Integration of Multifocal Microlens Array on Silicon Microcantilever via Femtosecond-Laser-Assisted Etching Technology

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

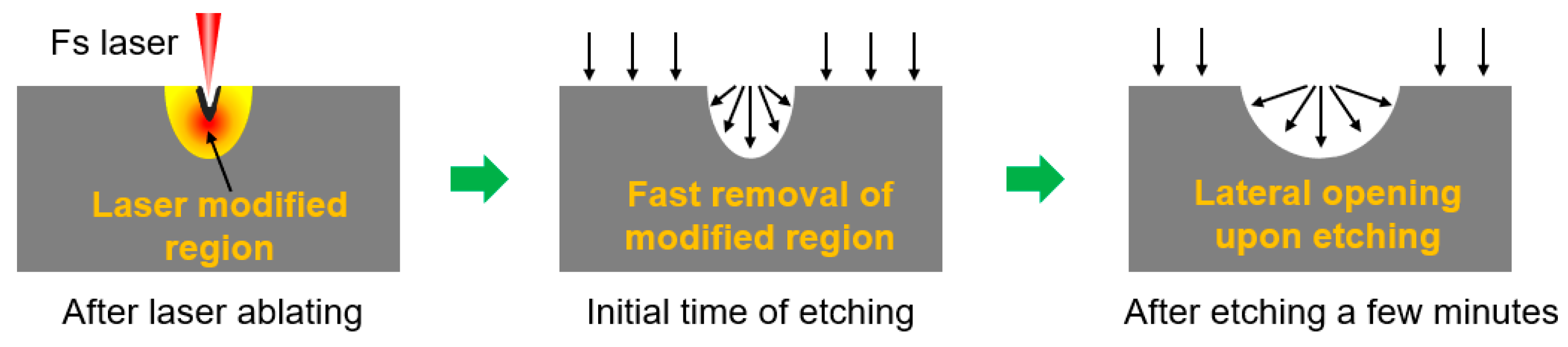

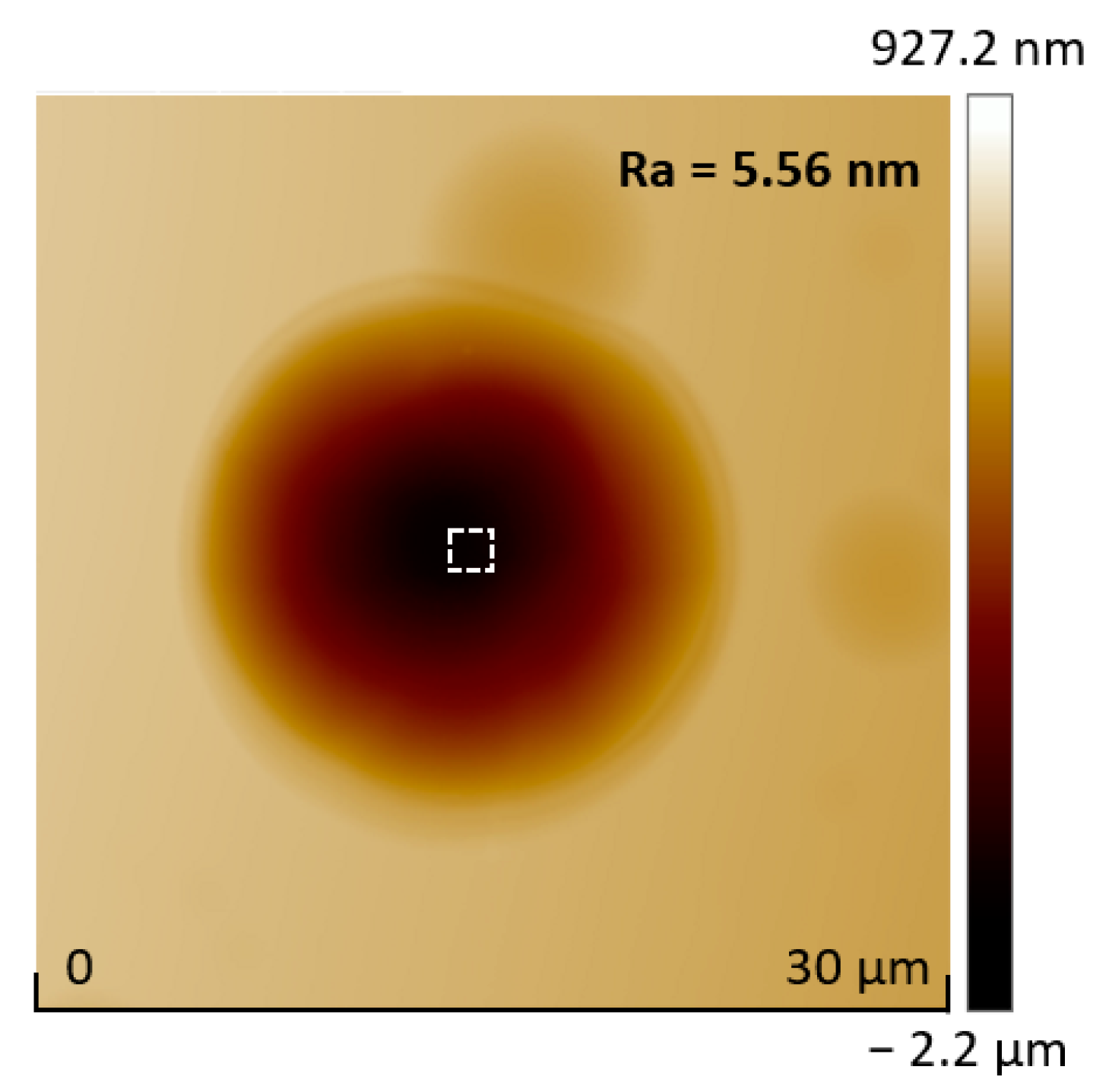

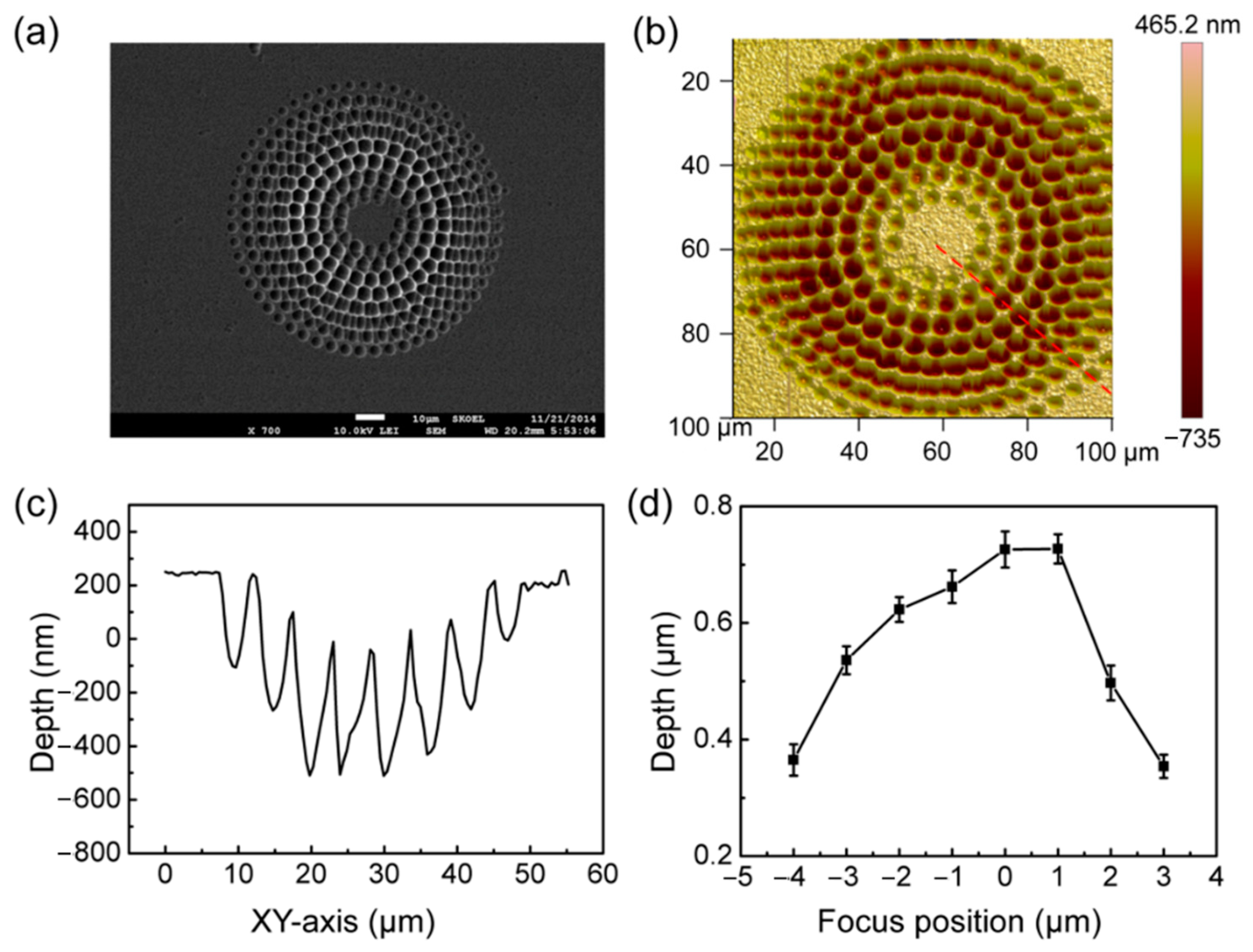

3.1. Preparation of Microlens

- (a)

