Design Optimization and FE Analysis of 3D Printed Carbon PEEK Based Mono Leaf Spring

Abstract

:1. Introduction

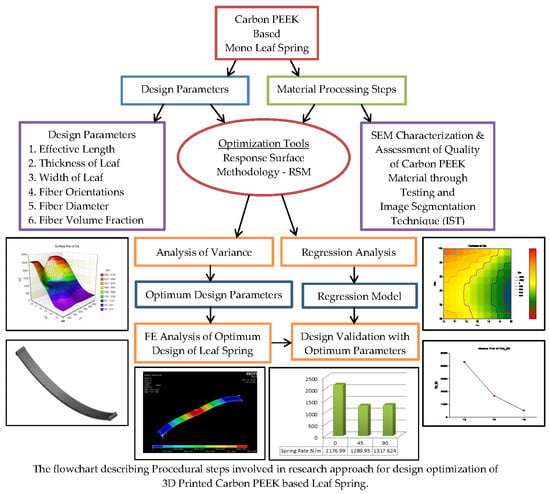

2. Research Methodology

3. Materials and Methods

3.1. 3D Printed Carbon PEEK Materials for Leaf Spring

3.2. 3D Printed Carbon PEEK Materials and the FFF Method

4. Design of Leaf Spring

5. Mathematical Modeling of a Mono Leaf Spring

6. Design Optimization

6.1. Response Surface Methodology

6.2. Regression Analysis

6.3. Multiple Regression Analysis

7. Finite Element Analysis

8. Results and Discussions

8.1. Effect of Total Leaf Span

8.2. Effect of Percentage Volume Fraction

8.3. Effect of Fiber Orientation

8.4. Effect of Fiber Diameter on Deflection

8.5. Estimation of Weight Reduction

8.6. Effect of Thickness on Deflection

9. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

- .

- Bls = Bending stress induced in Leaf spring

- .

- .

- .

- .

- .

- .

- .

- .

- .

- .

- .

- .

- .

- .

- .

- υpeek = Poisson’s ratio of PEEK

- υcpeek = Poisson’s ratio of carbon PEEK

- Wcpeek = Weight of carbon PEEK based leaf spring, kg

References

- Putti, S.R.; Revu, V. Modal and Harmonic Analysis of Leaf Spring Using Composite Materials. Int. J. Novel Res. Electr. Mechan. Eng. 2015, 2, 3. [Google Scholar]

- Sagar, B.M.; Swami, M.C.; Permeshwar, P. Design and Analysis of Mono Composite Leaf Spring by Varying Thickness using FEA. IOSR J. Mechan. Civil Eng. 2015, 12, 99–103. [Google Scholar]

- Yum, Y.J. Frictional Behavior of Automotive Leaf Spring. In Proceedings of the 4th Korea–Russia International Symposium on Science and Technology, Ulsan, South Korea, 27 June–1 July 2000; pp. 5–10. [Google Scholar]

- Charde, R.B.; Bhope, B.V. Investigation of stresses in master leaf of leaf spring by FEM and its experimental verification. Int. J. Eng. Sci. Technol. 2012, 4, 633–640. [Google Scholar]

- Patnaik, M.; Yadav, N.; Dewangan, R. Study of a Parabolic Leaf Spring by Finite Element Method & Design of Experiments. Int. J. Modern Eng. Res. 2012, 2, 1920–1922. [Google Scholar]

- Ozmen, B.; Altiok, B.; Guzel, A.; Kocyigit, I.; Atamer, S. A novel methodology with testing and simulation for the durability of leaf springs based on measured load collectives. Proc. Eng. 2015, 101, 363–371. [Google Scholar] [CrossRef]

- Malaga, A.K.; Charyul, T.N.; Ramesh, C.H. Design Optimization of Leaf Spring. Int. J. Eng. Res. Appl. 2012, 2, 6. [Google Scholar]

- Ghuku, S.; Saha, K.N. Experimental Analysis on Large Deflection of a Master Leaf under Three Point Bending Test. Proc. Int. Conf. Trends Ind. Mechan. Eng. 2016, 2, 393–402. [Google Scholar]

- Shijil, P.; Vargheese, A.; Aswin, D.; Christin, J.; Josin, J. Design and Analysis of suspension system for an All-Terrain Vehicle. Int. J. Sci. Eng. Res. 2016, 7, 3. [Google Scholar]

