Microstructure Evolution and Mechanical Properties of Needle-like ZrB2 Reinforced Cu Composites Manufactured by Laser Direct Energy Deposition

Abstract

:1. Introduction

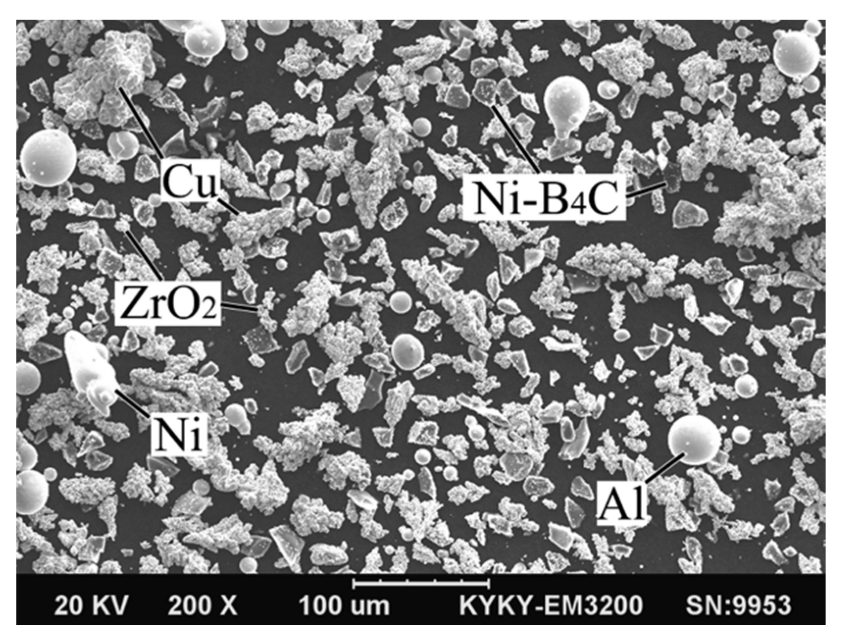

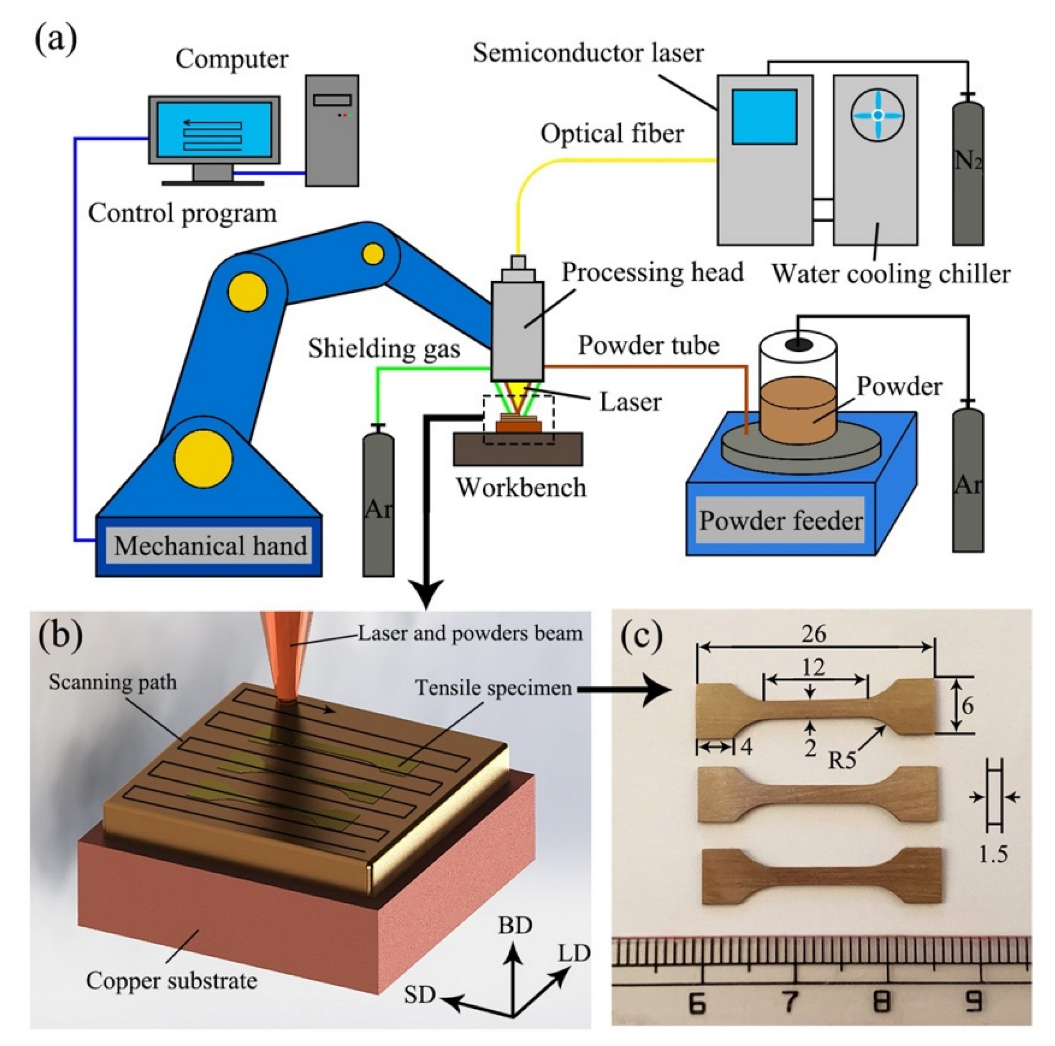