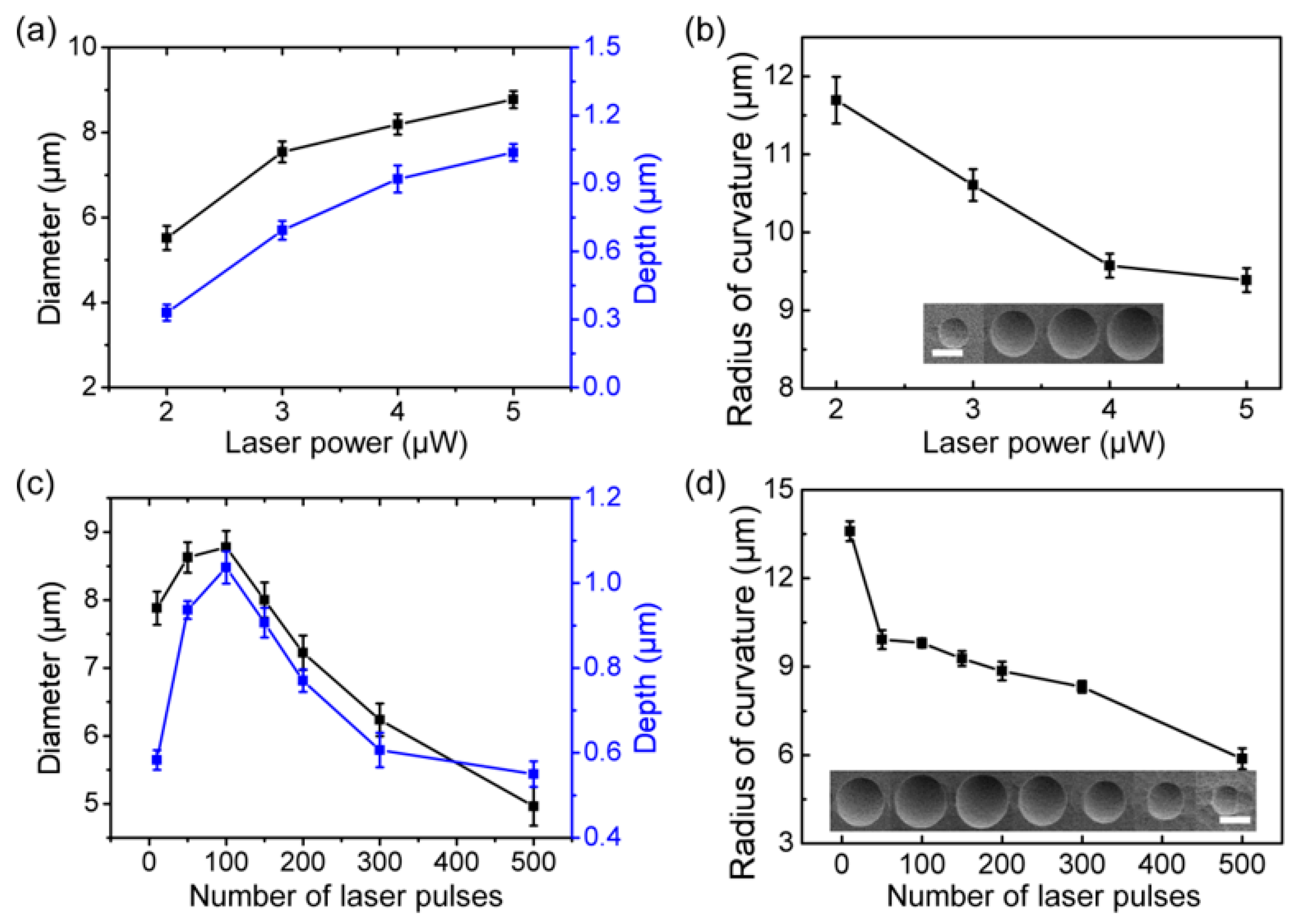

- Because the modified area increases with the laser power, the size of the silicon-based microlens increases after the ICP etching process. The diameter and depth of the silicon-based microlens showed an increasing trend as the power of the femtosecond laser increased, as shown in Figure 4a. By calculating the diameter and depth of the silicon-based concave microlens under different laser powers, the corresponding radius of curvature was obtained. The relationship between the radius of curvature and laser power is presented in Figure 4b.