- Shankar, G.S.S.; Vijayarangan, S. Mono composite leaf spring for light weight vehicle–design, end joint analysis and testing. Mater. Sci. 2006, 12, 220–225. [Google Scholar]

- Hou, J.P.; Cherruault, J.Y.; Nairne, I.; Jeronimidis, G.; Mayer, R.M. Evolution of the eye-end design of a composite leaf spring for heavy axle loads. Compos. Struct. 2007, 78, 351–358. [Google Scholar] [CrossRef]

- Jayaswal, P.; Kushwah, A.S. Rejection minimization in parabolic leaf spring manufacturing unit in India. Int. J. Appl. Res. Mechan. Eng. 2012, 2, 70–75. [Google Scholar]

- Kanbolat, A.; Soner, M. Load Simulation and Analysis in Automotive Engineering; SAE International Publisher: Warrendale, PA, USA, 2012. [Google Scholar]

- Patnaik, M.; Koushik, L.P.; Mathew, M. Determination of camber and leaf span of a parabolic leaf spring for optimized stress and displacement using artificial neural networks. Int. J. Modern Eng. Res. 2012, 2, 2771–2773. [Google Scholar]

- Dewangan, R.K.; Patnaik, M.; Yadav, N. Minimization of stress of a parabolic leaf spring by simulated annealing algorithm. Int. J. Eng. Res. Appl. 2012, 2, 457–460. [Google Scholar]

- Available online: https://www.roboze.com/en/3d-printing-materials/ (accessed on 25 April 2019).

- Molazemhosseini, A.; Tourani, H.; Naimi-Jamal, M.R.; Khavandi, A. Nanoindentation and nanoscratching responses of PEEK based hybrid composites reinforced with short carbon fibers and nano-silica. Polym. Test. 2013, 32, 525–534. [Google Scholar] [CrossRef]

- Ferencz, R.; Sanchez, J.; Blümich, B.; Herrmann, W. AFM nanoindentation to determine Young’s modulus for different EPDM elastomers. Polym. Test. 2012, 31, 425–432. [Google Scholar] [CrossRef]

- Sharma, M.; Bijwe, J.; Mader, E.; Kunze, K. Strengthening of CF/PEEK interface to improve the tribological performance in low amplitude oscillating wear mode. Wear 2013, 301, 735–739. [Google Scholar] [CrossRef]

- Li, E.Z.; Guo, W.L.; Wang, H.D.; Xu, B.S.; Liu, X.T. Research on tribological behavior of PEEK and glass fiber reinforced PEEK composite. Phys. Proc. 2013, 50, 453–460. [Google Scholar] [CrossRef]

- Patel, P.; Hull, T.R.; Lyon, R.E.; Stoliarov, S.I.; Walters, R.N.; Crowley, S.; Safronava, N. Investigation of the thermal decomposition and flammability of PEEK and its carbon and glass-fiber composites. Polym. Degrad. Stab. 2011, 96, 12–22. [Google Scholar] [CrossRef]

- Chen, B.B.; Wang, J.Z.; Yan, F.Y. Comparative investigation on the tribological behaviors of CF/PEEK composites under sea water lubrication. Tribol. Int. 2012, 52, 170–177. [Google Scholar] [CrossRef]

- Xie, G.Y.; Zhuang, G.S.; Sui, G.X.; Yang, R. Tribological behavior of PEEK/PTFE composites reinforced with potassium titanate whiskers. Wear 2010, 268, 424–430. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimisation of Dynamic Mechanical Thermal Properties of PC–ABS Parts Manufactured by FDM Process Using IV Optimal Design; Elsevier: Amsterdam, Netherlands, 2016. [Google Scholar]

- Mireles, J. Development of a Fused Deposition Modeling System for Low Melting Temperature Metal Alloys. J. Electron. Pack. 2013, 135, 11008. [Google Scholar] [CrossRef]

- Melenka, G.W.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation of dimensional accuracy and material properties of the Maker Bot 3D desktop printer. Rapid Prototyp. J. 2015, 21, 618–627. [Google Scholar] [CrossRef]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Kaka, D.O.; Rongong, J.A.; Hodzic, A.; Lord, C. Dynamic Mechanical Properties of Woven Carbon Fibre Reinforced Thermoplastic Composite. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Kvalsvig, A.; Yuan, X.; Potgieter, J.; Cao, P. 3D Printing of Fibre Reinforced Honeycomb Structured Composite Materials. In Proceedings of the 2016 23rd International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Nanjing, China, 28–30 November 2016. [Google Scholar]

