From Formulation to Application: Effects of Plasticizer on the Printability of Fluoro Elastomer Compounds and Additive Manufacturing of Specialized Seals

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Rubber Compounds

2.3. Additive Manufacturing

2.4. Characterization of Rubber Compounds

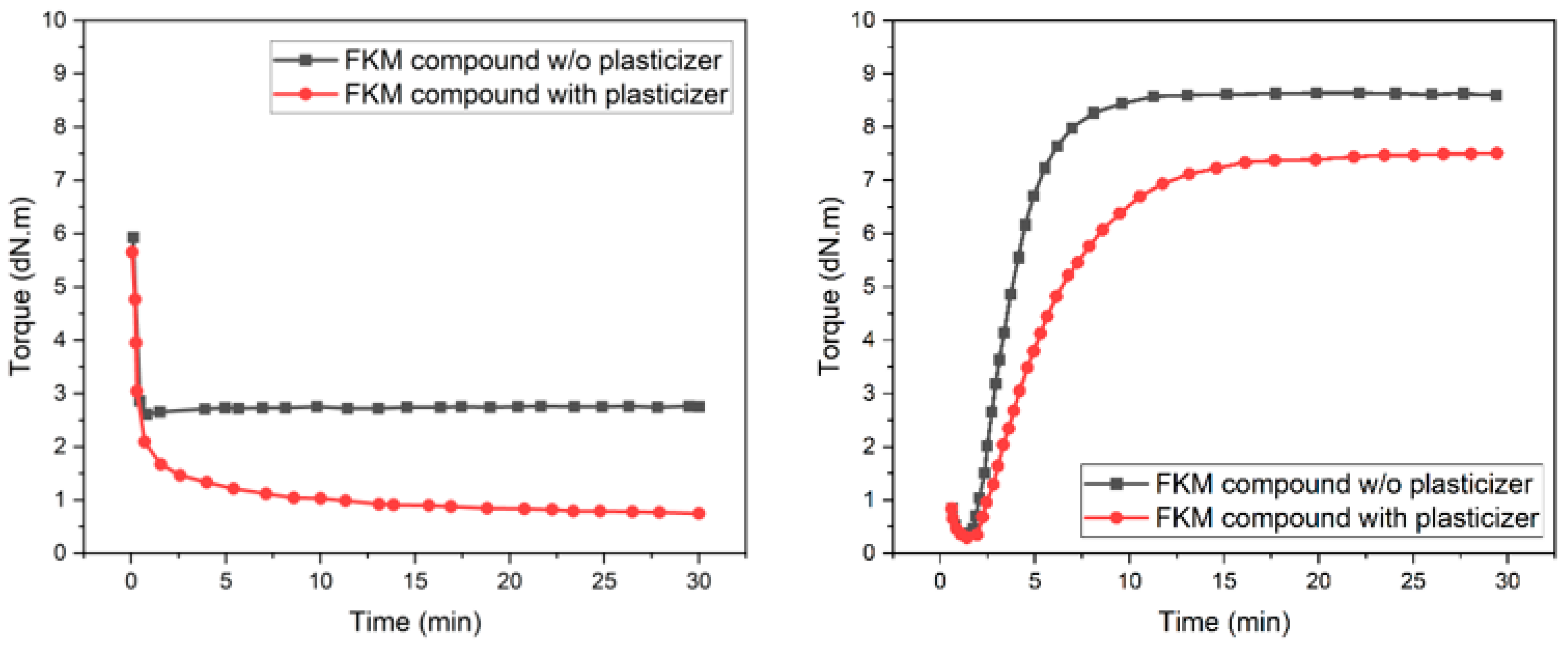

2.4.1. Cure Behavior and Formulation Viscosity

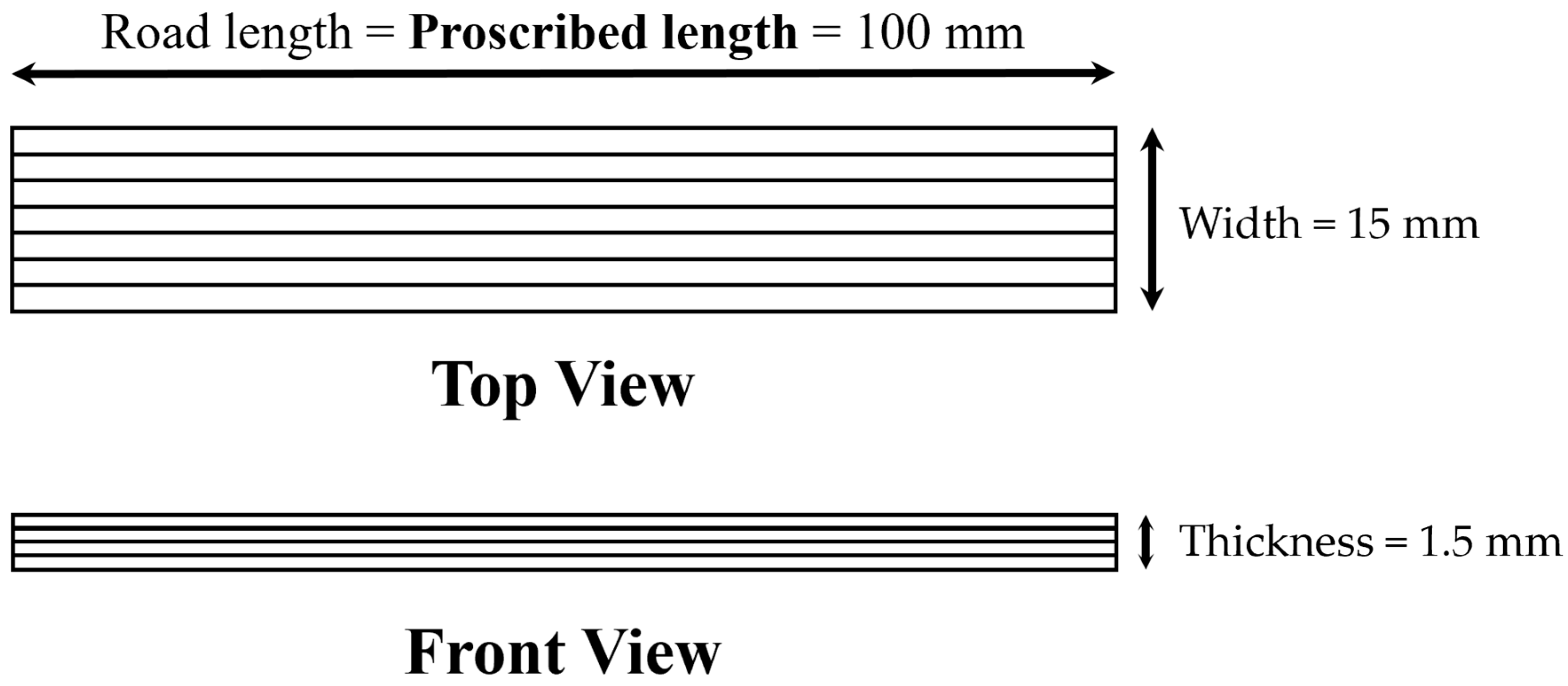

2.4.2. Post-print Shrinkage

2.4.3. Tensile Behavior