- (b)

- With an increase in the laser pulse number, the diameter and depth of the silicon-based concave microlens first increased and then decreased (Figure 4c). This is because the silicon surface would react with oxygen in the air with a greater number of laser pulses, generating a passivation layer on the silicon surface and preventing the etching progress. Therefore, the size of the silicon-based concave microlens decreased with an increase in the number of laser pulses. The different diameters and depths of the silicon-based concave microlens can be obtained by controlling the pulse numbers of the laser. The radius of curvature gradually decreased as the number of pulses increased, as shown in Figure 4d.

- (c)

- The focal lengths of the microlenses with varying radii of curvature also differ. The experimental results show that the size of the silicon-based concave microlens can be flexibly adjusted by changing the femtosecond laser power and pulse number, and the controllable preparation of microlenses with different focal lengths can be realized.

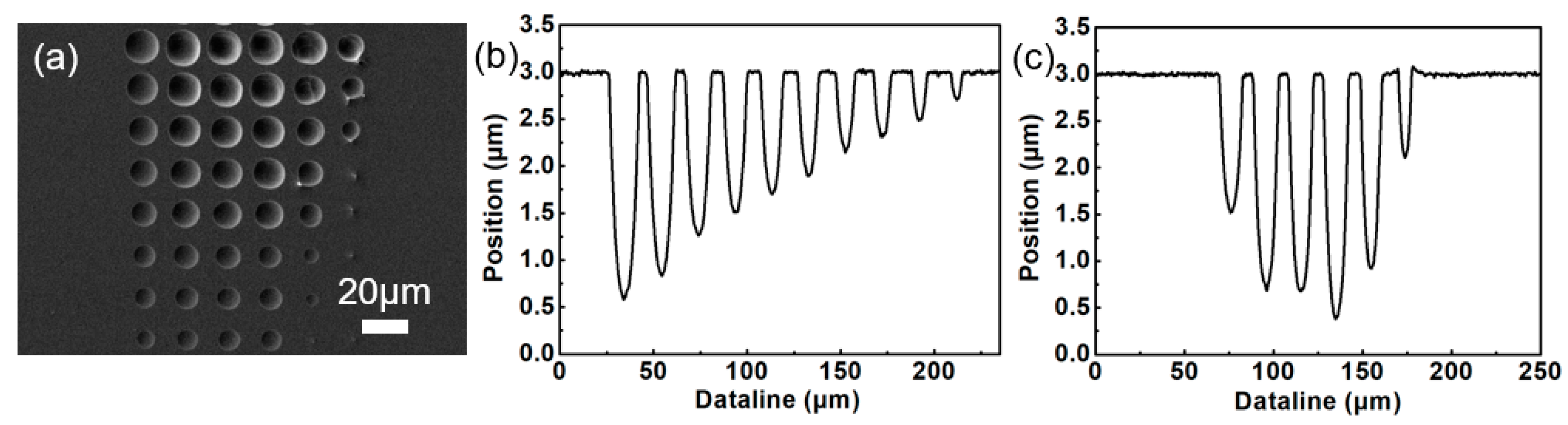

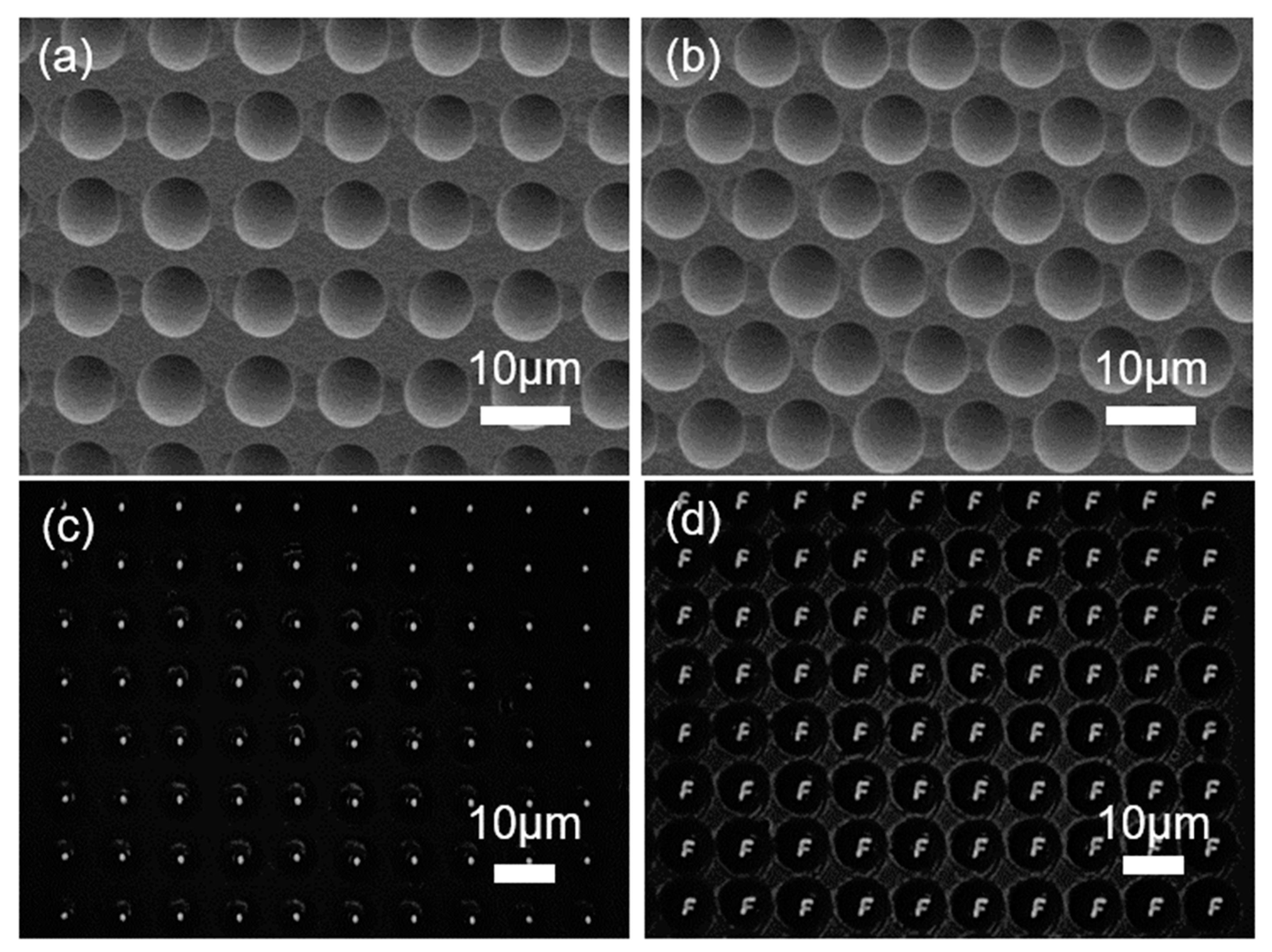

3.2. Microlens Array Fabrication

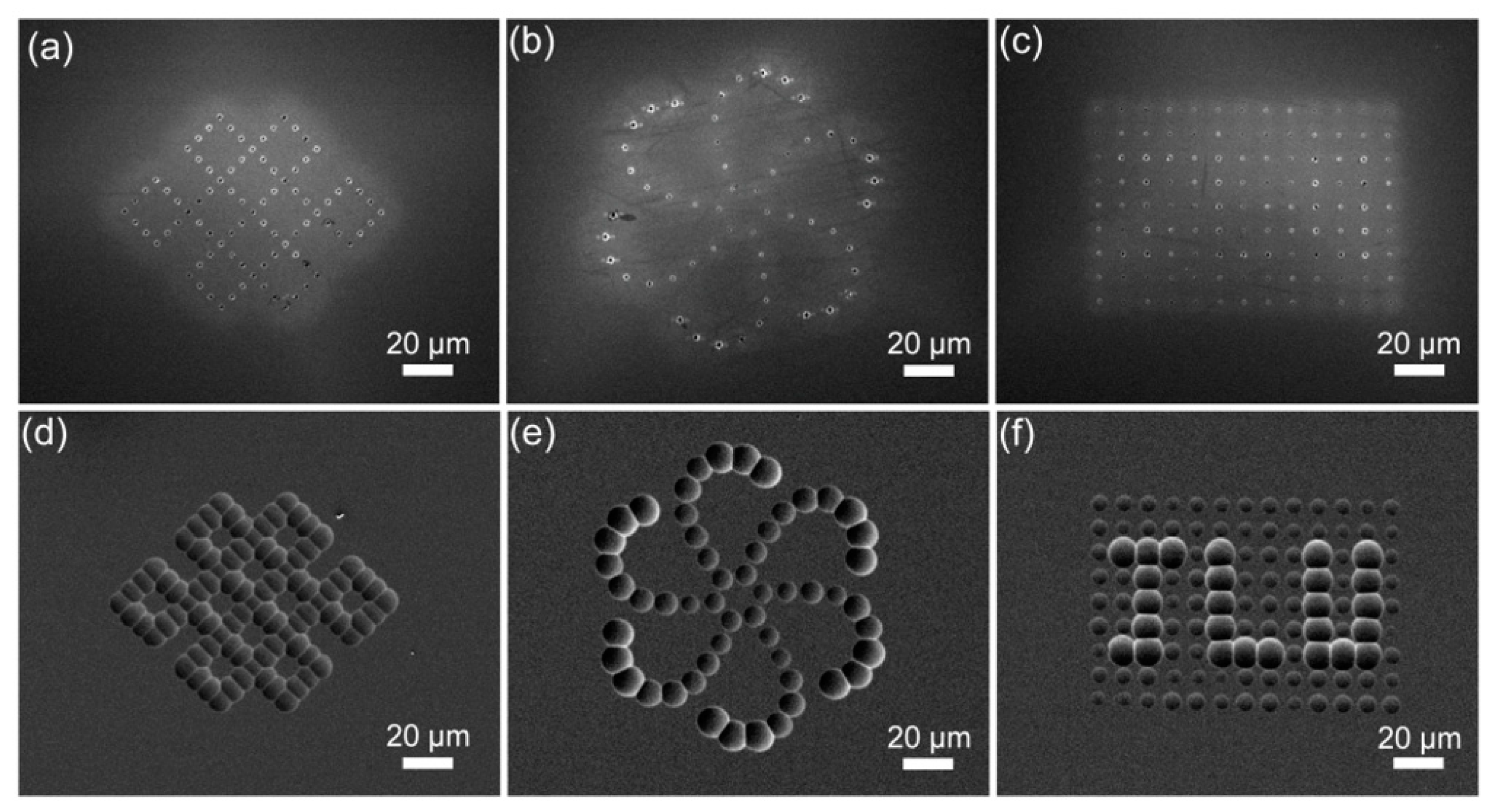

3.3. Multifocal Microlens Array Integration on Silicon Cantilever

