Non-Buffer Epi-AlGaN/GaN on SiC for High-Performance Depletion-Mode MIS-HEMTs Fabrication

Abstract

:1. Introduction

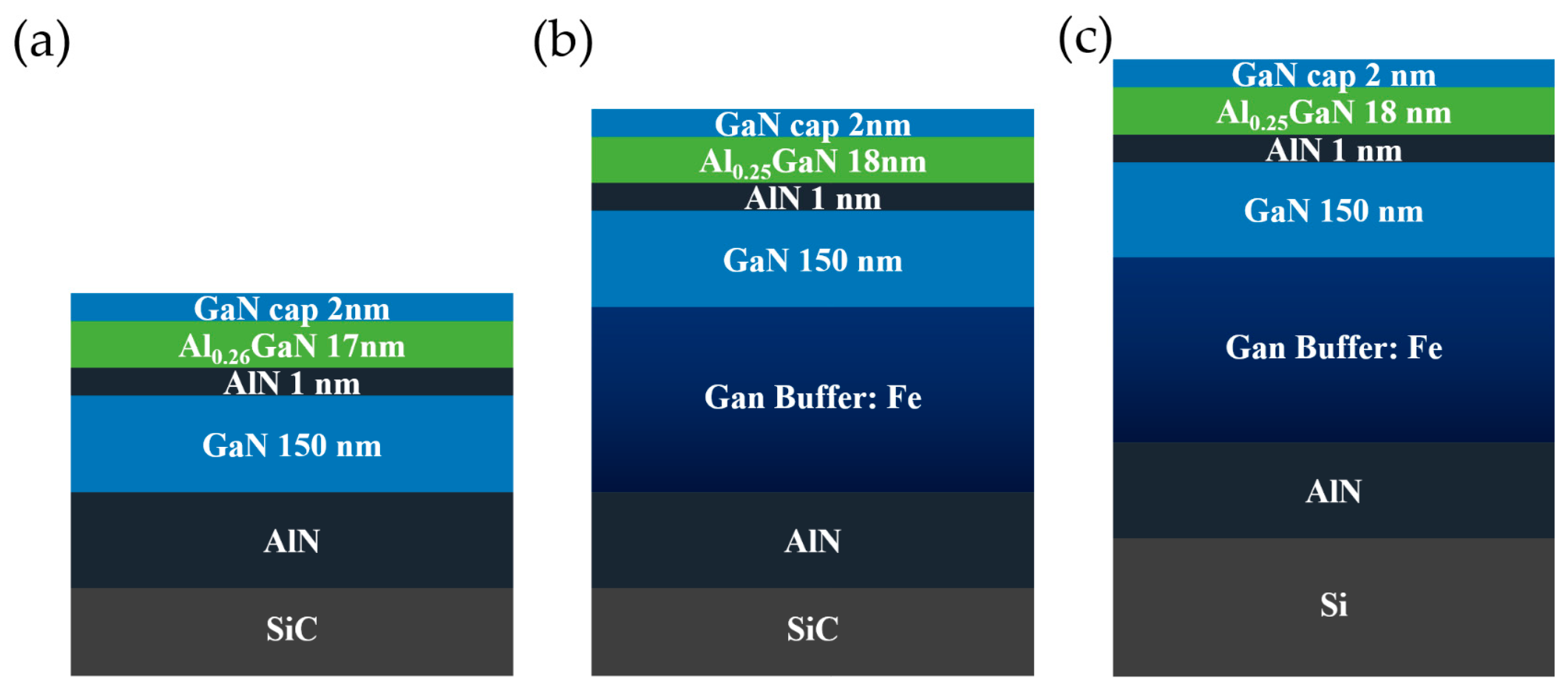

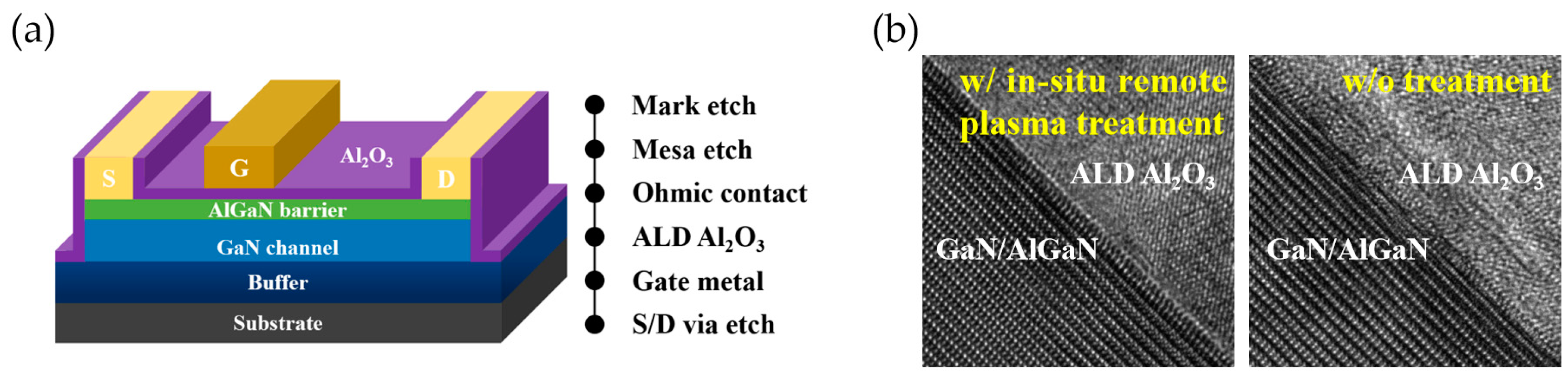

2. Experimental Section

3. Results and Discussion

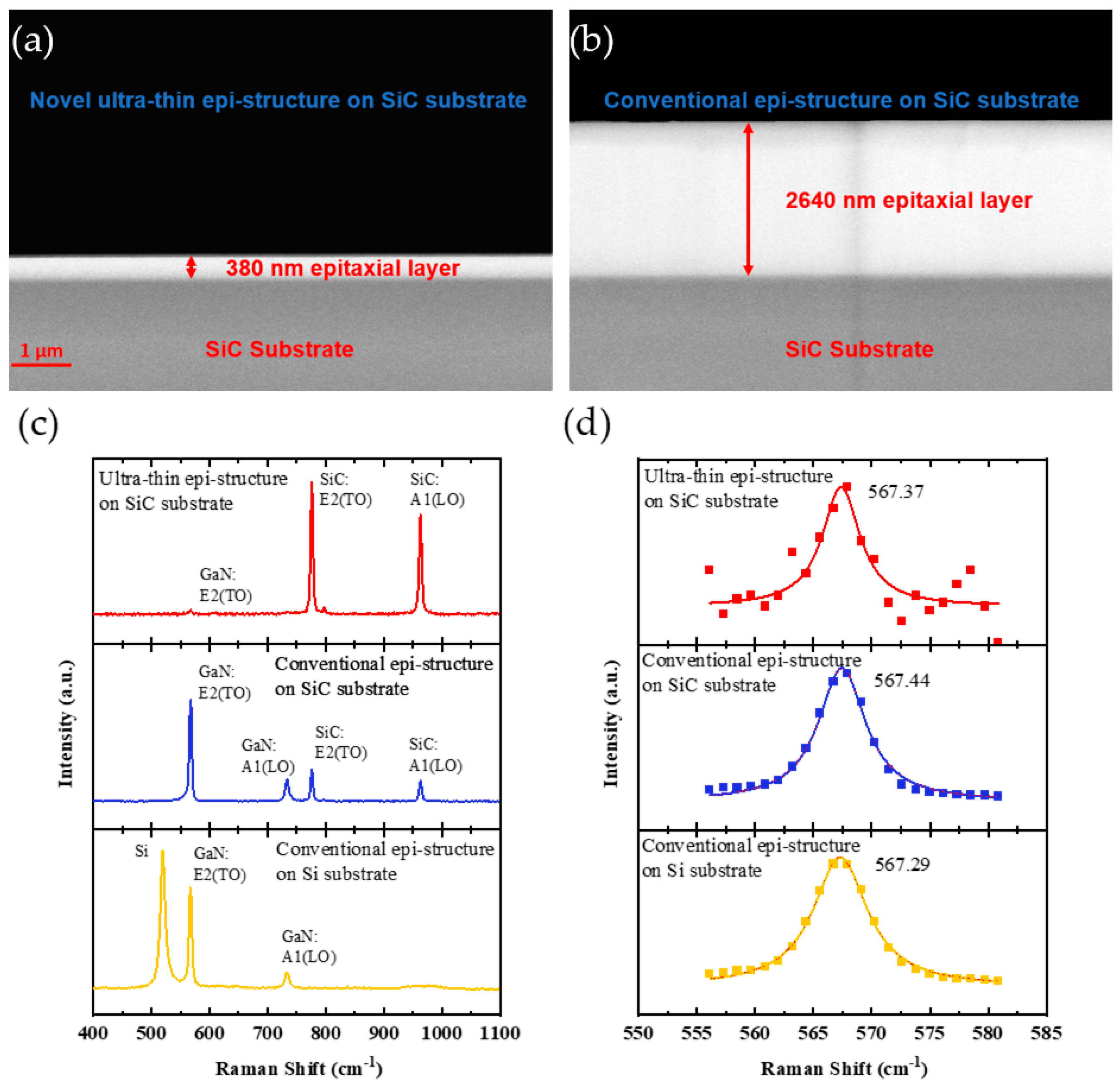

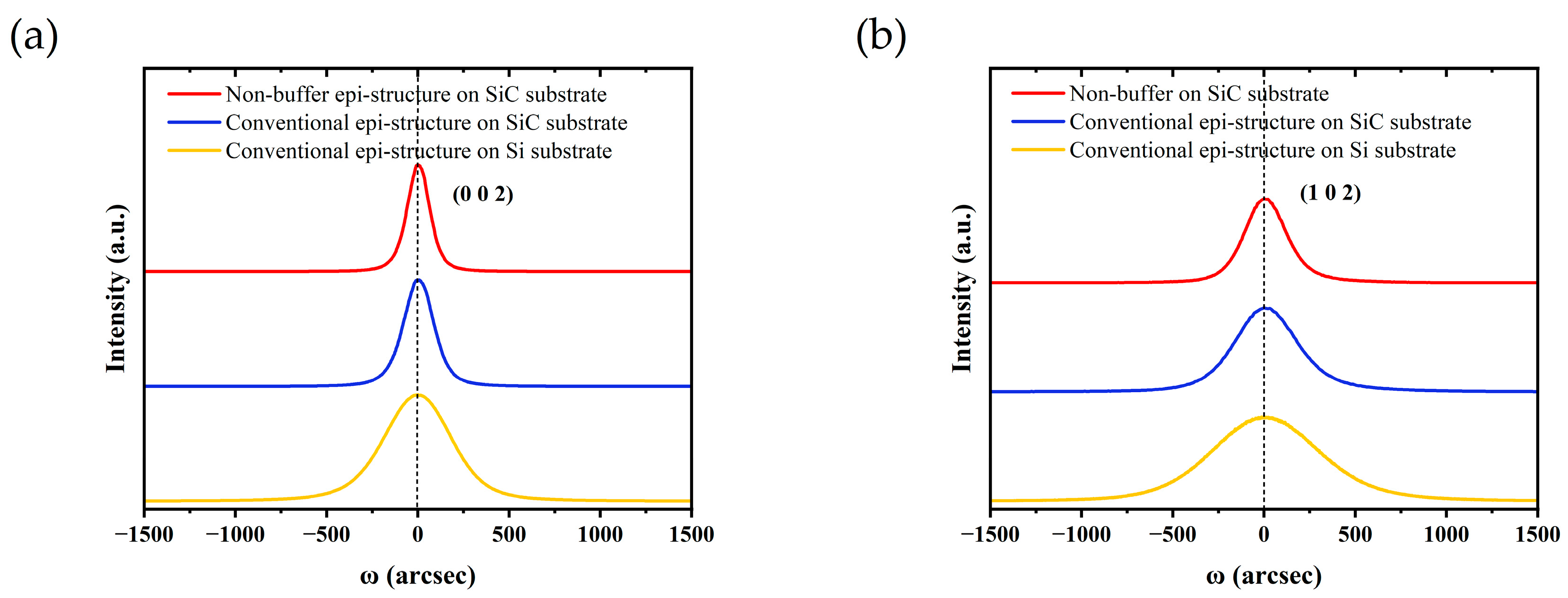

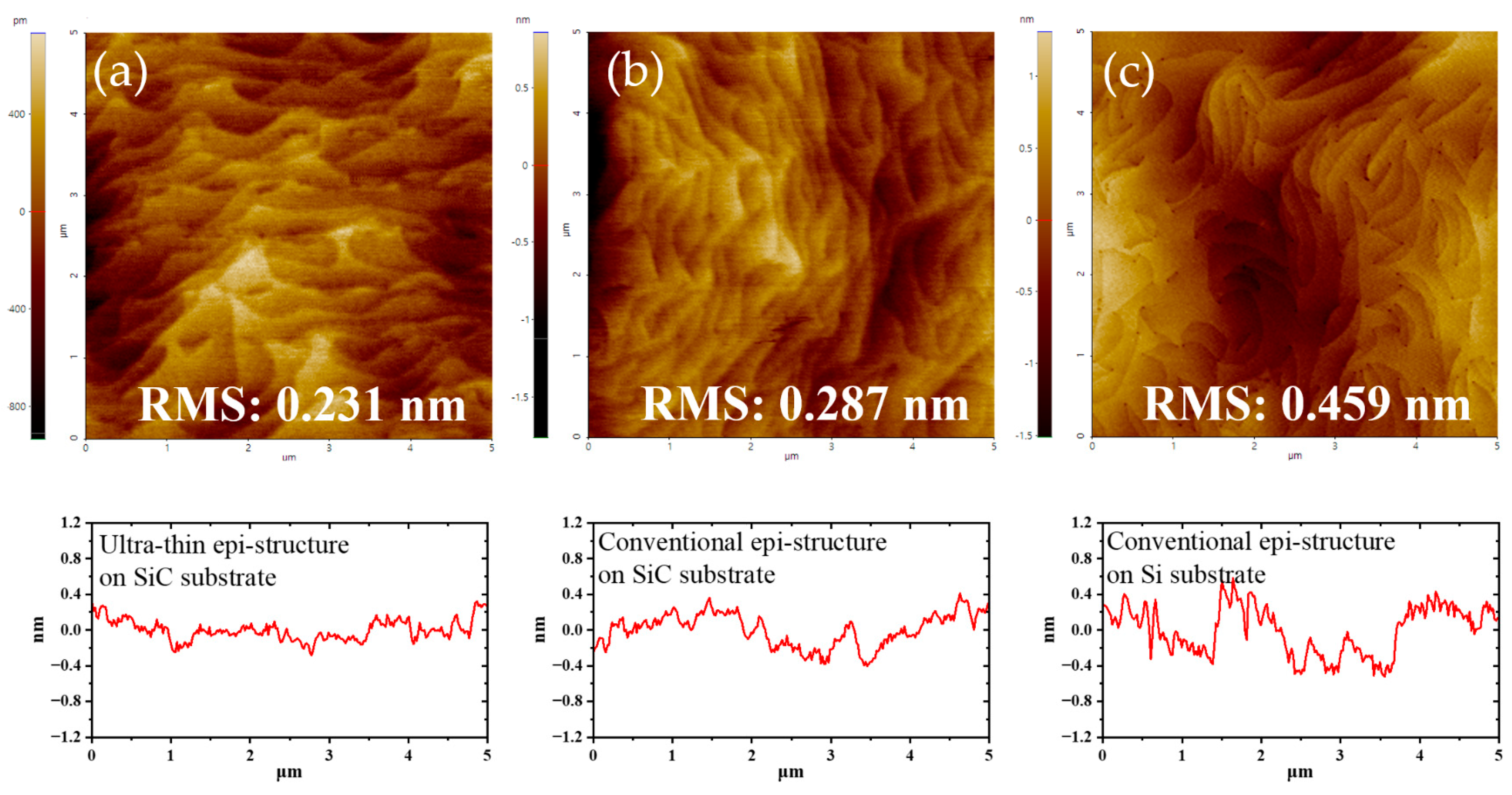

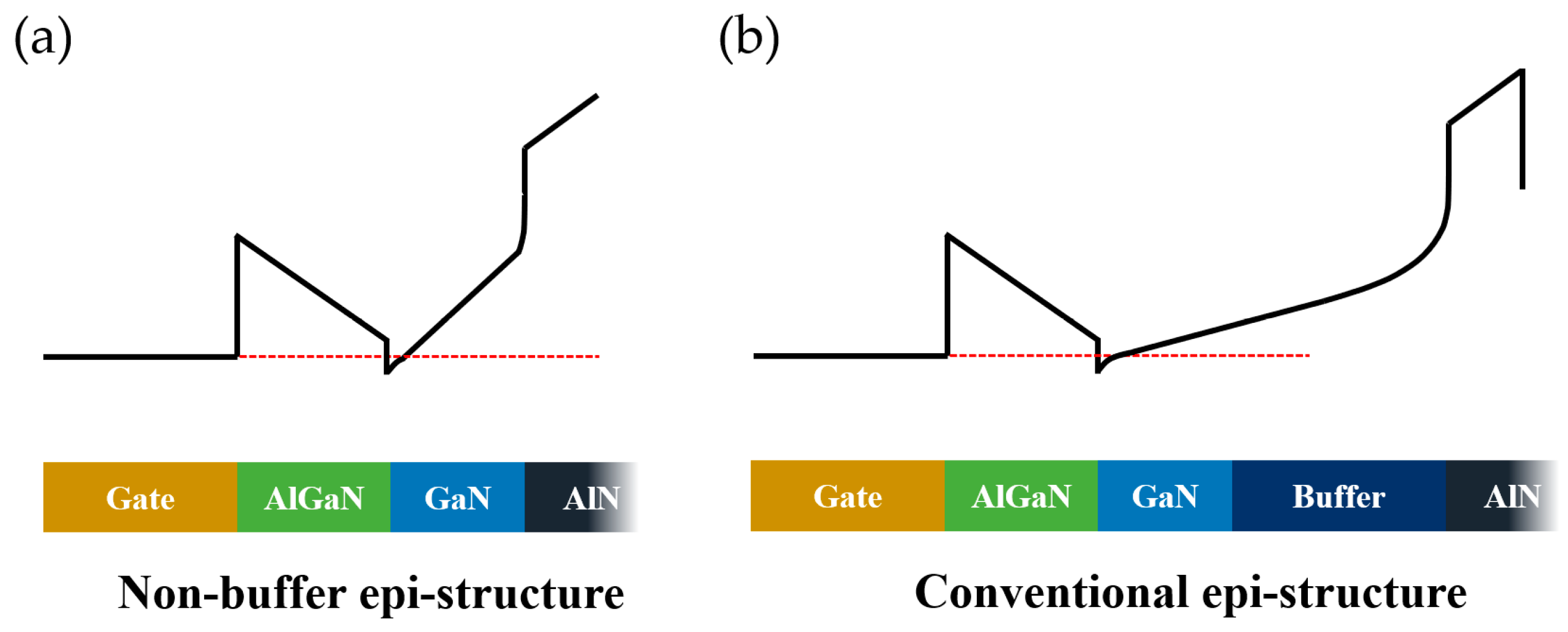

3.1. Epitaxial Wafer Quality Characterization

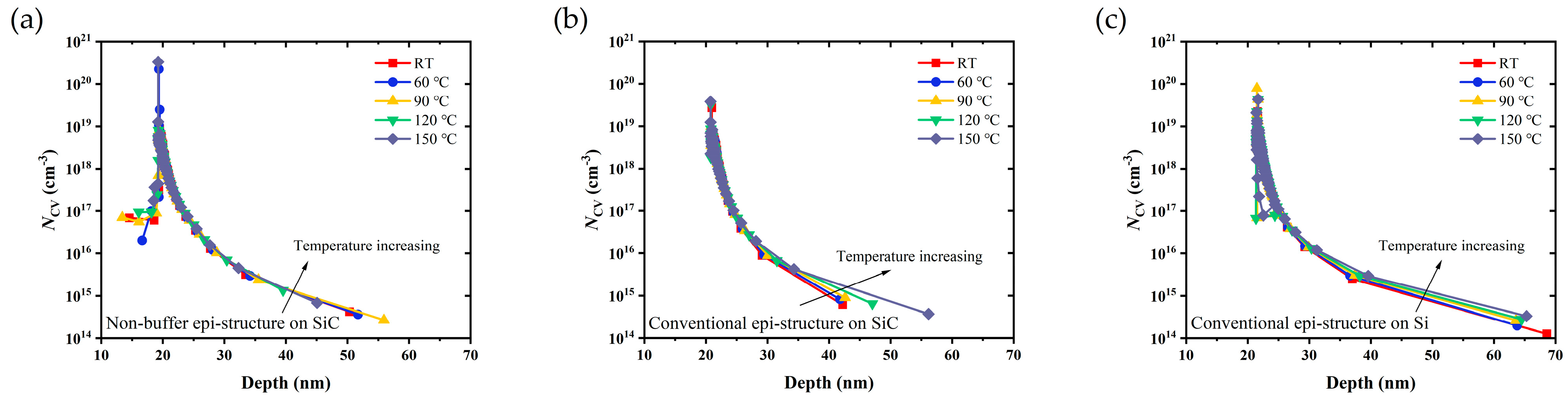

3.2. Temperature Changing Tests for Schottky Diodes

