Recent Progress in Microfluidic Models of the Blood-Brain Barrier

Abstract

:1. Introduction

2. Current Experimental Blood-Brain Barrier (BBB) Models

2.1. In Vivo Models

2.2. In Vitro Models

2.3. Computer Models

3. Microfluidic In Vitro Models

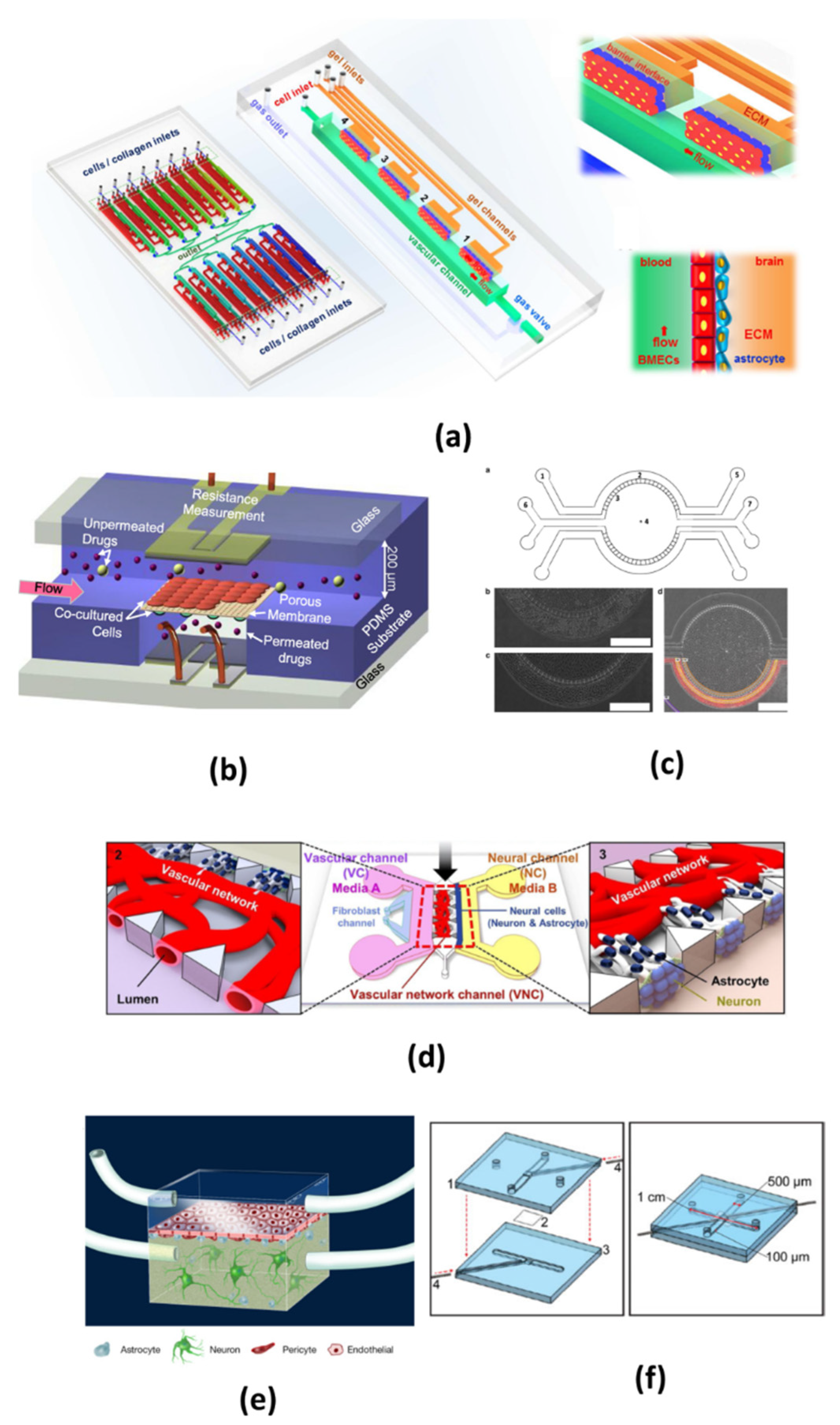

3.1. Design of Microfluidic Models

3.1.1. Chip Material

3.1.2. Porous Membranes

3.1.3. Endothelial Cells

3.1.4. Shear Stress

3.2. Assessment of Microfluidic Models

3.2.1. Determining Specific Tight Junction Markers

3.2.2. Trans-Epithelial Electric Resistance (TEER) Measurement

3.2.3. Permeability Assessment

3.3. Application of Microfluidic Models

4. Conclusions and Perspective

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cai, Z.; Qiao, P.F.; Wan, C.Q.; Cai, M.; Zhou, N.K.; Li, Q. Role of Blood-Brain Barrier in Alzheimer’s Disease. J. Alzheimers Dis. 2018, 63, 1223–1234. [Google Scholar] [CrossRef] [PubMed]

- Vargas-Osorio, Z.; Da Silva-Candal, A.; Piñeiro, Y.; Iglesias-Rey, R.; Sobrino, T.; Campos, F.; Castillo, J.; Rivas, J. Multifunctional Superparamagnetic Stiff Nanoreservoirs for Blood Brain Barrier Applications. Nanomaterials 2019, 9, 449. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, F.; Nishihara, H.; Kanda, T. Blood-brain barrier dysfunction in immuno-mediated neurological diseases. Immunol. Med. 2018, 41, 120–128. [Google Scholar] [CrossRef] [PubMed]

- Sharma, G.; Sharma, A.R.; Lee, S.S.; Bhattacharya, M.; Nam, J.S.; Chakraborty, C. Advances in nanocarriers enabled brain targeted drug delivery across blood brain barrier. Int. J. Pharm. 2019, 559, 360–372. [Google Scholar] [CrossRef] [PubMed]

