Numerical Analysis of a CZTS Solar Cell with MoS2 as a Buffer Layer and Graphene as a Transparent Conducting Oxide Layer for Enhanced Cell Performance

Abstract

:1. Introduction

2. Materials and Methods

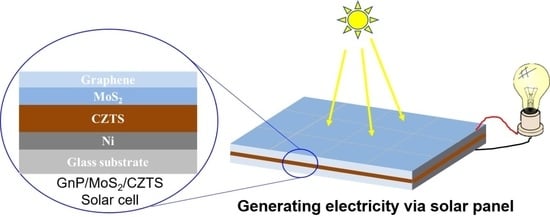

2.1. Structure of CZTS Solar Cell

2.2. Transparent Conducting Oxide or Window Layer

2.3. Buffer Layer

2.4. Absorber Layer

2.5. Back Contact

2.6. Soda Lime Glass Substrate

2.7. Mathematical Modeling

2.8. Numerical Simulation and Device Modeling

3. Results and Discussion

3.1. Effect of Buffer Layer Thickness

3.2. Effect of Absorber Layer Thickness

3.3. Effect of Doping Density of CZTS Absorber Layer

3.4. Effect of Temperature

3.5. Quantum Efficiency (QE)

3.6. Current Density–Voltage (J–V) Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Andreani, L.C.; Bozzola, A.; Kowalczewski, P.; Liscidini, M.; Redorici, L. Silicon solar cells: Toward the efficiency limits. Adv. Phys. 2019, 4, 1692. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Sánchez, R.A.; Rodriguez-Resendiz, J.; Álvarez-Alvarado, J.M.; Macías-Socarrás, I. Solar Energy-Based Future Perspective for Organic Rankine Cycle Applications. Micromachines 2022, 13, 944. [Google Scholar] [CrossRef] [PubMed]

- Chiappim, W., Jr.; Moreno, L.X.; Pessoa, R.S.; da Cunha, A.F.; Salomé, P.M.P.; Leitão, J.P. Novel dielectrics compounds grown by atomic layer deposition as sustainable materials for chalcogenides thin-films photovoltaics technologies. In Sustainable Material Solutions for Solar Energy Technologies: Processing Techniques and Applications; Fraga, M.A., Amos, D., Sonmezoglu, S., Subramaniam, V., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 71–100. [Google Scholar] [CrossRef]

- Gessert, T.A. Cadmium Telluride Photovoltaic Thin Film: CdTe. Compr. Renew. Energy 2012, 1, 423–438. [Google Scholar] [CrossRef]

- Shanks, W.C.P., III; Kimball, B.E.; Tolcin, A.C.; Guberman, D.E. Germanium and Indium. In Critical Mineral Resources of the United States—Economic and Environmental Geology and Prospects for Future Supply, 2nd ed.; Schulz, K.J., DeYoung, J.H., Jr., Seal, R.R., II, Bradley, D.C., Eds.; U.S. Geological Survey: Reston, VA, USA, 2017; Volume 1802, pp. I1–I27. [Google Scholar] [CrossRef] [Green Version]

- Gerhardsson, L. Tellurium. In Handbook on the Toxicology of Metals; Nordberg, G.F., Costa, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 2, pp. 783–794. [Google Scholar] [CrossRef]

- Dey, M.; Dey, M.; Alam, S.; Gupta, A.K.S.; Das, N.K.; Matin, M.A.; Amin, N. Design of ultra-Thin CZTS solar cells with Indium selenide as buffer layer. In Proceedings of the International Conference on Electrical, Computer and Communication Engineering (ECCE), Cox’s Bazar, Bangladesh, 16–18 February 2017. [Google Scholar] [CrossRef]

- Henry, J.; Mohanraj, K.; Sivakumar, G. Electrical and optical properties of CZTS thin films prepared by SILAR method. J. Asian Ceram. Soc. 2016, 4, 81–84. [Google Scholar] [CrossRef]

- Reyes, A.C.P.; Lázaro, R.C.A.; Leyva, K.M.; López, J.A.L.; Méndez, J.F.; Jiménez, A.H.H.; Muñoz Zurita, A.L.; Carrillo, F.S.; Durán, E.O. Study of a lead-free perovskite solar cell using CZTS as HTL to achieve a 20% PCE by SCAPS-1D simulation. Micromachines 2021, 12, 1508. [Google Scholar] [CrossRef]

