Engineered Nanomaterial Coatings for Food Packaging: Design, Manufacturing, Regulatory, and Sustainability Implications

Abstract

1. Introduction

1.1. Background of Food Packaging Challenges in Humanitarian Efforts

1.2. Antimicrobial Nanomaterials: Safeguarding Food Safety

1.3. Sustainability and Environmental Impact

2. Development and Design

2.1. Comparative Analysis: Nanoengineered vs. Traditional Packaging Methods

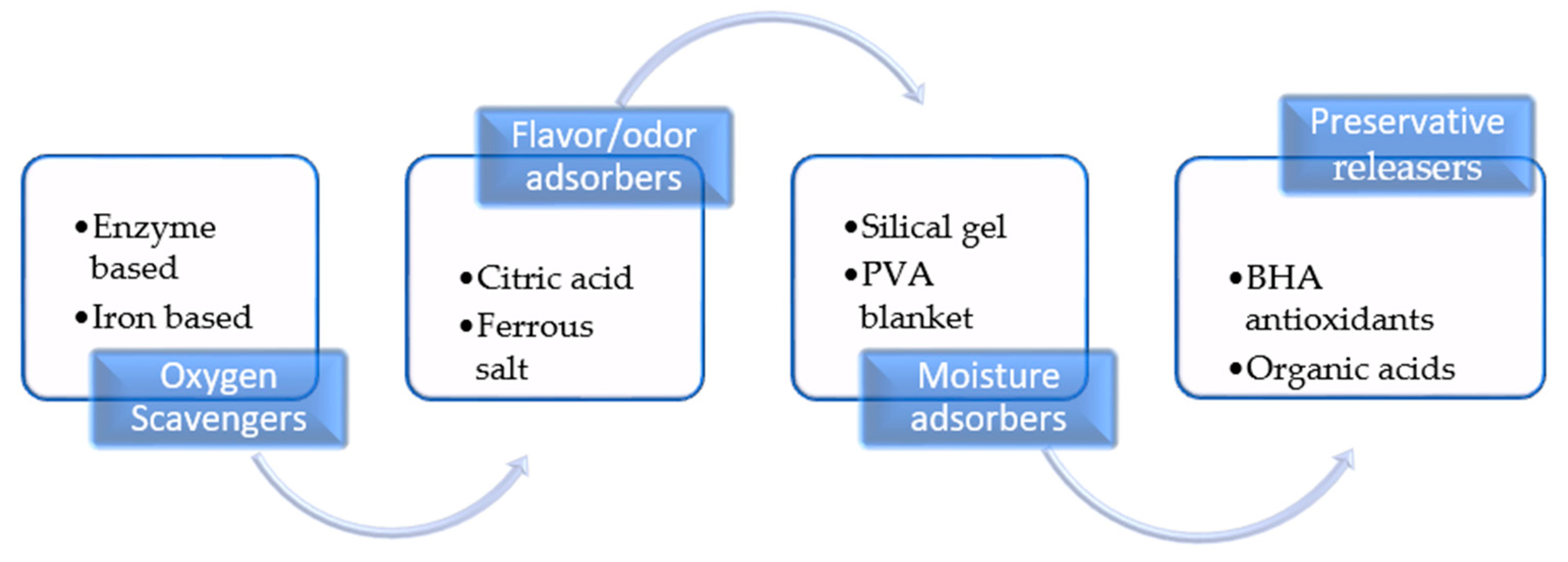

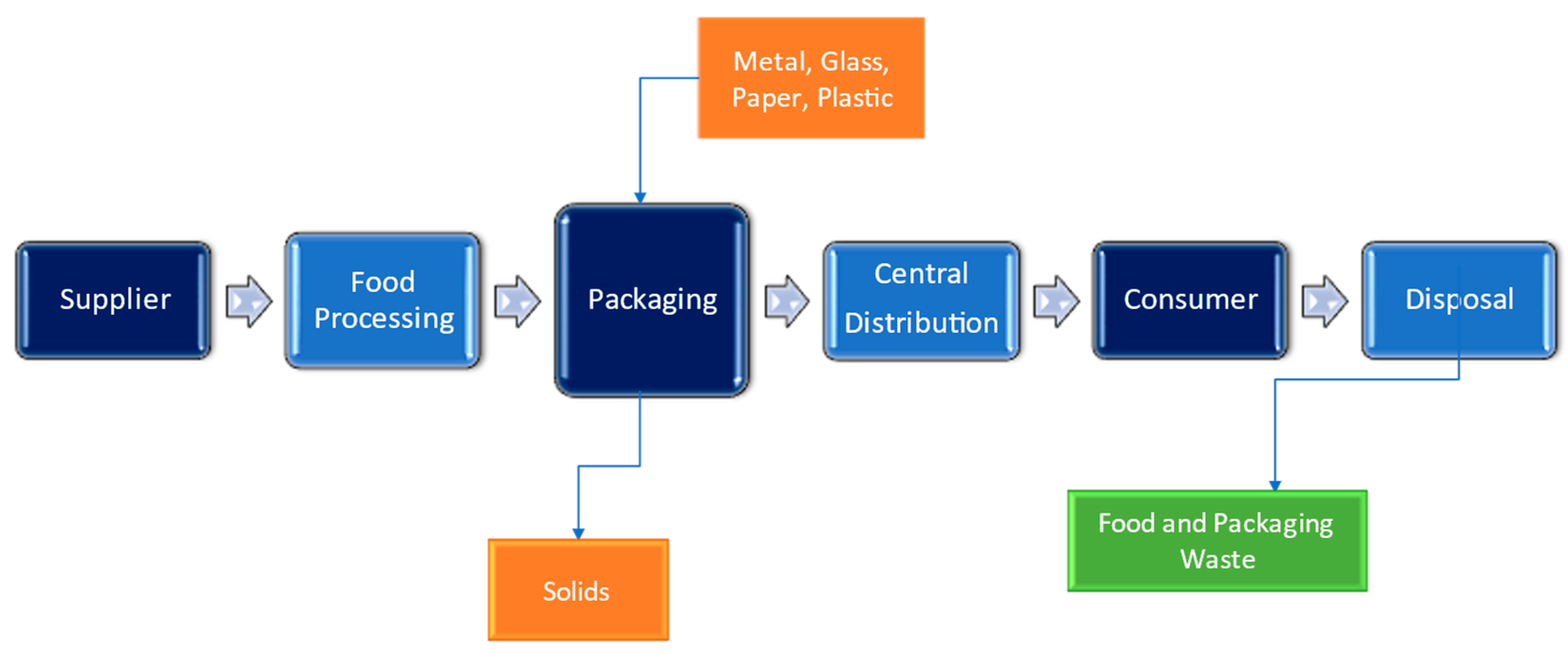

2.2. Active Packaging System

2.3. Overview of Coating Technology

2.4. Plastic Film Coating

2.5. Research Area of Nanomaterials Applied in Coatings

2.6. Manufacturing of Coatings

3. Nanomaterials in Food Packaging

3.1. Current State of Nanoengineering Applications in Food Packaging

3.2. Relevance of Nanomaterials for Food Packaging

3.3. Effect of Nanomaterial Composition on the Improvement of Barrier Properties

3.3.1. Impermeability

3.3.2. Thickness

3.3.3. Nanoscale Sensors

3.4. Chemically Released Nanopack

3.5. Nanostructured Materials in Food Packaging

3.5.1. Characteristics of Nanostructured Materials

3.5.2. Analytical Method for Characteristics of Nanomaterials

3.5.3. Testing of Nanomaterial Food Packaging

Paper Packaging

Plastic Films and Laminates

Glass Container

3.6. Types of Plastic Used in Packaging

3.6.1. Polyethylene Terephthalate (PET or PETE)

3.6.2. Polyvinyl Chloride (PVC)

3.6.3. Polystyrene (PS)

4. Shelf Life

4.1. Food Preservation and Shelf Life of Current Traditional Materials

4.2. Nanoscale Functionality: How Nanostructured Materials Improve Food Preservation

4.3. Impact of Nanomaterial Packaging on Food Quality, Shelf Life Extension, and Safety

4.3.1. Nano Packaging for Fruits

4.3.2. Nano Packaging for Beverages

4.3.3. Nano Packaging for Chocolates

4.3.4. Chicken and Spinach Nano Pack

4.4. Shelf Life Extension: Studies and Findings on Prolonged Freshness

4.5. Nanocoating Anti-Corrosion Technology for Food Preservation

5. Environmental, Safety, and Regulatory Implications

5.1. Sustainable Practices: Role of Nanostructured Materials in Green Packaging Solutions

5.2. Biodegradability and Environmental Impact of Nanostructured Materials

5.3. Reduction of Food Waste: Environmental Benefits

5.4. Regulatory Framework

5.4.1. Current Guidelines and Regulations for Nanostructured Food Packaging

5.4.2. Comparison of Regulatory Systems for Nanostructured Food Packaging

5.5. Safety

5.5.1. Nano-Based Antimicrobial Packaging

5.5.2. Ensuring Food Safety: Antimicrobial Properties and Pathogen Prevention

5.5.3. Effects of Nanomaterials on the Human Body

5.5.4. Safety Assessment Protocols: Evaluating Nanomaterials for Food Contact

5.5.5. Ethical Considerations: Balancing Innovation with Safety in Humanitarian Food Packaging

6. Nanoengineering and Humanitarian Considerations

6.1. Nanoengineering and Food Security Challenges in Vulnerable Regions

6.2. Addressing Food Security: The Role of Nanoengineering in Underprivileged Regions

6.3. Disaster-Prone Areas: Emergency Food Supplies and Nanoengineered Packaging

6.4. Case Studies: Successful Implementation in Challenging Environments

6.5. Implications for the Future: Prospects of Nanoengineering in Humanitarian Food Packaging

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ISO 4618:2023; Paints and Varnishes Vocabulary. ISO: Geneva, Switzerland, 2023.

