Enhanced Energy Absorption of Additive-Manufactured Ti-6Al-4V Parts via Hybrid Lattice Structures

Abstract

:1. Introduction

2. Experimental Section

2.1. PBF-Based 3D-Printing Processes

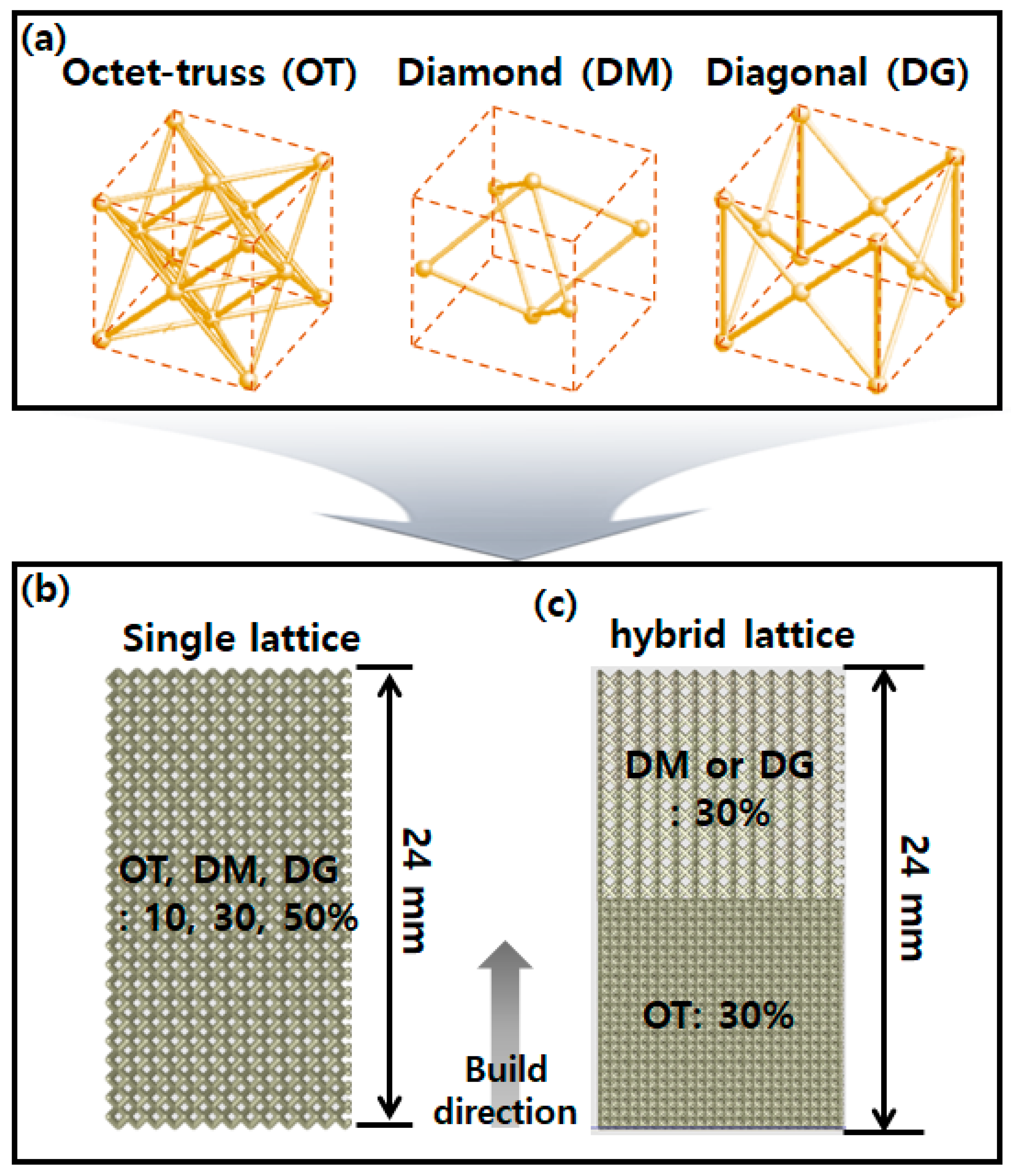

2.2. Design for Lattice Structures