- Abdullahi, W.; Tripathi, D.; Ronaldson, P.T. Blood-brain barrier dysfunction in ischemic stroke: Targeting tight junctions and transporters for vascular protection. Am. J. Physiol. Cell Physiol. 2018, 315, C343–C356. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Li, C.; Yuan, W.; Wu, J.; Li, J.; Li, Z.; Zhao, Y. Mild hypothermia alleviates brain oedema and blood-brain barrier disruption by attenuating tight junction and adherens junction breakdown in a swine model of cardiopulmonary resuscitation. PLoS ONE 2017, 12, e0174596. [Google Scholar] [CrossRef]

- Bhowmick, S.; D’Mello, V.; Caruso, D.; Wallerstein, A.; Abdul-Muneer, P.M. Impairment of pericyte-endothelium crosstalk leads to blood-brain barrier dysfunction following traumatic brain injury. Exp. Neurol. 2019, 317, 260–270. [Google Scholar] [CrossRef]

- Rajagopal, N.; Irudayanathan, F.J.; Nangia, S. Palmitoylation of Claudin-5 Proteins Influences Their Lipid Domain Affinity and Tight Junction Assembly at the Blood-Brain Barrier Interface. J. Phys. Chem. B 2019, 123, 983–993. [Google Scholar] [CrossRef]

- Iadecola, C. The Neurovascular Unit Coming of Age: A Journey through Neurovascular Coupling in Health and Disease. Neuron 2017, 96, 17–42. [Google Scholar] [CrossRef] [Green Version]

- Ozaki, T.; Nakamura, H.; Kishima, H. Therapeutic strategy against ischemic stroke with the concept of neurovascular unit. Neurochem. Int. 2019, 126, 246–251. [Google Scholar] [CrossRef]

- Guerra, M.; Blázquez, J.L.; Rodríguez, E.M. Blood-brain barrier and foetal-onset hydrocephalus, with a view on potential novel treatments beyond managing CSF flow. Fluids Barriers CNS 2017, 14, 19. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Kim, W.; Kim, Y.; Jeong, K.; Kang, C.S.; Kim, Y.; Koh, J.; Mahajan, S.D.; Prasad, P.N.; Kim, S. Multifunctional Photonics Nanoparticles for Crossing the Blood-Brain Barrier and Effecting Optically Trackable Brain Theranostics. Adv. Funct. Mater. 2016, 26, 7057–7066. [Google Scholar] [CrossRef] [PubMed]

- Miranda, A.; Cova, T.; Sousa, J.; Vitorino, C.; Pais, A. Computational modeling in glioblastoma: From the prediction of blood-brain barrier permeability to the simulation of tumor behavior. Future Med. Chem. 2018, 10, 121–131. [Google Scholar] [CrossRef] [PubMed]

- Rüber, T.; David, B.; Lüchters, G.; Nass, R.D.; Friedman, A.; Surges, R.; Stöcker, T.; Weber, B.; Deichmann, R.; Schlaug, G.; et al. Evidence for peri-ictal blood-brain barrier dysfunction in patients with epilepsy. Brain 2018, 141, 2952–2965. [Google Scholar] [CrossRef] [PubMed]

- Merali, Z.; Huang, K.; Mikulis, D.; Silver, F.; Kassner, A. Evolution of blood-brain-barrier permeability after acute ischemic stroke. PLoS ONE 2017, 12, e0171558. [Google Scholar] [CrossRef] [PubMed]

- Sweeney, M.D.; Sagare, A.P.; Zlokovic, B.V. Blood-brain barrier breakdown in Alzheimer disease and other neurodegenerative disorders. Nat. Rev. Neurol. 2018, 14, 133–150. [Google Scholar] [CrossRef]

- Akaishi, T.; Takahashi, T.; Nakashima, I. Oligoclonal bands and periventricular lesions in multiple sclerosis will not increase blood-brain barrier permeability. J. Neurol. Sci. 2018, 387, 129–133. [Google Scholar] [CrossRef]

- Galla, H.J. Monocultures of primary porcine brain capillary endothelial cells: Still a functional in vitro model for the blood-brain-barrier. J. Control. Release 2018, 285, 172–177. [Google Scholar] [CrossRef]

- Alluri, H.; Shaji, C.A.; Davis, M.L.; Tharakan, B.A. Mouse Controlled Cortical Impact Model of Traumatic Brain Injury for Studying Blood-Brain Barrier Dysfunctions. Methods Mol. Biol. 2018, 1717, 37–52. [Google Scholar]

- Zhong, Z.; Li, Z.; Chakrabarty, K.; Ho, T.Y.; Lee, C.Y. Micro-Electrode-Dot-Array Digital Microfluidic Biochips: Technology, Design Automation, and Test Techniques. IEEE Trans. Biomed. Circuits Syst. 2019, 13, 292–313. [Google Scholar] [CrossRef]

- Alam, M.K.; Koomson, E.; Zou, H.; Yi, C.; Li, C.W.; Xu, T.; Yang, M. Recent advances in microfluidic technology for manipulation and analysis of biological cells (2007–2017). Anal. Chim. Acta 2018, 1044, 29–65. [Google Scholar] [CrossRef] [PubMed]

- Chin, E.; Goh, E. Blood-brain barrier on a chip. Methods Cell Biol. 2018, 146, 159–182. [Google Scholar] [PubMed]

- Kuhnline Sloan, C.D.; Nandi, P.; Linz, T.H.; Aldrich, J.V.; Audus, K.L.; Lunte, S.M. Analytical and biological methods for probing the blood-brain barrier. Annu. Rev. Anal. Chem 2012, 5, 505–531. [Google Scholar] [CrossRef]

- Betzer, O.; Shilo, M.; Opochinsky, R.; Barnoy, E.; Motiei, M.; Okun, E.; Yadid, G.; Popovtzer, R. The effect of nanoparticle size on the ability to cross the blood-brain barrier: An in vivo study. Nanomedicine 2017, 12, 1533–1546. [Google Scholar] [CrossRef] [PubMed]

- Perrin, S. Preclinical research: Make mouse studies work. Nature 2017, 507, 423–425. [Google Scholar] [CrossRef] [PubMed]