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, Q.; Wang, Y.; Wang, X.; Yao, Y.; Wang, X.; Huang, W. Review of micromachined optical accelerometers: From mg to sub-mu g. Opto-Electron. Adv. 2021, 4, 200045. [Google Scholar] [CrossRef]

- Joshi, P.K. Recent Development in Applications of Optical MEMS: A Review. Helix 2018, 8, 4345–4348. [Google Scholar] [CrossRef] [Green Version]

- Tortschanoff, A.; Lenzhofer, M.; Frank, A.; Wildenhain, M.; Sandner, T.; Schenk, H.; Scherf, W.; Kenda, A. Position encoding and phase control of resonant MOEMS mirrors. Sens. Actuators A Phys. 2010, 162, 235–240. [Google Scholar] [CrossRef]

- Shao, Y.; Dickensheets, D.L. MOEMS 3-D scan mirror for single-point control of beam deflection and focus. J. Microlith. Microfab. 2005, 4, 041502. [Google Scholar] [CrossRef]

- Erdmann, L.; Deparnay, A.; Maschke, G.; Langle, M.L.; Brunner, R. MOEMS-Based lithography for the fabrication of micro-optical components. J. Microlith. Microfab. 2005, 4, 041601. [Google Scholar] [CrossRef]

- Toshiyoshi, H.; Su, G.-J.; LaCosse, J.; Wu, M.C. A surface micromachined optical scanner array using photoresist lenses fabricated by a thermal reflow process. J. Lightwave Techol. 2003, 21, 1700–1708. [Google Scholar] [CrossRef]

- Kwon, S.; Lee, L.P. Stacked Two Dimensional Microlens Scanner for Micro Confocal Imaging Array. In Proceedings of the Fifteenth IEEE International Conference on Micro Electro Mechanical Systems (Cat. No. 02CH37266), Las Vegas, NV, USA, 24 January 2002; pp. 483–486. [Google Scholar]

