Investigation on the Edge Chipping in Ultrasonic Assisted Sawing of Monocrystalline Silicon

Abstract

:1. Introduction

2. Kinematic Characteristics of an Abrasive Particle in Ultrasonic Assisted Sawing

3. Mechanism of Edge Chipping in Ultrasonic Assisted Sawing

4. Test Procedure

5. Results and Discussion

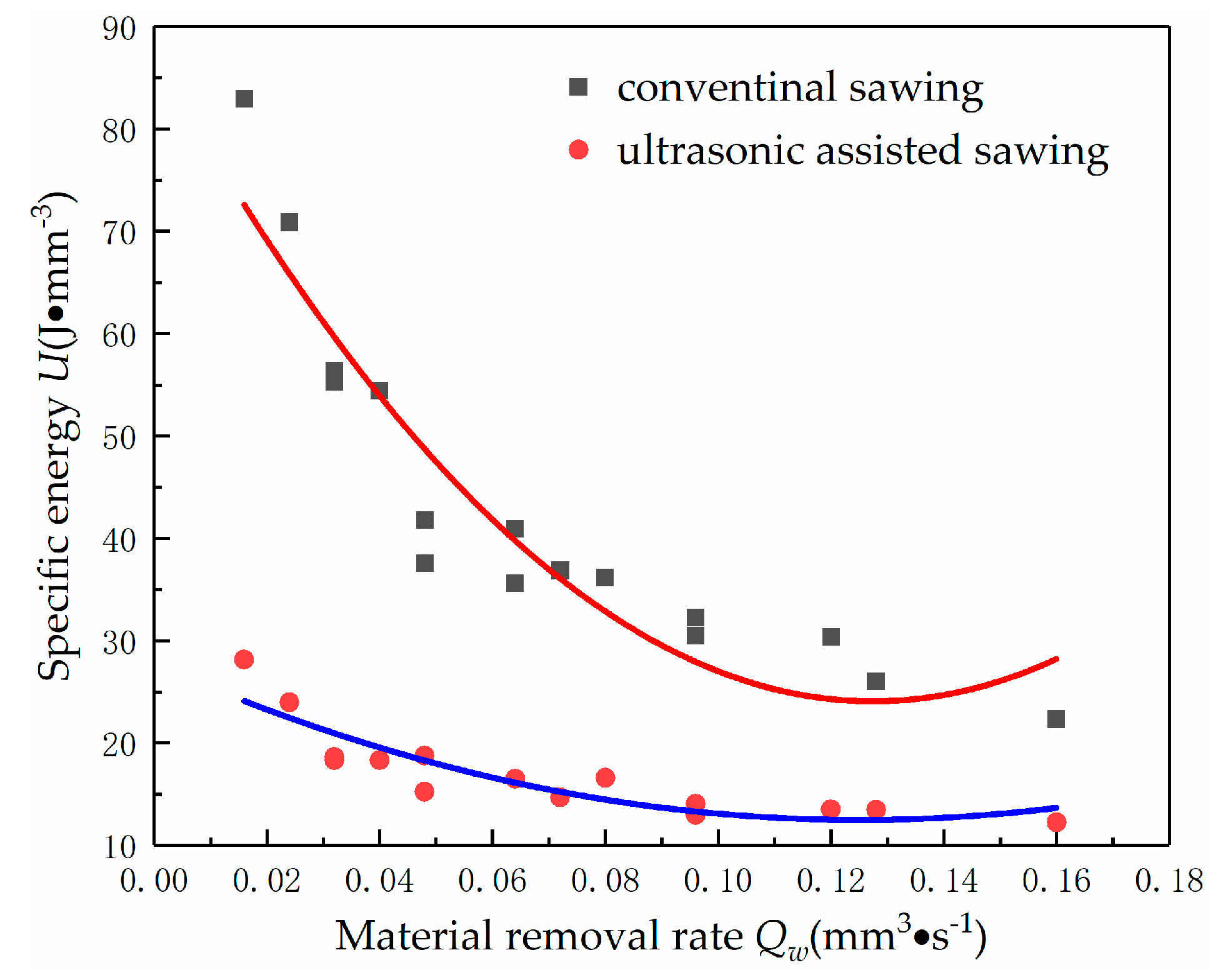

5.1. The Impact Force

5.2. The Edge Chipping Morphology

5.3. Theedge Chipping Size

6. Summary and Conclusions

- During the sawing process, when the transverse crack propagates to the workpiece surface, the edge chipping phenomenon occurs due to brittle fracture of the material. The impact force of abrasive particle on the workpiece has great effect on the transverse crack propagating and is the key factor that determinate the edge chipping size. Hence, reducing impact force is helpful to reduce the edge chipping size.

- The vibration in the ultrasonic assisted sawing changes the material removal mechanism to microcrack blasting mode compared to the continuous crack propagation in conventional sawing. This change has led to the brittle crack propagation stopped at the initial stage and just expended in a small distance, which reduces the maximus size of edge chipping. Simultaneously, the reduction of sawing force further decreases the length of crack propagation, especially transverse crack, during the sawing process. The combination of two factors would get the smaller size of edge chipping.

Author Contributions

Funding

Conflicts of Interest

References

- Khedher, N.; Hajji, M.; Bouaïcha, M.; Boujmil, M.F.; Ezzaouia, H.; Bessaïs, B.; Bennaceur, R. Improvement of transport parameters in solar grade monocrystalline silicon by application of a sacrificial porous silicon layer. Solid State Commun. 2002, 123, 7–10. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Drygała, A. Laser processing of multicrystalline silicon for texturization of solar cells. J. Mater Process Tech. 2007, 191, 228–231. [Google Scholar] [CrossRef]