- Hirvonen, J.-P.; Koskinen, J.; Jervis, J.R.; Nastasi, M. Present Progress in the Development of Low Friction Coatings. Surf. Coat. Technol. 1996, 80, 139–150. [Google Scholar] [CrossRef]

- Ahmad Khan, Z.; Latif, J.; Nazir, H.; Saeed, A.; Stokes, K. Predictive and Prognostic Modelling and Simulation of Coatings Subject to Corrosion and Mechanical Failures. Int. J. Comput. Methods Exp. Meas. 2017, 6, 487–498. [Google Scholar] [CrossRef]

- Bentley, J.; Desai, S.; Bastakoti, B.P. Porous Tungsten Oxide: Recent Advances in Design, Synthesis, and Applications. Chem. A Eur. J. 2021, 27, 9241–9252. [Google Scholar] [CrossRef] [PubMed]

- Desai, S.; Bidanda, B.; Bártolo, P.J. Emerging Trends in the Applications of Metallic and Ceramic Biomaterials. In Bio-Materials and Prototyping Applications in Medicine; Bártolo, P.J., Bidanda, B., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–17. ISBN 978-3-030-35875-4. [Google Scholar]

- Desai, S.; Shankar, M.R. Emerging Trends in Polymers, Composites, and Nano Biomaterial Applications. In Bio-Materials and Prototyping Applications in Medicine; Bártolo, P.J., Bidanda, B., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 19–34. ISBN 978-3-030-35875-4. [Google Scholar]

- Rodrigues, J.; Desai, S. The Nanoscale Leidenfrost Effect. Nanoscale 2019, 11, 12139–12151. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Xia, K.; Wu, D.; Mou, J.; Zheng, S. Technical Characteristics and Wear-Resistant Mechanism of Nano Coatings: A Review. Coatings 2020, 10, 233. [Google Scholar] [CrossRef]

- Aliofkhazraei, M. Nanocoatings: Size Effect in Nanostructured Films; Engineering Materials; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2011; ISBN 978-3-642-17966-2. [Google Scholar]

- Adarkwa, E.; Desai, S. Scalable Droplet Based Manufacturing Using In-Flight Laser Evaporation. J. Nanoeng. Nanomanufacturing 2016, 6, 87–92. [Google Scholar] [CrossRef]

- Akter, T.; Desai, S. Developing a Predictive Model for Nanoimprint Lithography Using Artificial Neural Networks. Mater. Des. 2018, 160, 836–848. [Google Scholar] [CrossRef]

- Kumar Parupelli, S.; Saudi, S.; Bhattarai, N.; Desai, S. 3D Printing of PCL-Ceramic Composite Scaffolds for Bone Tissue Engineering Applications. Int. J. Bioprint. 2023, 9, 0196. [Google Scholar] [CrossRef]

- Adarkwa, E.; Roy, A.; Ohodnicki, J.; Lee, B.; Kumta, P.N.; Desai, S. 3D Printing of Drug-Eluting Bioactive Multifunctional Coatings for Orthopedic Applications. Int. J. Bioprint. 2023, 9, 661. [Google Scholar] [CrossRef]

- Marquetti, I.; Desai, S. Nanoscale Topographical Effects on the Adsorption Behavior of Bone Morphogenetic Protein-2 on Graphite. Int. J. Mol. Sci. 2022, 23, 2432. [Google Scholar] [CrossRef]

- Marquetti, I.; Desai, S. An Atomistic Investigation of Adsorption of Bone Morphogenetic Protein-2 on Gold with Nanoscale Topographies. Surfaces 2022, 5, 176–185. [Google Scholar] [CrossRef]

- Marquetti, I.; Desai, S. Molecular Modeling the Adsorption Behavior of Bone Morphogenetic Protein-2 on Hydrophobic and Hydrophilic Substrates. Chem. Phys. Lett. 2018, 706, 285–294. [Google Scholar] [CrossRef]

- Gaikwad, A.; Odujole, J.; Desai, S. Atomistic Investigation of Process Parameter Variations on Material Deformation Behavior in Nanoimprint Lithography of Gold. Precis. Eng. 2020, 64, 7–19. [Google Scholar] [CrossRef]

- Gaikwad, A.; Desai, S. Molecular Dynamics Investigation of the Deformation Mechanism of Gold with Variations in Mold Profiles during Nanoimprinting. Materials 2021, 14, 2548. [Google Scholar] [CrossRef] [PubMed]

- Odujole, J.; Desai, S. Atomistic Investigation of Material Deformation Behavior of Polystyrene in Nanoimprint Lithography. Surfaces 2020, 3, 649–663. [Google Scholar] [CrossRef]

- Odujole, J.I.; Desai, S. Molecular Dynamics Investigation of Material Deformation Behavior of PMMA in Nanoimprint Lithography. AIP Adv. 2020, 10, 095102. [Google Scholar] [CrossRef]

- Gaikwad, A.; Desai, S. Understanding Material Deformation in Nanoimprint of Gold Using Molecular Dynamics Simulations. Am. J. Eng. Appl. Sci. 2018, 11, 837–844. [Google Scholar] [CrossRef][Green Version]

- Desai, S. Methods and Apparatus for Manufacturing Micro-and/or Nano-Scale Features. U.S. Patent 13/959,849, 28 November 2013. [Google Scholar]

- Behera, A.; Mallick, P.; Mohapatra, S.S. Nanocoatings for Anticorrosion. In Corrosion Protection at the Nanoscale; Elsevier: Amsterdam, The Netherlands, 2020; pp. 227–243. ISBN 978-0-12-819359-4. [Google Scholar]

- Adarkwa, E.; Kotoka, R.; Desai, S. 3D Printing of Polymeric Coatings on AZ31 Mg Alloy Substrate for Corrosion Protection of Biomedical Implants. Med. Devices Sens. 2021, 4, e10167. [Google Scholar] [CrossRef]

- Rodrigues, J.; Desai, S. Exploring the Relationship between Substrate Wettability and Surface Area Exposure Using Molecular Dynamics Modeling. In Proceedings of the Industrial Engineers Research Conference, Colombo, Sri Lanka, 22 October 2016. [Google Scholar]

- Cordeiro, J.; Desai, S. Process Parameter Studies of Molecular Dynamics Models to Control Substrate Wettability. In Proceedings of the ASME 2015 International Manufacturing Science and Engineering Conference, Charlotte, NC, USA, 8–12 June 2015; p. V001T02A025. [Google Scholar]

- Perkins, J.; Xu, Z.; Smith, C.; Roy, A.; Kumta, P.N.; Waterman, J.; Conklin, D.; Desai, S. Direct Writing of Polymeric Coatings on Magnesium Alloy for Tracheal Stent Applications. Ann. Biomed. Eng. 2015, 43, 1158–1165. [Google Scholar] [CrossRef]

- Perkins, J.; Hong, Y.; Ye, S.-H.; Wagner, W.R.; Desai, S. Direct Writing of Bio-Functional Coatings for Cardiovascular Applications: Direct Writing of Bio-Functional Coatings for Cardiovascular Applications. J. Biomed. Mater. Res. 2014, 102, 4290–4300. [Google Scholar] [CrossRef] [PubMed]

- Perkins, J.; Yi, H.; Ye, S.H.; Wagner, W.; Desai, S. Direct Write Manufacturing of Controlled Release Coatings for Drug Eluting Cardiovascular Stents. J. Biomed. Res. Part A 2014, 102, 4290–4300. [Google Scholar]

- Perkins, J.; Xu, Z.; Roy, A.; Kumta, P.; Waterman, J.D.; Desai, S. Polymeric Coatings for Biodegradable Implants. In Proceedings of the Advanced Engineering Solutions, Chongqing, China, 25–28 July 2014. [Google Scholar]

- Adarkwa, E.; Desai, S.; Ohodnicki, J.M.; Roy, A.; Lee, B.; Kumta, P.N. Amorphous Calcium Phosphate Blended Polymer Coatings for Biomedical Implants. In Proceedings of the IIE Annual Conference, Montréal, QC, Canada, 31 May–3 June 2014; Institute of Industrial and Systems Engineers (IISE): Peachtree Corners, GA, USA, 2014; p. 132. [Google Scholar]

- Grumezescu, V.; Negut, I. Nanocoatings and Thin Films. In Materials for Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 463–477. ISBN 978-0-08-102814-8. [Google Scholar]

- Cui, J.; Ren, S.; Lin, T.; Feng, Y.; Jia, S. Shielding Effects of Fe3+-Tannic Acid Nanocoatings for Immobilized Enzyme on Magnetic Fe3O4@silica Core Shell Nanosphere. Chem. Eng. J. 2018, 343, 629–637. [Google Scholar] [CrossRef]

- Zeng, A.; Yao, X.; Gui, Y.; Li, Y.; Jones, K.J.; Yu, L. Inhibiting Surface Crystallization and Improving Dissolution of Amorphous Loratadine by Dextran Sulfate Nanocoating. J. Pharm. Sci. 2019, 108, 2391–2396. [Google Scholar] [CrossRef] [PubMed]

- Alfadul, S.M.; Elneshwy, A.A. Use of Nanotechnology in Food Processing, Packaging and Safety—Review. Afr. J. Food Agric. Nutr. Dev. 2010, 10. [Google Scholar] [CrossRef]

- Morones, J.R.; Elechiguerra, J.L.; Camacho, A.; Holt, K.; Kouri, J.B.; Ramírez, J.T.; Yacaman, M.J. The Bactericidal Effect of Silver Nanoparticles. Nanotechnology 2005, 16, 2346–2353. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.S.; Kuk, E.; Yu, K.N.; Kim, J.-H.; Park, S.J.; Lee, H.J.; Kim, S.H.; Park, Y.K.; Park, Y.H.; Hwang, C.-Y.; et al. Antimicrobial Effects of Silver Nanoparticles. Nanomed. Nanotechnol. Biol. Med. 2007, 3, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Addo Ntim, S.; Thomas, T.A.; Begley, T.H.; Noonan, G.O. Characterisation and Potential Migration of Silver Nanoparticles from Commercially Available Polymeric Food Contact Materials. Food Addit. Contam. Part A 2015, 32, 1003–1011. [Google Scholar] [CrossRef]

- Smith, M.D.; Rabbitt, M.P.; Coleman-Jensen, A. Who Are the World’s Food Insecure? New Evidence from the Food and Agriculture Organization’s Food Insecurity Experience Scale. World Dev. 2017, 93, 402–412. [Google Scholar] [CrossRef]

- U.S. Government Global Food Security Strategy 2017–2021; U.S. Agency for International Development: Washington, DC, USA, 2016.