- Pandey, P.K.; Sharma, A.K.; Gupta, U. Blood brain barrier: An overview on strategies in drug delivery, realistic in vitro modeling and in vivo live tracking. Tissue Barriers 2015, 4, e1129476. [Google Scholar] [CrossRef] [PubMed]

- Gaston, J.D.; Bischel, L.L.; Fitzgerald, L.A.; Cusick, K.D.; Ringeisen, B.R.; Pirlo, R.K. Gene Expression Changes in Long-Term In Vitro Human Blood-Brain Barrier Models and Their Dependence on a Transwell Scaffold Material. J. Healthc. Eng. 2017, 2017, 5740975. [Google Scholar] [CrossRef]

- Hatherell, K.; Couraud, P.O.; Romero, I.A.; Weksler, B.; Pilkington, G.J. Development of a three-dimensional, all-human in vitro model of the blood-brain barrier using mono-, co-, and tri-cultivation Transwell models. J. Neurosci. Methods 2011, 199, 223–229. [Google Scholar] [CrossRef]

- Kaisar, M.A.; Sajja, R.K.; Prasad, S.; Abhyankar, V.V.; Liles, T.; Cucullo, L. New experimental models of the blood-brain barrier for CNS drug discovery. Expert Opin. Drug Discov. 2017, 12, 89–103. [Google Scholar] [CrossRef]

- Czupalla, C.J.; Liebner, S.; Devraj, K. In vitro models of the blood-brain barrier. Methods Mol. Biol. 2014, 1135, 415–437. [Google Scholar]

- Humpel, C. Organotypic brain slice cultures: A review. Neuroscience 2015, 305, 86–98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morin-Brureau, M.; De Bock, F.; Lerner-Natoli, M. Organotypic brain slices: A model to study the neurovascular unit micro-environment in epilepsies. Fluids Barriers CNS 2013, 10, 11. [Google Scholar] [CrossRef] [PubMed]

- Alcendor, D.J.; Block, F.E., 3rd; Cliffel, D.E.; Daniels, J.S.; Ellacott, K.L.; Goodwin, C.R.; Hofmeister, L.H.; Li, D.; Markov, D.A.; May, J.C.; et al. Neurovascular unit on a chip: Implications for translational applications. Stem Cell Res. Ther. 2013, 4, S18. [Google Scholar] [CrossRef] [PubMed]

- Wolff, A.; Antfolk, M.; Brodin, B.; Tenje, M. In Vitro Blood-Brain Barrier Models-An Overview of Established Models and New Microfluidic Approaches. J. Pharm. Sci. 2015, 104, 2727–2746. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.D.; Khafagy, E.S.; Khanafer, K.; Takayama, S.; ElSayed, M.E. Organization of Endothelial Cells, Pericytes, and Astrocytes into a 3D Microfluidic in Vitro Model of the Blood-Brain Barrier. Mol. Pharm. 2016, 13, 895–906. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Li, Z.; Yu, Y.; Sizdahkhani, S.; Ho, W.S.; Yin, F.; Wang, L.; Zhu, G.; Zhang, M.; Jiang, L.; et al. A dynamic in vivo-like organotypic blood-brain barrier model to probe metastatic brain tumors. Sci. Rep. 2016, 6, 36670. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Booth, R.; Kim, H. Characterization of a microfluidic in vitro model of the blood-brain barrier (μBBB). Lab Chip 2012, 12, 1784–1792. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Chen, Y.; Cai, X.; Xu, R. Predict drug permeability to blood-brain-barrier from clinical phenotypes: Drug side effects and drug indications. Bioinformatics 2017, 33, 901–908. [Google Scholar] [CrossRef]

- Toropov, A.A.; Toropova, A.P.; Beeg, M.; Gobbi, M.; Salmona, M. QSAR model for blood-brain barrier permeation. J. Pharmacol. Toxicol. Methods 2017, 88, 7–18. [Google Scholar] [CrossRef]

- Brown, J.A.; Pensabene, V.; Markov, D.A.; Allwardt, V.; Neely, M.D.; Shi, M.; Britt, C.M.; Hoilett, O.S.; Yang, Q.; Brewer, B.M.; et al. Recreating blood-brain barrier physiology and structure on chip: A novel neurovascular microfluidic bioreactor. Biomicrofluidics 2015, 9, 054124. [Google Scholar] [CrossRef] [Green Version]

- Virumbrales-Muñoz, M.; Ayuso, J.M.; Lacueva, A.; Randelovic, T.; Livingston, M.K.; Beebe, D.J.; Oliván, S.; Pereboom, D.; Doblare, M.; Fernández, L.; et al. Enabling cell recovery from 3D cell culture microfluidic devices for tumour microenvironment biomarker profiling. Sci. Rep. 2019, 9, 6199. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shang, M.; Soon, R.H.; Lim, C.T.; Khoo, B.L.; Han, J. Microfluidic modelling of the tumor microenvironment for anti-cancer drug development. Lab Chip 2019, 19, 369–386. [Google Scholar] [CrossRef] [PubMed]

- Michna, R.; Gadde, M.; Ozkan, A.; DeWitt, M.; Rylander, M. Vascularized microfluidic platforms to mimic the tumor microenvironment. Biotechnol. Bioeng. 2018, 115, 2793–2806. [Google Scholar] [CrossRef] [PubMed]

- Smith, G.D.; Takayama, S. Application of microfluidic technologies to human assisted reproduction. Mol. Hum. Reprod. 2017, 23, 257–268. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kou, S.; Cheng, D.; Sun, F.; Hsing, I.M. Microfluidics and microbial engineering. Lab Chip 2016, 16, 432–446. [Google Scholar] [CrossRef]

- Liu, Z.; Han, X.; Qin, L. Recent Progress of Microfluidics in Translational Applications. Adv. Healthc. Mater. 2016, 5, 871–888. [Google Scholar] [CrossRef]

- An, F.; Qu, Y.; Liu, X.; Zhong, R.; Luo, Y. Organ-on-a-Chip: New Platform for Biological Analysis. Anal. Chem. Insights 2015, 10, 39–45. [Google Scholar] [CrossRef] [Green Version]

