Influence of Radiation-Induced Displacement Defect in 1.2 kV SiC Metal-Oxide-Semiconductor Field-Effect Transistors

Abstract

:1. Introduction

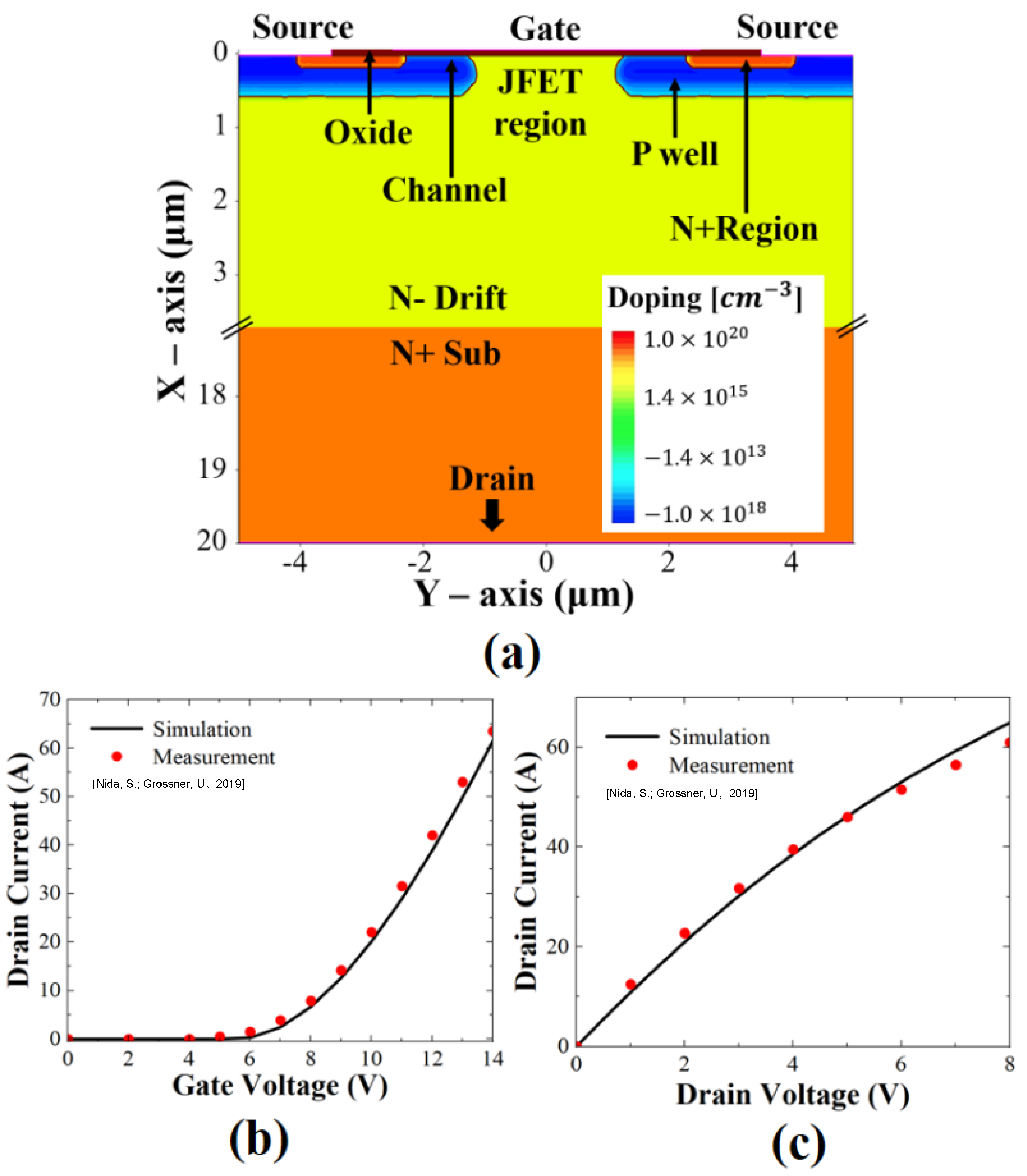

