Experimental Setup for Dynamic Analysis of Micro- and Nano-Mechanical Systems in Vacuum, Gas, and Liquid

Abstract

:1. Introduction

2. Materials and Methods

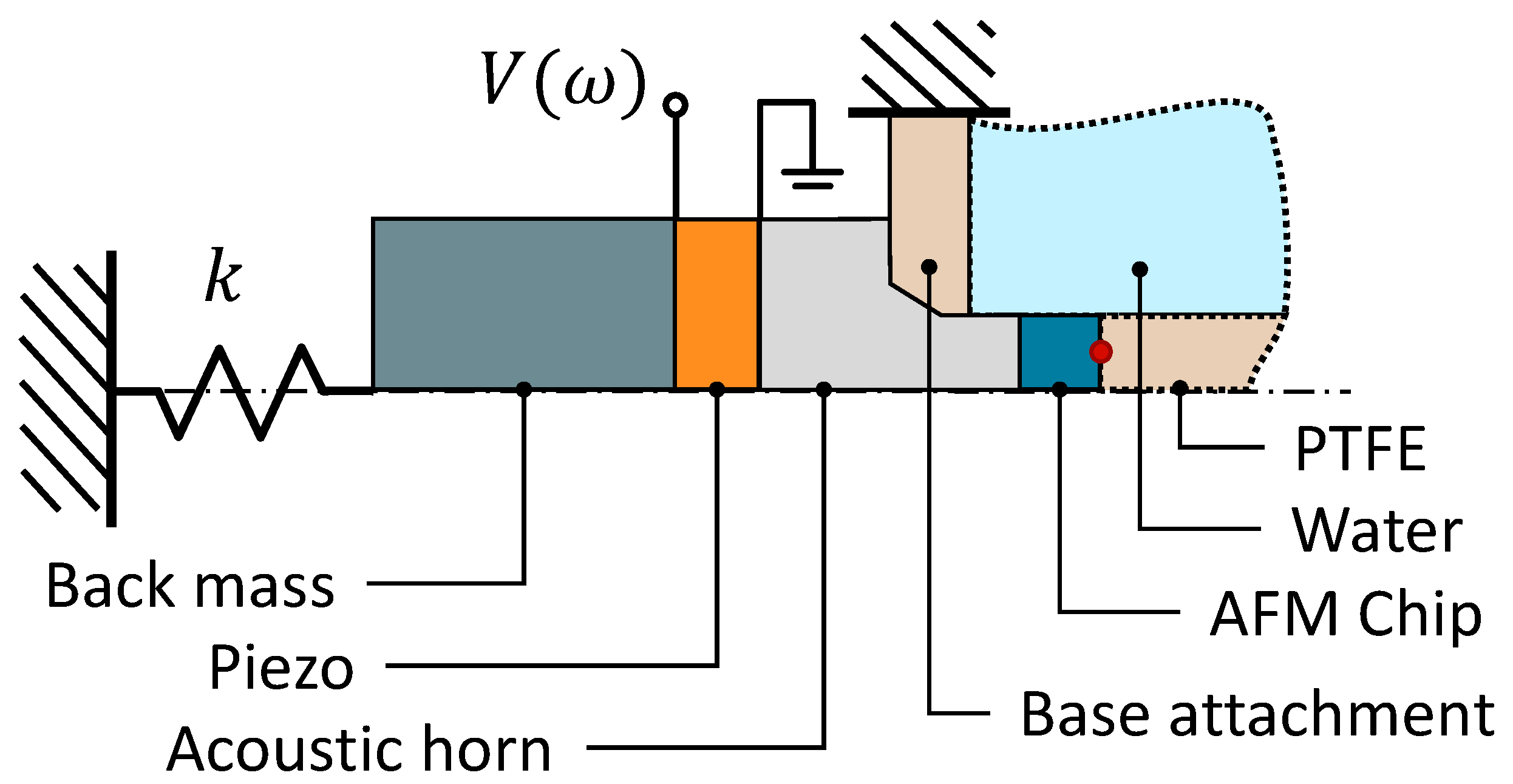

