Fabrication of Microwave Devices Based on Magnetic Nanowires Using a Laser-Assisted Process

Abstract

:1. Introduction

2. Results and Discussion

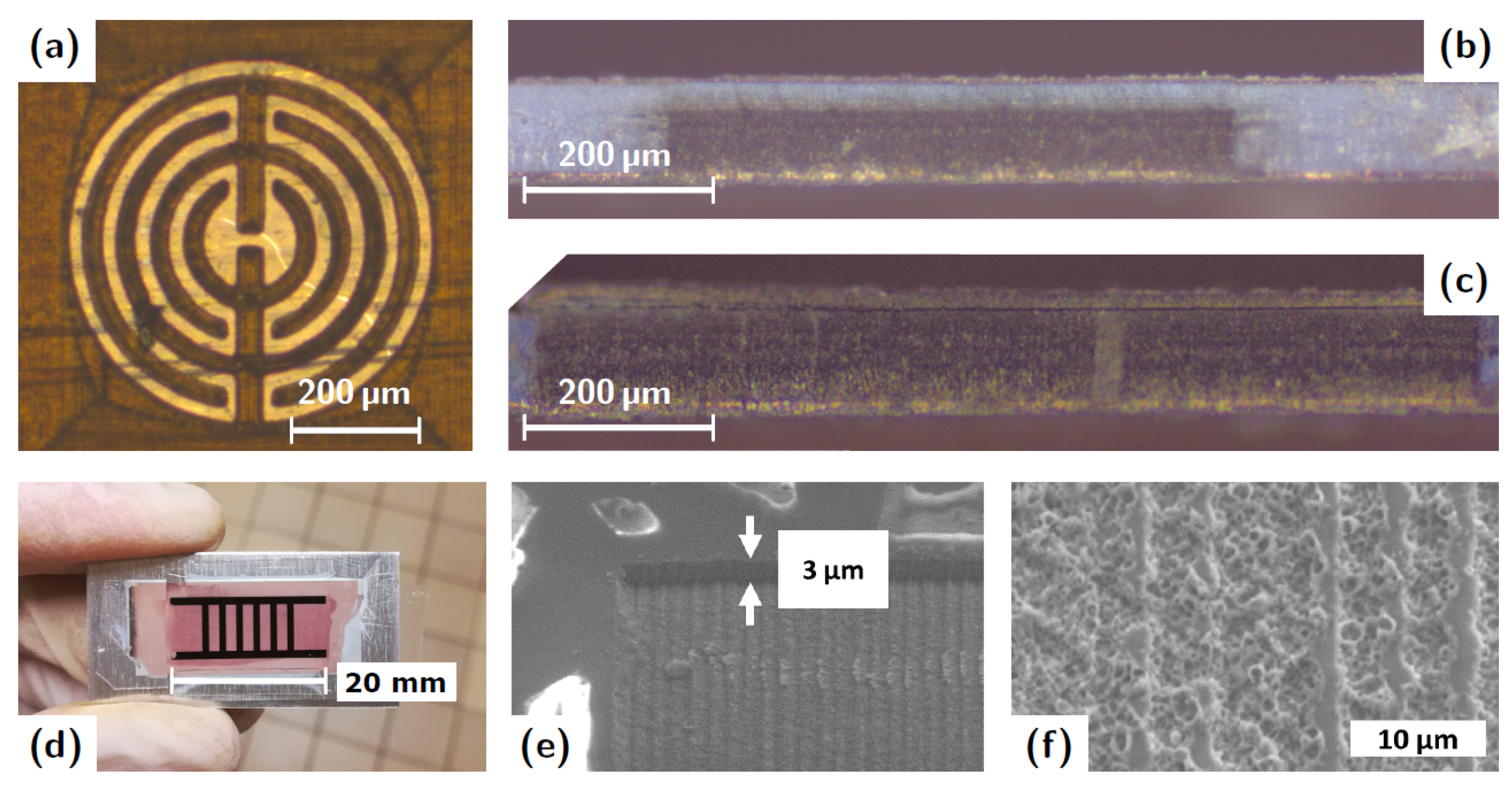

2.1. Nanowired Template

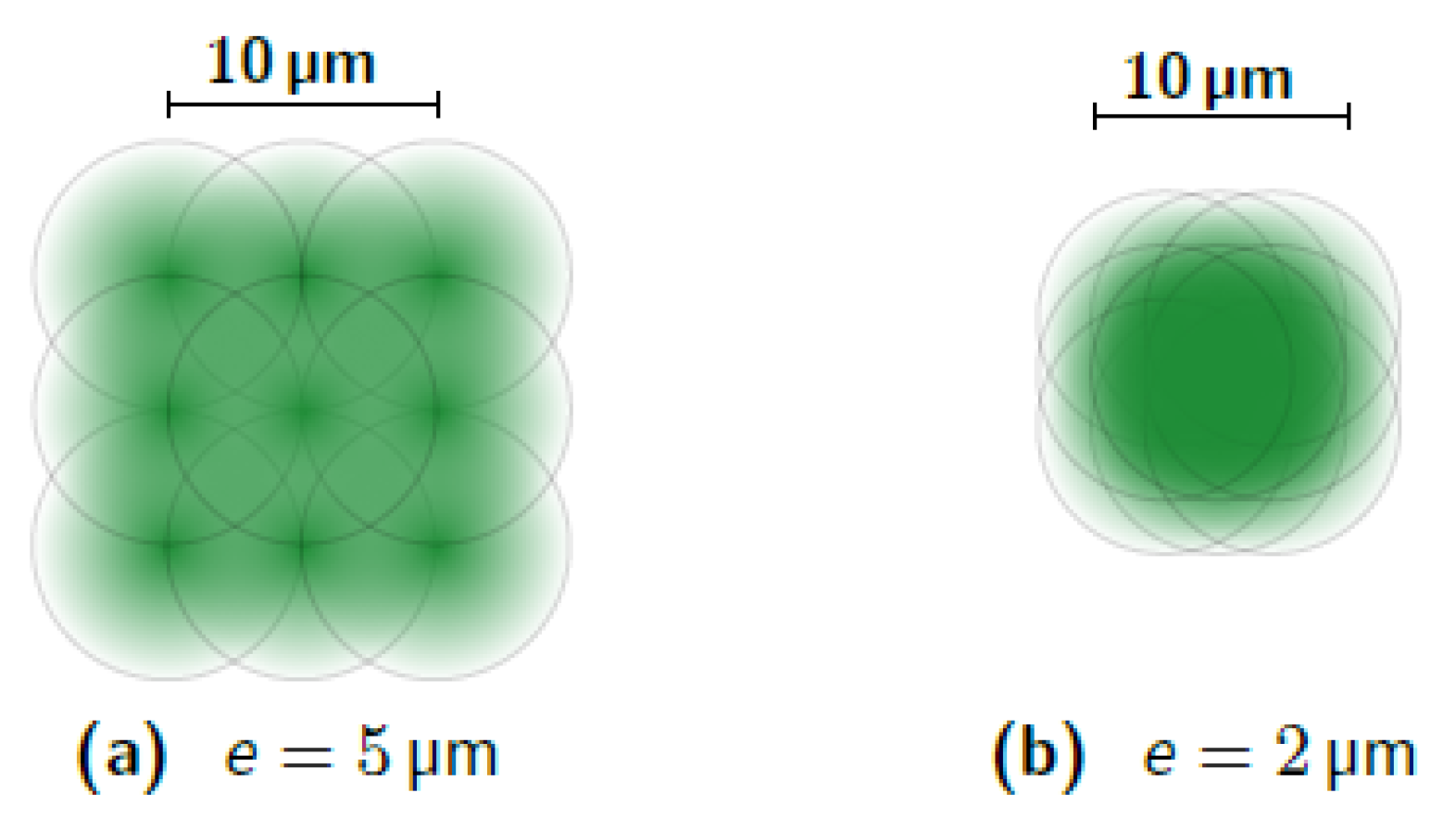

2.2. Design of NSIW Devices

2.3. Laser Etching Processes

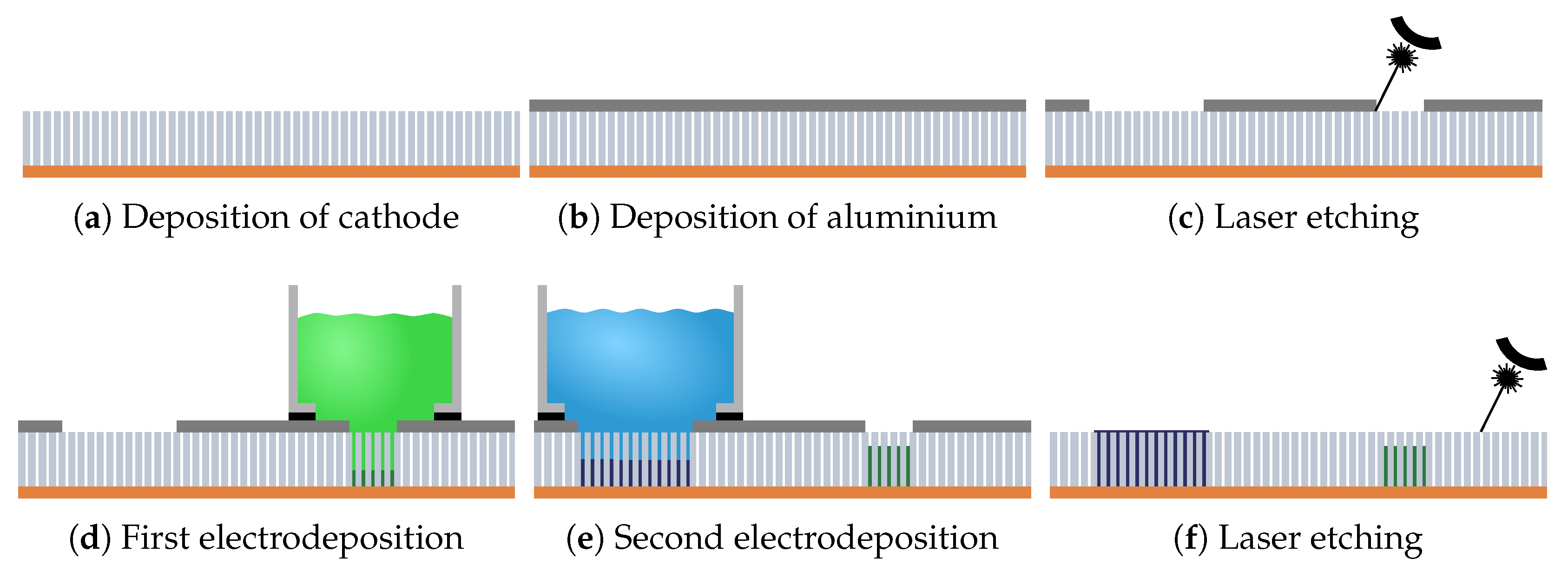

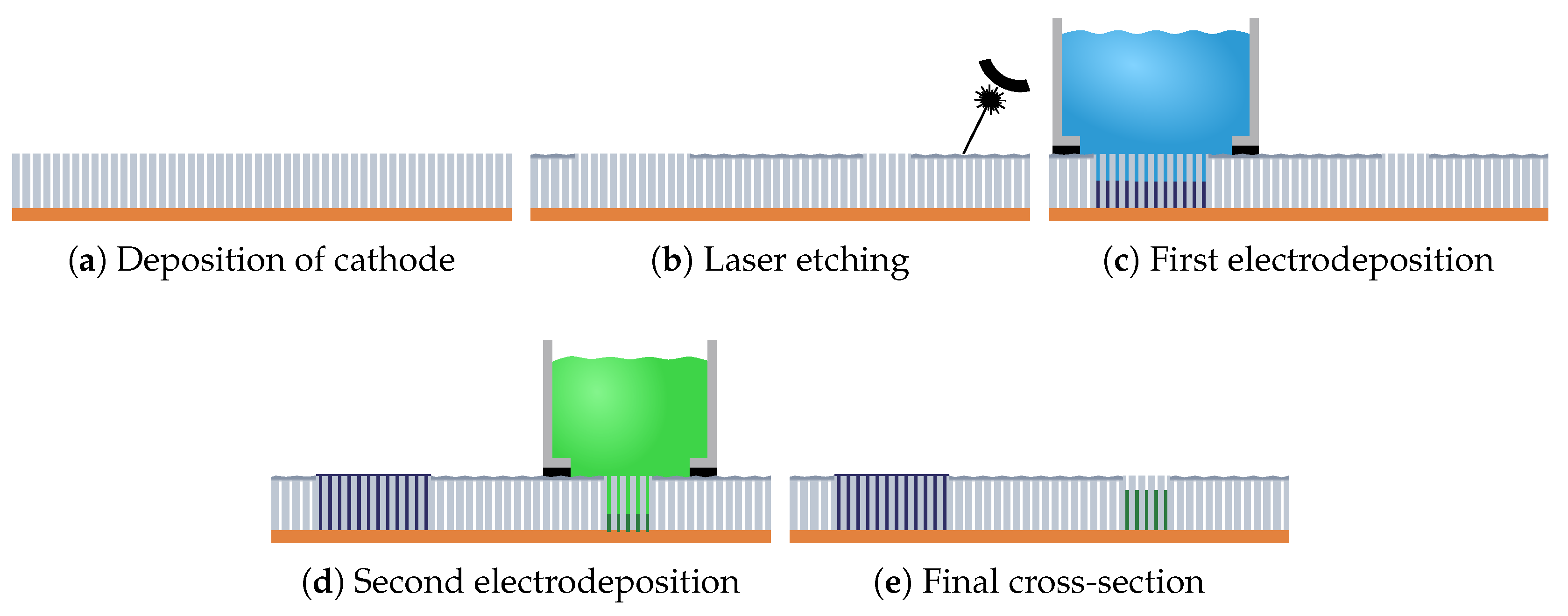

2.3.1. Laser Etching of Sacrificial Layer

2.3.2. Laser Etching of Pores

2.3.3. Comparison between LES and LEP Processes

2.4. Microwave Devices