- Rodriguez, C.; Crowder, S.L.; Rodriguez, M.; Redwine, L.; Stern, M. Food Insecurity and the Hispanic Population during the COVID-19 Pandemic. Ecol. Food Nutr. 2021, 60, 548–563. [Google Scholar] [CrossRef] [PubMed]

- Huizar, M.I.; Arena, R.; Laddu, D.R. The Global Food Syndemic: The Impact of Food Insecurity, Malnutrition and Obesity on the Healthspan amid the COVID-19 Pandemic. Prog. Cardiovasc. Dis. 2021, 64, 105–107. [Google Scholar] [CrossRef]

- Pollard, C.M.; Booth, S. Food Insecurity and Hunger in Rich Countries—It Is Time for Action against Inequality. Int. J. Environ. Res. Public Health 2019, 16, 1804. [Google Scholar] [CrossRef]

- Sosa, S.; Rother, B.; Mitra, P.; Kim, D.; Pierre, G.; Fayad, D.; Debbich, M.; Thevenot, C.; Kohler, L.; Kato, N.; et al. Tackling the Global Food Crisis. IMF Notes 2022, 2022, 38. [Google Scholar] [CrossRef]

- Mehrabi, Z.; Delzeit, R.; Ignaciuk, A.; Levers, C.; Braich, G.; Bajaj, K.; Amo-Aidoo, A.; Anderson, W.; Balgah, R.A.; Benton, T.G.; et al. Research Priorities for Global Food Security under Extreme Events. One Earth 2022, 5, 756–766. [Google Scholar] [CrossRef]

- Stevens, M.M. What’s in a Box: How Cutting-Edge Packaging Can Help Safeguard the Environment and Fight Hunger; WFP: Rome, Italy, 2021. [Google Scholar]

- Hannon, J.C.; Kerry, J.P.; Cruz-Romero, M.; Azlin-Hasim, S.; Morris, M.; Cummins, E. Assessment of the Migration Potential of Nanosilver from Nanoparticle-Coated Low-Density Polyethylene Food Packaging into Food Simulants. Food Addit. Contam. Part A 2015, 33, 167–178. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Deng, H.; Hwang, H. The Current Application of Nanotechnology in Food and Agriculture. J. Food Drug Anal. 2019, 27, 1–21. [Google Scholar] [CrossRef]

- Njoagwuani, E.I.; Onyeaka, H.; Mazi, I.M.; Akegbe, H.; Oladunjoye, I.O.; Ochulor, C.E.; Omotosho, A.D.; Odeyemi, O.A.; Nwaiwu, O.; Tamasiga, P. Food Safety in Vulnerable Populations: A Perspective on the Challenges and Solutions. FASEB J. 2023, 37, e22872. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.D. Nanocomposites for Food Packaging Applications. Food Res. Int. 2009, 42, 1240–1253. [Google Scholar] [CrossRef]

- McClements, D.J.; Xiao, H.; Demokritou, P. Physicochemical and Colloidal Aspects of Food Matrix Effects on Gastrointestinal Fate of Ingested Inorganic Nanoparticles. Adv. Colloid Interface Sci. 2017, 246, 165–180. [Google Scholar] [CrossRef]

- Drago, E.; Campardelli, R.; Pettinato, M.; Perego, P. Innovations in Smart Packaging Concepts for Food: An Extensive Review. Foods 2020, 9, 1628. [Google Scholar] [CrossRef]

- Hoseinnejad, M.; Jafari, S.M.; Katouzian, I. Inorganic and Metal Nanoparticles and Their Antimicrobial Activity in Food Packaging Applications. Crit. Rev. Microbiol. 2018, 44, 161–181. [Google Scholar] [CrossRef]

- Omerović, N.; Djisalov, M.; Živojević, K.; Mladenović, M.; Vunduk, J.; Milenković, I.; Knežević, N.Ž.; Gadjanski, I.; Vidić, J. Antimicrobial Nanoparticles and Biodegradable Polymer Composites for Active Food Packaging Applications. Comp. Rev. Food Sci. Food Saf. 2021, 20, 2428–2454. [Google Scholar] [CrossRef]

- Sharma, C.; Dhiman, R.; Rokana, N.; Panwar, H. Nanotechnology: An Untapped Resource for Food Packaging. Front. Microbiol. 2017, 8, 1735. [Google Scholar] [CrossRef]

- Shi, J.; Kantoff, P.W.; Wooster, R.; Farokhzad, O.C. Cancer Nanomedicine: Progress, Challenges and Opportunities. Nat. Rev. Cancer 2017, 17, 20–37. [Google Scholar] [CrossRef]

- Chen, G.; Roy, I.; Yang, C.; Prasad, P.N. Nanochemistry and Nanomedicine for Nanoparticle-Based Diagnostics and Therapy. Chem. Rev. 2016, 116, 2826–2885. [Google Scholar] [CrossRef]

- Gogotsi, Y. What Nano Can Do for Energy Storage. ACS Nano 2014, 8, 5369–5371. [Google Scholar] [CrossRef]

- Serrano, E.; Rus, G.; García-Martínez, J. Nanotechnology for Sustainable Energy. Renew. Sustain. Energy Rev. 2009, 13, 2373–2384. [Google Scholar] [CrossRef]

- Sangwan, V.K.; Hersam, M.C. Neuromorphic Nanoelectronic Materials. Nat. Nanotechnol. 2020, 15, 517–528. [Google Scholar] [CrossRef] [PubMed]

- Osada, M.; Sasaki, T. Two-Dimensional Dielectric Nanosheets: Novel Nanoelectronics From Nanocrystal Building Blocks. Adv. Mater. 2012, 24, 210–228. [Google Scholar] [CrossRef] [PubMed]

- Kessler, R. Engineered Nanoparticles in Consumer Products: Understanding a New Ingredient. Env. Health Perspect. 2011, 119, A120–A125. [Google Scholar] [CrossRef] [PubMed]

- Vermeiren, L.; Devlieghere, F.; Van Beest, M.; De Kruijf, N.; Debevere, J. Developments in the Active Packaging of Foods. Trends Food Sci. Technol. 1999, 10, 77–86. [Google Scholar] [CrossRef]

- Salem, M.A.; Ezzat, S.M. Nanoemulsions in Food Industry. In Some New Aspects of Colloidal Systems in Foods; Milani, J.M., Ed.; IntechOpen: Rijeka, Croatia, 2019; ISBN 978-1-78985-781-8. [Google Scholar]

- Bastarrachea, L.; Wong, D.; Roman, M.; Lin, Z.; Goddard, J. Active Packaging Coatings. Coatings 2015, 5, 771–791. [Google Scholar] [CrossRef]

- Butt, M.A. Thin-Film Coating Methods: A Successful Marriage of High-Quality and Cost-Effectiveness—A Brief Exploration. Coatings 2022, 12, 1115. [Google Scholar] [CrossRef]

- Zhu, Q.; Chua, M.H.; Ong, P.J.; Cheng Lee, J.J.; Le Osmund Chin, K.; Wang, S.; Kai, D.; Ji, R.; Kong, J.; Dong, Z.; et al. Recent Advances in Nanotechnology-Based Functional Coatings for the Built Environment. Mater. Today Adv. 2022, 15, 100270. [Google Scholar] [CrossRef]

- Pinson, J.; Thiry, D. (Eds.) Surface Modification of Polymers: Methods and Applications, 1st ed.; Wiley: Hoboken, NJ, USA, 2019; ISBN 978-3-527-34541-0. [Google Scholar]

- Zhang, J.; Zhu, W.; Xin, B.; Lin, S.; Jin, L.; Wang, H. Development of an Antibacterial Surface with a Self-Defensive and pH-Responsive Function. Biomater. Sci. 2019, 7, 3795–3800. [Google Scholar] [CrossRef]

- Lin, X.; Fukazawa, K.; Ishihara, K. Photoreactive Polymers Bearing a Zwitterionic Phosphorylcholine Group for Surface Modification of Biomaterials. ACS Appl. Mater. Interfaces 2015, 7, 17489–17498. [Google Scholar] [CrossRef]

- Sadeghi, K.; Seo, J. Facile Approach to the Solid Support Photografting Coating of Citric Acid as a Novel Biomimetic Iron Chelator Film. Surf. Interfaces 2021, 22, 100814. [Google Scholar] [CrossRef]

- Sadeghi, K.; Seo, J. Photografting of P-Anisidine-Glycidyl Methacrylate onto Polymeric Substrate for Developing Free-Radical Scavenging Films. Prog. Org. Coat. 2020, 149, 105925. [Google Scholar] [CrossRef]

- Yuce-Dursun, B.; Cigil, A.B.; Dongez, D.; Kahraman, M.V.; Ogan, A.; Demir, S. Preparation and Characterization of Sol–Gel Hybrid Coating Films for Covalent Immobilization of Lipase Enzyme. J. Mol. Catal. B Enzym. 2016, 127, 18–25. [Google Scholar] [CrossRef]

- Robert, T.; Eschig, S.; Biemans, T.; Scheifler, F. Bio-Based Polyester Itaconates as Binder Resins for UV-Curing Offset Printing Inks. J. Coat. Technol. Res. 2019, 16, 689–697. [Google Scholar] [CrossRef]

- Gao, N.; Zhang, Z.; Deng, J.; Guo, X.; Cheng, B.; Hou, H. Acoustic Metamaterials for Noise Reduction: A Review. Adv. Mater. Technol. 2022, 7, 2100698. [Google Scholar] [CrossRef]

- Cheng, H.; Xu, H.; Julian McClements, D.; Chen, L.; Jiao, A.; Tian, Y.; Miao, M.; Jin, Z. Recent Advances in Intelligent Food Packaging Materials: Principles, Preparation and Applications. Food Chem. 2022, 375, 131738. [Google Scholar] [CrossRef]

- Shen, Z.; Rajabi-Abhari, A.; Oh, K.; Yang, G.; Youn, H.J.; Lee, H.L. Improving the Barrier Properties of Packaging Paper by Polyvinyl Alcohol Based Polymer Coating—Effect of the Base Paper and Nanoclay. Polymers 2021, 13, 1334. [Google Scholar] [CrossRef]

- Shen, Z.; Kwon, S.; Oh, K.; Abhari, A.R.; Lee, H.L. Facile Fabrication of Hydrophobic Cellulosic Paper with Good Barrier Properties via PVA/AKD Dispersion Coating. Nord. Pulp Pap. Res. J. 2019, 34, 516–524. [Google Scholar] [CrossRef]

- Ashfaq, A.; Khursheed, N.; Fatima, S.; Anjum, Z.; Younis, K. Application of Nanotechnology in Food Packaging: Pros and Cons. J. Agric. Food Res. 2022, 7, 100270. [Google Scholar] [CrossRef]