2.1. Design

2.2. Fabrication

2.3. Experimental Setup

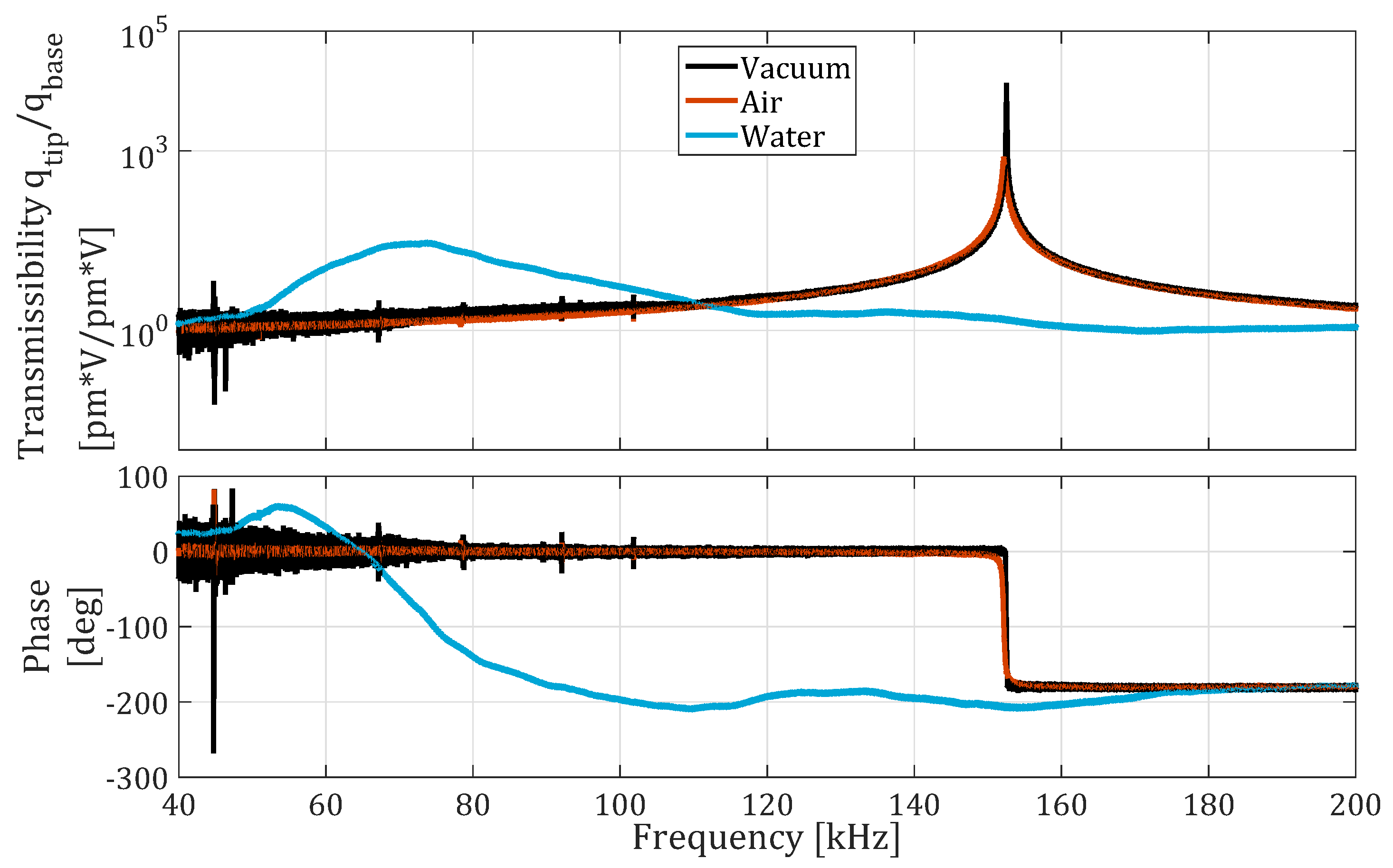

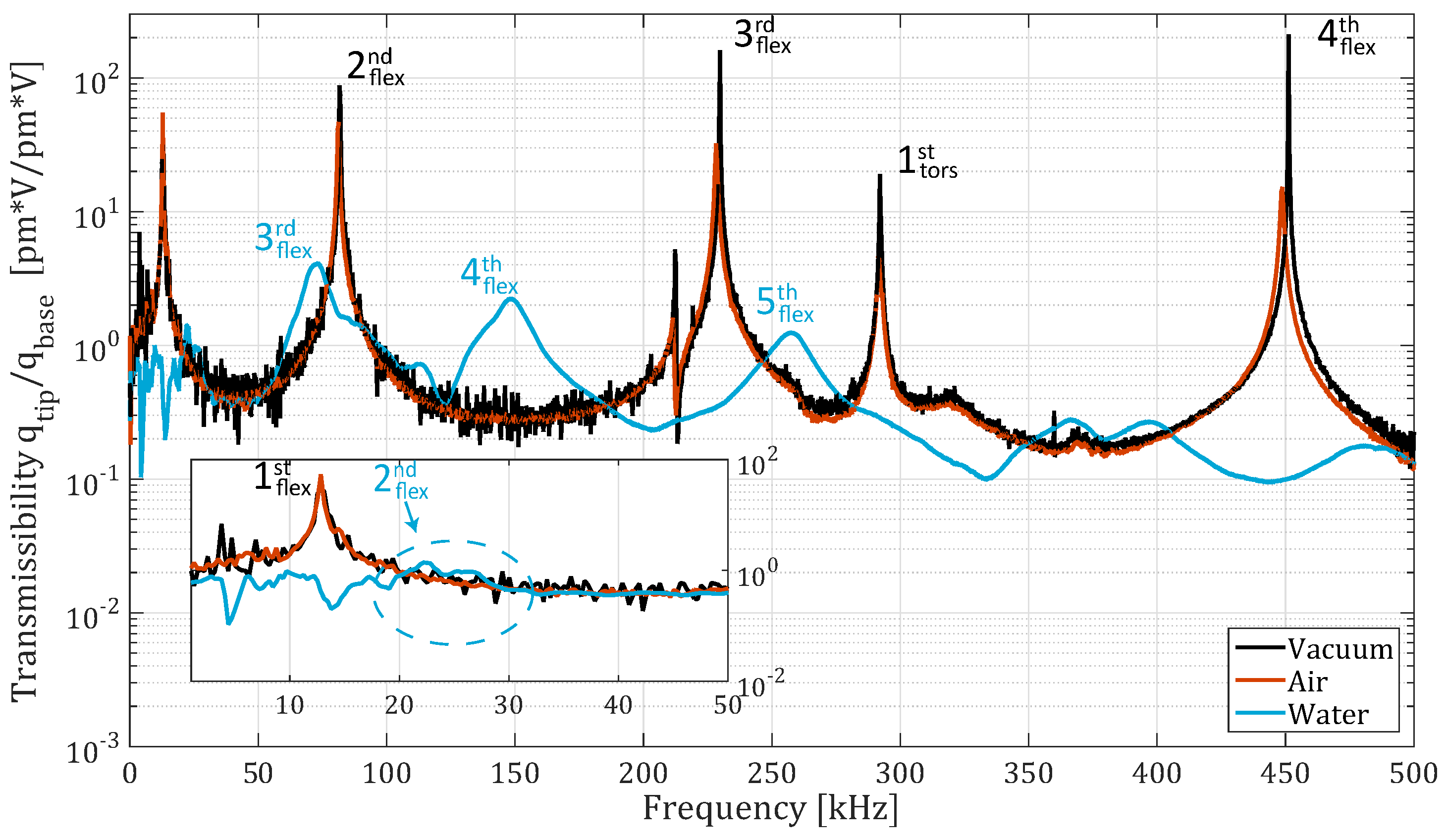

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, M.; Tang, H.X.; Roukes, M.L. Ultra-sensitive NEMS-based cantilevers for sensing, scanned probe and very high-frequency applications. Nat. Nanotechnol. 2007, 2, 114–120. [Google Scholar] [CrossRef] [PubMed]