- Ki, W.; Hillhouse, H.W. Earth-abundant element photovoltaics directly from soluble precursors with high yield using a non-toxic solvent. Adv. Energy Mater. 2011, 1, 732–735. [Google Scholar] [CrossRef]

- Zyoud, S.H.; Zyoud, A.H.; Ahmed, N.M.; Prasad, A.R.; Khan, S.N.; Abdelkader, A.F.I.; Shahwan, M. Numerical Modeling of High Conversion Efficiency FTO/ZnO/CdS/CZTS/MO Thin Film-Based Solar Cells: Using SCAPS-1D Software. Crystals 2021, 11, 1468. [Google Scholar] [CrossRef]

- Ahamed, E.M.K.I.; Gupta, A.K.S.; Qamruzzaman, M.; Matin, M.A. An Efficient CZTS Solar Cell from Numerical Analysis. In Proceedings of the 1st International Conference on Advances in Science, Engineering and Robotics Technology (ICASERT), Dhaka, Bangladesh, 3–5 May 2019. [Google Scholar]

- Jahagirdar, A.H.; Kadam, A.A.; Dhere, N.G. Role of i-ZnO in optimizing open circuit voltage of CIGS2 and CIGS thin film solar cells. In Proceedings of the IEEE 4th World Conference on Photovoltaic Energy Conference, Waikoloa, HI, USA, 7–12 May 2006. [Google Scholar] [CrossRef]

- Dey, M.; Dey, M.; Alam, S.; Das, N.K.; Matin, M.A.; Amin, N. Study of Molybdenum Sulphide as a Novel Buffer Layer for CZTS Solar Cells. In Proceedings of the 3rd International Conference on Electrical Engineering and Information Communication Technology, Dhaka, Bangladesh, 22–24 September 2016. [Google Scholar] [CrossRef]

- Chandrasekharan, R. Numerical Modeling of Tin-Based Absorber Devices for Cost-Effective Solar Photovoltaics. Ph.D. Thesis, Pennsylvania State University, State College, PA, USA, 2012. [Google Scholar]

- Yasmin, S.; Ferdous, J.; Saha, B.B.; Ghosh, S. A Simulation-Based Investigation of Cu2ZnSnS4 Solar Cells with Graphene as a Window Layer. In Proceedings of the International Exchange and Innovation Conference on Engineering & Sciences (IEICES), Fukuoka, Japan, 21 October 2021. [Google Scholar] [CrossRef]

- Jhuma, F.A.; Shaily, M.Z.; Rashid, M.J. Towards high-efficiency CZTS solar cell through buffer layer optimization. Mater. Renew. Sustain. Energy 2019, 8, 6. [Google Scholar] [CrossRef] [Green Version]

- Nawz, T.; Safdar, A.; Hussain, M.; Lee, D.S.; Siyar, M. Graphene to advanced MoS2: A review of structure, synthesis, and optoelectronic device application. Crystals 2020, 10, 902. [Google Scholar] [CrossRef]

- Liu, C.; Bai, Y.; Zhao, Y.; Yao, H.; Pang, H. MoS2/graphene composites: Fabrication and electrochemical energy storage. Energy Storage Mater. 2020, 33, 470–502. [Google Scholar] [CrossRef]

- Czerniak-Reczulska, M.; Niedzielska, A.; Jędrzejczak, A. Graphene as a Material for Solar Cells Applications. Adv. Mater. Sci. 2015, 15, 67–81. [Google Scholar] [CrossRef] [Green Version]

- Shi, Z.; Jayatissa, A.H. The Impact of Graphene on the Fabrication of Thin Film Solar Cells: Current Status and Future Prospects. Materials 2018, 11, 36. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stadler, A. Transparent Conducting Oxides—An Up-To-Date Overview. Materials 2012, 5, 661–683. [Google Scholar] [CrossRef] [PubMed]