- Ersumo, N.T.; Yalcin, C.; Antipa, N.; Pegard, N.; Waller, L.; Lopez, D.; Muller, R. A micromirror array with annular partitioning for high-speed random-access axial focusing. Light Sci. Appl. 2020, 9, 183. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.-B.; Qiu, H.-Y.; Zhang, H.-L.; Pang, X.-N.; Zhou, L.-D.; Liu, L.; Ren, H.; Wang, Q.-H.; Dong, J.-W. A broadband achromatic metalens array for integral imaging in the visible. Light Sci. Appl. 2019, 8, 67. [Google Scholar] [CrossRef] [Green Version]

- Zhao, R.; Huang, L.; Wang, Y. Recent advances in multi-dimensional metasurfaces holographic technologies. PhotoniX 2020, 1, 20. [Google Scholar] [CrossRef]

- Zou, X.; Zheng, G.; Yuan, Q.; Zang, W.; Chen, R.; Li, T.; Li, L.; Wang, S.; Wang, Z.; Zhu, S. Imaging based on metalenses. PhotoniX 2020, 1, 2. [Google Scholar] [CrossRef] [Green Version]

- Tanida, J.; Shogenji, R.; Kitamura, Y.; Yamada, K.; Miyamoto, M.; Miyatake, S. Color imaging with an integrated compound imaging system. Opt. Express 2003, 11, 2109–2117. [Google Scholar] [CrossRef] [PubMed]

- Horisaki, R.; Irie, S.; Ogura, Y.; Tanida, J. Three-Dimensional information acquisition using a compound imaging system. Opt. Rev. 2007, 14, 347–350. [Google Scholar] [CrossRef]