- Johnson, B.N.; Mutharasan, R. Biosensing using dynamic-mode cantilever sensors: A review. Biosens. Bioelectron. 2012, 32, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Calleja, M.; Kosaka, P.M.; San Paulo, Á.; Tamayo, J. Challenges for nanomechanical sensors in biological detection. Nanoscale 2012, 4, 4925–4938. [Google Scholar] [CrossRef] [PubMed]

- Braun, T.; Ghatkesar, M.K.; Backmann, N.; Grange, W.; Boulanger, P.; Letellier, L.; Lang, H.P.; Bietsch, A.; Gerber, C.; Hegner, M. Quantitative time-resolved measurement of membrane protein–ligand interactions using microcantilever array sensors. Nat. Nanotechnol. 2009, 4, 179–185. [Google Scholar] [CrossRef] [PubMed]

- Arlett, J.; Myers, E.; Roukes, M. Comparative advantages of mechanical biosensors. Nat. Nanotechnol. 2011, 6, 203–215. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, C.; Miller, M.H. Optimization Strategy for Resonant Mass Sensor Design in the Presence of Squeeze Film Damping. Micromachines 2010, 1, 112–128. [Google Scholar] [CrossRef] [Green Version]

- Hilt, J.Z.; Gupta, A.K.; Bashir, R.; Peppas, N.A. Ultrasensitive Biomems Sensors Based on Microcantilevers Patterned with Environmentally Responsive Hydrogels. Biomed. Microdevices 2003, 5, 177–184. [Google Scholar] [CrossRef]

- Corbin, E.A.; Millet, L.J.; Pikul, J.H.; Johnson, C.L.; Georgiadis, J.G.; King, W.P.; Bashir, R. Micromechanical properties of hydrogels measured with MEMS resonant sensors. Biomed. Microdevices 2013, 15, 311–319. [Google Scholar] [CrossRef] [PubMed]

- Rivest, C.; Morrison, D.W.G.; Ni, B.; Rubin, J.; Yadav, V.; Mahdavi, A.; Karp, J.; Khademhosseini, A. Microscale hydrogels for medicine and biology: Synthesis characteristics and applications. J. Mechan. Mater. Struct. 2007, 2. [Google Scholar] [CrossRef]

- Buenger, D.; Topuz, F.; Groll, J. Hydrogels in sensing applications. Prog. Polym. Sci. 2012, 37, 1678–1719. [Google Scholar] [CrossRef]

- Berger, R.; Gerber, C.; Lang, H.; Gimzewski, J. Micromechanics: A toolbox for femtoscale science: “Towards a laboratory on a tip”. Microelectron. Eng. 1997, 35, 373–379. [Google Scholar] [CrossRef]

- Urbiztondo, M.; Pellejero, I.; Villarroya, M.; Sesé, J.; Pina, M.; Dufour, I.; Santamaría, J. Zeolite-modified cantilevers for the sensing of nitrotoluene vapors. Sens. Actuators B Chem. 2009, 137, 608–616. [Google Scholar] [CrossRef]

- Pina, M.; Mallada, R.; Arruebo, M.; Urbiztondo, M.; Navascués, N.; de la Iglesia, O.; Santamaria, J. Zeolite films and membranes. Emerging applications. Microporous Mesoporous Mater. 2011, 144, 19–27. [Google Scholar] [CrossRef]