2. Materials and Methods

3. Results

3.1. Macroscopic Morphology

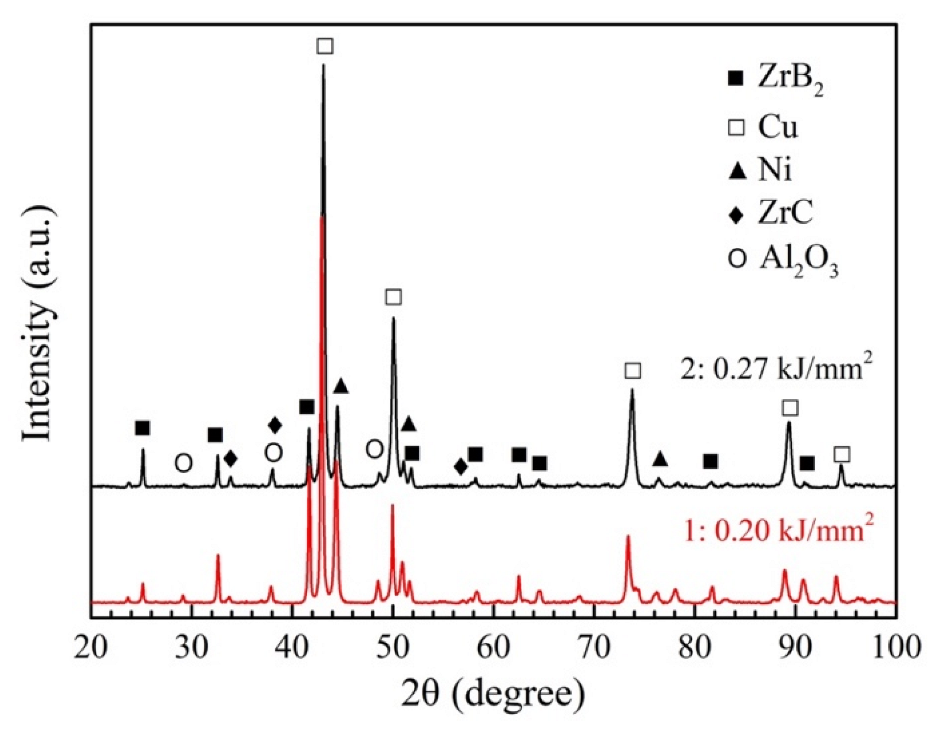

3.2. Phase Constituents

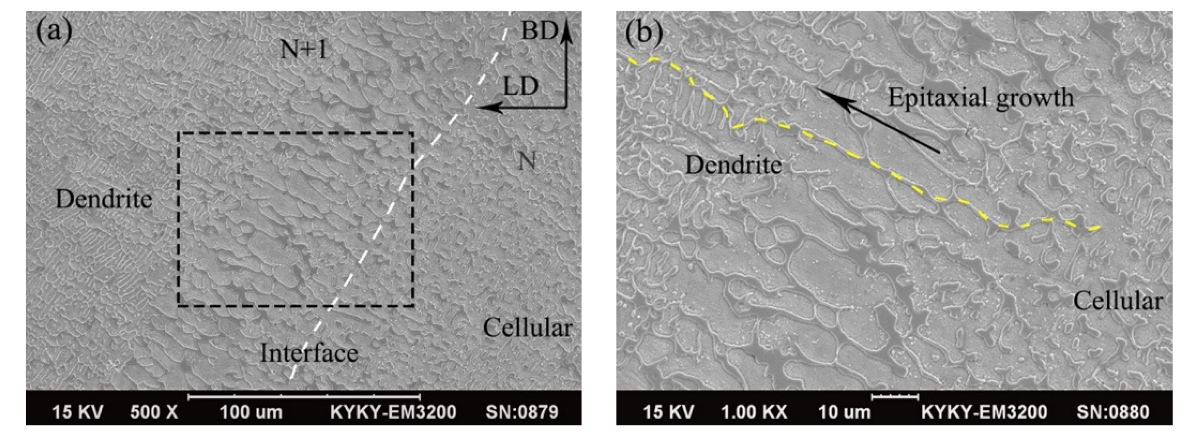

3.3. Microstructures of the Composites

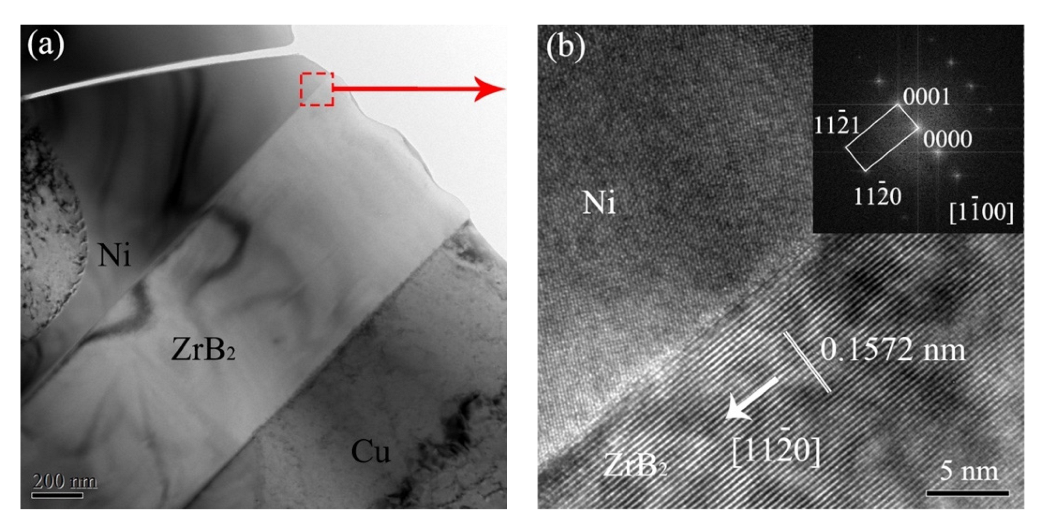