2.3. Compression Tests

3. Results and Discussions

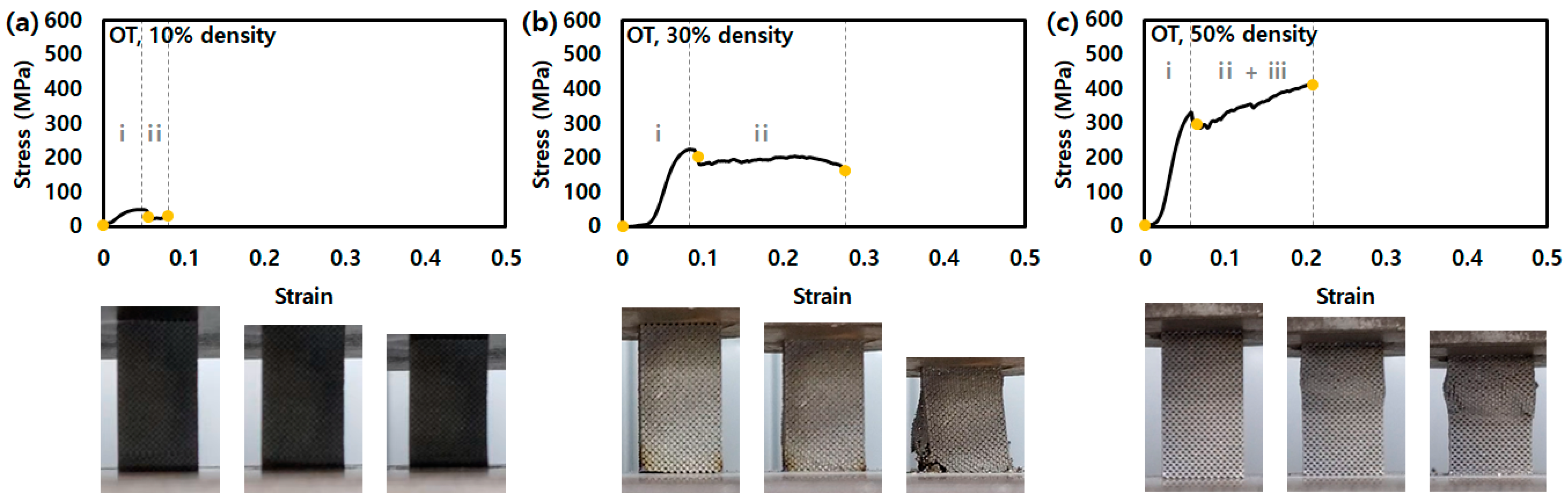

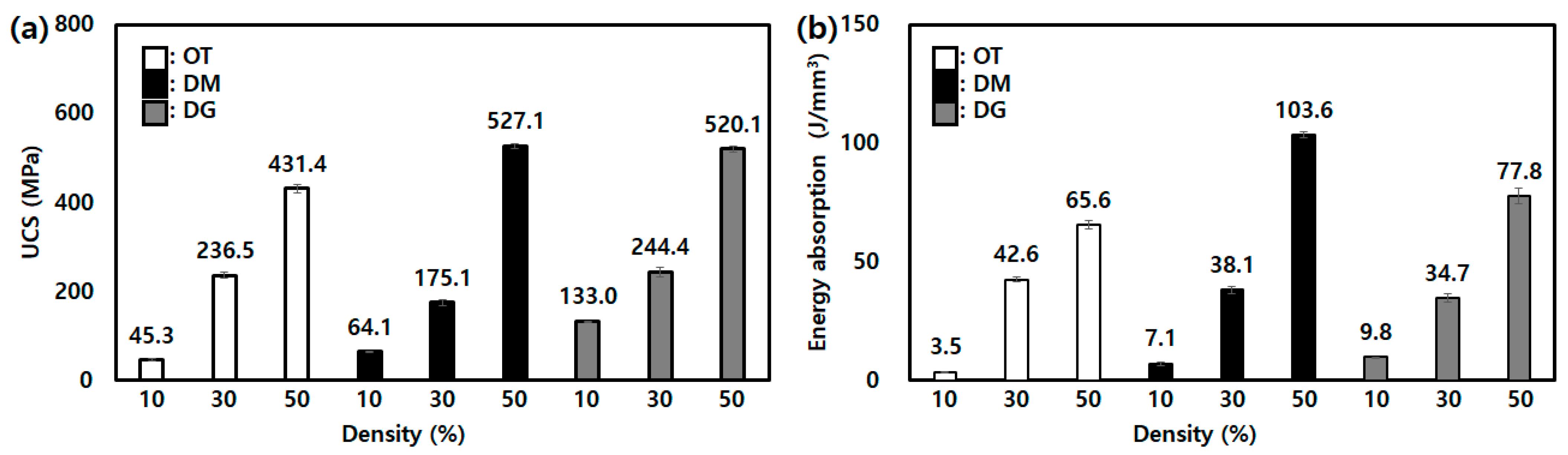

3.1. Compression Behavior of Single-Lattice Structures

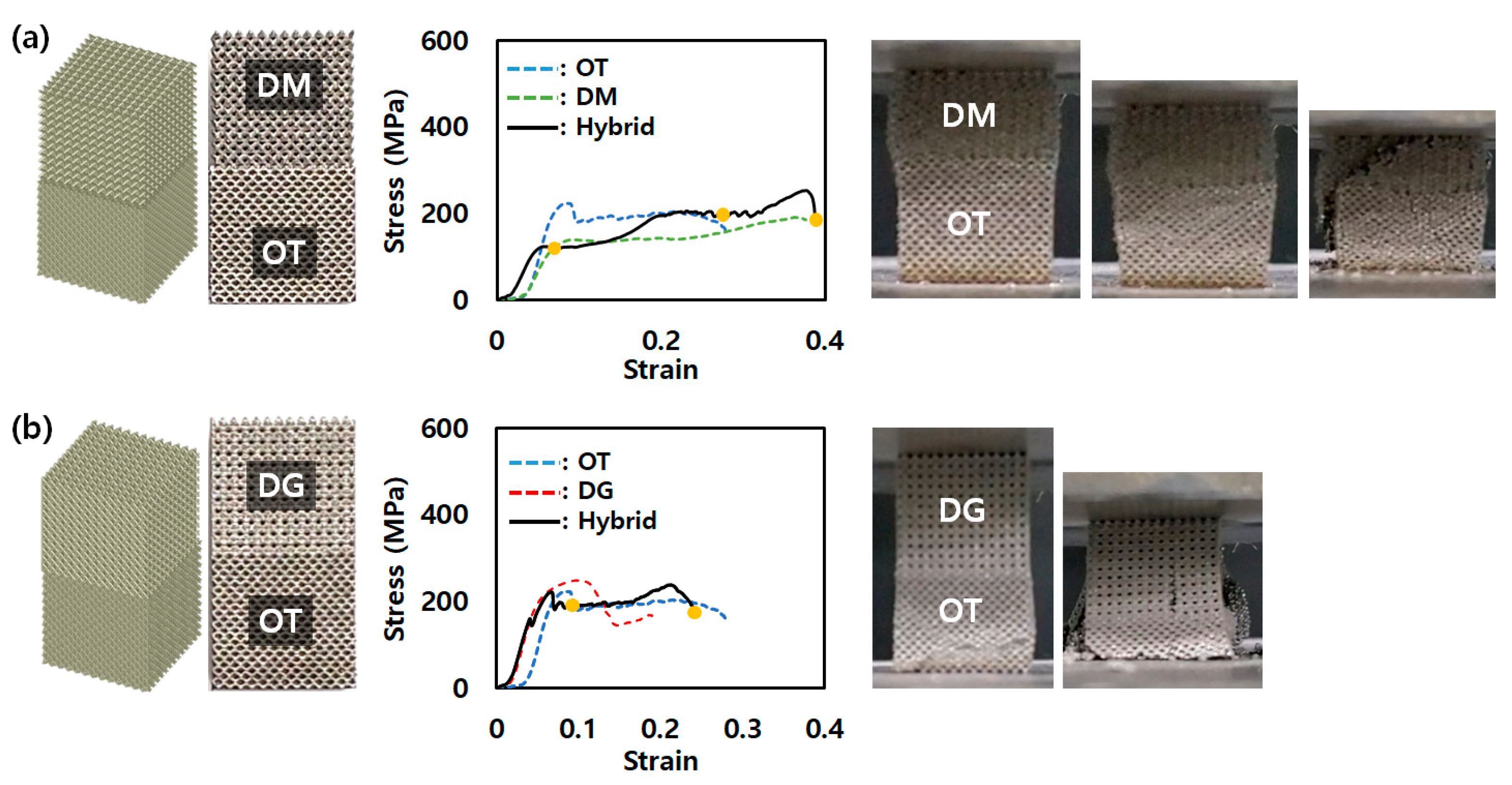