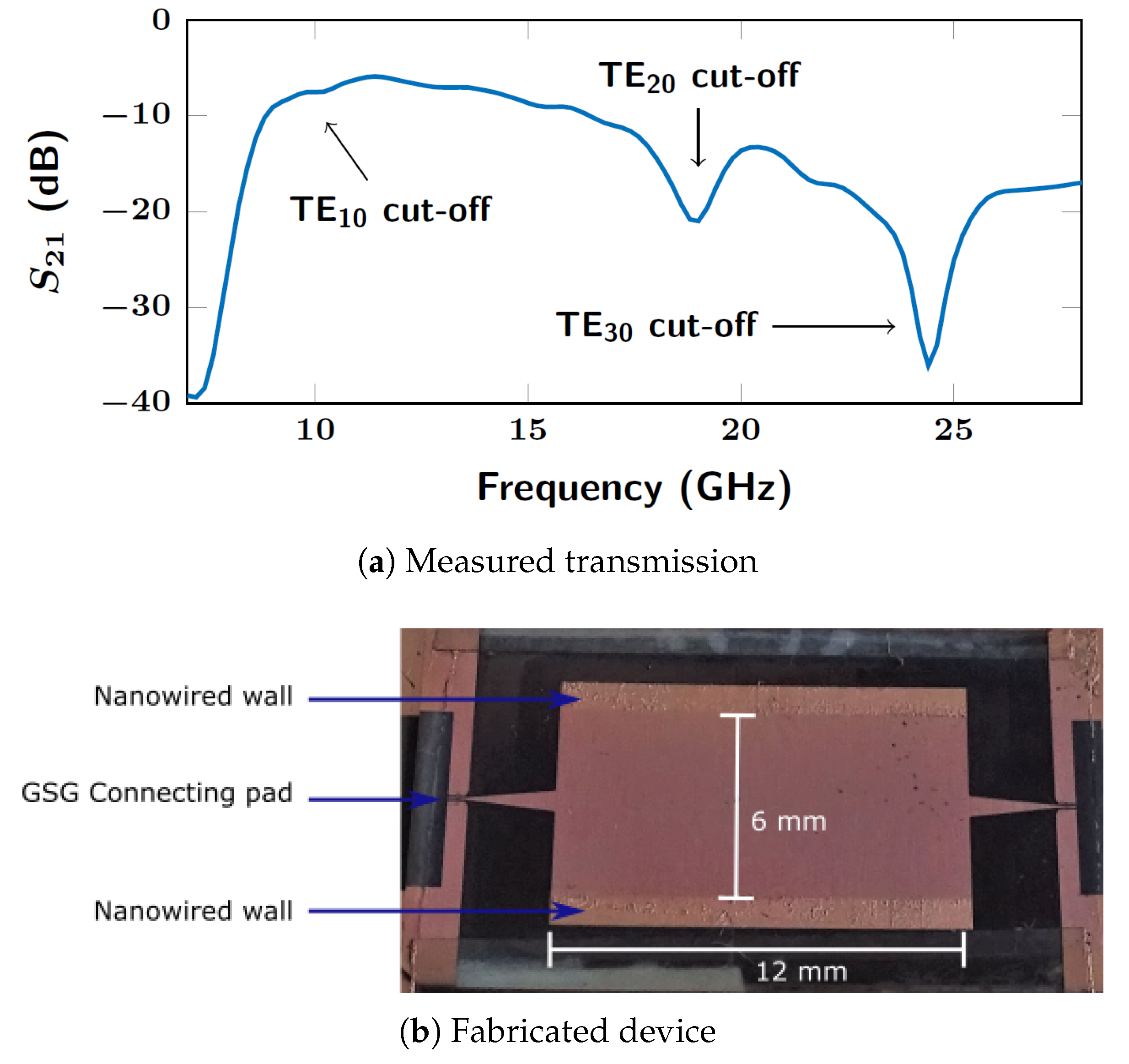

2.4.1. NSIW Line

2.4.2. NSIW Isolator

3. Materials and Methods

3.1. Nanoporous Template

3.2. Electrochemical Deposition Process (ECD)

- for NiFe nanowires:(1 M NiSO + 0.02 M FeSO + 0.5 M HBO), V = −1.05 V

- for Cu nanowires:(1 M Cu basis + 0.08 M HSO + chloride basis + organic additives), V = −0.015 VThe detailed composition of the Cu solution is a property of Sigma-Aldrich, Inc.

3.3. Pico-Second Laser System

3.4. Microwave Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AAO | Anodic Aluminium Oxide |