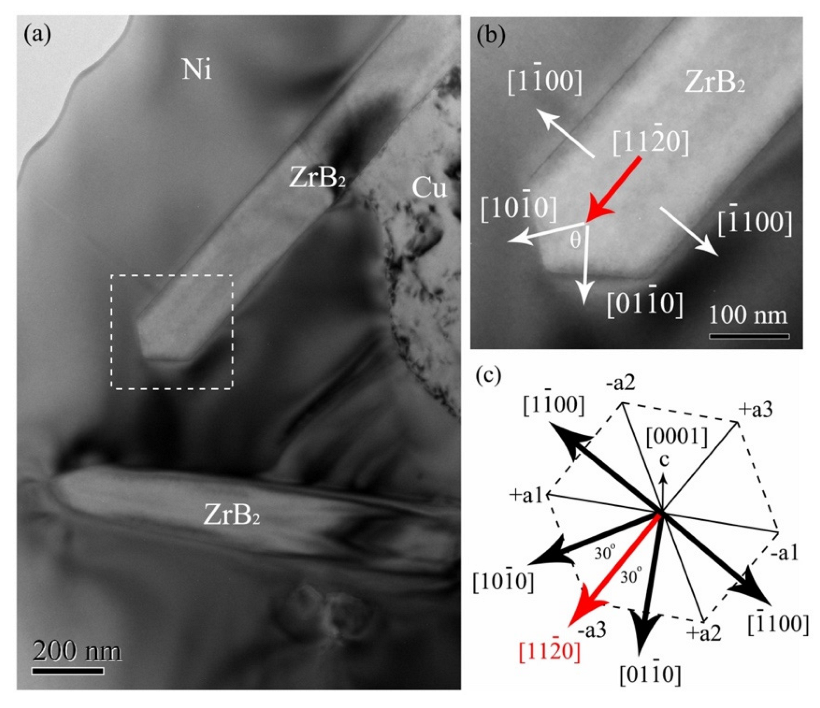

3.4. Growth Mechanism of ZrB2 Whisker Reinforcement

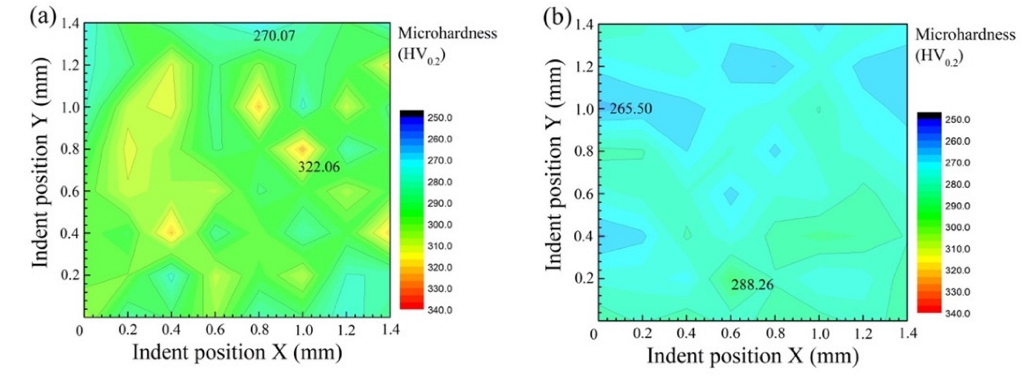

3.5. Microhardness of the Composites

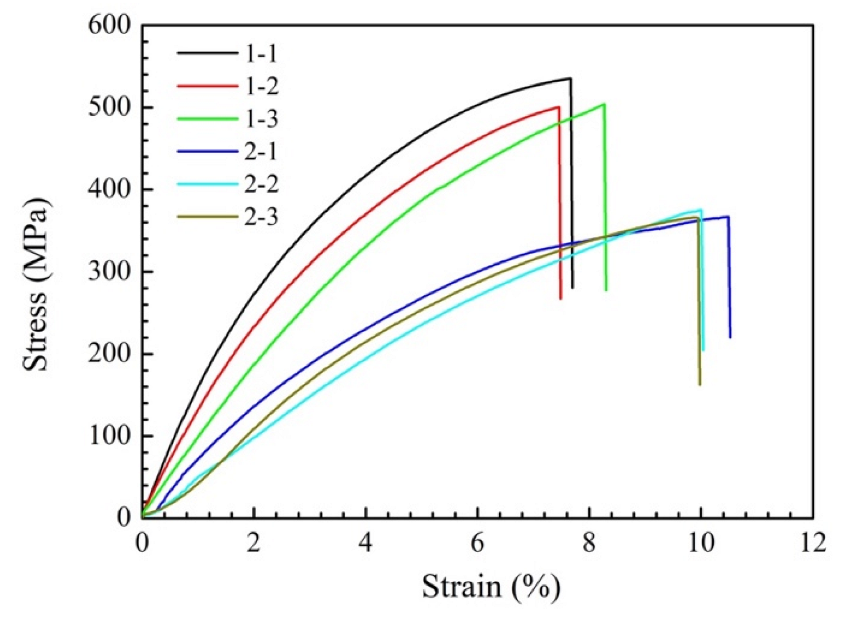

3.6. Tensile Strength of the Composites

4. Conclusions

- The needle-like ZrB2 reinforced Cu composites were successfully fabricated using laser direct energy deposition. The microstructure of the composites was mainly a composite structure composed of needle-like ZrB2, Ni dendrites, and a Cu matrix.