2. Simulation Modeling Methodology

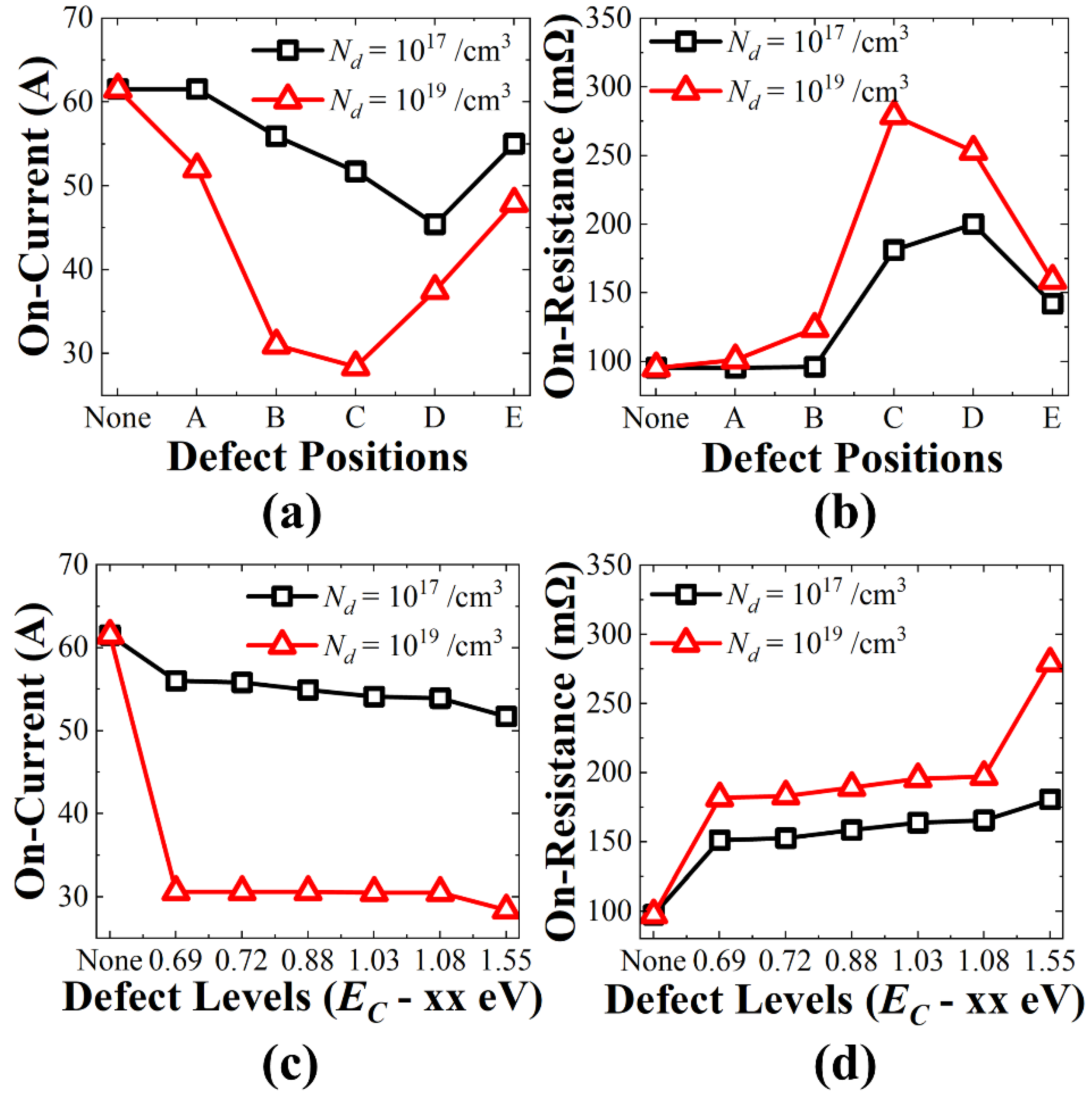

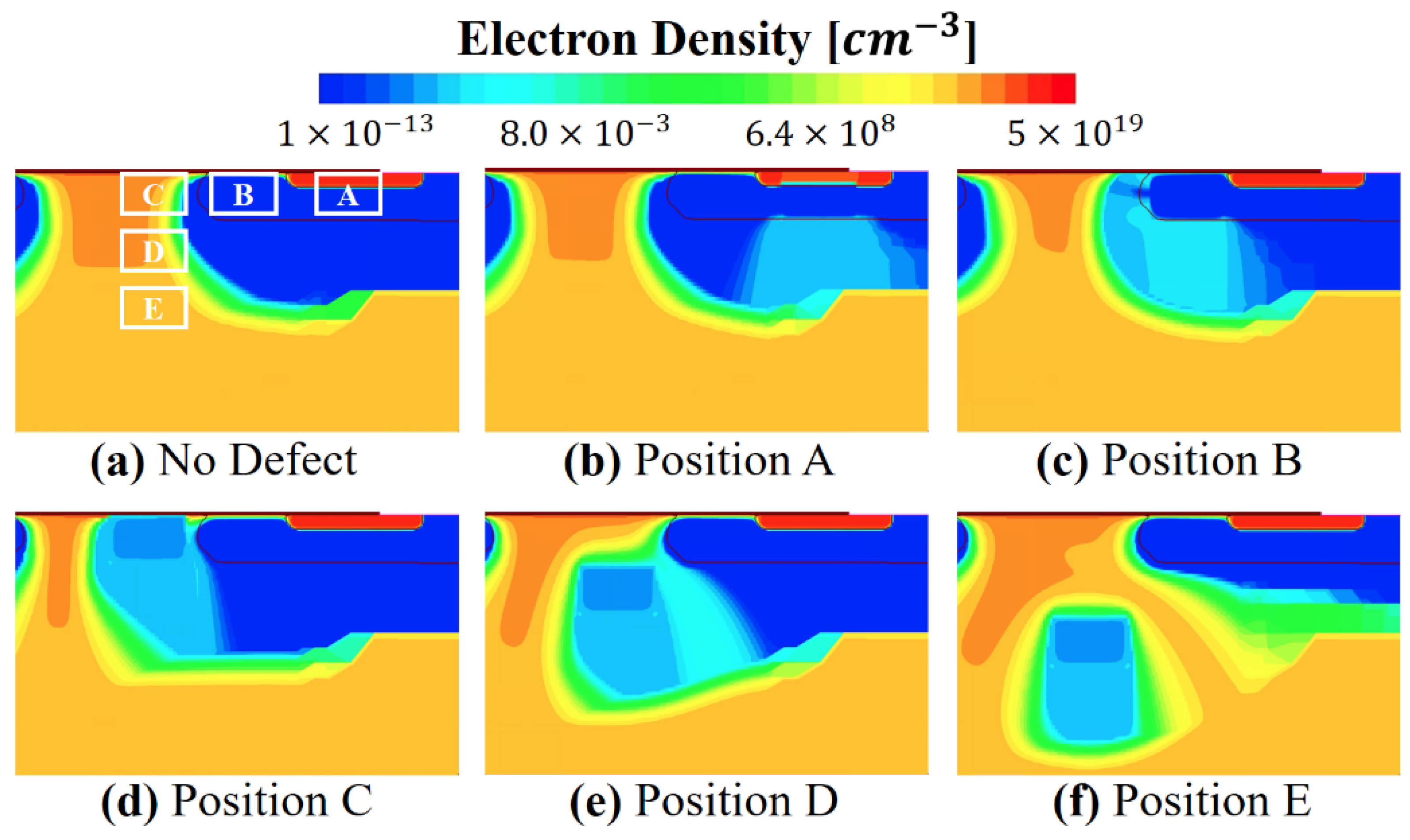

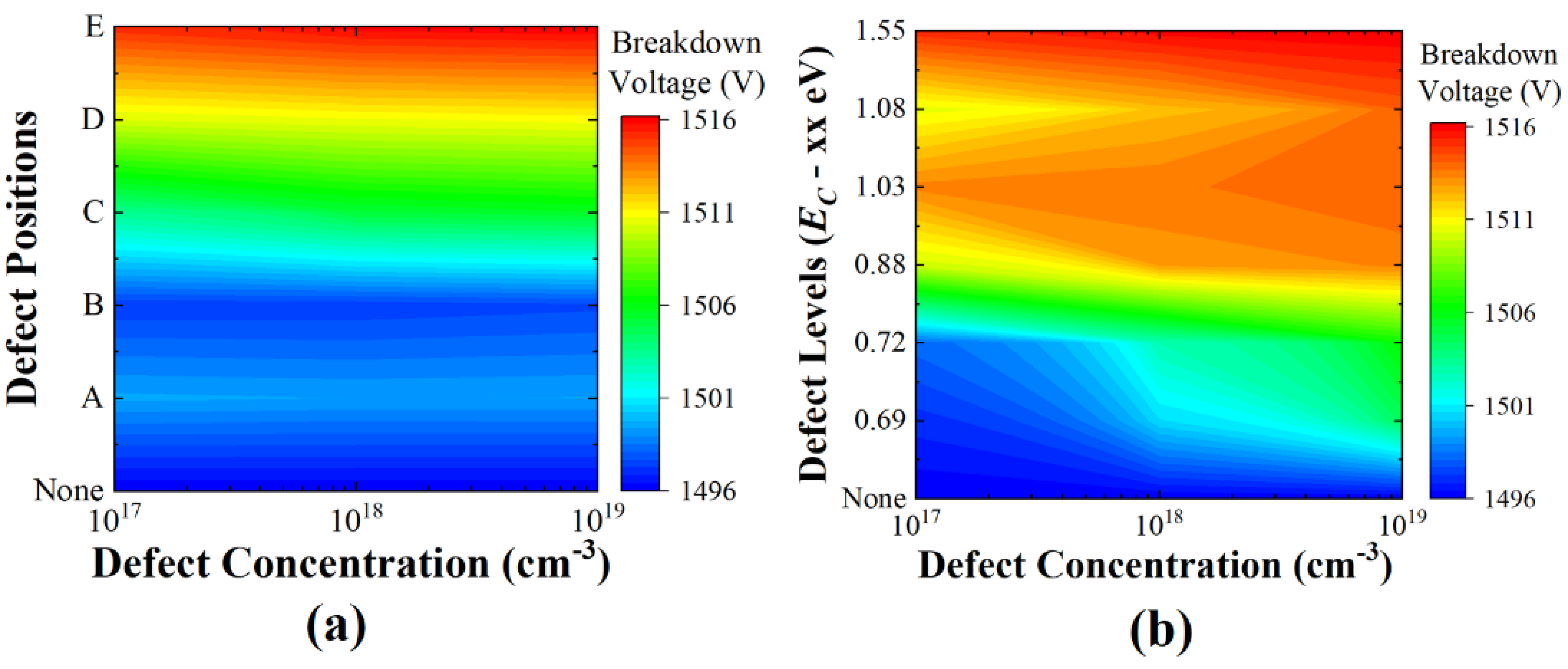