- Zhang, Y.; De Backer, W.; Harik, R.; Bernard, A. Build Orientation Determination for Multi-material Deposition Additive Manufacturing with Continuous Fibers. Proc. CIRP 2016, 50, 414–419. [Google Scholar] [CrossRef] [Green Version]

- Matsuzaki, R. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Van Der Klift, F.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y. 3D Printing of Continuous Carbon Fibre Reinforced Thermo-Plastic, CFRTP, Tensile Test Specimens. Compos. Mater. 2016, 6, 18–27. [Google Scholar] [CrossRef]

- Skirbutis, G.; Dzingutė, A.; Masiliūnaitė, V.; Šulcaitė, G.; Žilinskas, J. A review of PEEK polymer’s properties and its use in prosthodontics. Stomatol. Balt. Dent. Maxillofac. J. 2017, 19, 19–23. [Google Scholar]

- Cerneels, J.; Voet, A.; Ivens, J.; Kruth, J.-P. Additive manufacturing of thermoplastic composites. KU Leuven 2013, 18, 1–7. [Google Scholar]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Composites 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modeling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Yang, T.-S.; Shih, P.-J.; Lee, J.-J. Design of a spatial compliant translational joint. Mechan. Mach. Theory 2017, 107, 338–350. [Google Scholar] [CrossRef]

- Van Hoa, S. Development of composite springs using 4D printing method. Compos. Struct. 2019, 210, 869–876. [Google Scholar]

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes-II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Mahajan, C.; Cormier, D. 3D Printing of Carbon Fiber Composites with Preferentially Aligned Fibers. In Proceedings of the 2015 Industrial and Systems Engineering Research Conference, Nashville, Tenn, 30 May–2 June 2015; pp. 2953–2963. [Google Scholar]

- Kunc, V. Advances and Challenges in Large Scale Polymer Additive Manufacturing. In Proceedings of the 15th SPE Automotive Composites Conference, Novi, MI, USA, 9 September 2015. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 9th Edition. Available online: https://www.wiley.com/en-us/Design+and+Analysis+of+Experiments%2C+9th+Edition-p-9781119113478 (accessed on 25 April 2019).

| Parameters | Young’s Modulus | |

|---|---|---|

| Fiber Diameter | 5 µm | 6.0 GPa |

| Fiber Diameter | 9 µm | 5.1 GPa |

| Fiber Diameter | 10 µm | 5.0 GPa |

| Fiber Orientation | 0° | 7600 MPa |

| Fiber Orientation | 45° | 5000 MPa |

| Fiber Orientation | 90° | 4600 MPa |

| Percentage Volume Fraction | 10% | 7600 MPa |

| Percentage Volume Fraction | 30% | 28,000 MPa |

| Percentage Volume Fraction | 60% | 50,000 MPa |

| Chemical Agent | Al-Alloys | AISI-316 | Carbon PEEK | |

|---|---|---|---|---|

| 1 | Hydrogen Peroxide | R | Q | P |

| 2 | Hydrogen Sulfide | R | R | P |

| 3 | Nitrous Oxide | Q | Q | P |

| 4 | Ammonia | Q | Q | P |

| 5 | Petroleum | S | Q | P |

| 6 | Freon | S | R | P |

| 7 | Sea Water | Q | R | P |

| 8 | Sulfurous Gas | R | R | P |

| Position Accuracy | 0.025 mm |

| Printing Volume, X × Y × Z | 280 × 220 × 200 mm3 |

| Bed Temperature | 180 °C |

| Layer Height | 0.10 mm to 0.30 mm |

| Tolerance | 20–25 Microns |

| Nozzle Diameter | 0.35 mm |

| Nozzle Temperature | 250 °C |

| Nozzle Movement Speed | 100–200 mm/min |

| Nozzle Movement Pattern | Rectilinear |

| Extruder Width | 0.35 mm–0.50 mm |

| Parameters | Regression | Standard | Lower 95% | Upper 95% |

|---|---|---|---|---|

| Independent | Coefficient | Error | Conf. Limit | Conf. Limit |

| Intercept | −430.5 | 1489.7 | −4260.1 | 3398.9 |

| te | 447.3 | 39.4 | 346.0 | 548.6 |

| W | −100.1 | 4.8 | −112.5 | −87.6 |

| Le | 5.6 | 2.3 | −0.4 | 11.8 |

| Thickness te, mm | Width we, mm | Length Le, mm | Regression Model, mm | FEA mm | Difference | Standard Deviation | Error of the Mean |