- Xu, P.; Li, X.; Yu, H.; Xu, T. Advanced Nanoporous Materials for Micro-Gravimetric Sensing to Trace-Level Bio/Chemical Molecules. Sensors 2014, 14, 19023–19056. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, R.; Wang, W. Structural dynamics of microsystems—Current state of research and future directions. Mech. Syst. Signal Process. 2006, 20, 1015–1043. [Google Scholar] [CrossRef]

- Platz, D.; Pfusterschmied, G.; Schmid, U. Modelling Fluid Damping of Non-Conventional Vibration Modes in MEMS Resonators. Proceedings 2018, 2, 896. [Google Scholar] [CrossRef]

- Elmer, F.J.; Dreier, M. Eigenfrequencies of a rectangular atomic force microscope cantilever in a medium. J. Appl. Phys. 1997, 81, 7709. [Google Scholar] [CrossRef]

- Kirstein, S.; Mertesdorf, M.; Schonhoff, M. The influence of a viscous fluid on the vibration dynamics of scanning near-field optical microscopy fiber probes and atomic force microscopy cantilevers. J. Appl. Phys. 1998, 84, 1782–1790. [Google Scholar] [CrossRef]

- Sader, J.E. Frequency response of cantilever beams immersed in viscous fluids with applications to the atomic force microscope. J. Appl. Phys. 1998, 84. [Google Scholar] [CrossRef]

- Green, C.P.; Sader, J.E. Torsional frequency response of cantilever beams immersed in viscous fluids with applications to the atomic force microscope. J. Appl. Phys. 2002, 92. [Google Scholar] [CrossRef]

- Van Eysden, C.A.; Sader, J.E. Resonant frequencies of a rectangular cantilever beam immersed in a fluid. J. Appl. Phys. 2006, 100, 114916. [Google Scholar] [CrossRef]

- Van Eysden, C.A.; Sader, J.E. Frequency response of cantilever beams immersed in viscous fluids with applications to the atomic force microscope: Arbitrary mode order. J. Appl. Phys. 2007, 101, 044908. [Google Scholar] [CrossRef]

- Basak, S.; Raman, A.; Garimella, S.V. Hydrodynamic loading of microcantilevers vibrating in viscous fluids. J. Appl. Phys. 2006, 99, 114906. [Google Scholar] [CrossRef] [Green Version]

- Ricci, A.; Canavese, G.; Ferrante, I.; Marasso, S.L.; Ricciardi, C. A finite element model for the frequency spectrum estimation of a resonating microplate in a microfluidic chamber. Microfluid. Nanofluid. 2013, 15, 275–284. [Google Scholar] [CrossRef]

- Iqbal, F.; Lee, B. A Study on Measurement Variations in Resonant Characteristics of Electrostatically Actuated MEMS Resonators. Micromachines 2018, 9, 173. [Google Scholar] [CrossRef] [PubMed]

- Epp, D.; Ozdoganlar, O.; Chaplya, P. A base excitation test facility for dynamic testing of microsystems. In Proceedings of the 22nd International Modal Analysis Conference (IMAC-XXII), Dearborn, MI, USA, 26–29 January 2004. [Google Scholar]

- Putman, C.A.J.; Van der Werf, K.O.; De Grooth, B.G.; Van Hulst, N.F.; Greve, J. Tapping mode atomic force microscopy in liquid. Appl. Phys. Lett. 1994, 64, 2454. [Google Scholar] [CrossRef]

- Xu, X.; Raman, A. Comparative dynamics of magnetically, acoustically, and Brownian motion driven microcantilevers in liquids. J. Appl. Phys. 2007, 102, 034303. [Google Scholar] [CrossRef]

- Motamedi, R.; Wood-Adams, P.M. Influence of Fluid Cell Design on the Frequency Response of AFM Microcantilevers in Liquid Media. Sensors 2008, 8, 5927–5941. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kokavecz, J.; Mechler, A. Investigation of fluid cell resonances in intermittent contact mode atomic force microscopy. Appl. Phys. Lett. 2007, 91, 023113. [Google Scholar] [CrossRef]