- Shogenji, R.; Kitamura, Y.; Yamada, K.; Miyatake, S.; Tanida, J. Bimodal fingerprint capturing system based on compound-eye imaging module. Appl. Opt. 2004, 43, 1355–1359. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, X.T.; Peng, Y.Y.; Peng, R.; Zeng, X.Y.; Zhang, Y.A.; Guo, T.L. Fabrication of Large-Scale Microlens Arrays Based on Screen Printing for Integral Imaging 3D Display. ACS Appl. Mater. Interfaces 2016, 8, 24248–24255. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.I.; Kim, K.; Yang, S.; Jang, K.W.; Jeong, K.H. Multifocal microlens arrays using multilayer photolithography. Opt. Express 2020, 28, 9082–9088. [Google Scholar] [CrossRef]

- Lee, J.H.; Chang, S.; Kim, M.S.; Kim, Y.J.; Kim, H.M.; Song, Y.M. High-Identical Numerical Aperture, Multifocal Microlens Array through Single-Step Multi-Sized Hole Patterning Photolithography. Micromachines 2020, 11, 1068. [Google Scholar] [CrossRef] [PubMed]

- Lian, G.G.; Liu, Y.S.; Tao, K.K.; Xing, H.M.; Huang, R.X.; Chi, M.B.; Zhou, W.C.; Wu, Y.H. Fabrication and Characterization of Curved Compound Eyes Based on Multifocal Microlenses. Micromachines 2020, 11, 854. [Google Scholar] [CrossRef]

- Park, M.K.; Lee, H.J.; Park, J.S.; Kim, M.; Bae, J.M.; Mahmud, I.; Kim, H.R. Design and Fabrication of Multi-Focusing Micro lens Array with Different Numerical Apertures by using Thermal Reflow Method. J. Opt. Soc. Korea 2014, 18, 71–77. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.-Z.; Wang, L.; Fan, H.; Yu, Y.-H.; Chen, Q.-D.; Juodkazis, S.; Sun, H.-B. O-FIB: Far-Field-Induced near-field breakdown for direct nanowriting in an atmospheric environment. Light Sci. Appl. 2020, 9, 41. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Zhang, Y.-L.; Han, D.-D.; Wang, W.; Sun, H.-B. Laser fabrication of modular superhydrophobic chips for reconfigurable assembly and self-propelled droplet manipulation. PhotoniX 2021, 2, 17. [Google Scholar] [CrossRef]

- Yin, D.; Feng, J.; Ma, R.; Liu, Y.F.; Zhang, Y.L.; Zhang, X.L.; Bi, Y.G.; Chen, Q.D.; Sun, H.B. Efficient and mechanically robust stretchable organic light-emitting devices by a laser-programmable buckling process. Nat. Commun. 2016, 7, 11573. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.-Q.; Bai, B.-F.; Chen, Q.-D.; Sun, H.-B. Etching-Assisted femtosecond laser modification of hard materials. Opto-Electron. Adv. 2019, 2, 19002101–19002114. [Google Scholar] [CrossRef] [Green Version]

- Fang, H.H.; Yang, J.; Ding, R.; Chen, Q.D.; Wang, L.; Xia, H.; Feng, J.; Ma, Y.G.; Sun, H.B. Polarization dependent two-photon properties in an organic crystal. Appl. Phys. Lett. 2010, 97, 101101. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.L.; Dong, W.F.; Yang, R.Z.; Meng, X.; Zhang, L.; Chen, Q.D.; Sun, H.B. Dynamically Tunable Protein Microlenses. Angew. Chem. Int. Ed. 2012, 51, 1558–1562. [Google Scholar] [CrossRef]

- Jiang, H.B.; Zhang, Y.L.; Han, D.D.; Xia, H.; Feng, J.; Chen, Q.D.; Hong, Z.R.; Sun, H.B. Bioinspired Fabrication of Superhydrophobic Graphene Films by Two-Beam Laser Interference. Adv. Funct. Mater. 2014, 24, 4595–4602. [Google Scholar] [CrossRef]

- Feng, T.; Chen, G.; Han, H.; Qiao, J. Femtosecond-Laser-Ablation Dynamics in Silicon Revealed by Transient Reflectivity Change. Micromachines 2022, 13, 14. [Google Scholar] [CrossRef] [PubMed]

- Phillips, K.C.; Gandhi, H.H.; Mazur, E.; Sundaram, S.K. Ultrafast laser processing of materials: A review. Adv. Opt. Photon. 2015, 7, 684–712. [Google Scholar] [CrossRef]

- Lin, Z.; Hong, M. Femtosecond Laser Precision Engineering: From Micron, Submicron, to Nanoscale. Ultrafast Sci. 2021, 2021, 9783514. [Google Scholar] [CrossRef]