3.3. Device Performance of the MIS-HEMTs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ishida, M.; Ueda, T.; Tanaka, T.; Ueda, D. GaN on Si Technologies for Power Switching Devices. IEEE Trans. Electron Devices 2013, 60, 3053–3059. [Google Scholar] [CrossRef]

- Marcon, D.; Saripalli, Y.N.; Decoutere, S. 200 mm GaN-on-Si epitaxy and e-mode device technology. In Proceedings of the Electron Devices Meeting, San Francisco, CA, USA, 3–7 December 2016. [Google Scholar]

- Chen, K.J.; Hberlen, O.; Lidow, A.; Tsai, C.L.; Ueda, T.; Uemoto, Y.; Wu, Y. GaN-on-Si Power Technology: Devices and Applications. IEEE Trans. Electron Devices 2017, 64, 779–795. [Google Scholar] [CrossRef]

- Feltin, E.; Beaumont, B.; Laügt, M.; Mierry, P.D.; Gibart, P. Stress control in GaN grown on silicon (111) by metalorganic vapor phase epitaxy. Appl. Phys. Lett. 2001, 79, 3230–3232. [Google Scholar] [CrossRef]

- Marchand, H.; Zhao, L.; Zhang, N.; Moran, B.; Freitas, J.A. Metalorganic chemical vapor deposition of GaN on Si(111): Stress control and application to field-effect transistors. J. Appl. Phys. 2001, 89, 7846–7851. [Google Scholar] [CrossRef]