|---|---|---|---|---|---|---|---|

| 16 | 100 | 620 | 243.62 | 257.37 | 5% | 9.72 | 6.87 |

| S.No | Le | we | te | Dls-0, mm | Dls-45, mm | Dls-90, mm | Bls, N/mm2 |

|---|---|---|---|---|---|---|---|

| 1. | 623 | 50 | 10 | 2545.31 | 3868.87 | 4205.29 | 747.60 |

| 2. | 633 | 75 | 12 | 1030.04 | 1565.66 | 1701.80 | 351.66 |

| 3. | 643 | 100 | 16 | 341.60 | 519.23 | 564.38 | 150.70 |

| 4. | 632 | 75 | 12 | 1025.16 | 1558.25 | 1693.75 | 351.11 |

| 5. | 642 | 100 | 16 | 340.01 | 516.82 | 561.76 | 150.46 |

| 6. | 622 | 50 | 10 | 2533.07 | 3850.27 | 4185.08 | 746.40 |

| 7. | 620 | 100 | 16 | 306.24 | 465.48 | 505.96 | 145.31 |

| 8. | 640 | 50 | 10 | 2759.41 | 4194.30 | 4559.03 | 768.00 |

| 9. | 630 | 75 | 12 | 1015.46 | 1543.50 | 1677.72 | 350.00 |

| Digimizer Statistics of Fiber 0° Orientation in Image Segmentation Analysis. | ||||||

| Tool | Measure | n | Mean | SD | Min | Max |

| Length | Length | 8 | 144.57 | 41.34 | 69.77 | 183.05 |

| Circle | Area | 2 | 7279.98 | 2891.94 | 5235.06 | 9324.89 |

| Perimeter | 2 | 299.40 | 60.68 | 256.48 | 342.31 | |

| Red-Avg. Intensity | 2 | 0.25 | 0.06 | 0.20 | 0.30 | |

| Green -Avg. Intensity | 2 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Blue- Avg. Intensity | 2 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Radius | 2 | 47.65 | 9.65 | 40.82 | 54.48 | |

| Digimizer Statistics of Fiber 45° Orientation in Image Segmentation Analysis. | ||||||

| Tool | Measure | n | Mean | SD | Min | Max |

| Length | Length | 8 | 144.57 | 41.34 | 69.77 | 183.05 |

| Circle | Area | 2 | 7279.98 | 2891.94 | 5235.06 | 9324.89 |

| Perimeter | 2 | 299.40 | 60.68 | 256.48 | 342.31 | |

| Red-Avg. Intensity | 2 | 0.25 | 0.06 | 0.20 | 0.30 | |

| Green -Avg. Intensity | 2 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Blue- Avg. Intensity | 2 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Radius | 2 | 47.65 | 9.65 | 40.82 | 54.48 | |

| Tool | Measure | n | Mean | SD | Min | Max |

|---|---|---|---|---|---|---|

| Length | Length | 8 | 147.25 | 37.62 | 85.44 | 194.94 |

| Circle | Area | 2 | 7906.34 | 2653.90 | 6029.75 | 9782.94 |

| Perimeter | 2 | 312.94 | 53.28 | 275.26 | 350.62 | |

| Red-Avg. Intensity | 2 | 0.66 | 0.02 | 0.64 | 0.68 | |

| Green -Avg. Intensity | 2 | 0.00 | 0.00 | 0.00 | 0.01 | |

| Blue- Avg. Intensity | 2 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Radius | 2 | 49.80 | 8.48 | 43.18 | 55.80 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kessentini, A.; Mohammed Sayeed Ahmed, G.; Madiouli, J. Design Optimization and FE Analysis of 3D Printed Carbon PEEK Based Mono Leaf Spring. Micromachines 2019, 10, 279. https://doi.org/10.3390/mi10050279

Kessentini A, Mohammed Sayeed Ahmed G, Madiouli J. Design Optimization and FE Analysis of 3D Printed Carbon PEEK Based Mono Leaf Spring. Micromachines. 2019; 10(5):279. https://doi.org/10.3390/mi10050279

Chicago/Turabian StyleKessentini, Amir, Gulam Mohammed Sayeed Ahmed, and Jamel Madiouli. 2019. "Design Optimization and FE Analysis of 3D Printed Carbon PEEK Based Mono Leaf Spring" Micromachines 10, no. 5: 279. https://doi.org/10.3390/mi10050279