- Yulianto, N.; Kadja, G.T.M.; Bornemann, S.; Gahlawat, S.; Majid, N.; Triyana, K.; Abdi, F.F.; Wasisto, H.S.; Waag, A. Ultrashort Pulse Laser Lift-Off Processing of InGaN/GaN Light-Emitting Diode Chips. ACS Appl. Electron. Mater. 2021, 3, 778–788. [Google Scholar] [CrossRef]

- Yulianto, N.; Refino, A.D.; Syring, A.; Majid, N.; Mariana, S.; Schnell, P.; Wahyuono, R.A.; Triyana, K.; Meierhofer, F.; Daum, W.; et al. Wafer-Scale transfer route for top–down III-nitride nanowire LED arrays based on the femtosecond laser lift-off technique. Microsyst. Nanoeng. 2021, 7, 32. [Google Scholar] [CrossRef]

- Juodkazis, S.; Nishimura, K.; Misawa, H.; Ebisui, T.; Waki, R.; Matsuo, S.; Okada, T. Control over the crystalline state of sapphire. Adv. Mater. 2006, 18, 1361. [Google Scholar] [CrossRef]

- Liu, X.Q.; Chen, Q.D.; Guan, K.M.; Ma, Z.C.; Yu, Y.H.; Li, Q.K.; Tian, Z.N.; Sun, H.B. Dry-Etching-Assisted femtosecond laser machining. Laser Photonics Rev. 2017, 11, 3. [Google Scholar] [CrossRef]

- Liu, X.Q.; Yu, L.; Chen, Q.D.; Sun, H.B. Mask-Free construction of three-dimensional silicon structures by dry etching assisted gray-scale femtosecond laser direct writing. Appl. Phys. Lett. 2017, 110, 091602. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.Q.; Yang, S.N.; Yu, L.; Chen, Q.D.; Zhang, Y.L.; Sun, H.B. Rapid Engraving of Artificial Compound Eyes from Curved Sapphire Substrate. Adv. Funct. Mater. 2019, 29, 1900037. [Google Scholar] [CrossRef]

- Han, D.D.; Zhang, Y.L.; Ma, J.N.; Liu, Y.Q.; Han, B.; Sun, H.B. Light-Mediated Manufacture and Manipulation of Actuators. Adv. Mater. 2016, 28, 8328–8343. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Tian, Y.; Wang, H.; Ma, Z.C.; Han, D.D.; Niu, L.G.; Chen, Q.D.; Sun, H.B. Dual-3D Femtosecond Laser Nanofabrication Enables Dynamic Actuation. ACS Nano 2019, 13, 4041–4048. [Google Scholar] [CrossRef]

- Wang, W.; Liu, Y.Q.; Liu, Y.; Han, B.; Wang, H.; Han, D.D.; Wang, J.N.; Zhang, Y.L.; Sun, H.B. Direct Laser Writing of Superhydrophobic PDMS Elastomers for Controllable Manipulation via Marangoni Effect. Adv. Funct. Mater. 2017, 27, 1702946. [Google Scholar] [CrossRef]

- Huff, M. Recent Advances in Reactive Ion Etching and Applications of High-Aspect-Ratio Microfabrication. Micromachines 2021, 12, 991. [Google Scholar] [CrossRef]

- Refino, A.D.; Yulianto, N.; Syamsu, I.; Nugroho, A.P.; Hawari, N.H.; Syring, A.; Kartini, E.; Iskandar, F.; Voss, T.; Sumboja, A.; et al. Versatilely tuned vertical silicon nanowire arrays by cryogenic reactive ion etching as a lithium-ion battery anode. Sci. Rep. 2021, 11, 19779. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.-X.; Zheng, J.-X.; Qi, J.-Y.; Guo, M.-R.; Gao, B.-R.; Liu, X.-Q. Integration of Multifocal Microlens Array on Silicon Microcantilever via Femtosecond-Laser-Assisted Etching Technology. Micromachines 2022, 13, 218. https://doi.org/10.3390/mi13020218

Wang B-X, Zheng J-X, Qi J-Y, Guo M-R, Gao B-R, Liu X-Q. Integration of Multifocal Microlens Array on Silicon Microcantilever via Femtosecond-Laser-Assisted Etching Technology. Micromachines. 2022; 13(2):218. https://doi.org/10.3390/mi13020218

Chicago/Turabian StyleWang, Bao-Xu, Jia-Xin Zheng, Jin-Yong Qi, Ming-Rui Guo, Bing-Rong Gao, and Xue-Qing Liu. 2022. "Integration of Multifocal Microlens Array on Silicon Microcantilever via Femtosecond-Laser-Assisted Etching Technology" Micromachines 13, no. 2: 218. https://doi.org/10.3390/mi13020218