- Sivandzade, F.; Cucullo, L. In-vitro blood-brain barrier modeling: A review of modern and fast-advancing technologies. J. Cereb. Blood Flow Metab. 2018, 38, 1667–1681. [Google Scholar] [CrossRef]

- Thompson, A.J.; Ma, L.J.; Plegue, T.J.; Potkay, J.A. Design Analysis and Optimization of a Single-Layer PDMS Microfluidic Artificial Lung. IEEE Trans. Biomed. Eng. 2019, 66, 1082–1093. [Google Scholar] [CrossRef]

- Wilmer, M.J.; Ng, C.P.; Lanz, H.L.; Vulto, P.; Suter-Dick, L.; Masereeuw, R. Kidney-on-a-Chip Technology for Drug-Induced Nephrotoxicity Screening. Trends. Biotechnol. 2016, 34, 156–170. [Google Scholar] [CrossRef]

- Wilhelm, I.; Krizbai, I.A. In vitro models of the blood-brain barrier for the study of drug delivery to the brain. Mol. Pharm. 2014, 11, 1949–1963. [Google Scholar] [CrossRef] [PubMed]

- Faustino, V.; Catarino, S.O.; Lima, R.; Minas, G. Biomedical microfluidic devices by using low-cost fabrication techniques: A review. J. Biomech. 2016, 49, 2280–2292. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Takano, A.; Ogawa, T.; Tanaka, M.; Futai, N. On-chip incubation system for long-term microfluidic cell culture. Conf. Proc. IEEE Eng. Med. Biol. Soc. 2011, 2011, 8404–8407. [Google Scholar] [PubMed]

- Jenkins, G. Rapid prototyping of PDMS devices using SU-8 lithography. Methods Mol. Biol. 2013, 949, 153–168. [Google Scholar] [PubMed]

- Menon, N.V.; Chuah, Y.J.; Cao, B.; Lim, M.; Kang, Y. A microfluidic co-culture system to monitor tumor-stromal interactions on a chip. Biomicrofluidics 2014, 8, 064118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Du, G.; Fang, Q.; den Toonder, J.M. Microfluidics for cell-based high throughput screening platforms—A review. Anal. Chim. Acta 2016, 903, 36–50. [Google Scholar] [CrossRef] [PubMed]

- Wong, I.; Ho, C.M. Surface molecular property modifications for poly(dimethylsiloxane) (PDMS) based microfluidic devices. Microfluid. Nanofluid. 2009, 7, 291–306. [Google Scholar] [CrossRef] [Green Version]

- Booth, R.; Kim, H. Permeability analysis of neuroactive drugs through a dynamic microfluidic in vitro blood-brain barrier model. Ann. Biomed. Eng. 2014, 42, 2379–2391. [Google Scholar] [CrossRef]

- Terrell-Hall, T.B.; Ammer, A.G.; Griffith, J.I.; Lockman, P.R. Permeability across a novel microfluidic blood-tumor barrier model. Fluids Barriers CNS 2017, 14, 3. [Google Scholar] [CrossRef]

- Bang, S.; Lee, S.R.; Ko, J.; Son, K.; Tahk, D.; Ahn, J.; Im, C.; Jeon, N.L. A Low Permeability Microfluidic Blood-Brain Barrier Platform with Direct Contact between Perfusable Vascular Network and Astrocytes. Sci. Rep. 2017, 7, 8083. [Google Scholar] [CrossRef]

- Brown, J.A.; Codreanu, S.G.; Shi, M.; Sherrod, S.D.; Markov, D.A.; Neely, M.D.; Britt, C.M.; Hoilett, O.S.; Reiserer, R.S.; Samson, P.C.; et al. Metabolic consequences of inflammatory disruption of the blood-brain barrier in an organ-on-chip model of the human neurovascular unit. J. Neuroinflamm. 2016, 13, 306. [Google Scholar] [CrossRef] [PubMed]

- Griep, L.M.; Wolbers, F.; de Wagenaar, B.; ter Braak, P.M.; Weksler, B.B.; Romero, I.A.; Couraud, P.O.; Vermes, I.; van der Meer, A.D.; van den Berg, A. BBB on chip: Microfluidic platform to mechanically and biochemically modulate blood-brain barrier function. Biomed. Microdevices 2013, 15, 145–150. [Google Scholar] [CrossRef] [PubMed]

- Achyuta, A.K.; Conway, A.J.; Crouse, R.B.; Bannister, E.C.; Lee, R.N.; Katnik, C.P.; Behensky, A.A.; Cuevas, J.; Sundaram, S.S. A modular approach to create a neurovascular unit-on-a-chip. Lab Chip 2013, 13, 542–553. [Google Scholar] [CrossRef] [PubMed]

- Prabhakarpandian, B.; Shen, M.C.; Nichols, J.B.; Mills, I.R.; Sidoryk-Wegrzynowicz, M.; Aschner, M.; Pant, K. SyM-BBB: A microfluidic Blood Brain Barrier model. Lab Chip 2013, 13, 1093–1101. [Google Scholar] [CrossRef] [PubMed]

- Sellgren, K.L.; Hawkins, B.T.; Grego, S. An optically transparent membrane supports shear stress studies in a three-dimensional microfluidic neurovascular unit model. Biomicrofluidics 2015, 9, 061102. [Google Scholar] [CrossRef] [Green Version]

- Raasch, M.; Rennert, K.; Jahn, T.; Gärtner, C.; Schönfelder, G.; Huber, O.; Seiler, A.E.; Mosig, A.S. An integrative microfluidically supported in vitro model of an endothelial barrier combined with cortical spheroids simulates effects of neuroinflammation in neocortex development. Biomicrofluidics 2016, 10, 044102. [Google Scholar] [CrossRef] [PubMed]

- Walter, F.R.; Valkai, S.; Kincses, A.; Petneházi, A.; Czeller, T.; Veszelka, S.; Ormos, P.; Deli, M.A.; Dér, A. A versatile lab-on-a-chip tool for modeling biological barriers. Sens. Actuators B 2016, 222, 1209–1219. [Google Scholar] [CrossRef] [Green Version]