- Raghavan, S.; Redwing, J. Growth stresses and cracking in GaN films on (111) Si grown by metal-organic chemical-vapor deposition. I. AlN buffer layers. J. Appl. Phys. 2005, 98, 2653–2672. [Google Scholar] [CrossRef]

- Reiher, A.; Bläsing, J.; Dadgar, A.; Diez, A.; Krost, A. Efficient stress relief in GaN heteroepitaxy on Si(1 1 1) using low-temperature AlN interlayers. J. Cryst. Growth 2003, 248, 563–567. [Google Scholar] [CrossRef]

- Rowena, I.B.; Selvaraj, S.L.; Egawa, T. Buffer Thickness Contribution to Suppress Vertical Leakage Current with High Breakdown Field (2.3 MV/cm) for GaN on Si. IEEE Electron Device Lett. 2011, 32, 1534–1536. [Google Scholar] [CrossRef]

- Drechsel, P.; Stauss, P.; Bergbauer, W.; Rode, P.; Steegmüller, U. Impact of buffer growth on crystalline quality of GaN grown on Si(111) substrates. Phys. Status Solidi 2012, 209, 427–430. [Google Scholar] [CrossRef]

- Aggerstam, T.; Sjödin, M.; Lourdudoss, S. AlGaN/GaN high-electron-mobility transistors on sapphire with Fe-doped GaN buffer layer by MOVPE. Phys. Status Solidi 2010, 3, 2373–2376. [Google Scholar] [CrossRef]

- Haffouz, S.; Tang, H.; Bardwell, J.A.; Hsu, E.M.; Webb, J.B.; Rolfe, S. AlGaN/GaN field effect transistors with C-doped GaN buffer layer as an electrical isolation template grown by molecular beam epitaxy. Solid State Electron. 2005, 49, 802–807. [Google Scholar] [CrossRef]

- Meneghini, M.; Rossetto, I.; Bisi, D.; Stocco, A.; Chini, A.; Pantellini, A.; Lanzieri, C.; Nanni, A.; Meneghesso, G.; Zanoni, E. Buffer Traps in Fe-Doped AlGaN/GaN HEMTs: Investigation of the Physical Properties Based on Pulsed and Transient Measurements. IEEE Trans. Electron Devices 2014, 61, 4070–4077. [Google Scholar] [CrossRef]