- In-situ synthesized ZrB2 was shown to be a high-strength whisker reinforcement. In sample 1, the diameter of ZrB2 was less than 2 μm, and the aspect ratio was about 30:1. The long axis direction with the fastest growth rate of ZrB2 ceramic whiskers was {11-20}.

- In the Cu matrix, a network of Ni dendrites connected the needle-like ZrB2. The morphological changes of Ni dendrites could be observed at the interface inside the composite material: cellular crystals → large-sized columnar dendrites → small-sized dendrites (along the solidification direction).

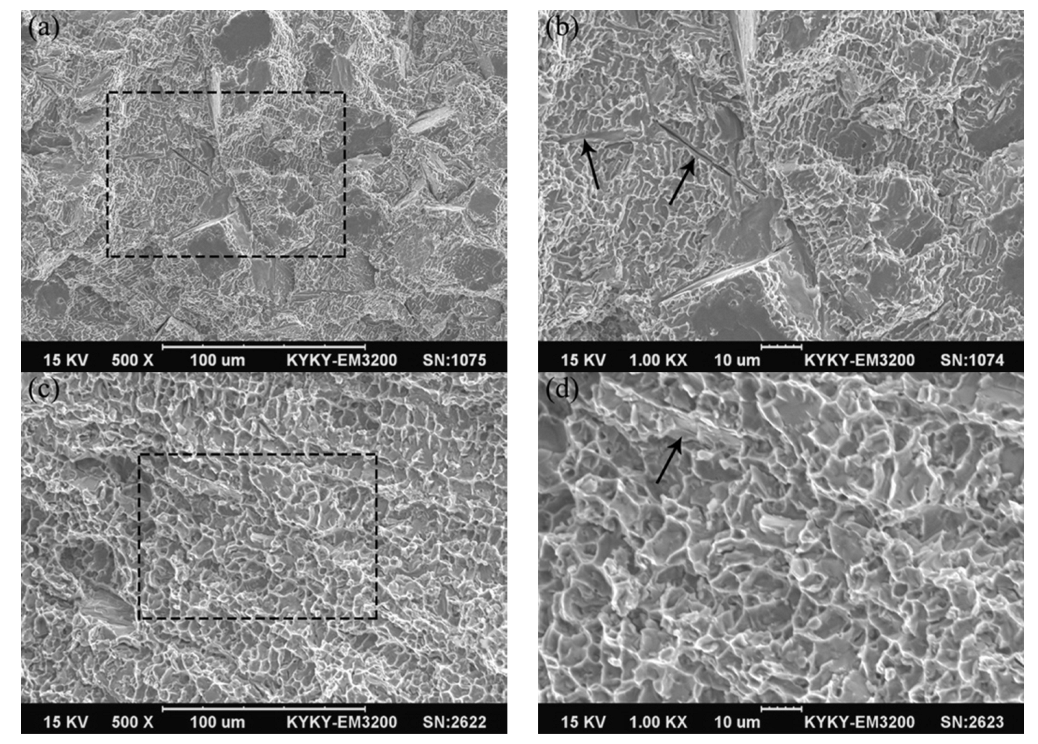

- ZrB2 ceramic reinforcement and Ni dendrites significantly improved the mechanical properties of the composite material. The microhardness and ultimate tensile strength of the composite material reached 322 HV0.2 and 535 MPa, respectively, and the tensile fracture of sample 1 was a mixed mechanism of ductile and brittle fracturing. As the laser energy density increased, the size of the in-situ synthesized ZrB2 increased, and the number and continuity of Ni dendrites decreased, which decreased the hardness and strength of the composite material, and the fracture mechanism of sample 2 was changed to ductile fracturing.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, Y.; Cong, W. A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites. Ceram. Int. 2018, 44, 20599–20612. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z.; Du, J.; Su, G.; Zhang, J.; Xu, C. On machinability and surface integrity in subsequent machining of additively-manufactured thick coatings: A review. J. Manuf. Process. 2020, 53, 123–143. [Google Scholar] [CrossRef]