- Herland, A.; van der Meer, A.D.; FitzGerald, E.A.; Park, T.E.; Sleeboom, J.J.; Ingber, D.E. Distinct Contributions of Astrocytes and Pericytes to Neuroinflammation Identified in a 3D Human Blood-Brain Barrier on a Chip. PLoS ONE 2016, 11, e0150360. [Google Scholar] [CrossRef]

- Van der Helm, M.W.; Odijk, M.; Frimat, J.P.; van der Meer, A.D.; Eijkel, J.C.T.; van den Berg, A.; Segerink, L.I. Direct quantification of transendothelial electrical resistance in organs-on-chips. Biosens. Bioelectron. 2016, 85, 924–929. [Google Scholar] [CrossRef] [Green Version]

- van der Helm, M.W.; Odijk, M.; Frimat, J.P.; van der Meer, A.D.; Eijkel, J.C.T.; van den Berg, A.; Segerink, L.I. Fabrication and Validation of an Organ-on-chip System with Integrated Electrodes to Directly Quantify Transendothelial Electrical Resistance. J. Vis. Exp. 2017, 127, e56334. [Google Scholar] [CrossRef]

- Falanga, A.P.; Pitingolo, G.; Celentano, M.; Cosentino, A.; Melone, P.; Vecchione, R.; Guarnieri, D.; Netti, P.A. Shuttle-mediated nanoparticle transport across an in vitro brain endothelium under flow conditions. Biotechnol. Bioeng. 2017, 114, 1087–1095. [Google Scholar] [CrossRef] [PubMed]

- Adriani, G.; Ma, D.; Pavesi, A.; Kamm, R.D.; Goh, E.L. A 3D neurovascular microfluidic model consisting of neurons, astrocytes and cerebral endothelial cells as a blood-brain barrier. Lab Chip 2017, 17, 448–459. [Google Scholar] [CrossRef] [PubMed]

- DeStefano, J.G.; Xu, Z.S.; Williams, A.J.; Yimam, N.; Searson, P.C. Effect of shear stress on iPSC-derived human brain microvascular endothelial cells (dhBMECs). Fluids Barriers CNS 2017, 14, 20. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.I.; Abaci, H.E.; Shuler, M.L. Microfluidic blood-brain barrier model provides in vivo-like barrier properties for drug permeability screening. Biotechnol. Bioeng. 2017, 114, 184–194. [Google Scholar] [CrossRef] [PubMed]

- Bonakdar, M.; Graybill, P.M.; Davalos, R.V. A microfluidic model of the blood-brain barrier to study permeabilization by pulsed electric fields. RSC Adv. 2017, 7, 42811–42818. [Google Scholar] [CrossRef] [PubMed]

- Partyka, P.P.; Godsey, G.A.; Galie, J.R.; Kosciuk, M.C.; Acharya, N.K.; Nagele, R.G.; Galie, P.A. Mechanical stress regulates transport in a compliant 3D model of the blood-brain barrier. Biomaterials 2017, 115, 30–39. [Google Scholar] [CrossRef]

- Jeong, S.; Kim, S.; Buonocore, J.; Park, J.; Welsh, C.J.; Li, J.; Han, A. A Three-Dimensional Arrayed Microfluidic Blood-Brain Barrier Model with Integrated Electrical Sensor Array. IEEE Trans. Biomed. Eng. 2018, 65, 431–439. [Google Scholar] [CrossRef]

- Tibbe, M.P.; Leferink, A.M.; van den Berg, A.; Eijkel, J.C.T.; Segerink, L.I. Microfluidic Gel Patterning Method by Use of a Temporary Membrane for Organ-On-Chip Applications. Adv. Mater. Technol. 2018, 3, 1700200. [Google Scholar] [CrossRef]

- Marino, A.; Tricinci, O.; Battaglini, M.; Filippeschi, C.; Mattoli, V.; Sinibaldi, E.; Ciofani, G. A 3D Real-Scale, Biomimetic, and Biohybrid Model of the Blood-Brain Barrier Fabricated through Two-Photon Lithography. Small 2018, 14, 1702959. [Google Scholar] [CrossRef]

- Wevers, N.R.; Kasi, D.G.; Gray, T.; Wilschut, K.J.; Smith, B.; van Vught, R.; Shimizu, F.; Sano, Y.; Kanda, T.; Marsh, G.; et al. A perfused human blood-brain barrier on-a-chip for high-throughput assessment of barrier function and antibody transport. Fluids Barriers CNS 2018, 15, 23. [Google Scholar] [CrossRef]

- Sahore, V.; Doonan, S.R.; Bailey, R.C. Droplet Microfluidics in Thermoplastics: Device Fabrication, Droplet Generation, and Content Manipulation using Integrated Electric and Magnetic Fields. Anal. Methods 2018, 10, 4264–4274. [Google Scholar] [CrossRef] [PubMed]

- Matellan, C.; Del Río Hernández, A.E. Cost-effective rapid prototyping and assembly of poly(methyl methacrylate) microfluidic devices. Sci. Rep. 2018, 8, 6971. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shao, J.; Wu, L.; Wu, J.; Zheng, Y.; Zhao, H.; Jin, Q.; Zhao, J. Integrated microfluidic chip for endothelial cells culture and analysis exposed to a pulsatile and oscillatory shear stress. Lab Chip 2009, 9, 3118–3125. [Google Scholar] [CrossRef] [PubMed]

- Fotticchia, I.; Guarnieri, D.; Fotticchia, T.; Falanga, A.P.; Vecchione, R.; Giancola, C.; Netti, P.A. Energetics of ligand-receptor binding affinity on endothelial cells: An in vitro model. Colloids Surf. B Biointerfaces 2016, 144, 250–256. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Du, S.; Lu, Y.; Jia, S.; Zhao, M.; Bai, J.; Li, P.; Wu, H. Influence of paeoniflorin and menthol on puerarin transport across MDCK and MDCK-MDR1 cells as blood-brain barrier in vitro model. J. Pharm. Pharmacol. 2018, 70, 349–360. [Google Scholar] [CrossRef] [PubMed]