- LaKind, J.S. Can Coatings for Foods and Beverages: Issues and Options. Int. J. Technol. Policy Manag. 2013, 13, 80–95. [Google Scholar] [CrossRef]

- Geueke, B. Fpf Dossier: Can Coatings; Zenodo: Geneva, Switzerland, 2016. [Google Scholar]

- Chandio, A.; Channa, I.; Rizwan, M.; Akram, S.; Javed, M.; Siyal, S.; Saleem, M.; Makhdoom, M.; Ashfaq, T.; Khan, S.; et al. Polyvinyl Alcohol and Nano-Clay Based Solution Processed Packaging Coatings. Coatings 2021, 11, 942. [Google Scholar] [CrossRef]

- Bárdos, L.; Baránková, H. Cold Atmospheric Plasma: Sources, Processes, and Applications. Thin Solid Film. 2010, 518, 6705–6713. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, X. Size-Dependent Creep Behaviour of Plasma-Enhanced Chemical Vapour Deposited Silicon Oxide Films. J. Phys. D Appl. Phys. 2006, 39, 5054–5063. [Google Scholar] [CrossRef]

- Hoex, B.; Peeters, F.J.J.; Creatore, M.; Blauw, M.A.; Kessels, W.M.M.; Van De Sanden, M.C.M. High-Rate Plasma-Deposited SiO2 Films for Surface Passivation of Crystalline Silicon. J. Vac. Sci. Technol. A Vac. Surf. Film. 2006, 24, 1823–1830. [Google Scholar] [CrossRef]

- Azlin-Hasim, S.; Cruz-Romero, M.C.; Cummins, E.; Kerry, J.P.; Morris, M.A. The Potential Use of a Layer-by-Layer Strategy to Develop LDPE Antimicrobial Films Coated with Silver Nanoparticles for Packaging Applications. J. Colloid Interface Sci. 2016, 461, 239–248. [Google Scholar] [CrossRef] [PubMed]

- An, J.; Zhang, M.; Wang, S.; Tang, J. Physical, Chemical and Microbiological Changes in Stored Green Asparagus Spears as Affected by Coating of Silver Nanoparticles-PVP. LWT—Food Sci. Technol. 2008, 41, 1100–1107. [Google Scholar] [CrossRef]

- Smolkova, B.; El Yamani, N.; Collins, A.R.; Gutleb, A.C.; Dusinska, M. Nanoparticles in Food. Epigenetic Changes Induced by Nanomaterials and Possible Impact on Health. Food Chem. Toxicol. 2015, 77, 64–73. [Google Scholar] [CrossRef]

- Chawengkijwanich, C.; Hayata, Y. Development of TiO2 Powder-Coated Food Packaging Film and Its Ability to Inactivate Escherichia Coli in Vitro and in Actual Tests. Int. J. Food Microbiol. 2008, 123, 288–292. [Google Scholar] [CrossRef] [PubMed]

- Maneerat, C.; Hayata, Y. Antifungal Activity of TiO2 Photocatalysis against Penicillium Expansum in Vitro and in Fruit Tests. Int. J. Food Microbiol. 2006, 107, 99–103. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Wang, X.; Tao, Q.; Wang, J.; Zheng, Z.; Wang, X. Lotus-like Paper/Paperboard Packaging Prepared with Nano-Modified Overprint Varnish. Appl. Surf. Sci. 2013, 266, 319–325. [Google Scholar] [CrossRef]

- Smolander, M.; Hurme, E.; Koivisto, M.; Kivinen, S. Indicator 2004. Available online: https://www.researchgate.net/publication/233730010_Intelligent_Packaging (accessed on 19 January 2024).

- Kurantowicz, N.; Sawosz, E.; Jaworski, S.; Kutwin, M.; Strojny, B.; Wierzbicki, M.; Szeliga, J.; Hotowy, A.; Lipińska, L.; Koziński, R.; et al. Interaction of Graphene Family Materials with Listeria Monocytogenes and Salmonella Enterica. Nanoscale Res. Lett. 2015, 10, 23. [Google Scholar] [CrossRef] [PubMed]

- Bumbudsanpharoke, N.; Choi, J.; Ko, S. Applications of Nanomaterials in Food Packaging. J. Nanosci. Nanotechnol. 2015, 15, 6357–6372. [Google Scholar] [CrossRef] [PubMed]

- E Trujillo, L.; Avalos, R. Nanotechnology Applications for Food and Bioprocessing Industries. Biol. Med. 2016, 8, 3. [Google Scholar] [CrossRef]

- Biswas, K.; Mohanta, Y.K.; Kumar, V.B.; Hashem, A.; Fathi Abd_Allah, E.; Mohanta, D.; Mohanta, T.K. Nutritional Assessment Study and Role of Green Silver Nanoparticles in Shelf-Life of Coconut Endosperm to Develop as Functional Food. Saudi J. Biol. Sci. 2020, 27, 1280–1288. [Google Scholar] [CrossRef]

- Carbone, M.; Donia, D.T.; Sabbatella, G.; Antiochia, R. Silver Nanoparticles in Polymeric Matrices for Fresh Food Packaging. J. King Saud Univ.-Sci. 2016, 28, 273–279. [Google Scholar] [CrossRef]

- Sharma, S.; Barkauskaite, S.; Jaiswal, A.K.; Jaiswal, S. Essential Oils as Additives in Active Food Packaging. Food Chem. 2021, 343, 128403. [Google Scholar] [CrossRef] [PubMed]

- Mohanta, T.K.; Mohanta, N.; Mohanta, Y.K.; Parida, P.; Bae, H. Genome-Wide Identification of Calcineurin B-Like (CBL) Gene Family of Plants Reveals Novel Conserved Motifs and Evolutionary Aspects in Calcium Signaling Events. BMC Plant Biol. 2015, 15, 189. [Google Scholar] [CrossRef] [PubMed]

- Mohanta, Y.K.; Behera, S.K. Biosynthesis, Characterization and Antimicrobial Activity of Silver Nanoparticles by Streptomyces Sp. SS2. Bioprocess Biosyst. Eng. 2014, 37, 2263–2269. [Google Scholar] [CrossRef]

- Toker, R.D.; Kayaman-Apohan, N.; Kahraman, M.V. UV-Curable Nano-Silver Containing Polyurethane Based Organic–Inorganic Hybrid Coatings. Prog. Org. Coat. 2013, 76, 1243–1250. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Sayed, S.M. Bionanocomposites Materials for Food Packaging Applications: Concepts and Future Outlook. Carbohydr. Polym. 2018, 193, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-C.; Lu, L.; Gunasekaran, S. Biopolymer/Gold Nanoparticles Composite Plasmonic Thermal History Indicator to Monitor Quality and Safety of Perishable Bioproducts. Biosens. Bioelectron. 2017, 92, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Suh, S.; Meng, X.; Ko, S. Proof of Concept Study for Different-Sized Chitosan Nanoparticles as Carbon Dioxide (CO2) Indicators in Food Quality Monitoring. Talanta 2016, 161, 265–270. [Google Scholar] [CrossRef] [PubMed]

- Wyrwa, J.; Barska, A. Innovations in the Food Packaging Market: Active Packaging. Eur. Food Res. Technol. 2017, 243, 1681–1692. [Google Scholar] [CrossRef]

- Ćwiek-Ludwicka, K.; Ludwicki, J.K. Nanomaterials in Food Contact Materials: Considerations for Risk Assessment. Rocz. Panstw. Zakl. Hig. 2017, 68, 321–329. [Google Scholar]

- Almasi, H.; Jafarzadeh, P.; Mehryar, L. Fabrication of Novel Nanohybrids by Impregnation of CuO Nanoparticles into Bacterial Cellulose and Chitosan Nanofibers: Characterization, Antimicrobial and Release Properties. Carbohydr. Polym. 2018, 186, 273–281. [Google Scholar] [CrossRef]

- Attaran, S.A.; Hassan, A.; Wahit, M.U. Materials for Food Packaging Applications Based on Bio-Based Polymer Nanocomposites: A Review. J. Thermoplast. Compos. Mater. 2017, 30, 143–173. [Google Scholar] [CrossRef]

- Perinelli, D.R.; Fagioli, L.; Campana, R.; Lam, J.K.W.; Baffone, W.; Palmieri, G.F.; Casettari, L.; Bonacucina, G. Chitosan-Based Nanosystems and Their Exploited Antimicrobial Activity. Eur. J. Pharm. Sci. 2018, 117, 8–20. [Google Scholar] [CrossRef] [PubMed]

- Morris, V.J.; Woodward, N.C.; Gunning, A.P. Atomic Force Microscopy as a Nanoscience Tool in Rational Food Design: Use of Atomic Force Microscopy in Food Design. J. Sci. Food Agric. 2011, 91, 2117–2125. [Google Scholar] [CrossRef]

- Gerloff, K.; Albrecht, C.; Boots, A.W.; Förster, I.; Schins, R.P.F. Cytotoxicity and Oxidative DNA Damage by Nanoparticles in Human Intestinal Caco-2 Cells. Nanotoxicology 2009, 3, 355–364. [Google Scholar] [CrossRef]

- Uboldi, C.; Giudetti, G.; Broggi, F.; Gilliland, D.; Ponti, J.; Rossi, F. Amorphous Silica Nanoparticles Do Not Induce Cytotoxicity, Cell Transformation or Genotoxicity in Balb/3T3 Mouse Fibroblasts. Mutat. Res./Genet. Toxicol. Environ. Mutagen. 2012, 745, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Oberdörster, G.; Oberdörster, E.; Oberdörster, J. Nanotoxicology: An Emerging Discipline Evolving from Studies of Ultrafine Particles. Environ. Health Perspect. 2005, 113, 823–839. [Google Scholar] [CrossRef] [PubMed]

- Torres-Giner, S.; Wilkanowicz, S.; Melendez-Rodriguez, B.; Lagaron, J.M. Nanoencapsulation of Aloe Vera in Synthetic and Naturally Occurring Polymers by Electrohydrodynamic Processing of Interest in Food Technology and Bioactive Packaging. J. Agric. Food Chem. 2017, 65, 4439–4448. [Google Scholar] [CrossRef]

- Chaudhary, P.; Fatima, F.; Kumar, A. Relevance of Nanomaterials in Food Packaging and Its Advanced Future Prospects. J. Inorg. Organomet. Polym. 2020, 30, 5180–5192. [Google Scholar] [CrossRef]