- Monfared, V.; Bakhsheshi-Rad, H.R.; Ramakrishna, S.; Razzaghi, M.; Berto, F. A brief review on additive manufacturing of polymeric composites and nanocomposites. Micromachines 2021, 12, 704. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in additive manufacturing on new materials: A review. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Gray, G.T.; Livescu, V.; Rigg, P.A.; Trujillo, C.P.; Cady, C.M.; Chen, S.R.; Carpenter, J.S.; Lienert, T.J.; Fensin, S.J. Structure/property (constitutive and spallation response) of additively manufactured 316L stainless steel. Acta Mater. 2017, 138, 140–149. [Google Scholar] [CrossRef]

- Yan, L.; Chen, Y.; Liou, F. Additive manufacturing of functionally graded metallic materials using laser metal deposition. Addit. Manuf. 2020, 31, 100901. [Google Scholar] [CrossRef]

- Nagesha, B.K.; Dhinakaran, V.; Varsha Shree, M.; Manoj Kumar, K.P.; Jagadeesha, T. A Review on weldability of additive manufactured titanium alloys. Mater. Today Proc. 2020, 33, 2964–2969. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components-Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Haley, J.C.; Zheng, B.; Bertoli, U.S.; Dupuy, A.D.; Schoenung, J.M.; Lavernia, E.J. Working distance passive stability in laser directed energy deposition additive manufacturing. Mater. Des. 2019, 161, 86–94. [Google Scholar] [CrossRef]

- Hemes, S.; Meiners, F.; Sizova, I.; Hama-Saleh, R.; Rohrens, D.; Weisheit, A.; Hafner, C.L.; Bambach, M. Microstructures and mechanical properties of hybrid, additively manufactured Ti6Al4V after thermomechanical processing. Materials 2021, 14, 1039. [Google Scholar] [CrossRef]

- Bhardwaj, T.; Shukla, M.; Paul, C.P.; Bindra, K.S. Direct energy deposition-laser additive manufacturing of titanium-molybdenum alloy: Parametric studies, microstructure and mechanical properties. J. Alloys Compd. 2019, 787, 1238–1248. [Google Scholar] [CrossRef]

- Wang, X.; Lei, L.; Yu, H. A review on microstructural features and mechanical properties of wheels/rails cladded by laser cladding. Micromachines 2021, 12, 152. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Li, Y.; Wang, H.; Cong, W. An investigation on Ni4Ti3 phase precipitation and its effects in laser directed energy deposition of TiC-NiTi composites. Mater. Sci. Eng. A 2021, 809, 140976. [Google Scholar] [CrossRef]

- Su, Y.Y.; Wang, Z.F.; Xie, J.C.; Xu, G.; Xing, F.; Luo, K.Y.; Lu, J.Z. Microstructures and mechanical properties of laser melting deposited Ti6Al4V/316L functional gradient materials. Mater. Sci. Eng. A 2021, 817, 141355. [Google Scholar] [CrossRef]

- Zhu, Y.; Yang, Y.; Mu, X.; Wang, W.; Yao, Z.; Yang, H. Study on wear and RCF performance of repaired damage railway wheels: Assessing laser cladding to repair local defects on wheels. Wear 2019, 430, 126–136. [Google Scholar] [CrossRef]

- Jia, L.; Yang, H.; Wang, Y.; Zhang, B.; Liu, H.; Hao, J. Direct bonding of copper foil and liquid crystal polymer by laser etching and welding. Optics Lasers Eng. 2021, 139, 106509. [Google Scholar] [CrossRef]