- Fang, F.Z.; Wu, H.; Liu, Y.C. Modelling and experimental investigation on nanometric cutting of monocrystalline silicon. Int. J. Mach. Tool Manuf. 2005, 45, 1681–1686. [Google Scholar] [CrossRef]

- Choi, W.; Kim, S.; Choi, S.; Lee, E.; Lee, C. Effect of pad’s surface deformation and oscillation on monocrystalline silicon wafer surface quality. Int. J. Precis. Eng. Man. 2014, 15, 2301–2307. [Google Scholar] [CrossRef]

- Chung, C.; Nhat, L.V. Generation of diamond wire sliced wafer surface based on the distribution of diamond grits. Int. J. Precis. Eng. Man. 2014, 15, 789–796. [Google Scholar] [CrossRef]

- Punturat, J.; Tangwarodomnukun, V.; Dumkum, C. Surface characteristics and damage of monocrystalline silicon induced by wire-EDM. Appl. Surf. Sci. 2014, 320, 83–92. [Google Scholar] [CrossRef]

- Gangopadhyay, U.; Dhungel, S.K.; Mondal, A.K.; Saha, H.; Yi, J. Novel low-cost approach for removal of surface contamination before texturization of commercial monocrystalline silicon solar cells. Sol. Energ. Mat. Sol. C 2007, 91, 1147–1151. [Google Scholar] [CrossRef]

- Wu, X.; Li, L.; He, N.; Zhao, G.; Shen, J. Experimental Investigation on Direct Micro Milling of Cemented Carbide. Micromachines 2019, 10, 147. [Google Scholar] [CrossRef]

- Pei, Z.J. A study on surface grinding of 300 mm silicon wafers. Int. J. Mach. Tool Manuf. 2002, 42, 385–393. [Google Scholar] [CrossRef]

- Azar, A.S.; Holme, B.; Nielsen, Ø. Effect of sawing induced micro-crack orientations on fracture properties of silicon wafers. Eng. Fract. Mech. 2016, 154, 262–271. [Google Scholar] [CrossRef]

- Gao, S.; Kang, R.; Dong, Z.; Zhang, B. Edge chipping of silicon wafers in diamond grinding. Int. J. Mach. Tools Manuf. 2013, 64, 31–37. [Google Scholar] [CrossRef]