- Garcia, C.V.; Shin, G.H.; Kim, J.T. Metal Oxide-Based Nanocomposites in Food Packaging: Applications, Migration, and Regulations. Trends Food Sci. Technol. 2018, 82, 21–31. [Google Scholar] [CrossRef]

- Saedi, S.; Garcia, C.V.; Kim, J.T.; Shin, G.H. Physical and Chemical Modifications of Cellulose Fibers for Food Packaging Applications. Cellulose 2021, 28, 8877–8897. [Google Scholar] [CrossRef]

- Oun, A.A.; Bae, A.Y.; Shin, G.H.; Park, M.-K.; Kim, J.T. Comparative Study of Oregano Essential Oil Encapsulated in Halloysite Nanotubes and Diatomaceous Earth as Antimicrobial and Antioxidant Composites. Appl. Clay Sci. 2022, 224, 106522. [Google Scholar] [CrossRef]

- European Commission. Commission Staff Working Paper: Types and Uses of Nanomaterials, Including Safety Aspects; European Union Commission: Brussels, Belgium, 2012. [Google Scholar]

- Sekhon, B.S. Nanotechnology in agri-food production: An overview. Nanotechnol. Sci. Appl. 2014, 7, 31–53. [Google Scholar] [CrossRef]

- Lorenz, C.; Von Goetz, N.; Scheringer, M.; Wormuth, M.; Hungerbühler, K. Potential Exposure of German Consumers to Engineered Nanoparticles in Cosmetics and Personal Care Products. Nanotoxicology 2011, 5, 12–29. [Google Scholar] [CrossRef]

- Katja, N.; Krug, H.; Kuhnel, D.; Mathes, B.; Richter, V.; Scholz, S.; Steinbach, C.; Zimmer, R. Acquisition, Evaluation and Public-Oriented Presentation of Socially Relevant Data and Findings for Nanomaterials (DaNa). 2011. Available online: https://nanopartikel.info/en/research/projects/dana/ (accessed on 19 January 2024).

- European Food Safety Authority Report of ESCO WG on Non-plastic Food Contact Materials. EFS3 2011, 8, 139E. [CrossRef]

- Gaiser, B.K.; Hirn, S.; Kermanizadeh, A.; Kanase, N.; Fytianos, K.; Wenk, A.; Haberl, N.; Brunelli, A.; Kreyling, W.G.; Stone, V. Effects of Silver Nanoparticles on the Liver and Hepatocytes In Vitro. Toxicol. Sci. 2013, 131, 537–547. [Google Scholar] [CrossRef] [PubMed]

- Mennini, T. Nanotechnology-Enabled Foods and Food Contact Materials on the UK Market. Nutrafoods 2013, 12, 29. [Google Scholar] [CrossRef]

- Market Publishers. Nano-Enabled Packaging for the Food and Beverage Industry: A Technology, Industry and Market Analysis; Innovative Research & Products, Inc.: Novi, MI, USA, 2009; p. 107. [Google Scholar]

- He, X.; Hwang, H.-M. Nanotechnology in Food Science: Functionality, Applicability, and Safety Assessment. J. Food Drug Anal. 2016, 24, 671–681. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Eral, H.B.; Hatton, T.A.; Doyle, P.S. Nanoemulsions: Formation, Properties and Applications. Soft Matter 2016, 12, 2826–2841. [Google Scholar] [CrossRef] [PubMed]

- Singh, T.; Shukla, S.; Kumar, P.; Wahla, V.; Bajpai, V.K.; Rather, I.A. Application of Nanotechnology in Food Science: Perception and Overview. Front. Microbiol. 2017, 8, 1501. [Google Scholar] [CrossRef]

- Garcia, C.V. Editorial: Nanomaterials in Food Packaging. Front. Nutr. 2022, 9, 1083185. [Google Scholar] [CrossRef] [PubMed]

- Bumbudsanpharoke, N.; Ko, S. Nano-Food Packaging: An Overview of Market, Migration Research, and Safety Regulations. J. Food Sci. 2015, 80, R910–R923. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Qurashi, A.; Sheehan, D. Nano Packaging—Progress and Future Perspectives for Food Safety, and Sustainability. Food Packag. Shelf Life 2023, 35, 100997. [Google Scholar] [CrossRef]

- Hills, F. Nanotechnology in Packaging: A Revolution in Waiting. Food Eng. Ingred. 2008, 33, 6–9. [Google Scholar]

- Nachay, K. Analyzing Nanotechnology. Food Technol. 2007, 61, 34–36. [Google Scholar]

- Vorbau, M.; Hillemann, L.; Stintz, M. Method for the Characterization of the Abrasion Induced Nanoparticle Release into Air from Surface Coatings. J. Aerosol Sci. 2009, 40, 209–217. [Google Scholar] [CrossRef]

- Guiot, A.; Golanski, L.; Tardif, F. Measurement of Nanoparticle Removal by Abrasion. J. Phys. Conf. Ser. 2009, 170, 012014. [Google Scholar] [CrossRef]

- Gohler, D.; Stintz, M.; Hillemann, L.; Vorbau, M. Characterization of Nanoparticle Release from Surface Coatings by the Simulation of a Sanding Process. Ann. Occup. Hyg. 2010, 54, 615–624. [Google Scholar] [CrossRef]

- Göhler, D.; Nogowski, A.; Fiala, P.; Stintz, M. Nanoparticle Release from Nanocomposites Due to Mechanical Treatment at Two Stages of the Life-Cycle. J. Phys. Conf. Ser. 2013, 429, 012045. [Google Scholar] [CrossRef]

- Nobile, M.A.d.; Cannarsi, M.; Altieri, C.; Sinigaglia, M.; Favia, P.; Iacoviello, G.; D’Agostino, R. Effect of Ag-containing Nano-composite Active Packaging System on Survival of Alicyclobacillus acidoterrestris. J. Food Sci. 2004, 69, E379–E383. [Google Scholar] [CrossRef]

- LaCoste, A.; Schaich, K.M.; Zumbrunnen, D.; Yam, K.L. Advancing Controlled Release Packaging through Smart Blending. Packag. Technol. Sci. 2005, 18, 77–87. [Google Scholar] [CrossRef]

- Lopez-Rubio, A.; Gavara, R.; Lagaron, J.M. Bioactive Packaging: Turning Foods into Healthier Foods through Biomaterials. Trends Food Sci. Technol. 2006, 17, 567–575. [Google Scholar] [CrossRef]

- Lovern, S.B.; Klaper, R. Daphnia Magna Mortality When Exposed to Titanium Dioxide and Fullerene (C60) Nanoparticles. Environ. Toxicol. Chem. 2006, 25, 1132–1137. [Google Scholar] [CrossRef] [PubMed]

- Kaegi, R.; Ulrich, A.; Sinnet, B.; Vonbank, R.; Wichser, A.; Zuleeg, S.; Simmler, H.; Brunner, S.; Vonmont, H.; Burkhardt, M.; et al. Synthetic TiO2 Nanoparticle Emission from Exterior Facades into the Aquatic Environment. Environ. Pollut. 2008, 156, 233–239. [Google Scholar] [CrossRef] [PubMed]

- Kaegi, R.; Sinnet, B.; Zuleeg, S.; Hagendorfer, H.; Mueller, E.; Vonbank, R.; Boller, M.; Burkhardt, M. Release of Silver Nanoparticles from Outdoor Facades. Environ. Pollut. 2010, 158, 2900–2905. [Google Scholar] [CrossRef] [PubMed]

- Duncan, T.V. Applications of Nanotechnology in Food Packaging and Food Safety: Barrier Materials, Antimicrobials and Sensors. J. Colloid Interface Sci. 2011, 363, 1–24. [Google Scholar] [CrossRef]

- Jayakumar, A.; Radoor, S.; Kim, J.T.; Rhim, J.W.; Nandi, D.; Parameswaranpillai, J.; Siengchin, S. Recent Innovations in Bionanocomposites-Based Food Packaging Films—A Comprehensive Review. Food Packag. Shelf Life 2022, 33, 100877. [Google Scholar] [CrossRef]

- Edmundson, M.; Thanh, N.T.; Song, B. Nanoparticles Based Stem Cell Tracking in Regenerative Medicine. Theranostics 2013, 3, 573–582. [Google Scholar] [CrossRef]

- Gonçalves, B.C.; Lopes Barbosa, M.G.; Silva Olak, A.P.; Belebecha Terezo, N.; Nishi, L.; Watanabe, M.A.; Marinello, P.; Zendrini Rechenchoski, D.; Dejato Rocha, S.P.; Faccin-Galhardi, L.C. Antiviral Therapies: Advances and Perspectives. Fundam. Clin. Pharmacol. 2021, 35, 305–320. [Google Scholar] [CrossRef]

- Chen, N.; Zheng, Y.; Yin, J.; Li, X.; Zheng, C. Inhibitory Effects of Silver Nanoparticles against Adenovirus Type 3 in Vitro. J. Virol. Methods 2013, 193, 470–477. [Google Scholar] [CrossRef]

- Xiang, D.; Zheng, C.; Zheng, Y.; Li, X.; Yin, J.; O’ Conner, M.; Marappan, M.; Miao, Y.; Xiang, B.; Duan, W.; et al. Inhibition of A/Human/Hubei/3/2005 (H3N2) Influenza Virus Infection by Silver Nanoparticles in Vitro and in Vivo. Int. J. Nanomed. 2013, 8, 4103. [Google Scholar] [CrossRef]

- Carlos, K.S.; Treblin, M.; De Jager, L.S. Comparison and Optimization of Three Commercial Methods with an LC–MS/MS Method for the Determination of Sulfites in Food and Beverages. Food Chem. 2019, 286, 537–540. [Google Scholar] [CrossRef] [PubMed]

- Chaudhry, Q.; Scotter, M.; Blackburn, J.; Ross, B.; Boxall, A.; Castle, L.; Aitken, R.; Watkins, R. Applications and Implications of Nanotechnologies for the Food Sector. Food Addit. Contam. Part A 2008, 25, 241–258. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Suppakul, P. Active and Intelligent Packaging: The Indication of Quality and Safety. Crit. Rev. Food Sci. Nutr. 2018, 58, 808–831. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Yeo, L.P.; Ong, A.J.; Zhiwei, W.; Mandler, D.; Magdassi, S.; Tok, A.I.Y. Electrochromic Smart Glass Coating on Functional Nano-Frameworks for Effective Building Energy Conservation. Mater. Today Energy 2020, 18, 100496. [Google Scholar] [CrossRef]

- Dahlan, A.S. Smart and Functional Materials Based Nanomaterials in Construction Styles in Nano-Architecture. Silicon 2019, 11, 1949–1953. [Google Scholar] [CrossRef]

- Gasonoo, A.; Ahn, H.-S.; Jang, E.-J.; Kim, M.-H.; Gwag, J.; Lee, J.-H.; Choi, Y. Fabrication of Multi-Layer Metal Oxides Structure for Colored Glass. Materials 2021, 14, 2437. [Google Scholar] [CrossRef]

- Watanabe, T.; Fukayama, S.; Miyauchi, M.; Fujishima, A.; Hashimoto, K. Photocatalytic Activity and Photo-Induced Wettability Conversion of TiO2 Thin Film Prepared by Sol-Gel Process on a Soda-Lime Glass. J. Sol-Gel Sci. Technol. 2000, 19, 71–76. [Google Scholar] [CrossRef]

- Shah, K.W. A Review on Enhancement of Phase Change Materials—A Nanomaterials Perspective. Energy Build. 2018, 175, 57–68. [Google Scholar] [CrossRef]

- ASTM (1965) C 162-56; Standard Definition of Terms Relating to Glass Products. Part 13; American Society for Testing Materials: West Conshohocken, PA, USA, 1965; pp. 145–159.