| CCD | Charge-Coupled-Device |

| CPW | Coplanar Waveguide |

| Cu | Copper |

| DUT | Device Under Test |

| EBG | Electromagnetic Band Gap |

| ECD | Electro-Chemical Deposition |

| GSG | Ground-Signal-Ground |

| IDE | Interdigitated Electrode |

| NiFe | nickel-iron alloy |

| MMIC | Monolithic Microwave Integrated Circuit |

| LEP | Laser Etching of Pores |

| LES | Laser Etching of Sacrificial layer |

| LTTC | Low Temperature Co-fired Ceramics |

| NW | Nanowire |

| NSIW | Nanowired Substrate Integrated Waveguide |

| OM | Optical Microscope |

| PCB | Printed Circuits Boards |

| RF | Radio Frequency |

| SEM | Scanning Electron Microscope |

| SOLT | Short-Open-Line-Thru |

| SIW | Substrate Integrated Waveguide |

| VNA | Vector Network Analyzer |

References

- Qiao, L.; Han, X.; Gao, B.; Wang, J.; Wen, F.; Li, F. Microwave absorption properties of the hierarchically branched Ni nanowire composites. J. Appl. Phys. 2009, 105, 053911. [Google Scholar] [CrossRef]

- Chen, W.; Han, M.; Deng, L. High frequency microwave absorbing properties of cobalt nanowires with transverse magnetocrystalline anisotropy. Phys. B Condens. Matter 2010, 405, 1484–1488. [Google Scholar] [CrossRef]

- Hamoir, G.; Piraux, L.; Huynen, I. Q-factor improvement of integrated inductors using high aspect ratio ferromagnetic nanowires. Microw. Opt. Technol. Lett. 2012, 54, 1484–1488. [Google Scholar] [CrossRef]

- Kuanr, B.; Veerakumar, V.; Marson, R.; Mishra, S.; Kuanr, A.; Camley, R.; Celinski, Z. Nickel Nano-Wires Filled Alumina Templates for Microwave Electronics. IEEE Trans. Magn. Lett. 2009, 45, 4052–4055. [Google Scholar] [CrossRef]