- Patel, K.; Tyagi, P.K. Multilayer graphene as a transparent conducting electrode in silicon heterojunction solar cells. AIP Adv. 2015, 5, 077165. [Google Scholar] [CrossRef] [Green Version]

- Khatami, Y.; Liu, W.; Kang, J.; Banerjee, K. Prospects of graphene electrodes in photovoltaics. Mater. Sci. 2013, 8824, 88240T. [Google Scholar] [CrossRef]

- Nikita, K.N.; Gaffar, M.A.; Chowdhury, M.I.B. Exploring the opportunity of using graphene as the transparent conducting layer in CZTS-based thin film solar cells. In Proceedings of the 3rd International Conference on Electrical Engineering and Information Communication Technology (ICEEICT), Dhaka, Bangladesh, 22–24 September 2016. [Google Scholar] [CrossRef]

- Von Roedern, B.; Bauer, G.H. Material requirements for buffer layers used to obtain solar cells with high open circuit voltages. MRS Online Proc. Libr. 1999, 557, 761–766. [Google Scholar] [CrossRef] [Green Version]

- Kupfer, B.; Majhi, K.; Keller, D.A.; Bouhadana, Y.; Rühle, S.; Barad, H.N.; Anderson, A.Y.; Zaban, A. Thin film Co3O4/TiO2 heterojunction solar cells. Adv. Energy Mater. 2015, 5, 1401007. [Google Scholar] [CrossRef]

- Mebarkia, C.; Dib, D.; Zerfaoui, H.; Belghit, R. The Role of Buffer Layers and Double Windows Layers in a Solar Cell CZTS Performances. AIP Conf. Proc. 2016, 1758, 030034. [Google Scholar] [CrossRef]

- Ali, F.; Hossain, F. Influence of Front and Back Contacts on Photovoltaic Performances of p-n Homojunction Si Solar Cell: Considering an Electron-Blocking Layer. Int. J. Photoenergy 2017, 2017, 7415851. [Google Scholar] [CrossRef] [Green Version]

- Bansal, N.; Mohanty, B.C.; Singh, K. Designing composition tuned glasses with enhanced properties for use as substrate in Cu2ZnSnS4 based thin film solar cells. J. Alloys Compd. 2020, 819, 152984. [Google Scholar] [CrossRef]

- Obi, U.C.; Sanni, D.M.; Bello, A. Effect of Absorber Layer Thickness on the Performance of Bismuth-Based Perovskite Solar Cells. Fiz. Tekhnika Poluprovodn. 2021, 55, 354. [Google Scholar]

- Niemegeers, A.; Burgelman, M.; Decock, K.; Verschraegen, J.; Degrave, S. SCAPS Manual. Ph.D. Thesis, University of Gent, Gent-Zwijnaarde, Belgium, 2016. [Google Scholar]

- Mandadapu, U.; Vedanayakam, S.V.; Thyagarajan, K. Simulation and Analysis of Lead based Perovskite Solar Cell using SCAPS-1D. Indian J. Sci. Technol. 2017, 10, 65–72. [Google Scholar] [CrossRef]

- Lin, J.; Xu, J.; Yang, Y. Numerical analysis of the effect of MoS2 interface layers on copper-zinc-tin-sulfur thin film solar cells. Optik 2020, 201, 163496. [Google Scholar] [CrossRef]

- Yasin, S.; Waar, Z.A.; al Zoubi, T. Development of high efficiency CZTS solar cell through buffer layer parameters optimization using SCAPS-1D. Mater. Today Proc. 2020, 33, 1825–1829. [Google Scholar] [CrossRef]

- Airao, B.; Gheravada, D.; Bhargava, K. Exploring the utility of Graphene as window layer towards efficiency improvement in CIGS solar cells using numerical simulations. In Proceedings of the 3rd International Conference for Convergence in Technology (I2CT), Pune, India, 6–8 April 2018. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Ang, L.K.; Ang, Y.S.; Guo, J. Designing few-layer graphene Schottky contact solar cells: Theoretical efficiency limits and parametric optimization. Appl. Phys. Lett. 2021, 118, 053103. [Google Scholar] [CrossRef]