3.2. Compression Behavior of Hybrid Lattice Structures

3.3. Compression Behavior of Hybrid Lattice Structure with a Reinforcement

4. Conclusions

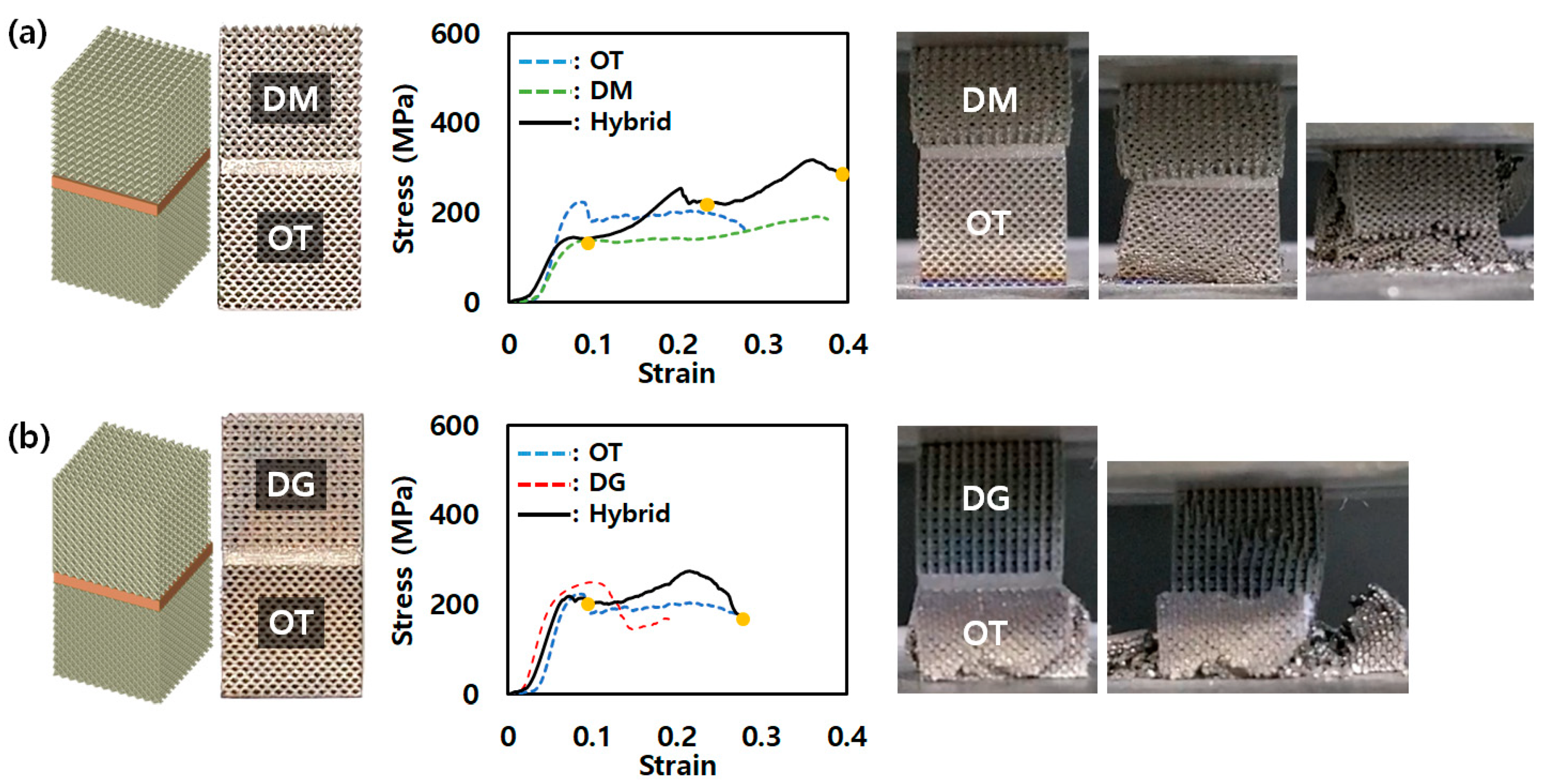

- Hybrid lattice structures, which combined different lattice types (OT, DM, and DG), demonstrated higher energy absorption than single-lattice structures of the same density. This indicates that the hybrid configuration overcomes the inherent limitations of single-lattice structures in terms of energy absorption.