3. Result and Discussion

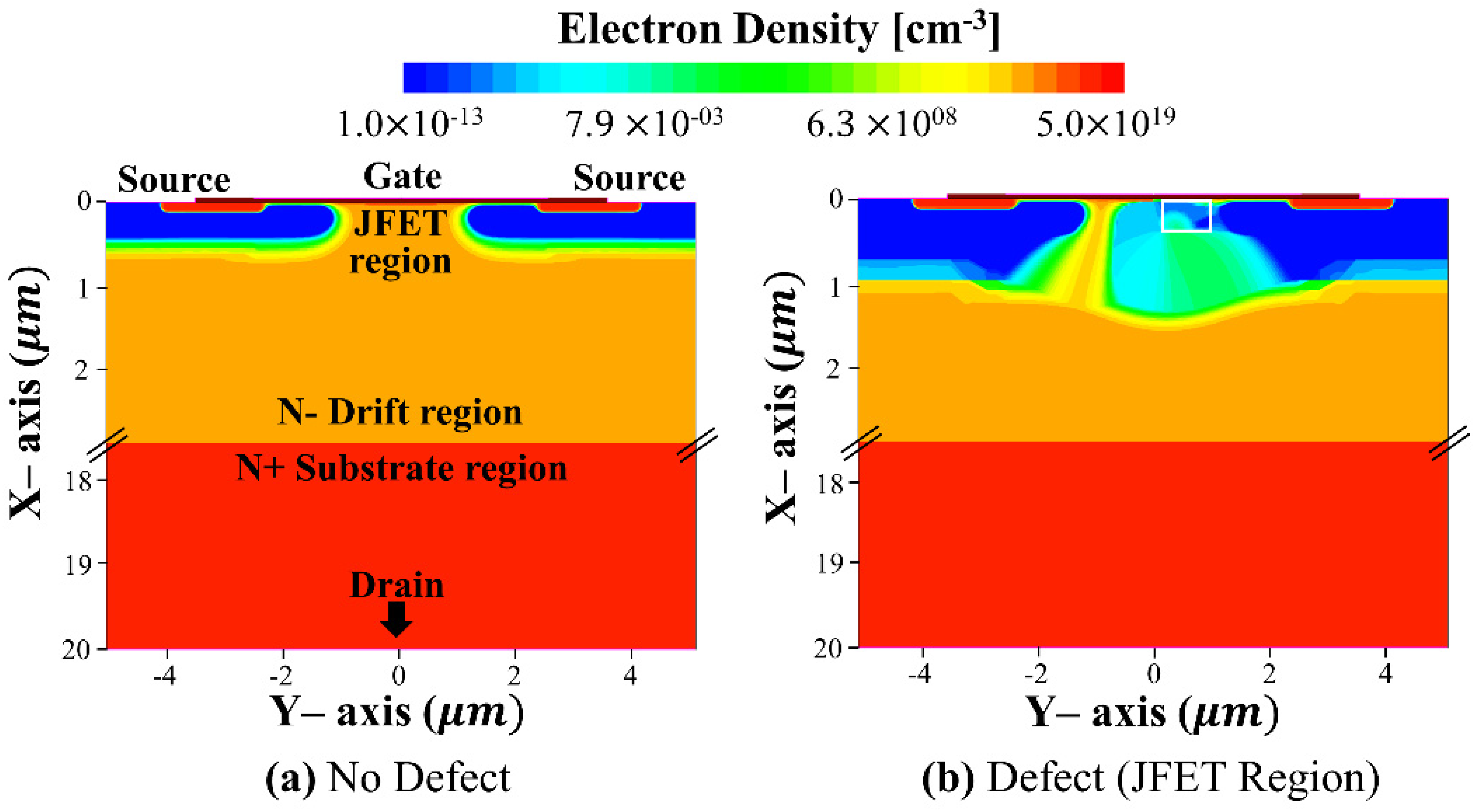

3.1. DC Characteristics

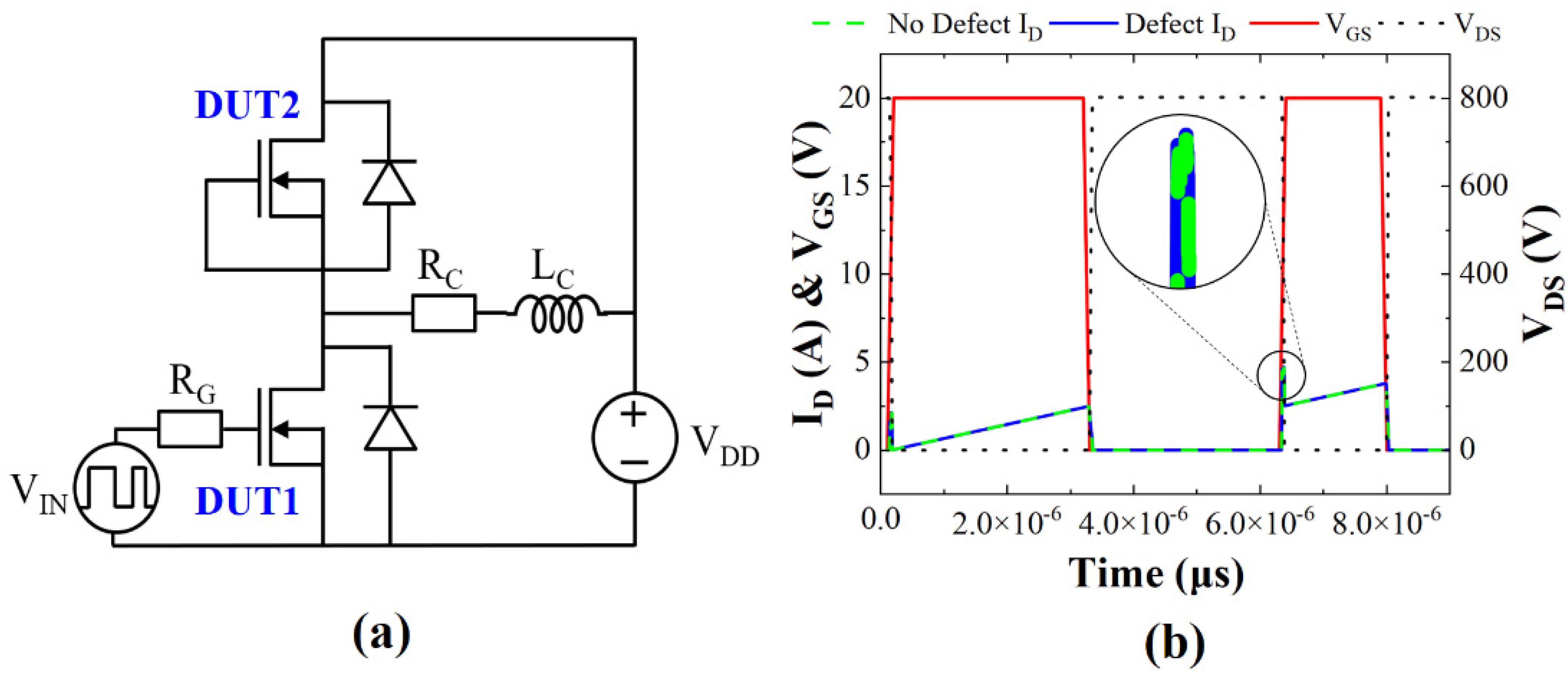

3.2. Double-Pulse Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Cooper, J.A.; Melloch, M.R.; Singh, R.; Agarwal, A.; Palmour, J.W. Status and prospects for SiC power MOSFETs. IEEE Trans. Electron Devices 2002, 49, 658–664. [Google Scholar] [CrossRef]

- Biela, J.; Schweizer, M.; Waffler, S.; Kolar, J.W. SiC versus Si—Evaluation of Potentials for Performance Improvement of Inverter and DC–DC Converter Systems by SiC Power Semiconductors. IEEE Trans. Ind. Electron. 2011, 58, 2872–2882. [Google Scholar] [CrossRef]