- Li, Y.F.; Yang, W.; Tu, Z.Q.; Liu, Z.C.; Yang, F.; Zhang, L.Q.; Hatekeyama, R. Schottky junction solar cells based on graphene with different numbers of layers. Appl. Phys. Lett. 2014, 104, 4–8. [Google Scholar] [CrossRef]

- Dey, M.; Rahman, N.; Tasnim, I.; Dey, M.; Das, N.K. Design and Numerical Analysis of Efficient Gallium Arsenide Solar Cell with Graphene as Window Layer Material. In Proceedings of the 2nd International Conference on Electrical, Computer and Communication Engineering (ECCE), Cox’s Bazar, Bangladesh, 7–9 February 2019. [Google Scholar] [CrossRef]

- Bouarissa, A.; Gueddim, A.; Bouarissa, N.; Maghraoui-Meherezi, H. Modeling of ZnO/MoS2/CZTS photovoltaic solar cell through window, buffer and absorber layers optimization. Mater. Sci. Eng. B 2019, 263, 114816. [Google Scholar] [CrossRef]

- Cherouana, A.; Labbani, R. Study of CZTS and CZTSSe solar cells for buffer layers selection. Appl. Surf. Sci. 2017, 424, 251–255. [Google Scholar] [CrossRef]

| Parameters | Graphene | MoS2 | CZTS |

|---|---|---|---|

| Energy bandgap (eV) | 1.80 | 1.3 | 1.52 |

| Electron affinity (eV) | 3.92 | 4 | 4.50 |

| Relative permittivity | 10 | 4 | 10 |

| Conduction band effective density of states (×1018 cm−3) | 1000 | 0.75 | 2.2 |

| Valance band effective density of states (×1019 cm−3) | 100 | 0.18 | 1.8 |

| Electron thermal velocity (×107 cm s−1) | 5.2 | 0.01 | 1.0 |

| Hole thermal velocity (×107 cm s−1) | 5.0 | 1.0 | 1.0 |

| Electron mobility (cm2 v−1 s−1) | 1.0 × 109 | 100 | 100 |

| Hole mobility (cm2 v−1 s−1) | 10 | 150 | 20 |

| Doping density (×1018 cm−3) | 9000 | 1000 | 0.01 |

| Solar Cell Structure | Voc (V) | Jsc (mA cm−2) | FF (%) | η (%) | Ref. |

|---|---|---|---|---|---|

| Graphene/MoS2/CZTS | 0.85 | 25.30 | 84.76 | 18.27 | This work |

| Graphene/ZnO/CZTS | 0.85 | 23.81 | 84.70 | 17.14 | [16] |

| i-ZnO/MoS2/CZTS | 1.01 | 29.42 | 57.40 | 17.03 | [14] |

| ZnO/InSe/CZTS | 1.00 | 28.06 | 58.40 | 16.30 | [7] |

| Al:ZnO/i-ZnO/CdS/CZTS | 0.78 | 27.98 | 72.86 | 15.84 | [12] |

| ZnO/ZnS/CZTS | 0.64 | 23.96 | 65.20 | 10.00 | [41] |

| ZnO/CdS/CZTS | 0.61 | 26.95 | 57.20 | 9.47 | [41] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghosh, S.; Yasmin, S.; Ferdous, J.; Saha, B.B. Numerical Analysis of a CZTS Solar Cell with MoS2 as a Buffer Layer and Graphene as a Transparent Conducting Oxide Layer for Enhanced Cell Performance. Micromachines 2022, 13, 1249. https://doi.org/10.3390/mi13081249

Ghosh S, Yasmin S, Ferdous J, Saha BB. Numerical Analysis of a CZTS Solar Cell with MoS2 as a Buffer Layer and Graphene as a Transparent Conducting Oxide Layer for Enhanced Cell Performance. Micromachines. 2022; 13(8):1249. https://doi.org/10.3390/mi13081249

Chicago/Turabian StyleGhosh, Sampad, Samira Yasmin, Jannatul Ferdous, and Bidyut Baran Saha. 2022. "Numerical Analysis of a CZTS Solar Cell with MoS2 as a Buffer Layer and Graphene as a Transparent Conducting Oxide Layer for Enhanced Cell Performance" Micromachines 13, no. 8: 1249. https://doi.org/10.3390/mi13081249