Solvent-Dependent Electrical Characteristics and Mechanical Stability of Flexible Organic Ferroelectric Field-Effect Transistors

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Auciello, O.; Scott, J.F.; Ramesh, R. The Physics of Ferroelectric Memories. Phys. Today 1998, 51, 22–27. [Google Scholar] [CrossRef]

- Ling, Q.-D.; Liaw, D.-J.; Zhu, C.; Chan, D.S.-H.; Kang, E.-T.; Neoh, K.-G. Polymer electronic memories: Materials, devices and mechanisms. Prog. Polym. Sci. 2008, 33, 917–978. [Google Scholar] [CrossRef]

- Heremans, P.; Gelinck, G.H.; Müller, R.; Baeg, K.-J.; Kim, D.-Y.; Noh, Y.-Y. Polymer and Organic Nonvolatile Memory Devices. Chem. Mater. 2011, 23, 341–358. [Google Scholar] [CrossRef]

- Ducharme, S.; Reece, T.; Othon, C.; Rannow, R. Ferroelectric polymer Langmuir-Blodgett films for nonvolatile memory applications. IEEE Trans. Device Mater. Reliab. 2005, 5, 720–735. [Google Scholar] [CrossRef]

- Naber, R.C.G.; Tanase, C.; Blom, P.W.M.; Gelinck, G.H.; Marsman, A.W.; Touwslager, F.J.; Setayesh, S.; De Leeuw, D.M. High-performance solution-processed polymer ferroelectric field-effect transistors. Nat. Mater. 2005, 4, 243–248. [Google Scholar] [CrossRef] [Green Version]

- Naber, R.C.G.; Asadi, K.; Blom, P.W.M.; de Leeuw, D.M.; de Boer, B. Organic nonvolatile memory devices based on ferroelectricity. Adv. Mater. 2010, 22, 933–945. [Google Scholar] [CrossRef]

- Chiu, Y.-C.; Chen, T.-Y.; Chen, Y.; Satoh, T.; Kakuchi, T.; Chen, W.-C. High-Performance Nonvolatile Organic Transistor Memory Devices Using the Electrets of Semiconducting Blends. ACS Appl. Mater. Interfaces 2014, 6, 12780–12788. [Google Scholar] [CrossRef]

- Lill, A.T.; Eftaiha, F.A.; Huang, J.; yang, H.; Seifrid, M.; Wang, M.; Bazan, G.C.; Nguyen, T.-Q. High-k fluoropolymer gate dieelectric in electrically stable organic field-effect transistors. ACS Appl. Mater. Interfaces 2019, 11, 15821–15828. [Google Scholar] [CrossRef]

- Kim, M.G.; Han, D.H.; Park, K.E. Solution-processed organic ferroelectric field-effect transistors on ultra-flexible substrates. Appl. Phys. Lett. 2016, 109, 163502. [Google Scholar]

- Furukawa, T.; Nakajima, T.; Takahashi, Y. Factors governing ferroelectric switching characteristics of thin VDF/TrFE copolymer films. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 1120–1131. [Google Scholar] [CrossRef]

- Laudari, A.; Guha, S. Polarization-induced transport in ferroelectric organic field-effect transistors. J. Appl. Phys. 2015, 117, 105501. [Google Scholar] [CrossRef]

- Kim, S.-J.; Lee, J.-S. Flexible Organic Transistor Memory Devices. Nano Lett. 2010, 10, 2884–2890. [Google Scholar] [CrossRef]

- Han, S.-T.; Zhou, Y.; Roy, V.A.L. Towards the Development of Flexible Non-Volatile Memories. Adv. Mater. 2013, 25, 5425–5449. [Google Scholar] [CrossRef] [PubMed]

- Cramer, T.; Travaglini, L.; Lai, S.; Patruno, L.; De Miranda, S.; Bonfiglio, A.; Cosseddu, P.; Fraboni, B. Direct imaging of defect formation in strained organic flexible electronics by Scanning Kelvin Probe Microscopy. Sci. Rep. 2016, 6, 38203. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, F.-C.; Chen, T.-D.; Zeng, B.-R.; Chung, Y.-W. Influence of mechanical strain on the electrical properties of flexible organic thin-film transistors. Semicond. Sci. Technol. 2011, 26, 34005. [Google Scholar] [CrossRef]