- Alexander, S. The Properties of Glass. By George W. Morey. J. Phys. Chem. 1939, 43, 547–548. [Google Scholar] [CrossRef]

- Hardesty, B.D.; Roman, L.; Leonard, G.H.; Mallos, N.; Pragnell-Raasch, H.; Campbell, I.; Wilcox, C. Socioeconomics Effects on Global Hotspots of Common Debris Items on Land and the Seafloor. Glob. Environ. Change 2021, 71, 102360. [Google Scholar] [CrossRef]

- Arp, H.P.H.; Kühnel, D.; Rummel, C.; MacLeod, M.; Potthoff, A.; Reichelt, S.; Rojo-Nieto, E.; Schmitt-Jansen, M.; Sonnenberg, J.; Toorman, E.; et al. Weathering Plastics as a Planetary Boundary Threat: Exposure, Fate, and Hazards. Environ. Sci. Technol. 2021, 55, 7246–7255. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Food Contact Chemicals Database (FCCdb) | Food Packaging Forum. Available online: https://www.foodpackagingforum.org/fccdb (accessed on 19 January 2024).

- An Inventory of Sources and Environmental Releases of Dioxin-Like Compounds in the United States for the Years 1987, 1995, and 2000; National Center for Environmental Assessment: Washington, DC, USA, 2006; p. 677.

- Zhang, M.; Buekens, A.; Jiang, X.; Li, X. Dioxins and Polyvinylchloride in Combustion and Fires. Waste Manag. Res. 2015, 33, 630–643. [Google Scholar] [CrossRef] [PubMed]

- Thabet, A.; Ebnalwaled, A.A. Improvement of Surface Energy Properties of PVC Nanocomposites for Enhancing Electrical Applications. Measurement 2017, 110, 78–83. [Google Scholar] [CrossRef]

- Arora, A.; Choudhary, V.; Sharma, D.K. Effect of Clay Content and Clay/Surfactant on the Mechanical, Thermal and Barrier Properties of Polystyrene/Organoclay Nanocomposites. J. Polym. Res. 2011, 18, 843–857. [Google Scholar] [CrossRef]

- Arroqui, C.; Lopez, A.; Esnoz, A.; Virseda, P. Mathematical Model of Heat Transfer and Enzyme Inactivation in an Integrated Blancher Cooler. J. Food Eng. 2003, 58, 215–225. [Google Scholar] [CrossRef]

- Barrett, D.; Theerakulkait, C. Quality Indicators in Blanched, Frozen, Stored Vegetables. Food Technol. 1995, 49, 62–65. [Google Scholar]

- Abbas, K.; Saleh, A.; Mohamed, A.; MohdAzhan, N. The Recent Advances in the Nanotechnology and Its Applications in Food Processing: A Review. Food Agric. Environ. 2009, 7, 14–17. [Google Scholar]

- Aigbogun, I.; Mohammed, S.; Orukotan, A.; Tanko, J. The Role of Nanotechnology in Food Industries—A Review. J. Adv. Microbiol. 2018, 7, 1–9. [Google Scholar] [CrossRef]

- Ubbink, J.; Krüger, J. Physical Approaches for the Delivery of Active Ingredients in Foods. Trends Food Sci. Technol. 2006, 17, 244–254. [Google Scholar] [CrossRef]

- Esse, R.; Saari, A. Shelf-Life and Moisture Management. In Understanding and Measuring the Shelf-Life of Food; Elsevier: Amsterdam, The Netherlands, 2004; pp. 24–41. ISBN 978-1-85573-732-7. [Google Scholar]

- Yang, F.M.; Li, H.M.; Li, F.; Xin, Z.H.; Zhao, L.Y.; Zheng, Y.H.; Hu, Q.H. Effect of Nano-Packing on Preservation Quality of Fresh Strawberry (Fragaria Ananassa Duch. Cv Fengxiang) during Storage at 4 °C. J. Food Sci. 2010, 75, C236–C240. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, P.; Salem, K.S.; Hubbe, M.A.; Pal, L. Advances in Barrier Coatings and Film Technologies for Achieving Sustainable Packaging of Food Products—A Review. Trends Food Sci. Technol. 2021, 115, 461–485. [Google Scholar] [CrossRef]

- Babu, P.J. Nanotechnology Mediated Intelligent and Improved Food Packaging. Int. Nano Lett. 2022, 12, 1–14. [Google Scholar] [CrossRef]

- Reyes, T.M.; Wagoner, M.P.; Zorn, V.E.; Coursen, M.M.; Wilborn, B.S.; Bonner, T.; Brandebourg, T.D.; Rodning, S.P.; Sawyer, J.T. Vacuum Packaging Can Extend Fresh Color Characteristics of Beef Steaks during Simulated Display Conditions. Foods 2022, 11, 520. [Google Scholar] [CrossRef] [PubMed]

- Nicosia, C.; Fava, P.; Pulvirenti, A.; Antonelli, A.; Licciardello, F. Domestic Use Simulation and Secondary Shelf Life Assessment of Industrial Pesto Alla Genovese. Foods 2021, 10, 1948. [Google Scholar] [CrossRef] [PubMed]

- Panza, O.; Lacivita, V.; Palermo, C.; Conte, A.; Del Nobile, M.A. Food By-Products to Extend Shelf Life: The Case of Cod Sticks Breaded with Dried Olive Paste. Foods 2020, 9, 1902. [Google Scholar] [CrossRef]

- Nambeesan, S.; Datsenka, T.; Ferruzzi, M.G.; Malladi, A.; Mattoo, A.K.; Handa, A.K. Overexpression of Yeast Spermidine Synthase Impacts Ripening, Senescence and Decay Symptoms in Tomato. Plant J. 2010, 63, 836–847. [Google Scholar] [CrossRef] [PubMed]

- Aslam, R.; Mobin, M.; Aslam, J. Nanomaterials as Corrosion Inhibitors. In Inorganic Anticorrosive Materials; Elsevier: Amsterdam, The Netherlands, 2022; pp. 3–20. ISBN 978-0-323-90410-0. [Google Scholar]

- Reig, C.S.; Lopez, A.D.; Ramos, M.H.; Ballester, V.A.C. Nanomaterials: A Map for Their Selection in Food Packaging Applications. Packag. Technol. Sci. 2014, 27, 839–866. [Google Scholar] [CrossRef]

- Tsagkaris, A.S.; Tzegkas, S.G.; Danezis, G.P. Nanomaterials in Food Packaging: State of the Art and Analysis. J. Food Sci. Technol. 2018, 55, 2862–2870. [Google Scholar] [CrossRef]

- Xiao, F.; Ruan, C.; Liu, L.; Yan, R.; Zhao, F.; Zeng, B. Single-Walled Carbon Nanotube-Ionic Liquid Paste Electrode for the Sensitive Voltammetric Determination of Folic Acid. Sens. Actuators B Chem. 2008, 134, 895–901. [Google Scholar] [CrossRef]

- Ranjan, S.; Dasgupta, N.; Chakraborty, A.R.; Melvin Samuel, S.; Ramalingam, C.; Shanker, R.; Kumar, A. Nanoscience and Nanotechnologies in Food Industries: Opportunities and Research Trends. J. Nanopart. Res. 2014, 16, 2464. [Google Scholar] [CrossRef]

- Singh, R.; Dutt, S.; Sharma, P.; Sundramoorthy, A.K.; Dubey, A.; Singh, A.; Arya, S. Future of Nanotechnology in Food Industry: Challenges in Processing, Packaging, and Food Safety. Glob. Chall. 2023, 7, 2200209. [Google Scholar] [CrossRef]

- El-Sayed, S.M.; Youssef, A.M. Eco-Friendly Biodegradable Nanocomposite Materials and Their Recent Use in Food Packaging Applications: A Review. Sustain. Food Technol. 2023, 1, 215–227. [Google Scholar] [CrossRef]

- Mestdagh, F.; De Meulenaer, B.; De Clippeleer, J.; Devlieghere, F.; Huyghebaert, A. Protective Influence of Several Packaging Materials on Light Oxidation of Milk. J. Dairy Sci. 2005, 88, 499–510. [Google Scholar] [CrossRef] [PubMed]

- Poudel, P.R.; Kataoka, I.; Mochioka, R. Effect of Red- and Blue-Light-Emitting Diodes on Growth and Morphogenesis of Grapes. Plant Cell Tiss. Organ. Cult. 2008, 92, 147–153. [Google Scholar] [CrossRef]

- Gore, A.H.; Prajapat, A.L. Biopolymer Nanocomposites for Sustainable UV Protective Packaging. Front. Mater. 2022, 9, 855727. [Google Scholar] [CrossRef]

- Halada, G.P.; Orlov, A. Environmental Degradation of Engineered Nanomaterials. In Handbook of Environmental Degradation of Materials; Elsevier: Amsterdam, The Netherlands, 2018; pp. 225–239. ISBN 978-0-323-52472-8. [Google Scholar]

- Ray, P.C.; Yu, H.; Fu, P.P. Toxicity and Environmental Risks of Nanomaterials: Challenges and Future Needs. J. Environ. Sci. Health Part C 2009, 27, 1–35. [Google Scholar] [CrossRef] [PubMed]