- Kaminski, N.; Hilt, O. SiC and GaN devices–wide bandgap is not all the same. IET Circuits Devices Syst. 2014, 8, 227–236. [Google Scholar] [CrossRef]

- Levinshtein, M.E.; Rumyantsev, S.L.; Shur, M.S. Properties of Advanced Semiconductor Materials: GaN, AIN, InN, BN, SiC, SiGe; John and Wiley and Sons: Hoboken, NJ, USA, 2001. [Google Scholar]

- Chen, D.Y.; Malmros, A.; Thorsell, M.; Hjelmgren, H.; Rorsman, N. Microwave Performance of ‘Buffer-Free’ GaN-on-SiC High Electron Mobility Transistors. IEEE Electron Device Lett. 2020, 41, 828–831. [Google Scholar] [CrossRef]

- Hult, B.; Thorsell, M.; Chen, J.-T.; Rorsman, N. High Voltage and Low Leakage GaN-on-SiC MISHEMTs on a “Buffer-Free” Heterostructure. IEEE Electron Device Lett. 2022, 43, 781–784. [Google Scholar] [CrossRef]

- Davydov, V.Y.; Kitaev, Y.E.; Goncharuk, I.; Smirnov, A.; Graul, J.; Semchinova, O.; Uffmann, D.; Smirnov, M.; Mirgorodsky, A.; Evarestov, R. Phonon dispersion and Raman scattering in hexagonal GaN and AlN. Phys. Rev. B 1998, 58, 12899. [Google Scholar] [CrossRef] [Green Version]

- Perlin, P.; Jauberthie-Carillon, C.; Itie, J.P.; San Miguel, A.; Grzegory, I.; Polian, A. Raman scattering and x-ray-absorption spectroscopy in gallium nitride under high pressure. Phys. Rev. B Condens. Matter 1992, 45, 83–89. [Google Scholar] [CrossRef] [PubMed]

- Kuball, M. Raman spectroscopy of GaN, AlGaN and AlN for process and growth monitoring/control. Surf. Interface Anal. 2001, 31, 987–999. [Google Scholar] [CrossRef]

- Heinke, H.; Kirchner, V.; Einfeldt, S.; Hommel, D. X-ray diffraction analysis of the defect structure in epitaxial GaN. Appl. Phys. Lett. 2000, 77, 2145–2147. [Google Scholar] [CrossRef]

- Li, Y.; Ng, G.I.; Arulkumaran, S.; Ye, G.; Liu, Z.H.; Ranjan, K.; Ang, K.S. Investigation of gate leakage current mechanism in AlGaN/GaN high-electron-mobility transistors with sputtered TiN. J. Appl. Phys. 2017, 121, 044504. [Google Scholar] [CrossRef]

| Epi-Structures | Rsheet (Ω/sq) | μ2DEG (cm2/V·s) | ns (1012 cm−2) |

|---|---|---|---|

| Non-buffer epi-structure on SiC | 292 | 2287 | 9.4 |

| Conventional epi-structure on SiC | 284 | 2245 | 9.8 |

| Conventional epi-structure on Si | 365 | 1835 | 9.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Wang, L.; Zhu, K.; Wang, Q.; Pan, M.; Huang, Z.; Yang, Y.; Xie, X.; Huang, H.; Hu, X.; et al. Non-Buffer Epi-AlGaN/GaN on SiC for High-Performance Depletion-Mode MIS-HEMTs Fabrication. Micromachines 2023, 14, 1523. https://doi.org/10.3390/mi14081523

Zhang P, Wang L, Zhu K, Wang Q, Pan M, Huang Z, Yang Y, Xie X, Huang H, Hu X, et al. Non-Buffer Epi-AlGaN/GaN on SiC for High-Performance Depletion-Mode MIS-HEMTs Fabrication. Micromachines. 2023; 14(8):1523. https://doi.org/10.3390/mi14081523

Chicago/Turabian StyleZhang, Penghao, Luyu Wang, Kaiyue Zhu, Qiang Wang, Maolin Pan, Ziqiang Huang, Yannan Yang, Xinling Xie, Hai Huang, Xin Hu, and et al. 2023. "Non-Buffer Epi-AlGaN/GaN on SiC for High-Performance Depletion-Mode MIS-HEMTs Fabrication" Micromachines 14, no. 8: 1523. https://doi.org/10.3390/mi14081523