- Constantin, L.; Wu, Z.; Li, N.; Fan, L.; Silvain, J.F.; Lu, Y.F. Laser 3D printing of complex copper structures. Addit. Manuf. 2020, 35, 101268. [Google Scholar] [CrossRef]

- Maki, K.; Ito, Y.; Matsunaga, H.; Mori, H. Solid-solution copper alloys with high strength and high electrical conductivity. Scr. Mater. 2013, 68, 777–780. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.; Chang, C.; Dong, D.; Gao, S.; Ma, W.; Liu, M.; Liao, H.; Yin, S. Microstructure and mechanical properties of pure copper manufactured by selective laser melting. Mater. Sci. Eng. A 2020, 789, 139615. [Google Scholar] [CrossRef]

- Qin, Y.Q.; Tian, Y.; Peng, Y.Q.; Luo, L.M.; Zan, X.; Xu, Q.; Wu, Y.C. Research status and development trend of preparation technology of ceramic particle dispersion strengthened copper-matrix composites. J. Alloys Compd. 2020, 848, 156475. [Google Scholar] [CrossRef]

- Shu, D.; Li, Z.; Zhang, K.; Yao, C.; Li, D.; Dai, Z. In situ synthesized high volume fraction WC reinforced Ni-based coating by laser cladding. Mater. Lett. 2017, 195, 178–181. [Google Scholar] [CrossRef]

- Masanta, M.; Shariff, S.M.; Choudhury, A.R. Microstructure and properties of TiB2-TiC-Al2O3 coating prepared by laser assisted SHS and subsequent cladding with micro-/nano-TiO2 as precursor constituent. Mater. Des. 2016, 90, 307–317. [Google Scholar] [CrossRef]

- Zhang, S.; Kang, H.; Li, R.; Zou, C.; Guo, E.; Chen, Z.; Wang, T. Microstructure evolution, electrical conductivity and mechanical properties of dual-scale Cu5Zr/ZrB2 particulate reinforced copper matrix composites. Mater. Sci. Eng. A 2019, 762, 138108. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Wang, J.; Ma, Q. In-situ synthesized Ni–Zr intermetallic/ceramic reinforced composite coatings on zirconium substrate by high power diode laser. J. Alloys Compd. 2015, 624, 234–240. [Google Scholar] [CrossRef]

- Yu, W.H.; Sing, S.L.; Chua, C.K.; Kuo, C.N.; Tian, X.L. Particle-reinforced metal matrix nanocomposites fabricated by selective laser melting: A state of the art review. Prog. Mater. Sci. 2019, 104, 330–379. [Google Scholar] [CrossRef]

- Traxel, K.D.; Bandyopadhyay, A. Influence of in situ ceramic reinforcement towards tailoring titanium matrix composites using laser-based additive manufacturing. Addit. Manuf. 2020, 31, 101004. [Google Scholar] [CrossRef] [PubMed]

- Oukach, S.; Pateyron, B.; Pawłowski, L. Physical and chemical phenomena occurring between solid ceramics and liquid metals and alloys at laser and plasma composite coatings formation: A review. Surf. Sci. Rep. 2019, 74, 213–241. [Google Scholar] [CrossRef]

- Zhou, W.; Sun, X.; Kikuchi, K.; Nomura, N.; Yoshimi, K.; Kawasaki, A. In situ synthesized TiC/Mo-based composites via laser powder bed fusion. Mater. Des. 2018, 146, 116–124. [Google Scholar] [CrossRef]

- Nartu, M.S.K.K.Y.; Mantri, S.A.; Pantawane, M.V.; Ho, Y.H.; McWilliams, B.; Cho, K.; Dahotre, N.B.; Banerjee, R. In situ reactions during direct laser deposition of Ti-B4C composites. Scr. Mater. 2020, 183, 28–32. [Google Scholar] [CrossRef]

- Yu, T.; Chen, J.; Wen, Y.; Deng, Q. High temperature phase stability and wear behavior of laser clad Ta reinforced NiCrBSi coating. Appl. Surf. Sci. 2021, 547, 149171. [Google Scholar] [CrossRef]