- Saib, A.; Vanhoenacker-Janvier, D.; Huynen, I.; Encinas, A.; Piraux, L.; Ferain, E.; Legras, R. Magnetic photonic band-gap material at microwave frequencies based on ferromagnetic nanowires. Appl. Phys. Lett. 2003, 83, 2378. [Google Scholar] [CrossRef]

- Saib, A.; Darques, M.; Piraux, L.; Vanhoenacker-Janvier, D.; Huynen, I. An unbiased integrated microstrip circulator based on magnetic nanowired substrate. IEEE Trans. Microw. Theory Tech. 2003, 83, 2378. [Google Scholar] [CrossRef]

- Carignan, L.; Caloz, C.; Menard, D. Dual-band integrated self-biased edge-mode isolator based on the double ferromagnetic resonance of a bistable nanowire substrate. In Proceedings of the 2010 IEEE MTT-S International Microwave Symposium, Anaheim, CA, USA, 23–28 May 2010; pp. 1336–1339. [Google Scholar]

- Hamoir, G.; Medina, J.D.; Piraux, L.; Huynen, I. Self-Biased Nonreciprocal Microstrip Phase Shifter on Magnetic Nanowired Substrate Suitable for Gyrator Applications. IEEE Trans. Microw. Theory Tech. 2012, 60, 152–2157. [Google Scholar] [CrossRef]

- Spiegel, J.; de la Torre, J.; Darques, M.; Piraux, L.; Huynen, I. Permittivity Model for Ferromagnetic Nanowired Substrates. IEEE Microw. Wirel. Compon. Lett. 2007, 60, 492–494. [Google Scholar] [CrossRef]

- Serrano, A.; Franc, A.-L.; Assis, D.; Podevin, F.; Rehder, G.; Corrao, N.; Ferrari, P. Slow-wave microstrip line on nanowire-based alumina membrane. In Proceedings of the 2014 IEEE MTT-S International Microwave Symposium (IMS2014), Tampa, FL, USA, 1–6 June 2014; pp. 1–4. [Google Scholar]

- Ramirez-Villegas, R.; Huynen, I.; Piraux, L.; Encinas, A.; Medina, J.D.L.T. Configurable Microwave Filter for Signal Processing Based on Arrays of Bistable Magnetic Nanowires. IEEE Trans. Microw. Theory Tech. 2016, 65, 72–77. [Google Scholar] [CrossRef]

- Van Kerckhoven, V.; Piraux, L.; Huynen, I. A novel laser-assisted fabrication process for nanowired substrate integrated devices. In Proceedings of the 2018 13th European Microwave Integrated Circuits Conference (EuMIC), Madrid, Spain, 23–25 September 2018; pp. 170–173. [Google Scholar]

- Wu, K.; Deslandes, D.; Cassivi, Y. The substrate integrated circuits—A new concept for high-frequency electronics and optoelectronics. In Proceedings of the 6th International Conference on Telecommunications in Modern Satellite, Cable and Broadcasting Service 2003—TELSIKS 2003, Nis, Yugoslavia, 1–3 October 2003. [Google Scholar]

- Pazian, M.; Bozzi, M.; Perregrini, L. Crosstalk in Substrate Integrated Waveguides. IEEE Trans. Electromagn. Compat. 2015, 57, 80–86. [Google Scholar] [CrossRef]

- Simpson, J.J.; Taflove, A.; Mix, J.A.; Heck, H. Substrate integrated waveguides optimized for ultrahighspeed digital interconnects. IEEE Trans. Microw. Theory Tech. 2006, 54, 1983–1990. [Google Scholar] [CrossRef]

- Lai, Q.H.; Fumeaux, C.; Hong, W. Mutual coupling between parallel half-mode substrate integrated waveguides. In Proceedings of the 2012 International Conference on Microwave and Millimeter Wave Technology (ICMMT), Shenzhen, China, 5–8 May 2012; Volume 5. [Google Scholar]

- Bozzi, M.; Georgiadis, A.; Wu, K. Review of substrate-integrated waveguide circuits and antennas. IET Microw. Antennas Propag. 2011, 5, 909. [Google Scholar] [CrossRef]

- Moro, R.; Bozzi, M.; Collado, A.; Georgiadis, A.; Via, S. Plastic-based Substrate Integrated Waveguide (SIW) components and antennas. In Proceedings of the 2012 7th European Microwave Integrated Circuit Conference, Amsterdam, The Netherlands, 29–30 October 2012; pp. 627–630. [Google Scholar]