- Single-lattice structures exhibited distinct compression behaviors depending on their dominant structural characteristics. OT structures, representing stretch-dominant structures, showed oscillation during plastic deformation. DM structures, representing bending-dominant structures, exhibited plateau stress without a stress drop, while DG structures showed the blunt onset of plasticity and early brittle failure due to z-direction struts.

- Among single-lattice structures, DG with a 50% density displayed behavior similar to that of solid structures after the onset of plasticity, indicating early brittle fracture. On the other hand, OT with a 30% density demonstrated the best UCS and energy absorption, while DM with a 30% density exhibited the weakest UCS among the 30% density structures.

- Hybrid lattice structures composed of OT-DM and OT-DG combinations exhibited the sequential collapse of the single lattices, leading to superior energy absorption compared to single-lattice structures. This indicates that hybrid configurations can enhance energy absorption capability by utilizing the specific properties of individual lattice types.

- To further enhance energy absorption, a solid center plate was added as reinforcement between the lattice structures. The enhanced hybrid lattice structures demonstrated the highest energy absorption among the tested configurations, highlighting the potential to control energy absorption by modifying the geometry of the reinforcement.

Author Contributions

Funding

Conflicts of Interest

References

- Moon, S.K.; Tan, Y.E.; Hwang, J.; Yoon, Y.-J. Application of 3D printing technology for designing light-weight unmanned aerial vehicle wing structures. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 223–228. [Google Scholar] [CrossRef]

- Vasiliev, V.V.; Barynin, V.A.; Razin, A.F. Anisogrid composite lattice structures—Development and aerospace applications. Compos. Struct. 2012, 94, 1117–1127. [Google Scholar] [CrossRef]

- Niutta, C.B.; Ciardiello, R.; Tridello, A. Experimental and Numerical Investigation of a Lattice Structure for Energy Absorption: Application to the Design of an Automotive Crash Absorber. Polymers 2022, 14, 1116. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Yeon, S.-M.; Lee, J.H.; Kim, Y.W.; Lee, H.; Park, J.; Lee, N.-K.; Choi, J.P.; Aranas, C.; Lee, Y.J.; et al. Additive manufacturing of a shift block via laser powder bed fusion: The simultaneous utilisation of optimised topology and a lattice structure. Virtual Phys. Prototyp. 2020, 15, 460–480. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, J.H.; Yang, J.; Heogh, W.; Kang, D.; Yeon, S.M.; Kim, S.H.; Hong, S.; Son, Y.; Park, J. Lightweight injection mold using additively manufactured Ti-6Al-4V lattice structures. J. Manuf. Process. 2022, 79, 759–766. [Google Scholar] [CrossRef]

- Nagesha, B.K.; Dhinakaran, V.; Shree, M.V.; Kumar, K.P.M.; Chalawadi, D.; Sathish, T. Review on characterization and impacts of the lattice structure in additive manufacturing. Mater. Today Proc. 2020, 21, 916–919. [Google Scholar] [CrossRef]

- Seharing, A.; Azman, A.H.; Abdullah, S. A review on integration of lightweight gradient lattice structures in additive manufacturing parts. Adv. Mech. Eng. 2020, 12, 1687814020916951. [Google Scholar] [CrossRef]

- Cutolo, A.; Engelen, B.; Desmet, W.; Van Hooreweder, B. Mechanical properties of diamond lattice Ti–6Al–4V structures produced by laser powder bed fusion: On the effect of the load direction. J. Mech. Behav. Biomed. Mater. 2020, 104, 103656. [Google Scholar] [CrossRef] [PubMed]

- Kladovasilakis, N.; Tsongas, K.; Kostavelis, I.; Tzovaras, D.; Tzetzis, D. Effective Mechanical Properties of Additive Manufactured Strut-Lattice Structures: Experimental and Finite Element Study. Adv. Eng. Mater. 2022, 24, 2100879. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; Sun, S.; Vcelka, M.; Shidid, D.; Brandt, M. Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2016, 84, 1391–1411. [Google Scholar] [CrossRef]

- Sun, J.; Xu, Y.; Wang, L. Evaluation of the Elastic Modulus and Plateau Stress of a 2D Porous Aluminum Alloy Based on a Convolutional Neural Network. Metals 2023, 13, 284. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Singh, A.; Karathanasopoulos, N. Strut and sheet metal lattices produced via AM-assisted casting and powder bed fusion: A comparative study. Addit. Manuf. Lett. 2023, 4, 100118. [Google Scholar] [CrossRef]