- Henderson, J.T.; Piquette-Miller, M. Blood-brain barrier: An impediment to neuropharmaceuticals. Clin. Pharmacol. Ther. 2015, 97, 308–313. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Mei, S.; Jin, H.; Zhu, B.; Tian, Y.; Huo, J.; Cui, X.; Guo, A.; Zhao, Z. Identification of two immortalized cell lines, ECV304 and bEnd3, for in vitro permeability studies of blood-brain barrier. PLoS ONE 2017, 12, e0187017. [Google Scholar] [CrossRef]

- Cucullo, L.; Hossain, M.; Puvenna, V.; Marchi, N.; Janigro, D. The role of shear stress in Blood-Brain Barrier endothelial physiology. BMC Neurosci. 2011, 12, 40. [Google Scholar] [CrossRef] [PubMed]

- Papademetriou, I.; Vedula, E.; Charest, J.; Porter, T. Effect of flow on targeting and penetration of angiopep- decorated nanoparticles in a microfluidic model blood-brain barrier. PLoS ONE 2018, 13, e0205158. [Google Scholar] [CrossRef]

- Wong, A.D.; Ye, M.; Levy, A.F.; Rothstein, J.D.; Bergles, D.E.; Searson, P.C. The blood-brain barrier: An engineering perspective. Front. Neuroeng. 2013, 6, 7. [Google Scholar] [CrossRef]

- Deosarkar, S.P.; Prabhakarpandian, B.; Wang, B.; Sheffield, J.B.; Krynska, B.; Kiani, M.F. A Novel Dynamic Neonatal Blood-Brain Barrier on a Chip. PLoS ONE 2015, 10, e0142725. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Guo, D.; Xiong, L.; Wu, B.; Xu, X.; Fu, J.; Kong, L.; Liu, Z.; Xie, C. TLR4/PKCα/occludin signaling pathway may be related to blood-brain barrier damage. Mol. Med. Rep. 2018, 18, 1051–1057. [Google Scholar] [CrossRef] [PubMed]

- Greene, C.; Hanley, N.; Campbell, M. Claudin-5: Gatekeeper of neurological function. Fluids Barriers CNS 2019, 16, 3. [Google Scholar] [CrossRef] [PubMed]

- De Lange, E.C.M.; Vd Berg, D.J.; Bellanti, F.; Voskuyl, R.A.; Syvänen, S. P-glycoprotein protein expression versus functionality at the blood-brain barrier using immunohistochemistry, microdialysis and mathematical modeling. Eur. J. Pharm. Sci. 2018, 124, 61–70. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, B.; Kolli, A.R.; Esch, M.B.; Abaci, H.E.; Shuler, M.L.; Hickman, J.J. TEER measurement techniques for in vitro barrier model systems. J. Lab. Autom. 2015, 20, 107–126. [Google Scholar] [CrossRef] [PubMed]

- Hajal, C.; Campisi, M.; Mattu, C.; Chiono, V.; Kamm, R.D. In vitro models of molecular and nano-particle transport across the blood-brain barrier. Biomicrofluidics 2018, 12, 042213. [Google Scholar] [CrossRef] [PubMed]

- Odijk, M.; van der Meer, A.D.; Levner, D.; Kim, H.J.; van der Helm, M.W.; Segerink, L.I.; Frimat, J.P.; Hamilton, G.A.; Ingber, D.E.; van den Berg, A. Measuring direct current trans-epithelial electrical resistance in organ-on-a-chip microsystems. Lab Chip 2015, 15, 745–752. [Google Scholar] [CrossRef]

- Patel, M.M.; Patel, B.M. Crossing the Blood-Brain Barrier: Recent Advances in Drug Delivery to the Brain. CNS Drugs 2017, 31, 109–133. [Google Scholar] [CrossRef]

- Battiston, K.G.; Cheung, J.W.; Jain, D.; Santerre, J.P. Biomaterials in co-culture systems: Towards optimizing tissue integration and cell signaling within scaffolds. Biomaterials 2014, 35, 4465–4476. [Google Scholar] [CrossRef]

- Geraili, A.; Jafari, P.; Hassani, M.S.; Araghi, B.H.; Mohammadi, M.H.; Ghafari, A.M.; Tamrin, S.H.; Modarres, H.P.; Kolahchi, A.R.; Ahadian, S.; et al. Controlling Differentiation of Stem Cells for Developing Personalized Organ-on-Chip Platforms. Adv. Healthc. Mater. 2017, 1700426. [Google Scholar] [CrossRef]

- Tazawa, H.; Sunaoshi, S.; Tokeshi, M.; Kitamori, T.; Ohtani-Kaneko, R. An Easy-to-Use Polystyrene Microchip-based Cell Culture System. Anal. Sci. 2016, 32, 349–353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Source | Main Character of Chip Design | Source of Endothelial Cells | Co-Cultured Cells | Character of Membranes | Protein Used for Channel Coating | Electrode in Chip | Markers Used in Tight Junction Determination | TEER Value of the Models | Molecule Used in Permeability Test | Application |

|---|---|---|---|---|---|---|---|---|---|---|

| Ref. [36] | 16 independent function units, each unit consists of four uniform BBB regions, replicate the complex multicellular architecture, mechanical properties, 3D extracellular matrix | Primary rat BMECs | Primary rat astrocytes | No membrane | Rat tail type-I collagen | No electrode in chip, normal resistance meter | VE-Cadherin, ZO-1, Claunin-5, etc. (immunofluorescence staining) | 1298 Ω∙cm2 | Sodium fluorescein (376 Da) | Examination of brain metastasis and the therapeutic response of brain tumors |

| Ref. [40] | Three PDMS layers plus the PC membrane that divides the two chambers. | Primary human BMECs | Primary pericytes, Primary astrocytes and pluripotent stem cell -derived neurons | PC membrane (0.2 μm pores) | Laminin | 23 ga stainless steel, not in chip | ZO-1 (immunofluorescence staining) | Reported in Ω/cm2, need to be converted | FITC-dextran (10 and 70 kDa) | Ascorbate transport across the BBB as an indication of active transport |