- Martínez, G.; Merinero, M.; Pérez-Aranda, M.; Pérez-Soriano, E.; Ortiz, T.; Villamor, E.; Begines, B.; Alcudia, A. Environmental Impact of Nanoparticles’ Application as an Emerging Technology: A Review. Materials 2020, 14, 166. [Google Scholar] [CrossRef]

- Innocenti, F.D. Biodegradability and Compostability. In Biodegradable Polymers and Plastics; Chiellini, E., Solaro, R., Eds.; Springer: Boston, MA, USA, 2003; pp. 33–45. ISBN 978-1-4613-4854-2. [Google Scholar]

- Ma, B.; Martín, C.; Kurapati, R.; Bianco, A. Degradation-by-Design: How Chemical Functionalization Enhances the Biodegradability and Safety of 2D Materials. Chem. Soc. Rev. 2020, 49, 6224–6247. [Google Scholar] [CrossRef]

- Manatunga, D.C.; Dassanayake, R.S.; Liyanage, R.N. Novel Acumens into Biodegradation: Impact of Nanomaterials and Their Contribution. In Biodegradation Technology of Organic and Inorganic Pollutants; Ferreira Mendes, K., Nogueira De Sousa, R., Cabral Mielke, K., Eds.; IntechOpen: Rijeka, Croatia, 2022; ISBN 978-1-83968-895-9. [Google Scholar]

- Harvard, T.H. Chan, School of Public Health. Food Waste: The Big Picture. Available online: https://www.hsph.harvard.edu/nutritionsource/sustainability/food-waste/ (accessed on 2 December 2023).

- Gunders, D. Wasted: How America Is Losing up to 40 Percent of Its Food from Farm to Fork to Landfill; NRDC: New York, NY, USA, 2012. [Google Scholar]

- How the Right Packaging Can Reduce Food Waste. Available online: https://goldenwestpackaging.com/wp/how-the-right-packaging-can-reduce-food-waste/ (accessed on 2 December 2023).

- EFSA Scientific Committee; More, S.; Bampidis, V.; Benford, D.; Bragard, C.; Halldorsson, T.; Hernández-Jerez, A.; Bennekou, S.H.; Koutsoumanis, K.; Lambré, C.; et al. Guidance on Technical Requirements for Regulated Food and Feed Product Applications to Establish the Presence of Small Particles Including Nanoparticles. EFS2 2021, 19, e06769. [Google Scholar] [CrossRef]

- Rijk, R.; Veraart, R. (Eds.) Global Legislation for Food Packaging Materials, 1st ed.; Wiley: Hoboken, NJ, USA, 2010; ISBN 978-3-527-31912-1. [Google Scholar]

- Clark, M.N. Nanotechnology Regulation of Food Packaging | PackagingLaw.com. Keller & Heckman 2012. Available online: https://www.packaginglaw.com/special-focus/nanotechnology-regulation-food-packaging (accessed on 19 January 2024).

- Stieger, G. Regulation of Nanomaterials in the EU | Food Packaging Forum. Available online: https://www.foodpackagingforum.org/news/regulation-of-nanomaterials-in-the-eu (accessed on 19 January 2024).

- Nanotechnology-Based Health Products and Food; Canada Health: Vancouver, BC, Canada, 2011.

- Manova, E. Australia: Calls for Nanomaterial Ban in Food and Packaging. 2022. Available online: https://www.foodpackagingforum.org/news/australia-calls-for-nanomaterial-ban-in-food-and-packaging (accessed on 19 January 2024).

- Parkinson, L. EFSA Updates Guidance on Nanomaterials in the Food Chain. 2021. Available online: https://www.foodpackagingforum.org/news/efsa-updates-guidance-on-nanomaterials-in-the-food-chain (accessed on 19 January 2024).

- Jarvis, D.; Richmond, N. Regulation and Governance of Nanotechnology in China: Regulatory Challenges and Effectiveness. Eur. J. Law Technol. 2011, 2. [Google Scholar]

- Chavez-Hernandez, J.A.; Velarde-Salcedo, A.J.; Navarro-Tovar, G.; Gonzalez, C. Safe Nanomaterials: From Their Use, Application and Disposal to Regulations. Nanoscale Adv. 2024. [Google Scholar] [CrossRef]

- Regulations of Nanomaterials in USA. 2016. Available online: https://www.chemsafetypro.com/Topics/USA/Regulations_of_Nanomaterials_in_USA.html (accessed on 19 January 2024).

- Control of Nanoscale Materials under the Toxic Substances Control Act; Environmental Protection Agency: Washington, DC, USA, 2023.

- Nanomaterials—ECHA. Available online: https://echa.europa.eu/regulations/nanomaterials (accessed on 19 January 2024).

- Nielsen, C.; Skaggs, K. Food Packaging Regulations in Australia and New Zealand. 2017. Available online: https://www.packaginglaw.com/special-focus/food-packaging-regulations-australia-and-new-zealand (accessed on 19 January 2024).

- Jagadish, C.; Barnard, A. Nanotechnology Regulation in Australia. Available online: https://www.science.org.au/curious/technology-future/nanotechnology-regulation-australia (accessed on 19 January 2024).

- Ettinger, D.; Li, J.X.; Hu, C.; Eric, G.; Dai, Y.; Tian, S. China Food Packaging Year-In-Review: Looking Back on the Ox and Forward to the Tiger. Available online: https://www.natlawreview.com/article/china-food-and-food-packaging-laws (accessed on 20 January 2024).

- FDA’s Approach to Regulation of Nanotechnology Products; FDA: Silver Spring, ML, USA, 2018.

- Comparative Analysis of Nanomaterial Regulations in Cosmetics: A Closer Look at EU and China. Available online: https://www.zmuni.com/en/news/comparative-analysis-nanomaterial-regulations-cosmetics-closer-look-eu-and-china/ (accessed on 19 January 2024).

- ElAmin, A. Carbon Nanotubes Could Be New Pathogen Weapon. 2008. Available online: https://www.foodnavigator.com/Article/2007/08/31/Carbon-nanotubes-could-be-new-pathogen-weapon (accessed on 19 January 2024).

- Jones, N.; Ray, B.; Ranjit, K.T.; Manna, A.C. Antibacterial Activity of ZnO Nanoparticle Suspensions on a Broad Spectrum of Microorganisms. FEMS Microbiol. Lett. 2008, 279, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Qi, L.; Xu, Z.; Jiang, X.; Hu, C.; Zou, X. Preparation and Antibacterial Activity of Chitosan Nanoparticles. Carbohydr. Res. 2004, 339, 2693–2700. [Google Scholar] [CrossRef] [PubMed]

- Sanpui, P.; Murugadoss, A.; Prasad, P.; Ghosh, S.; Chattopadhyay, A. The Antibacterial Properties of a Novel Chitosan–Ag-Nanoparticle Composite. Int. J. Food Microbiol. 2008, 124, 142–146. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Du, Y.; Yang, J.; Wang, X.; Shi, X.; Hu, Y. Preparation, Characterization and Antimicrobial Activity of Chitosan/Layered Silicate Nanocomposites. Polymer 2006, 47, 6738–6744. [Google Scholar] [CrossRef]

- Dalal, A.; Rana, J.S.; Kumar, A. Ultrasensitive Nanosensor for Detection of Malic Acid in Tomato as Fruit Ripening Indicator. Food Anal. Methods 2017, 10, 3680–3686. [Google Scholar] [CrossRef]

- Shah, A. A Novel Electrochemical Nanosensor for the Simultaneous Sensing of Two Toxic Food Dyes. ACS Omega 2020, 5, 6187–6193. [Google Scholar] [CrossRef] [PubMed]

- Lück, E.; Jager, M. Antimicrobial Food Additives; Springer: Berlin/Heidelberg, Germany, 1997; ISBN 978-3-642-63896-1. [Google Scholar]

- Donaldson, K.; Tran, L.; Jimenez, L.A.; Duffin, R.; Newby, D.E.; Mills, N.; MacNee, W.; Stone, V. Combustion-Derived Nanoparticles: A Review of Their Toxicology Following Inhalation Exposure. Part. Fibre Toxicol. 2005, 2, 10. [Google Scholar] [CrossRef]

- Naseer, B.; Srivastava, G.; Qadri, O.S.; Faridi, S.A.; Islam, R.U.; Younis, K. Importance and Health Hazards of Nanoparticles Used in the Food Industry. Nanotechnol. Rev. 2018, 7, 623–641. [Google Scholar] [CrossRef]

- Takenaka, S.; Karg, E.; Roth, C.; Schulz, H.; Ziesenis, A.; Heinzmann, U.; Schramel, P.; Heyder, J. Pulmonary and Systemic Distribution of Inhaled Ultrafine Silver Particles in Rats. Environ. Health Perspect. 2001, 109, 547–551. [Google Scholar] [CrossRef]

- Youssef, A.M. Polymer Nanocomposites as a New Trend for Packaging Applications. Polym.-Plast. Technol. Eng. 2013, 52, 635–660. [Google Scholar] [CrossRef]

- Rovera, C.; Ghaani, M.; Farris, S. Nano-Inspired Oxygen Barrier Coatings for Food Packaging Applications: An Overview. Trends Food Sci. Technol. 2020, 97, 210–220. [Google Scholar] [CrossRef]

- Choi, J.I.; Chae, S.J.; Kim, J.M.; Choi, J.C.; Park, S.J.; Choi, H.J.; Bae, H.; Park, H.J. Potential Silver Nanoparticles Migration from Commercially Available Polymeric Baby Products into Food Simulants. Food Addit. Contam. Part A 2018, 35, 996–1005. [Google Scholar] [CrossRef]

- De Azeredo, H.M.C. Antimicrobial Nanostructures in Food Packaging. Trends Food Sci. Technol. 2013, 30, 56–69. [Google Scholar] [CrossRef]

- Huang, Y.; Mei, L.; Chen, X.; Wang, Q. Recent Developments in Food Packaging Based on Nanomaterials. Nanomaterials 2018, 8, 830. [Google Scholar] [CrossRef]

- Su, S.; Kang, P.M. Systemic Review of Biodegradable Nanomaterials in Nanomedicine. Nanomaterials 2020, 10, 656. [Google Scholar] [CrossRef]