- Asakawa, H.; Fukuma, T. Spurious-free cantilever excitation in liquid by piezoactuator with flexure drive mechanism. Rev. Sci. Instrum. 2009, 80, 103703. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carrasco, C.; Ares, P.; de Pablo, P.J.; Gomez-Herrero, J. Cutting down the forest of peaks in acoustic dynamic atomic force microscopy in liquid. Rev. Sci. Instrum. 2008, 79, 126106. [Google Scholar] [CrossRef] [PubMed]

- Maali, A.; Hurth, C.; Cohen-Bouhacina, T.; Couturier, G.; Aime, J.P. Improved acoustic excitation of atomic force microscope cantilevers in liquids. Appl. Phys. Lett. 2006, 88, 163504. [Google Scholar] [CrossRef]

- van den Brink, B. Design of a Setup for Modal Testing of Micro-Cantilevers Immersed in Liquid. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2017. [Google Scholar]

- Katzir, S. Who knew piezoelectricity? Rutherford and Langevin on submarine detection and the invention of sonar. Notes Rec. R. Soc. 2012, 66. [Google Scholar] [CrossRef]

- Moreno, E.; Acevedo, P.; Fuentes, M.; Sotomayor, A.; Borroto, L.; Villafuerte, M.; Leija, L. Design and construction of a bolt-clamped Langevin transducer. In Proceedings of the 2005 2nd International Conference on Electrical and Electronics Engineering, Mexico City, Mexico, 7–9 September 2005; pp. 393–395. [Google Scholar]

- Eaton, P.; West, P. Atomic Force Microscopy; Oxford University Press: Oxford, UK, 2010. [Google Scholar]

- Gary, X.; Li, H.G.H. Review of viscous damping in micromachined structures. Proc. SPIE 2000, 4176. [Google Scholar] [CrossRef]

| Mode | ||||||

|---|---|---|---|---|---|---|

| [kHz] | [kHz] | [kHz] | [kHz] | [kHz] | [kHz] | |

| 152.47 | 152.76 | 152.07 | 152.27 | 72.10 | 85.51 |

| Mode | |||||

|---|---|---|---|---|---|

| 8214 | 497 | 680 | 7 | 9 |

| Mode | ||||||

|---|---|---|---|---|---|---|

| [kHz] | [kHz] | [kHz] | [kHz] | [kHz] | [kHz] | |

| Flex. | ||||||

| 12.98 | 13.01 | 12.80 | 12.92 | - | 4.25 | |

| 81.80 | 81.55 | 81.22 | 81.41 | 25 ± 3 | 27.18 | |

| 229.88 | 228.34 | 228.44 | 228.83 | 71.58 | 78.46 | |

| 451.40 | 447.46 | 448.89 | 449.49 | 148.71 | 158.98 | |

| - | 739.69 | - | 736.78 | 259.61 | 269.31 | |

| Tors. | ||||||

| 292.26 | 293.77 | 292.06 | 291.76 | - | 149.18 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

van den Brink, B.; Alijani, F.; Ghatkesar, M.K. Experimental Setup for Dynamic Analysis of Micro- and Nano-Mechanical Systems in Vacuum, Gas, and Liquid. Micromachines 2019, 10, 162. https://doi.org/10.3390/mi10030162

van den Brink B, Alijani F, Ghatkesar MK. Experimental Setup for Dynamic Analysis of Micro- and Nano-Mechanical Systems in Vacuum, Gas, and Liquid. Micromachines. 2019; 10(3):162. https://doi.org/10.3390/mi10030162

Chicago/Turabian Stylevan den Brink, Bram, Farbod Alijani, and Murali Krishna Ghatkesar. 2019. "Experimental Setup for Dynamic Analysis of Micro- and Nano-Mechanical Systems in Vacuum, Gas, and Liquid" Micromachines 10, no. 3: 162. https://doi.org/10.3390/mi10030162