- Stašić1, J.; Rajković1, V.; Ružić1, J.; Božić1, D. An investigation on synthesis development of high hardened, high conductivity Cu-Zr and Cu-Zr-ZrB2 alloys through green compact laser sintering. Int. J. Adv. Manuf. Technol. 2015, 80, 1049–1057. [Google Scholar] [CrossRef]

- Lv, X.; Zhan, Z.; Cao, H.; Guo, C. Microstructure and properties of the laser cladded in-situ ZrB2-ZrC/Cu composite coatings on copper substrate. Surf. Coat. Technol. 2020, 396, 125937. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, P.; Yu, Z.; Li, C.; Li, R. Development and characterization of laser surface cladding (Ti, W)C reinforced Ni-30Cu alloy composite coating on copper. Opt. Laser Technol. 2012, 44, 1351–1358. [Google Scholar] [CrossRef]

- Li, J.; Zhou, X.; Brochu, M.; Provatas, N.; Zhao, Y.F. Solidification microstructure simulation of Ti-6Al-4V in metal additive manufacturing: A review. Addit. Manuf. 2020, 31, 100989. [Google Scholar] [CrossRef]

- Markov, I. Crystal Growth for Beginners: Fundamentals of Nucleation, Crystal Growth and Epitaxy, 2nd ed.; World Scientific: Singapore, 2017. [Google Scholar]

- Flemings, M. Solidification Processing; McGraw-Hill: New York, NY, USA, 1974. [Google Scholar]

- Ye, D.; Hu, J. Practical Inorganic Thermodynamics Manual; Metallurgical Industry Press: Beijing, China, 2002. [Google Scholar]

- Shu, D.; Li, Z.; Zhang, K.; Yao, C.; Li, D.; Yuan, Y.; Dai, Z. Phase constituents and growth mechanism of laser in situ synthesized WC reinforced composite coating with W-C-Ni system. J. Mater. Res. 2016, 32, 557–565. [Google Scholar] [CrossRef]

- Prywer, J. Explanation of some peculiarities of crystal morphology deduced from the BFDH law. J. Cryst. Growth 2004, 270, 699–710. [Google Scholar] [CrossRef]

| Material | Cu | Ni | ZrO2 | Al | Ni-B4C |

|---|---|---|---|---|---|

| Purity (%) | 99.9 | 99.9 | 99.9 | 99.5 | 99.5 |

| Size (μm) | 53–75 | 48–75 | 25–48 | 38–75 | 25–48 |

| Content (wt%) | 70.00 | 13.96 | 10.41 | 3.04 | 2.59 |

| {uvtw} | {0001} | |||

|---|---|---|---|---|

| d{uvtw} (Å) | 3.5305 | 2.7445 | 2.1663 | 1.5843 |

| Number | Ultimate Tensile Strength (MPa) | Tensile Elongation (%) | Mean Ultimate Tensile Strength (MPa) | Mean Tensile Elongation (%) |

|---|---|---|---|---|

| 1-1 | 535.24 | 7.67 | 513.19 | 7.80 |

| 1-2 | 500.46 | 7.46 | ||

| 1-3 | 503.88 | 8.27 | ||

| 2-1 | 366.77 | 10.49 | 368.96 | 10.15 |

| 2-2 | 374.85 | 10.01 | ||

| 2-3 | 365.27 | 9.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, X.; Zhan, Z.; Cao, H. Microstructure Evolution and Mechanical Properties of Needle-like ZrB2 Reinforced Cu Composites Manufactured by Laser Direct Energy Deposition. Micromachines 2022, 13, 212. https://doi.org/10.3390/mi13020212

Lv X, Zhan Z, Cao H. Microstructure Evolution and Mechanical Properties of Needle-like ZrB2 Reinforced Cu Composites Manufactured by Laser Direct Energy Deposition. Micromachines. 2022; 13(2):212. https://doi.org/10.3390/mi13020212

Chicago/Turabian StyleLv, Xiangzhe, Zaiji Zhan, and Haiyao Cao. 2022. "Microstructure Evolution and Mechanical Properties of Needle-like ZrB2 Reinforced Cu Composites Manufactured by Laser Direct Energy Deposition" Micromachines 13, no. 2: 212. https://doi.org/10.3390/mi13020212