data Source and Multi-Sensor Approach for the 3D Reconstruction and Web Visualization of a Complex Archaelogical Site: The Case Study of “Tolmo De Minateda”. Remote Sens. 2016, 8, 550. [Google Scholar] [CrossRef]

- Besl, P.J.; McKay, N.D. Method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Lan, Y. The form and transition of Chinese ancient plank road. Study Hist. Nat. Sci. 1992, 1, 68–76. [Google Scholar]

- Li, D. Commentary on the Waterway; Chen, Q., Translator; Zhonghua Book Company: Beijing, China, 2009; p. 223. [Google Scholar]

- Qiu, G.; Qiu, L.; Yang, P. Measurement. In Chinese Technology History; Science Press: Beijing, China, 2001; pp. 268–270. (In Chinese) [Google Scholar]

| Technical Indicator of Cross Beam and Column Type Plank Road | Value | Value Type |

|---|---|---|

| Wood (Spruce) density ρ (g/cm3) | 0.33 | set value |

| Spacing between cross beams L (mm) | 3000 | set value |

| Cantilever length B (mm) | 3600 | set value |

| Height of primary cross beam h (mm) | 250 | set value |

| Width of primary cross beam b (mm) | 300 | set value |

| Number of longitudinal beams paved on every cross beam | 4 | set value |

| Height of section of secondary longitudinal beam h1 (mm) | 120 | set value |

| Width of section of secondary longitudinal beam b1 (mm) | 120 | set value |

| Plank thickness d1 (mm) | 30 | set value |

| Preset safety factor k | 3 | set value |

| Permanent load g (N/mm) | 0.70 | caculated value |

| Variable load q (N/mm) | 12 | calculated value |

| Total load p(g + q) (N/mm) | 12.70 | calculated value |

| Total load on every plank road P (N) | 45,730.44 | calculated value |

| Checking of bending strength of primary cross beam k × M/W (it shall be ≤FM) | 19.76 ≤ 49.8 | calculated value |

| Checking of bending strength of secondary longitudinal beam k × M1/W1 (it shall be ≤fm) | 44.66 ≤ 49.8 | calculated value |

| Checking of bending strength of plank k × M2/W2 (it shall be ≤fm) | 43.20 ≤ 49.8 | calculated value |

| Checking of shearing strength of primary cross beam k × VS/(I × b) (it shall be ≤fv) | 1.71 ≤ 5 | calculated value |

| Checking of shearing strength of secondary longitudinal beam k × V1 × S1/(I1 × b1) (it shall be ≤fv) | 1.79 ≤ 5 | calculated value |

| Column diameter D (mm) | 200 | set value |

| Column length L1 | 3000 | set value |

| Checking of compression strength of column k × N/An (it shall be ≤fc) | 1.64 ≤ 27.6 | calculated value |

| Column length factor μ | 1 | calculated value |

| Slenderness ratio λ | 60.00 | calculated value |

| Stability coefficient Φ | 0.54 | calculated value |

| Checking of stability of column under stress K × N/(Φ × A0) (it shall be ≤fc) | 3.03 ≤ 27.6 | calculated value |

| Technical Indicator of Chiya Plank Road | Value of Chiya Plank Road |

|---|---|

| Wood (Spruce) density ρ (g/cm3) | 0.33 |

| Spacing between cross beams L (mm) | 3000 |

| Cantilever length B (mm) | 3600 |

| Height of primary cross beam h (mm) | 240 |

| Width of primary cross beam b (mm) | 288 |

| Number of longitudinal beams paved on every cross beam | 4 |

| Height of section of secondary longitudinal beam h1 (mm) | 120 |

| Width of section of secondary longitudinal beam b1 (mm) | 120 |

| Plank thickness d1 (mm) | 36 |

| Preset safety factor k | 3 |

| Permanent load g (N/mm) | 0.74 |

| Variable load q (N/mm) | 12.00 |

| Total load p(g + q) (N/mm) | 12.74 |

| Total load on every plank road P (N) | 45,874.43 |

| Checking of bending strength of primary cross beam k × M/W (it shall be ≤fm) | 22.40 ≤ 49.80 |

| Checking of bending strength of secondary longitudinal beam k × M1/W1 (it shall be ≤fm) | 44.80 ≤ 49.80 |

| Checking of bending strength of plank k × M2/W2 (it shall be ≤fm) | 30.00 ≤ 49.80 |

| Checking of shearing strength of primary cross beam k × VS/(I × b) (it shall be ≤fv) | 1.87 ≤ 5 |

| Checking of shearing strength of secondary longitudinal beam k × V1 × S1/(I1 × b1) (it shall be ≤fv) | 1.79 ≤ 5 |

| Column diameter D (mm) | 196 |

| Column length L1 | 2000 |

| Checking of compression strength of column k × N/An (it shall be ≤fc) | 1.36 ≤ 27.6 |

| Column length factor μ | 1 |

| Slenderness ratio λ | 36.73 |

| Stability coefficient Φ | 0.76 |

| Checking of stability of column under stress K × N/(Φ × A0) (it shall be ≤fc) | 2.26 ≤ 27.6 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Hu, Q.; Wang, S.; Yang, H. A Virtual Restoration Approach for Ancient Plank Road Using Mechanical Analysis with Precision 3D Data of Heritage Site. Remote Sens. 2016, 8, 828. https://doi.org/10.3390/rs8100828

Chen S, Hu Q, Wang S, Yang H. A Virtual Restoration Approach for Ancient Plank Road Using Mechanical Analysis with Precision 3D Data of Heritage Site. Remote Sensing. 2016; 8(10):828. https://doi.org/10.3390/rs8100828

Chicago/Turabian StyleChen, Siliang, Qingwu Hu, Shaohua Wang, and Hongjun Yang. 2016. "A Virtual Restoration Approach for Ancient Plank Road Using Mechanical Analysis with Precision 3D Data of Heritage Site" Remote Sensing 8, no. 10: 828. https://doi.org/10.3390/rs8100828

APA StyleChen, S., Hu, Q., Wang, S., & Yang, H. (2016). A Virtual Restoration Approach for Ancient Plank Road Using Mechanical Analysis with Precision 3D Data of Heritage Site. Remote Sensing, 8(10), 828. https://doi.org/10.3390/rs8100828