- Djerafi, T.; Doghri, A.; Wu, K. Handbook of Antenna Technologies; Springer Science+Business Media: Singapore, 2005; Chapter 5. [Google Scholar]

- Debnath, P.; Chatterjee, S. Substrate integrated waveguide antennas and arrays. In Proceedings of the 2017 1st International Conference on Electronics, Materials Engineering and Nano-Technology (IEMENTech) (ICMMT), Kolkata, India, 28–29 April 2017. [Google Scholar]

- Kumar, A.; Raghavan, S. A Review: Substrate Integrated Waveguide Antennas and Arrays. J. Telecommun. Electron. Comput. Eng. 2016, 8, 95–104. [Google Scholar]

- Alibakhshikenari, M.; Virdee, B.S.; Shukla, P.; See, C.H.; Abd-Alhameed, R.; Khalily, M.; Limiti, E. Interaction Between Closely Packed Array Antenna Elements for Applications Such as MIMO Systems and Synthetic Aperture Radars. Radio Sci. 2018, 53, 1368–1381. [Google Scholar] [CrossRef]

- Alibakhshikenari, M. Beam-scanning leaky-wave antenna based on CRLH-metamaterial for millimetre-wave applications. IET Microw. Antennas Propag. 2018, 12, 2241–2447. [Google Scholar] [CrossRef]

- Alibakhshikenari, M.; Virdee, B.S.; See, C.H.; Abd-Alhameed, R.A.; Falcone, F.; Limiti, E. Mutual-Coupling Isolation Using Embedded Metamaterial EM Bandgap Decoupling Slab for Densely Packed Array Antennas. IEEE Access 2019, 7, 5182–51840. [Google Scholar] [CrossRef]

- Alibakhshikenari, M.; Khalily, M.; Virdee, B.S.; See, C.H.; Abd-Alhameed, R.A.; Limiti, E. Mutual coupling suppression between two closely placed microstrip patches using EM-bandgap metamaterial fractal loading. IEEE Access 2019, 7, 23606–23614. [Google Scholar] [CrossRef]

- Van Kerckhoven, V.; Piraux, L.; Huynen, I. Substrate integrated waveguide isolator based on ferromagnetic nanowires in porous alumina template. Appl. Phys. Lett. 2014, 105, 183107. [Google Scholar] [CrossRef]

- Van Kerckhoven, V.; Piraux, L.; Huynen, I. A laser-assisted process to produce patterned growth of vertically aligned nanowire arrays for monolithic microwave integrated devices. Nanotechnology 2016, 65, 72–77. [Google Scholar] [CrossRef]

- Pozar, D. Microwave Engineering, 4th ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Ashraf, N.; Haraz, O.; Ashraf, M.A.; Alshebeili, S. 28/38-GHz dual-band millimeter wave SIW array antenna with EBG structures for 5G applications. In Proceedings of the International Conference on Information and Communication Technology Research (ICTRC), Abu Dhabi, UAE, 17–19 May 2015. [Google Scholar]

- Ghahramani, E.; Sadeghzadeh, R.A.; Boroomandisorkhabi, B.; Karami, M. Reducing mutual coupling of SIW slot array antenna using uniplanar compact EBG (UC-EBG) structure. In Proceedings of the 8th European Conference on Antennas and Propagation (EuCAP 2014), The Hague, The Netherlands, 6–11 April 2014; pp. 2002–2004. [Google Scholar]

- Lopez, D.; Coves, A.; Bronchalo, E.; Torregrosa, G.; Bozzi, M. Practical Design of a Band-Pass Filter using EBG SIW Technology. In Proceedings of the 48th Microwave European Conference, Madrid, Spain, 23–27 September 2018; pp. 77–80. [Google Scholar]

- Li, D.; Tong, C.; Bao, J.; Peng, P.; Yu, D. A novel bandpass filter of substrate integrated waveguide (SIW) based on S-shaped EBG. Prog. Electromagn. Res. Lett. 2013, 36, 191–200. [Google Scholar] [CrossRef]