- Wu, X.; Li, L.; He, N.; Zhao, G.; Shen, J. Investigation on the surface formation mechanism in micro milling of cemented carbide. Int. J. Refract. Met. Hard Mat. 2019, 78, 61–67. [Google Scholar] [CrossRef]

- Wu, X.; Li, L.; He, N.; Zhao, G.; Shen, J. Laser induced oxidation of cemented carbide during micro milling. Ceram. Int. 2019, 45, 15156–15163. [Google Scholar] [CrossRef]

- Efrat, U. Optimizing the wafer dicing process. In Proceedings of the 15th IEEE/CHMT International Electronic Manufacturing Technology Symposium, Santa Clara, CA, USA, 4–6 October 1993; pp. 245–253. [Google Scholar]

- Lin, J.; Cheng, M. Investigation of chipping and wear of silicon wafer dicing. J. Manuf. Process 2014, 16, 373–378. [Google Scholar] [CrossRef]

- Luo, S.Y.; Wang, Z.W. Studies of chipping mechanisms for dicing silicon wafers. Int. J. Adv. Manuf. Tech. 2008, 35, 1206–1218. [Google Scholar] [CrossRef]

- Cvetković, S.; Morsbach, C.; Rissing, L. Ultra-precision dicing and wire sawing of silicon carbide (SiC). Microelectron. Eng. 2011, 88, 2500–2504. [Google Scholar] [CrossRef]

- Lv, D.; Wang, H.; Tang, Y.; Huang, Y.; Li, Z. Influences of vibration on surface formation in rotary ultrasonic machining of glass BK7. Precis. Eng. 2013, 37, 839–848. [Google Scholar] [CrossRef]

- Zha, X.M.; Chen, F.B.; Jiang, F.; Xu, X.P. Correlation of the fatigue impact resistance of bilayer and nanolayered PVD coatings with their cutting performance in machining Ti-6Al-4V. Ceram. Int. 2019, 45, 14704–14717. [Google Scholar] [CrossRef]

- Wang, N.C.; Jiang, F.; Xu, X.P.; Duan, N.; Wen, Q.L.; Lu, X.Z. Research on the machinability of A-plane sapphire under diamond wire sawing in different sawing directions. Ceram. Int. 2019, 45, 10310–10320. [Google Scholar] [CrossRef]

- Ning, F.; Wang, H.; Cong, W.; Fernando, P.K.S.C. A mechanistic ultrasonic vibration amplitude model during rotary ultrasonic machining of CFRP composites. Ultrasonics 2017, 76, 44–51. [Google Scholar] [CrossRef] [Green Version]

- Komaraiah, M.; Reddy, P.N. Rotary ultrasonic machining—A new cutting process and its performance. Int. J. Prod. Res. 1991, 29, 2177–2187. [Google Scholar] [CrossRef]

- Shen, J.Y.; Wang, J.Q.; Jiang, B.; Xu, X.P. Study on wear of diamond wheel in ultrasonic vibration-assisted grinding ceramic. Wear 2015, 332, 788–793. [Google Scholar] [CrossRef]

- Zhang, C.; Rentsch, R.; Brinksmeier, E. Advances in micro ultrasonic assisted lapping of microstructures in hard–brittle materials: A brief review and outlook. Int. J. Mach. Tool Manuf. 2005, 45, 881–890. [Google Scholar] [CrossRef]

- Yan, W.; Lin, B.; Wang, S.; Cao, X. Study on the system matching of ultrasonic vibration assisted grinding for hard and brittle materials processing. Int. J. Mach. Tool Manuf. 2014, 77, 66–73. [Google Scholar]

- Wang, J.; Zhang, J.; Feng, P.; Ping, G. Damage formation and suppression in rotary ultrasonic machining of hard and brittle materials: A critical review. Ceram. Int. 2018, 44, 1227–1239. [Google Scholar] [CrossRef]