- She, X.; Huang, A.Q.; Oscar, L.; Ozpineci, B. Review of Silicon Carbide Power Devices and Their Applications. IEEE Trans. Ind. Electron. 2017, 64, 8193–8205. [Google Scholar] [CrossRef]

- Kumar, V.; Verma, J.; Maan, A.S.; Akhtar, J. Epitaxial 4H-SiC based Schottky diode temperature sensors in ultra-low current range. Vacuum 2020, 182, 109590. [Google Scholar] [CrossRef]

- Millán, J.; Godignon, P.; Perpiñà, X.; Pérez-Tomás, A.; Rebollo, J. A Survey of Wide Bandgap Power Semiconductor Devices. IEEE Trans. Power Electron. 2014, 29, 2155–2163. [Google Scholar] [CrossRef]

- Martinella, C.; Ziemann, T.; Stark, R.; Tsibizov, A.; Voss, K.O.; Alia, R.G.; Kadi, Y.; Grossner, U.; Javanainen, A. Heavy-Ion Microbeam Studies of Single-Event Leakage Current Mechanism in SiC VD-MOSFETs. IEEE Trans. Nucl. Sci. 2020, 67, 1381–1389. [Google Scholar] [CrossRef]

- Akturk, A.; McGarrity, J.M.; Potbhare, S.; Goldsman, N. Radiation Effects in Commercial 1200 V 24 A Silicon Carbide Power MOSFETs. IEEE Trans. Nucl. Sci. 2012, 59, 3258–3264. [Google Scholar] [CrossRef]

- Asai, H.; Nashiyama, I.; Sugimoto, K.; Shiba, K.; Sakaide, Y.; Ishimaru, Y.; Okazaki, Y.; Noguchi, K.; Morimura, T. Tolerance Against Terrestrial Neutron-Induced Single-Event Burnout in SiC MOSFETs. IEEE Trans. Nucl. Sci. 2014, 61, 3109–3114. [Google Scholar] [CrossRef]

- Witulski, A.F.; Ball, D.R.; Galloway, K.F.; Javanainen, A.; Lauenstein, J.-M.; Sternberg, A.L.; Schrimpf, R.D. Single-Event Burnout Mechanisms in SiC Power MOSFETs. IEEE Trans. Nucl. Sci. 2018, 65, 1951–1955. [Google Scholar] [CrossRef]

- Lu, J.; Liu, J.; Tian, X.; Chen, H.; Tang, Y.; Bai, Y.; Li, C.; Liu, X. Impact of Varied Buffer Layer Designs on Single-Event Response of 1.2-kV SiC Power MOSFETs. IEEE Trans. Electron Devices 2020, 67, 3698–3704. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, M.; Li, X.-J.; Wu, X.; Yang, J.-Q.; Bao, M.-T.; Yu, C.-H.; Cao, F. Single-Event Burnout Hardness for the 4H-SiC Trench-Gate MOSFETs Based on the Multi-Island Buffer Layer. IEEE Trans. Electron Devices 2019, 66, 4264–4272. [Google Scholar] [CrossRef]

- Gordon, M.S.; Goldhagen, P.; Rodbell, K.P.; Zabel, T.H.; Tang, H.H.K.; Clem, J.M.; Bailey, P. Measurement of the flux and energy spectrum of cosmic-ray induced neutrons on the ground. IEEE Trans. Nucl. Sci. 2004, 51, 3427–3434. [Google Scholar] [CrossRef]

- Li, W.; Wang, L.; Bian, L.; Dong, F.; Song, M.; Shao, J.; Jiang, S.; Guo, H. Threshold displacement energies and displacement cascades in 4H-SiC: Molecular dynamic simulations. Aip Adv. 2019, 9, 055007. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.; Park, B. Estimation of Residual Radioactivity and Radiation Damage in SiC After Neutron Irradiation. IEEE Trans. Nucl. Sci. 2020, 67, 1374–1380. [Google Scholar] [CrossRef]