- Yu, M.-X.; Shi, Z.-Z. A novel millimetre wave EBG-SIW wideband delay line. Int. J. Electron. 2013, 100, 762–769. [Google Scholar] [CrossRef]

- Raman, S.; Rucky, F.; Rebeiz, G. A High-Performance W-Band Uniplanar Subharmonic Mixer. IEEE Trans. Microw. Theory Tech. 1997, 45, 955–959. [Google Scholar] [CrossRef]

- Kim, J.; Qian, Y.; Feng, G.; Ma, P.; Judy, J.; Chang, M.F.; Itoh, T. A Novel Low-Loss Low-Crosstalk Interconnect for Broad-Band Mixed-Signal Silicon MMIC’s. IEEE Trans. Microw. Theory Tech. 1999, 47, 1830–1834. [Google Scholar]

- Dancila, D.; Rottenberg, X.; Tilmans, H.A.C.; De Aedt, W.R.; Huynen, I. 57-64 GHz Seven-Pole Bandpass Filter Substrate Integrated Waveguide (SIW) in LTCC. In Proceedings of the 2011 IEEE MTT-S International Microwave Workshop on Millimeter Wave Integration Technologies, Sitges, Spain, 15–16 September 2011; pp. 200–203. [Google Scholar]

- Hizan, H.M.; Ambak, Z.; Ibrahim, A.; Yusoff, M.Z.M.; Kanesan, T. Effect of Insertion Losses on Millimeter-Wave SIW Filters Using LTCC Technology. In Proceedings of the 2015 IEEE International RF and Microwave Conference (RFM 2015), Kuching, Malaysia, 14–16 December 2015; pp. 64–68. [Google Scholar]

- Bertrand, M.; Rehder, G.P.; Serrano, A.L.C.; Gomes, L.G.; Pinheiro, J.M.; Alvarenga, R.C.A.; Kabbani, N.; Kaddour, D.; Puyal, V.; Ferrari, P. Integrated Waveguides in Nanoporous Alumina Membrane for Millimeter-Wave Interposer. IEEE Microw. Wirel. Compon. Lett. 2019, 29, 83–87. [Google Scholar] [CrossRef]

- Hamoir, G. Microwave Devices Based on Unbiased Tunable Ferromagnetic Nanowire Arrays. Ph.D. Thesis, Université catholique de Louvain, Ottignies-Louvain-la-Neuve, Belgium, 2014. [Google Scholar]

- Lasers, O. J-1064/355 System—Operation Manual; Technical Report; Oxford Lasers Ltd.: Didcot, Oxon, UK, 2010. [Google Scholar]

- Emplit, A.; Tooten, E.; Xhurdebise, V.; Huynen, I. Multifunctional material structures based on laser etched carbon nanotubes arrays. Micromachines 2014, 5, 756–765. [Google Scholar] [CrossRef]

- Eul, H.; Schiek, B. Reducing the Number of Calibration Standards for Network Analyzer Calibration. IEEE Trans. Instrum. Meas. 1991, 40, 732–735. [Google Scholar] [CrossRef]

| Technology | Lithography | Laser |

|---|---|---|

| accuracy | good (<100 nm) | good (<1000 nm) |

| reproducibility | good (mastered process) | poor for LES (unstability of power source) |

| cost | high (fabrication of masks) | cheaper |

| handling | intricate | easy and fast |

| versatility | poor (1 mask needed per set of devices) | easy reconfigurable for each size and topology |

| risks | clogging of pores by resins | impact of rugosity on RF losses |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Kerckhoven, V.; Piraux, L.; Huynen, I. Fabrication of Microwave Devices Based on Magnetic Nanowires Using a Laser-Assisted Process. Micromachines 2019, 10, 475. https://doi.org/10.3390/mi10070475

Van Kerckhoven V, Piraux L, Huynen I. Fabrication of Microwave Devices Based on Magnetic Nanowires Using a Laser-Assisted Process. Micromachines. 2019; 10(7):475. https://doi.org/10.3390/mi10070475

Chicago/Turabian StyleVan Kerckhoven, Vivien, Luc Piraux, and Isabelle Huynen. 2019. "Fabrication of Microwave Devices Based on Magnetic Nanowires Using a Laser-Assisted Process" Micromachines 10, no. 7: 475. https://doi.org/10.3390/mi10070475