- Li, Z.C.; Cai, L.W.; Pei, Z.J.; Treadwell, C. Edge-chipping reduction in rotary ultrasonic machining of ceramics: Finite element analysis and experimental verification. Int. J. Mach. Tool Manuf. 2006, 46, 1469–1477. [Google Scholar] [CrossRef] [Green Version]

- Cong, W.L.; Feng, Q.; Pei, Z.J.; Deines, T.W.; Treadwell, C. Edge chipping in rotary ultrasonic machining of silicon. Int. J. Manuf. Res. 2012, 7, 311–329. [Google Scholar] [CrossRef]

- Chen, Y.; Pei, Z.J.; Treadwell, C. Investigations on Edge Chipping in Rotary Ultrasonic Machining Using Finite Element Analysis. Mat. Sci. Forum 2006, 532, 969–972. [Google Scholar] [CrossRef]

- Wang, J.; Zha, H.; Feng, P.; Zhang, J. On the mechanism of edge chipping reduction in rotary ultrasonic drilling: A novel experimental method. Precis. Eng. 2016, 44, 231–235. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, F.; Yan, L.; Wang, N.C.; Zha, X.M.; Lu, X.Z.; Wen, Q.L. Study on mechanism of crack propagation of sapphire single crystals of four different orientations under impact load and static load. Ceram. Int. 2019, 45, 7359–7375. [Google Scholar] [CrossRef]

- Wang, J.; Feng, P.; Zhang, J. Reducing edge chipping defect in rotary ultrasonic machining of optical glass by compound step-taper tool. J. Manuf. Process 2018, 32, 213–221. [Google Scholar] [CrossRef]

- Shen, J.; Chen, J.; Wang, J.; Xipeng, X.U. Study on Manufacturing of Radial Ultrasonic Sawing System and Its Application. J. Mech. Eng. 2017, 53, 202–208. [Google Scholar]

- Shen, J.; Zhu, X.; Li, Z.; Xu, X. The abrasive grain action mechanism in the process of sawing monocrystalline with radial ultrasonic vibration assistance. J. Shanxi Norm. Univ. (Nat. Sci. Ed.) 2018, 46, 21–25. [Google Scholar]

- Wang, J.; Feng, P.; Zhang, J.; Zhang, C.; Pei, Z. Modeling the dependency of edge chipping size on the material properties and cutting force for rotary ultrasonic drilling of brittle materials. Int. J. Mach. Tool Manuf. 2016, 101, 18–27. [Google Scholar] [CrossRef]

- Lambropoulos, J.; Jacobs, S.D.; Ruckman, J. Material removal mechanisms from grinding to polishing. Ceram. Trans. 1999, 102, 113–128. [Google Scholar]

| Properties. | Density (g/cm3) | Crystal Orientation | Elastic Modulus (GPa) | Fracture Toughness (MPa·m1/2) |

|---|---|---|---|---|

| Value | 2.33 | 100 | 130 | 0.8 |

| Parameters | Line Velocity vs (m/s) | Feed Rate fw (mm/min) | Depth ap (μm) | Ultrasonic Amplitude (μm) | Frequency f (kHz) |

|---|---|---|---|---|---|

| Value | 10.5, 18.3, 26.2, 34.0. | 80, 160, 240, 320 | 40, 60, 80, 100 | 4 | 28 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Zhu, X.; Chen, J.; Tao, P.; Wu, X. Investigation on the Edge Chipping in Ultrasonic Assisted Sawing of Monocrystalline Silicon. Micromachines 2019, 10, 616. https://doi.org/10.3390/mi10090616

Shen J, Zhu X, Chen J, Tao P, Wu X. Investigation on the Edge Chipping in Ultrasonic Assisted Sawing of Monocrystalline Silicon. Micromachines. 2019; 10(9):616. https://doi.org/10.3390/mi10090616

Chicago/Turabian StyleShen, Jianyun, Xu Zhu, Jianbin Chen, Ping Tao, and Xian Wu. 2019. "Investigation on the Edge Chipping in Ultrasonic Assisted Sawing of Monocrystalline Silicon" Micromachines 10, no. 9: 616. https://doi.org/10.3390/mi10090616