- Han, J.W.; Meyyappan, M.; Kim, J. Single Event Hard Error due to Terrestrial Radiation. In Proceedings of the 2021 IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 21–25 March 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Popelka, S.; Hazdra, P.; Sharma, R.; Záhlava, V.; Vobecký, J. Effect of Neutron Irradiation on High Voltage 4H-SiC Vertical JFET Characteristics: Characterization and Modeling. IEEE Trans. Nucl. Sci. 2014, 61, 3030–3036. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.; Han, J.; Meyyappan, M. Caution: Abnormal Variability Due to Terrestrial Cosmic Rays in Scaled-Down FinFETs. IEEE Trans. Electron Devices 2019, 66, 1887–1891. [Google Scholar] [CrossRef]

- Kumar, V.; Maan, A.S.; Akhtar, J. Defect levels in high energy heavy ion implanted 4H-SiC. Mat. Lett. 2022, 308, 131150. [Google Scholar] [CrossRef]

- Synopsys Inc. Sentaurus Device User Guide; L-Version: Mountain View, CA, USA, 2016. [Google Scholar]

- Kim, K.; Kim, J. Insights into radiation displacement defect in an insulated-gate bipolar transistor. AIP Adv. 2021, 11, 025137. [Google Scholar] [CrossRef]

- Nida, S.; Grossner, U. High-Temperature Impact-Ionization Model for 4H-SiC. IEEE Trans. Electron Devices 2019, 66, 1899–1904. [Google Scholar] [CrossRef]

- Datasheet C2M0080120D; Cree, Inc.: Durham, NC, USA, 2015; Available online: https://www.micro-semiconductor.com/datasheet/d6-C2M0080120D.pdf (accessed on 6 June 2022).

- Li, H.; Wang, J.; Ren, N.; Xu, H.; Sheng, K. Investigation of 1200 V SiC MOSFETs’ Surge Reliability. Micromachines 2019, 10, 485. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Müting, J.; Natzke, P.; Tsibizov, A.; Grossner, U. Influence of Process Variations on the Electrical Performance of SiC Power MOSFETs. IEEE Trans. Electron Devices 2021, 68, 230–235. [Google Scholar] [CrossRef]

- Nava, F.; Castaldini, A.; Cavallini, A.; Errani, P.; Cindro, V. Radiation Detection Properties of 4H-SiC Schottky Diodes Irradiated Up to 1016 n/cm2 by 1 MeV Neutrons. IEEE Trans. Nucl. Sci. 2006, 53, 2977–2982. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, B.; Wang, F.F.; Jones, E.A.; Tolbert, L.M.; Blalock, B.J. Methodology for Wide Band-Gap Device Dynamic Characterization. IEEE Trans. Power Electron. 2017, 32, 9307–9318. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, G.; Ha, J.; Kim, K.; Bae, H.; Kim, C.-E.; Kim, J. Influence of Radiation-Induced Displacement Defect in 1.2 kV SiC Metal-Oxide-Semiconductor Field-Effect Transistors. Micromachines 2022, 13, 901. https://doi.org/10.3390/mi13060901

Lee G, Ha J, Kim K, Bae H, Kim C-E, Kim J. Influence of Radiation-Induced Displacement Defect in 1.2 kV SiC Metal-Oxide-Semiconductor Field-Effect Transistors. Micromachines. 2022; 13(6):901. https://doi.org/10.3390/mi13060901

Chicago/Turabian StyleLee, Gyeongyeop, Jonghyeon Ha, Kihyun Kim, Hagyoul Bae, Chong-Eun Kim, and Jungsik Kim. 2022. "Influence of Radiation-Induced Displacement Defect in 1.2 kV SiC Metal-Oxide-Semiconductor Field-Effect Transistors" Micromachines 13, no. 6: 901. https://doi.org/10.3390/mi13060901