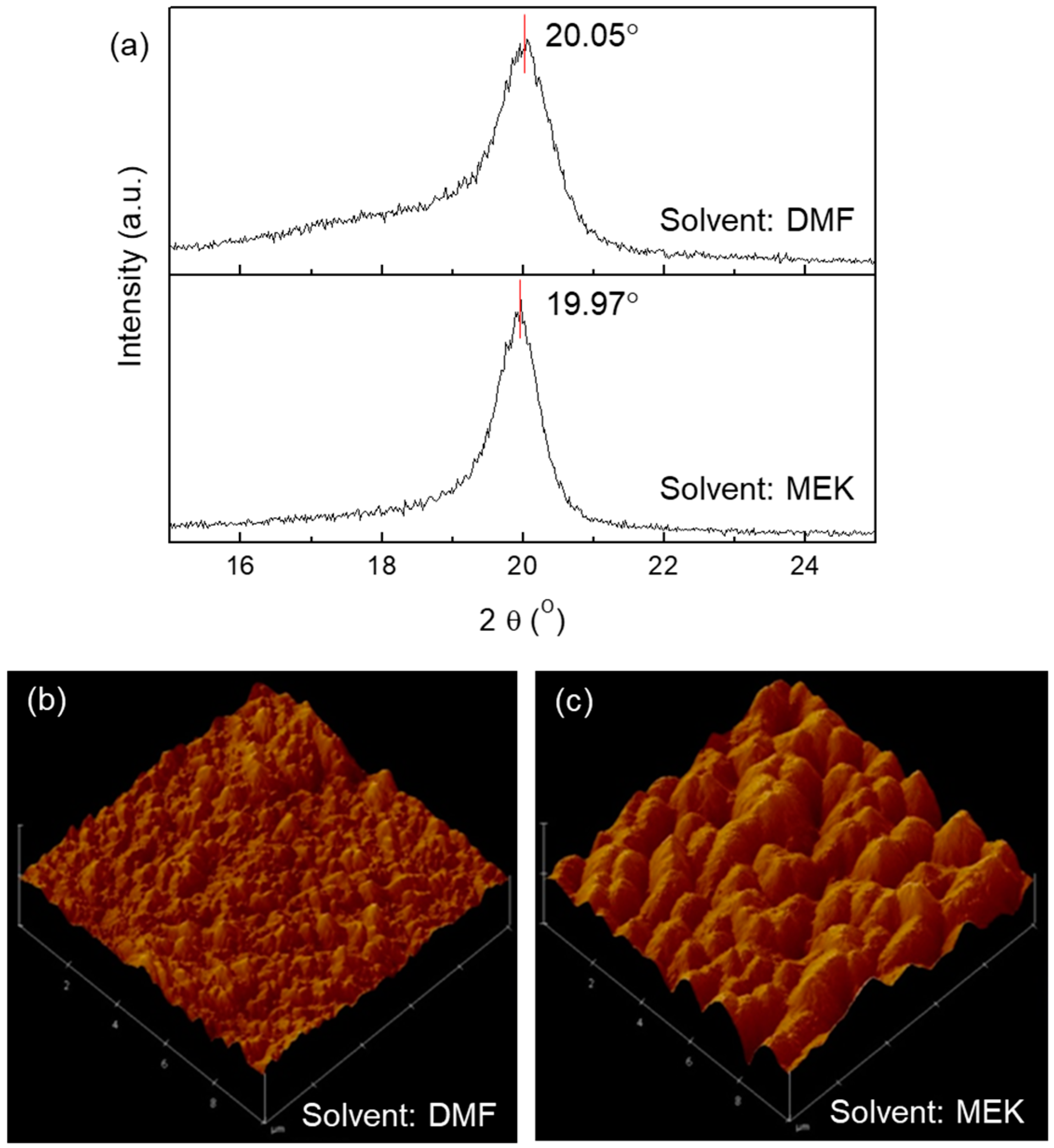

- Knotts, G.; Bhaumik, A.; Ghosh, K.; Guha, S. Enhanced performance of ferroelectric-based all organic capacitors and transistors through choice of solvent. Appl. Phys. Lett. 2014, 104, 233301. [Google Scholar] [CrossRef]

- Han, S.; Yu, X.; Shi, W.; Zhuang, X.; Yu, J. Solvent-dependent electrical properties improvement of organic field-effect transistor based on disordered conjugated polymer/insulator blends. Org. Electron. 2015, 27, 160–166. [Google Scholar] [CrossRef]