| Ref. [58] | Multi-layered channel structure made from patterned PDMS substrate with embedded electrode layers. | bEnd.3 cell line | Astrocytes C6 cell line | PC membrane (10 μm thick, 0.4 μm pores) | Poly-lysine and fibronectin | Two sets AgCl electrodes. | ZO-1 (immunofluorescence staining) | 223–280 Ω∙cm2 | Not used | Permeability of seven neuroactive drugs and TEER were quantified in models. |

| Ref. [59] | 3 μm pores to allow diffusion of media and tracer between the central and outer compartments | HUVECs | Astrocytes CTX-TNA2 cell line | 3 μm pores | Martrigel and fibronectin | No electrode | Not detected | Not measured | Texas red dextran (370 kDa) and rhodamine 123 | Comparing permeability of three passive permeability markers and one marker subject to efflux |

| Ref. [60] | Two separate microchannels supply their respective co-culture tissues independently of one another, and can serve as the microenvironment of the outside and the inside of the BBB respectively. | HUVECs and human lung fibroblasts | Primary rat astrocyte and neurons | No membrane, using fibrin hydrogel | Fibrin hydrogel | No electrode | ZO-1. (immunofluorescence staining) | Not measured | FITC-dextran (20 kDa, 70 kDa) | A platform exhibits direct contact between neural and vascular tissues and a corresponding low permeability characteristic of in vivo BBB |

| Ref. [61] | Two-chamber system divided by PC membrane | Primary human BMECs | Human induced pluripotent stem cell-derived neurons and astrocytes | PC membrane (0.2 μm pores) | Laminin | Custom-built multifrequency impedance analyzer | ZO-1, claudin -5 (immunofluorescence staining) | Reported in Ω, need to be converted | FITC-dextran (10 kDa) | Understand responses to inflammatory stimulation |

| Ref. [62] | Small model, two-layer microchannel and membrane with platinum electrodes. | hCMEC/D3 cell line | No co-cultured cells | PC membrane (10 μm thick, 0.4 μm pores) | Collagen I | Platinum electrodes (diameter 200 μm) | ZO-1 (immunofluorescence staining) | 36.9–120 Ω∙cm2 | Not used | Observe shear stress and TNF-α on BBB function |

| Ref. [63] | Vascular conduit overlaid on top of a neural chamber separated by a PC membrane | RBE4 cell line | Mixture of neurons (4%), astrocytes (95%), and microglia (1%). | PC membrane (8 μm pores) | Poly-lysine and fibronectin | No electrode | ZO-1 (western blot) | Not measured | Alexafluor-dextran (3 kDa) | TNF-α simulation triggered neuroinflammation |

| Ref. [64] | The apical and basolateral side separated by 3 μm gaps formed by microfabricated pillars. | RBE4 cell line | No co-cultured cells | No membrane, micro-gaps (50 μm long, 3 μm wide, 3 μm deep) in PDMS wall | Fibronectin | No electrode | ZO-1, claudin (western blot) and P-glycoprotein protein efflux | Not measured | FITC- dextran (3–5 kDa) | Astrocyte-conditioned medium on BBB function |

| Ref. [65] | Two-compartment microfluidic devices were a membrane between two channels. | bEnd.3 cell line | C8D1A astrocytes cell line | PTFE or PE membrane (0.4 μm pores) | Fibronectin or collagen I | No electrode | Claudin-5 (immunofluorescence staining) | Not measured | FITC-dextran (70 kDa) | Study the optically transparent membrane used in models |

| Ref. [66] | Composed of an upper and a lower part that are combined with an adhesive film, three microchannel systems are integrated | hCMEC/D3 cell line | Mouse embryonic stem cells derived cortical spheroids | Polyethylene terephthalate membrane and PC membrane | Collagen A | No electrode | VE cadherin, ᵦ-catenin, ZO-1 (immunofluorescence staining) | Not measured | FITC-dextran (3 kDa) | Detect effects of neuroinflammation upon disruption of the endothelial layer in response to inflammatory signals. |

| Ref. [67] | The porous membrane is situated between the upper and the lower channels made of PDMS. This core is sandwiched by two glass slides with gold electrodes. | hCMEC/D3 cell line, primary rat brain endothelial cells | primary astrocytes and brain pericytes. | PET membrane, (23 μm thick, 0.45 μm pores, pore density 2 × 106/cm2) | Rat tail collagen | A pair of 25-nm thick, transparent, gold electrodes was formed on each glass slide | ᵦ-catenin, ZO-1 (immunofluorescence staining) | monolayer: 28.5 ± 7.2 Ω∙cm2 Co-culture: 114.2 ± 35.7 Ω∙cm2 | Sodium fluorescein (376 Da), FITC- dextran (4.4 kDa), Evans blue-labeled albumin (67 kDa) | Design a new device, which can co-culture of 3 types of cells, observe the cells by microscopy, monitor the TEER, and measure the monolayer permeability |

| Ref. [68] | Creating a cylindrical collagen gel containing a central hollow lumen inside a microchannel | Primary human BMECs | Primary human brain pericytes, primary human brain astrocytes | No membrane | Rat tail collagen I | No electrode | VEcadherin, ZO-1 (immunofluorescence staining) | Not measured | Alexa488- dextran (3 kDa) | Study the secretion profiles of G-CSF, IL-6 and IL-8 when the BBB stimulated with TNF-α |

| Ref. [69,70] | Two PDMS components are separated by PC membrane and form two-chamber system | hCMEC/D3 cell line | No co-cultured cells | PC membrane (0.4 μm pores) | Fibronectin | Four platinum wire electrodes inserted into two channels | ZO-1 (immunofluorescence staining) | 22 ± 1.3 Ω∙cm2 | Not used | Developed a stable and easily method to determine TEER in organ-on-chip applications. |