- Weeger, O.; Valizadeh, I.; Mistry, Y.; Bhate, D. Inelastic finite deformation beam modeling, simulation, and validation of additively manufactured lattice structures. Addit. Manuf. Lett. 2023, 4, 100111. [Google Scholar] [CrossRef]

- Kang, D.; Park, S.; Son, Y.; Yeon, S.; Kim, S.H.; Kim, I. Multi-lattice inner structures for high-strength and light-weight in metal selective laser melting process. Mater. Des. 2019, 175, 107786. [Google Scholar] [CrossRef]

- Sargini, M.I.M.; Masood, S.H.; Palanisamy, S.; Jayamani, E.; Kapoor, A. Additive manufacturing of an automotive brake pedal by metal fused deposition modelling. Mater. Today Proc. 2021, 45, 4601–4605. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Zhong, T.; He, K.; Li, H.; Yang, L. Mechanical properties of lightweight 316L stainless steel lattice structures fabricated by selective laser melting. Mater. Des. 2019, 181, 108076. [Google Scholar] [CrossRef]

- Pham, M.-S.; Liu, C.; Todd, I.; Lertthanasarn, J. Damage-tolerant architected materials inspired by crystal microstructure. Nature 2019, 565, 7739. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.P.; Guo, Y.B.; Shim, V.P.W. Characterisation and modeling of additively-manufactured polymeric hybrid lattice structures for energy absorption. Int. J. Mech. Sci. 2021, 191, 106101. [Google Scholar] [CrossRef]

- Xiao, L.; Xu, X.; Feng, G.; Li, S.; Song, W.; Jiang, Z. Compressive performance and energy absorption of additively manufactured metallic hybrid lattice structures. Int. J. Mech. Sci. 2022, 219, 107093. [Google Scholar] [CrossRef]

- Li, X.; Ye, J.; Ding, Y.; Wu, G. Study on the Mechanical Behavior of a Dual-Density Hybrid Lattice Structure under Quasi-Static and Dynamic Compressions. Materials 2023, 16, 3822. [Google Scholar] [CrossRef] [PubMed]

- Sengsri, P.; Fu, H.; Kaewunruen, S. Mechanical Properties and Energy-Absorption Capability of a 3D-Printed TPMS Sandwich Lattice Model for Meta-Functional Composite Bridge Bearing Applications. J. Compos. Sci. 2022, 6, 71. [Google Scholar] [CrossRef]

- Bolan, M.; Dean, M.; Bardelcik, A. The Energy Absorption Behavior of 3D-Printed Polymeric Octet-Truss Lattice Structures of Varying Strut Length and Radius. Polymers 2023, 15, 713. [Google Scholar] [CrossRef] [PubMed]

- Ling, C.; Cernicchi, A.; Gilchrist, M.D.; Cardiff, P. Mechanical behaviour of additively-manufactured polymeric octet-truss lattice structures under quasi-static and dynamic compressive loading. Mater. Des. 2019, 162, 106–118. [Google Scholar] [CrossRef]

- Wagner, M.A.; Lumpe, T.S.; Chen, T.; Shea, K. Programmable, active lattice structures: Unifying stretch-dominated and bending-dominated topologies. Extreme Mech. Lett. 2019, 29, 100461. [Google Scholar] [CrossRef]

- Mora, S.; Pugno, N.M.; Misseroni, D. 3D printed architected lattice structures by material jetting. Mater. Today 2022, 59, 107–132. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.J.; Lee, J.H.; Yang, J.; Moon, S.K.; Son, Y.; Park, J. Enhanced Energy Absorption of Additive-Manufactured Ti-6Al-4V Parts via Hybrid Lattice Structures. Micromachines 2023, 14, 1982. https://doi.org/10.3390/mi14111982

Park SJ, Lee JH, Yang J, Moon SK, Son Y, Park J. Enhanced Energy Absorption of Additive-Manufactured Ti-6Al-4V Parts via Hybrid Lattice Structures. Micromachines. 2023; 14(11):1982. https://doi.org/10.3390/mi14111982

Chicago/Turabian StylePark, Seong Je, Jun Hak Lee, Jeongho Yang, Seung Ki Moon, Yong Son, and Jiyong Park. 2023. "Enhanced Energy Absorption of Additive-Manufactured Ti-6Al-4V Parts via Hybrid Lattice Structures" Micromachines 14, no. 11: 1982. https://doi.org/10.3390/mi14111982