- Sanda, S.; Nakamichi, R.; Nagase, T.; Kobayashi, T.; Takimiya, K.; Sadamitsu, Y.; Naito, H. Effect of non-chlorinated solvents on the enhancement of field-effect mobility in dioctylbenzothienobenzothiophene-based top-gate organic transistors processed by spin coating. Org. Electron. 2019, 69, 181–189. [Google Scholar] [CrossRef]

- Rubinger, C.P.L.; Haneef, H.F.; Hewitt, C.; Carroll, D.; Anthony, J.E.; Jurchescu, O.D. Influence of solvent additives on the morphology and electrical properties of diF-TES ADT organic field-effect transistors. Org. Electron. 2019, 68, 205–211. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, S.; Kim, H.; Lee, J. Solvent-dependent performance of solution-processed small-molecule organic field-effect transistors. Org. Electron. 2018, 52, 184–189. [Google Scholar] [CrossRef]

- Kim, N.-K.; Shin, E.S.; Noh, Y.-Y.; Kim, D.-Y. A selection rule of solvent for highly aligned diketopyrrolopyrrole-based conjugated polymer film for high performance organic field-effect transistors. Org. Electron. 2018, 55, 6–14. [Google Scholar] [CrossRef]

- Wahid, M.H.M.; Dahan, R.M.; Sa’Ad, S.Z.; Arshad, A.N.; Sarip, M.N.; Mahmood, M.R.; Chen, G.W.; Haliza, A.M.W. Effect of Annealing Temperature on the Crystallinity, Morphology and Ferroelectric of Polyvinylidenefluoride-Trifluoroethylene (PVDF-TrFE) Thin Film. Adv. Mater. Res. 2013, 812, 60–65. [Google Scholar] [CrossRef]

- Furukawa, T. Structure and functional properties of ferroelectric polymers. Adv. Colloid Interface Sci. 1997, 71, 183–208. [Google Scholar] [CrossRef]

- Shao, M.; He, Y.; Hong, K.; Rouleau, C.M.; Geohegan, D.B.; Xiao, K. A water-soluble polythiophene for organic field-effect transistors. Polym. Chem. 2013, 4, 5270. [Google Scholar] [CrossRef]

- Chang, J.-F.; Sun, B.; Breiby, D.W.; Nielsen, M.M.; Sölling, T.I.; Giles, M.; McCulloch, I.; Sirringhaus, H. Enhanced Mobility of Poly(3-hexylthiophene) Transistors by Spin-Coating from High-Boiling-Point Solvents. Chem. Mater. 2004, 16, 4772–4776. [Google Scholar] [CrossRef]

- Gu, X.; Reinspach, J.; Worfolk, B.J.; Diao, Y.; Zhou, Y.; Yan, H.; Gu, K.; Mannsfeld, S.; Toney, M.F.; Bao, Z. Compact Roll-to-Roll Coater for in Situ X-ray Diffraction Characterization of Organic Electronics Printing. ACS Appl. Mater. Interfaces 2016, 8, 1687–1694. [Google Scholar] [CrossRef]

- Nguyen, C.; Mhaisalkar, S.; Ma, J.; Lee, P.S. Enhanced organic ferroelectric field effect transistor characteristics with strained poly(vinylidene fluoride-trifluoroethylene) dielectric. Org. Electron. 2008, 9, 1087–1092. [Google Scholar] [CrossRef]

- Kim, J.-H.; Bae, J.-H.; Kim, M.-H. Roughness Reduction of PVDF-TrFE Insulator by Reverse Transfer Printing for Enhanced Performance of Ferroelectric Organic Memory Transistors. J. Nanosci. Nanotechnol. 2017, 17, 4149–4152. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.-K.; Lee, H.; Zhang, X.; Bae, J.-H.; Park, J. Solvent-Dependent Electrical Characteristics and Mechanical Stability of Flexible Organic Ferroelectric Field-Effect Transistors. Micromachines 2019, 10, 727. https://doi.org/10.3390/mi10110727

Kim D-K, Lee H, Zhang X, Bae J-H, Park J. Solvent-Dependent Electrical Characteristics and Mechanical Stability of Flexible Organic Ferroelectric Field-Effect Transistors. Micromachines. 2019; 10(11):727. https://doi.org/10.3390/mi10110727

Chicago/Turabian StyleKim, Do-Kyung, Hyeonju Lee, Xue Zhang, Jin-Hyuk Bae, and Jaehoon Park. 2019. "Solvent-Dependent Electrical Characteristics and Mechanical Stability of Flexible Organic Ferroelectric Field-Effect Transistors" Micromachines 10, no. 11: 727. https://doi.org/10.3390/mi10110727