| Ref. [71] | Transparent polyester porous membrane sandwiched between a top and a bottom overlying channel made of PMMA. | bEnd.3 cell line | No co-cultured cells | Polyester membrane (3 μm pores) | Not used | Platinum electrodes | Claudin-5 (immunofluorescence staining) | About 1000 Ω∙cm2 | FITC- bovine serum albumin | Test the ability of a peptide to transport nanoparticles across BBB under flow conditions. |

| Ref. [72] | Two central hydrogel regions for co-culturing astrocytes and neurons, two side channels for hosting endothelial cells and media. | HUVECs and hCMEC/D3 cell line | Primary rat neurons and astrocytes | No membrane, separated by 9 trapezoidal structures | Poly-lysine and collagen I | No electrode | ZO-1 (immunofluorescence staining) | Not measured | Oregon green 488- dextran (10 kDa), Texas red dextran (70 kDa) | Compounds and factors on neural growth and maturation |

| Ref. [73] | Four rectangular channels with different heights to allow simultaneous measurements at different shear stresses. | Human BMECs from the BC1 human induced pluripotent stem cell line | No co-cultured cells | No membrane | Fibronectin and collagen IV | No electrode | claudin-5, occludin, and ZO-1 (immunofluorescence staining) | Not measured | Not used | Study the role of shear stress in modulating the character of human brain microvascular endothelial cells derived from induced pluripotent stem cells. |

| Ref. [74] | Consists of a cell insert and three 3D printed plastic layers with two electrodes | BMECs from human induced pluripotent stem cells | Primary rat astrocytes | PC membrane (0.4 μm pores) | Collagen IV and fibronectin | Two 0.8 mm diameter Ag/AgCl pellet electrode | ZO-1, Claunin-5. (immunofluorescence staining) | Peaked above 4000 Ω·cm2, sustained above 2000 Ω·cm2 | FITC-dextran (70, 20 and 4 kDa), Caffeine, cimetidine, and doxorubicin | Model research |

| Ref. [75] | A double layer microfluidic device with an embedded membrane, the top layer contains a single channel, the bottom channel contains an array of 6 channels | hCMEC | No co-cultured cells | Polyester membrane (0.4 μm pores) | Fibronectin | No electrode | Not detected | Not measured | fluorescent sodium salt (376 Da), FITC- dextran (70 kDa) | Pulsed electric fields may enhance drug delivery to the brain by disrupting the integrity of the BBB and allowing otherwise impermeable drugs to reach target areas. |

| Ref. [76] | Two isolated compartments with the hydrogel reservoir | hCMEC/D3 cell line | p5–p7 normal human astrocytes | No membrane | Collagen I, matrigel, hyaluronan | No electrode in chip, normal impedance spectroscopy | ZO-1. (immunofluorescence staining) | Static condition: about 200 Ω·cm2 flow condition: about 1000 Ω·cm2 | FITC-dextran (4 kDa) | Indicated that the mechanical stress exerted by blood flow is an important regulator of transport both across and along the walls of cerebral microvasculature. |

| Ref. [77] | A 4 × 4 intersecting microchannel array forms 16 BBB sites on a chip, with a multielectrode array integrated to measure the TEER from all 16 different sites. | Primary mouse BMECs | Primary mouse astrocytes | PC membrane (10 μm thick, 0.4 μm pores) | Fibronectin or matrigel | Multielectrode arrays, a thin titanium adhesion layer and a gold layer | ZO-1. (immunofluorescence staining) | Reported in Ω, need to be converted | Texas Red dextran (3 kDa), Alexa 546 dextran (10 kDa), FITC dextran (70 kDa) | Developed multisite BBB chip is expected to be used for screening drug by more accurately predicting their permeability through BBB as well as their toxicity. |

| Ref. [78] | Microchannel with temporary chitosan-based membrane | hCMEC/D3 cell line | P6-P10 human astrocytes from the cerebral cortex | temporary chitosan-based membrane | Hydrogel matrigel | No electrode | Not detected | Not measured | Not used | To obtain a co-culture without a nonphysiological membrane making use of a temporary chitosan membrane in a microfluidic channel. |

| Ref. [79] | Bio-printing, 10 μm average diameter tubes encasing a liquid flow having around 1 mm·s−1 average speed. On the surface of each tube regular pores allowing for mass transport. | bEnd.3 cell line | U87 glioblastoma cells | No membrane, porous tubular structures on tube surface (pore diameter: 1 μm) | Not used | No electrode in chip, commercially Voltohmmeter with two electrodes | ZO-1. (immunofluorescence staining) | 75 ± 2 Ω∙cm2 | Dextran | Presented a dynamic 3D biohybrid model of the BBB able to reproduce at 1:1 scale the capillaries of the neurovascular system. |

| Ref. [80] | High-throught, the model harbors 96 or 40 chips in a 384-well plate. In each chip, a perfused vessel of BMECs was grown against an extracellular matrix gel, astrocytes and pericytes were added on the other side of the gel to complete the BBB model. | Human TY10 cell line (isolated from normal brain tissue from a patient with meningioma) | Human hBPCT cell line pericytes from brain tissue of a patient t. Human hAst cell line astrocytes from human primary astrocytes distributed by Lonza. | No artificial membranes, using extracellular matrix gel | Collagen-I | No electrode | claudin-5, VE-cadherin, PECAM-1 (immunofluorescence staining) | Not measured | FITC-dextran (20 kDa) | Developed a high-throughput plate-based model, and used to assess passage of large biopharmaceuticals across the BBB. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Li, S.; Zheng, J.; Li, Y.; Huang, H. Recent Progress in Microfluidic Models of the Blood-Brain Barrier. Micromachines 2019, 10, 375. https://doi.org/10.3390/mi10060375

Jiang L, Li S, Zheng J, Li Y, Huang H. Recent Progress in Microfluidic Models of the Blood-Brain Barrier. Micromachines. 2019; 10(6):375. https://doi.org/10.3390/mi10060375

Chicago/Turabian StyleJiang, Lili, Shu Li, Junsong Zheng, Yan Li, and Hui Huang. 2019. "Recent Progress in Microfluidic Models of the Blood-Brain Barrier" Micromachines 10, no. 6: 375. https://doi.org/10.3390/mi10060375