- Bellanthudawa, B.K.A.; Nawalage, N.M.S.K.; Handapangoda, H.M.A.K.; Suvendran, S.; Wijayasenarathne, K.A.S.H.; Rathnasuriya, M.L.D.; Wickramasinghe, P.G.M.U.; Aberathna, A.A.A.U.; Tennakoon, A.; Perera, I.J.J.U.N. A Perspective on Biodegradable and Non-Biodegradable Nanoparticles in Industrial Sectors: Applications, Challenges, and Future Prospects. Nanotechnol. Environ. Eng. 2023, 8, 975–1013. [Google Scholar] [CrossRef]

- Cohen, D. Achieving Food Security in Vulnerable Populations. BMJ 2005, 331, 775–777. [Google Scholar] [CrossRef][Green Version]

- Royer, M.F.; Wharton, C. The FINDING-Food Intervention: A Mixed-Methods Feasibility Study Addressing Food Insecurity. Challenges 2023, 14, 43. [Google Scholar] [CrossRef]

- Lugani, Y.; Sooch, B.S.; Singh, P.; Kumar, S. Nanobiotechnology Applications in Food Sector and Future Innovations. In Microbial Biotechnology in Food and Health; Elsevier: Amsterdam, The Netherlands, 2021; pp. 197–225. ISBN 978-0-12-819813-1. [Google Scholar]

- Saritha, G.N.G.; Anju, T.; Kumar, A. Nanotechnology—Big Impact: How Nanotechnology Is Changing the Future of Agriculture? J. Agric. Food Res. 2022, 10, 100457. [Google Scholar] [CrossRef]

- Khan, F.; Pandey, P.; Upadhyay, T.K. Applications of Nanotechnology-Based Agrochemicals in Food Security and Sustainable Agriculture: An Overview. Agriculture 2022, 12, 1672. [Google Scholar] [CrossRef]

- Onyeaka, H.; Passaretti, P.; Miri, T.; Al-Sharify, Z.T. The Safety of Nanomaterials in Food Production and Packaging. Curr. Res. Food Sci. 2022, 5, 763–774. [Google Scholar] [CrossRef]

- Durán, N.; Marcato, P.D. Nanobiotechnology Perspectives. Role of Nanotechnology in the Food Industry: A Review. Int. J. Food Sci. Technol. 2013, 48, 1127–1134. [Google Scholar] [CrossRef]

- Biswas, R.; Alam, M.; Sarkar, A.; Haque, M.I.; Hasan, M.M.; Hoque, M. Application of Nanotechnology in Food: Processing, Preservation, Packaging and Safety Assessment. Heliyon 2022, 8, e11795. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Li, S.; Chen, Z.; Zhu, J.; Hao, W.; Jia, G.; Chen, W.; Zheng, Y.; Qu, W.; Liu, Y. Safety Assessment of Nanoparticles in Food: Current Status and Prospective. Nano Today 2021, 39, 101169. [Google Scholar] [CrossRef]

- Amini, S.M.; Gilaki, M.; Karchani, M. Safety of Nanotechnology in Food Industries. Electron. Physician 2014, 6, 962–968. [Google Scholar] [CrossRef]

| Nanomaterial | Property Enhancement | Applications |

|---|---|---|

| Titanium nitride | Improvement of thermal properties [119], antimicrobial and deodorant agent [120], UV filter [121] | PET, fridges [120] |

| Zinc oxide | UV filter, antimicrobial and fungi static agent [122], deodorant [120] | Plastic glasses, plastic films |

| Carbon black | Additive [123] | Rubber, silicones, printing inks |

| Silver | Antimicrobial [124], anti-biotic, antistatic agent | Reusable food containers [120] |

| Nanoclay (bentonite) | Improvement of barrier properties [125] | PE, PET, PP, PS, TPO and nylon [120,126] |

| Aluminum | Filler in polymers, scratch- and abrasion-resistance in coatings [123], improvement of barrier properties, UV filter [120] | |

| Silicon dioxide | Anti-slip agent | Printing inks, paper and boards, rubbers, silicones |

| Size, size distribution, shape [152] | Scanning electron microscopy (SEM) |

| Transmission electron microscopy (TEM) | |

| Atomic force microscopy (AFM) | |

| X-ray diffraction (XRD) for crystalline nanoparticles | |

| Differential mobility analysis | |

| Crystallinity, crystal structure [152] | X-ray diffraction (XRD) |

| Electron diffraction in a transmission electron microscope (ED) | |

| Chemical composition and purity of a nanoparticle ensemble (powder sample) | Inductively coupled mass spectroscopy (ICPMS) |

| Inductively coupled plasma atomic emission spectroscopy (ICP-AES) | |

| Chemical properties of single nanoparticles [152] | Atom-absorption spectroscopy (AAS) |

| X-ray fluorescence spectroscopy (XRF) | |

| X-ray photoemission spectroscopy (XPS) | |

| Time-of-flight secondary ion mass spectroscopy (TOF-SIMS) | |

| Ultraviolet-visible spectroscopy (UV-Vis) | |

| Fourier-transform infrared spectroscopy (FTIR) | |

| Energy-dispersive (wavelength) dispersive X-ray spectroscopy in an electron microscope | |

| Surface chemistry and surface reactivity [152] | X-ray photoemission spectroscopy (XPS) |

| Electron spin resonance (ESR) | |

| Auger electron spectroscopy (AES) | |

| Surface area as an indicator for agglomeration [152] | Isothermal gas adsorption/BET |

| Criteria | United States | European Union | Canada | Australia | China |

|---|---|---|---|---|---|

| Regulatory Body | FDA (Food and Drug Administration), EPA (Environmental Protection Agency) [203] | European Chemicals Agency (ECHA), European Food Safety Authority (EFSA) [204] | Health Canada, Environment nada [205] | National Industrial Chemicals Notification and Assessment Scheme (NICNAS), Food Standards Australia New Zealand (FSANZ), Therapeutic Goods Administration (TGA), National Industrial Chemicals Notification and Assessment Scheme (NICNAS) The Australian Competition and Consumer Commission (ACCC) [206] | State Food and Drug Administration (SFDA) The National Health Commission of China, The National Medical Products Administration (NMPA) (Yu) National Nanotechnology Standardization Technical Committee (NSTC) Standardization Administration of China/Technical Committee (SAC/279) [207,208] |

| Responsibility | The FDA is responsible for ensuring products meet safety standards and comply with legal requirements. [203,209] EPA regulates nanomaterials under TSCA, requiring reporting and recordkeeping for nanoscale chemical substances [210,211] | Nanomaterials are assessed to ensure that their uses are properly evaluated, and any risks are controlled. [212] EFSA provides guidance on risk assessment which includes considerations for nanomaterials in food and Food Contact Materials (FCMs) [207] | Health Canada does not regulate nanomaterials in these products [131,203]. | FSANZ regulates nanotechnologies in food. TGA manages nanoparticles in therapeutic goods and medical devices [213]. NICNAS is responsible for industrial nanomaterials in consumer goods and coatings The ACCC regulates all consumer products containing nanomaterials that do not fall under other regulatory jurisdictions [214]. | The SAC/TC279 serves as the coordinating body to draft essential nanotechnology standards. [208] These bodies are responsible for managing risks and appropriate frameworks for nanotechnology |

| Legislation | Federal Food, Drug, and Cosmetic Act, Toxic Substances Control Act (TSCA) | REACH, CLP, Biocidal Products Regulation (BPR) [119] | Framework for risk assessment of manufactured nanomaterials under CEPA 1999 [205] | Food Standards Australia New Zealand (FSANZ)—under the joint Australia New Zealand Food Standards Code (the Code) [213] | Environmental Administration of New Chemical Substances made effective in September 2003 [208] Standard for the Use of Food Additives (GB 2760-2014), General Standard for the Labeling of Prepackaged Foods (GB7718-2011), Standard for the Nutritional Labeling of Prepackaged Foods (GB 28050-2011). [215] |

| Labelling Requirements | FDA recommends voluntary labeling for cosmetics [216] | Mandatory labeling for certain nanomaterials in cosmetics and other products [204] | Labeling not explicitly required for nanomaterials [131,205] | The Code mandates that food packaging must be safe and reported [206] | Mandatory labeling and reporting requirements [208,217] |

| Product Bans or Restrictions | Varies by product type; e.g., certain sunscreens with nanomaterials regulated [211,216] | Bans or restrictions on certain nanomaterials in cosmetics [119] | General guidance and risk assessment for products containing nanomaterials are under existing legislative frameworks [205] | Some restrictions on nanomaterials transferring from packaging to food [213] | Stringent regulations on the use of nanomaterials in cosmetics. - Requirement for specific physicochemical indicators and toxicological test data for nanomaterials. - Use of nanotechnology in children’s cosmetics is restricted [217] |

| Reporting of Nanomaterial Use | EPA requires reporting [211] | Mandatory reporting under REACH [207] | Reporting under CEPA [205] | Reporting required [206] | Mandatory reporting [208,215] |

| Company | Product Name | Active Ingredient |

|---|---|---|

| Bactiblock, Zaragoza, Spain | BactiBlock 920 B4 | silver ions-based |

| Nanopack Technology & packaging, Girona, Spain | Aglon | Silver zeolites |

| BASF, Beaumont, TX, USA | Irgguard | Silver |

| Tessara-Grapetek, Cape Town, South Africa | Uvacy TM | Sulphur dioxide |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olawore, O.; Ogunmola, M.; Desai, S. Engineered Nanomaterial Coatings for Food Packaging: Design, Manufacturing, Regulatory, and Sustainability Implications. Micromachines 2024, 15, 245. https://doi.org/10.3390/mi15020245

Olawore O, Ogunmola M, Desai S. Engineered Nanomaterial Coatings for Food Packaging: Design, Manufacturing, Regulatory, and Sustainability Implications. Micromachines. 2024; 15(2):245. https://doi.org/10.3390/mi15020245

Chicago/Turabian StyleOlawore, Oluwafemi, Motunrayo Ogunmola, and Salil Desai. 2024. "Engineered Nanomaterial Coatings for Food Packaging: Design, Manufacturing, Regulatory, and Sustainability Implications" Micromachines 15, no. 2: 245. https://doi.org/10.3390/mi15020245

APA StyleOlawore, O., Ogunmola, M., & Desai, S. (2024). Engineered Nanomaterial Coatings for Food Packaging: Design, Manufacturing, Regulatory, and Sustainability Implications. Micromachines, 15(2), 245. https://doi.org/10.3390/mi15020245