3. Results and Discussion

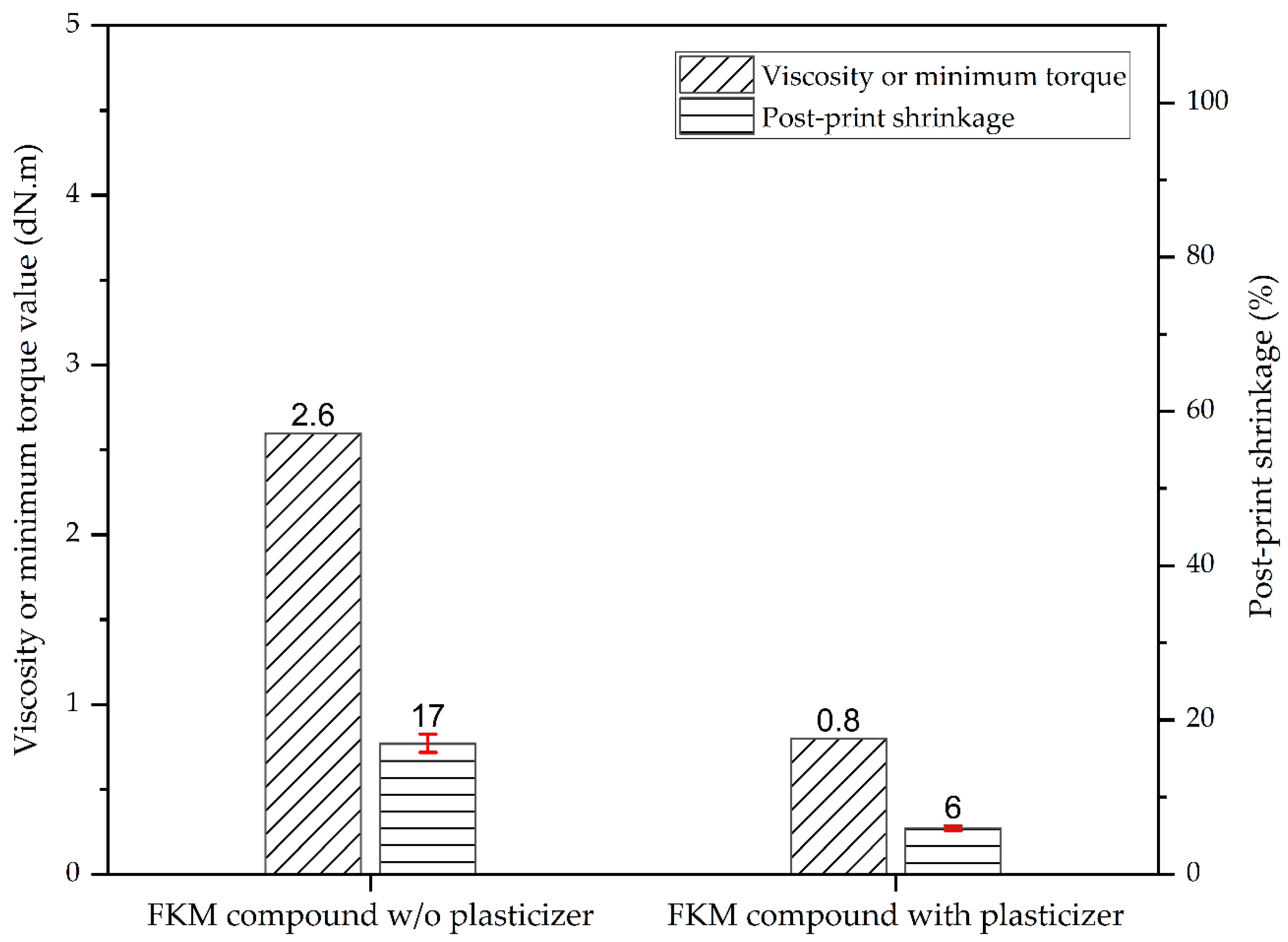

3.1. Effect of Material Formulation

3.1.1. Rheology and Cure Behavior of FKM Compounds

3.1.2. Post-print Shrinkage

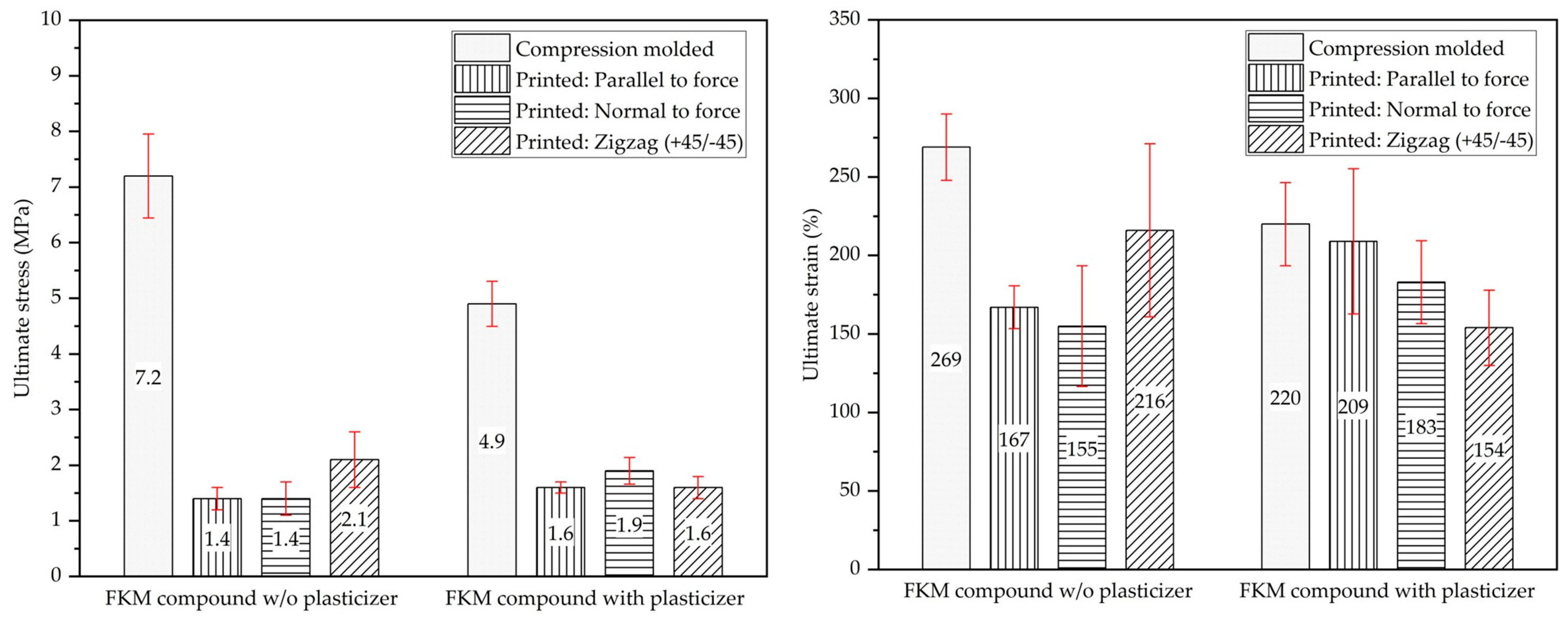

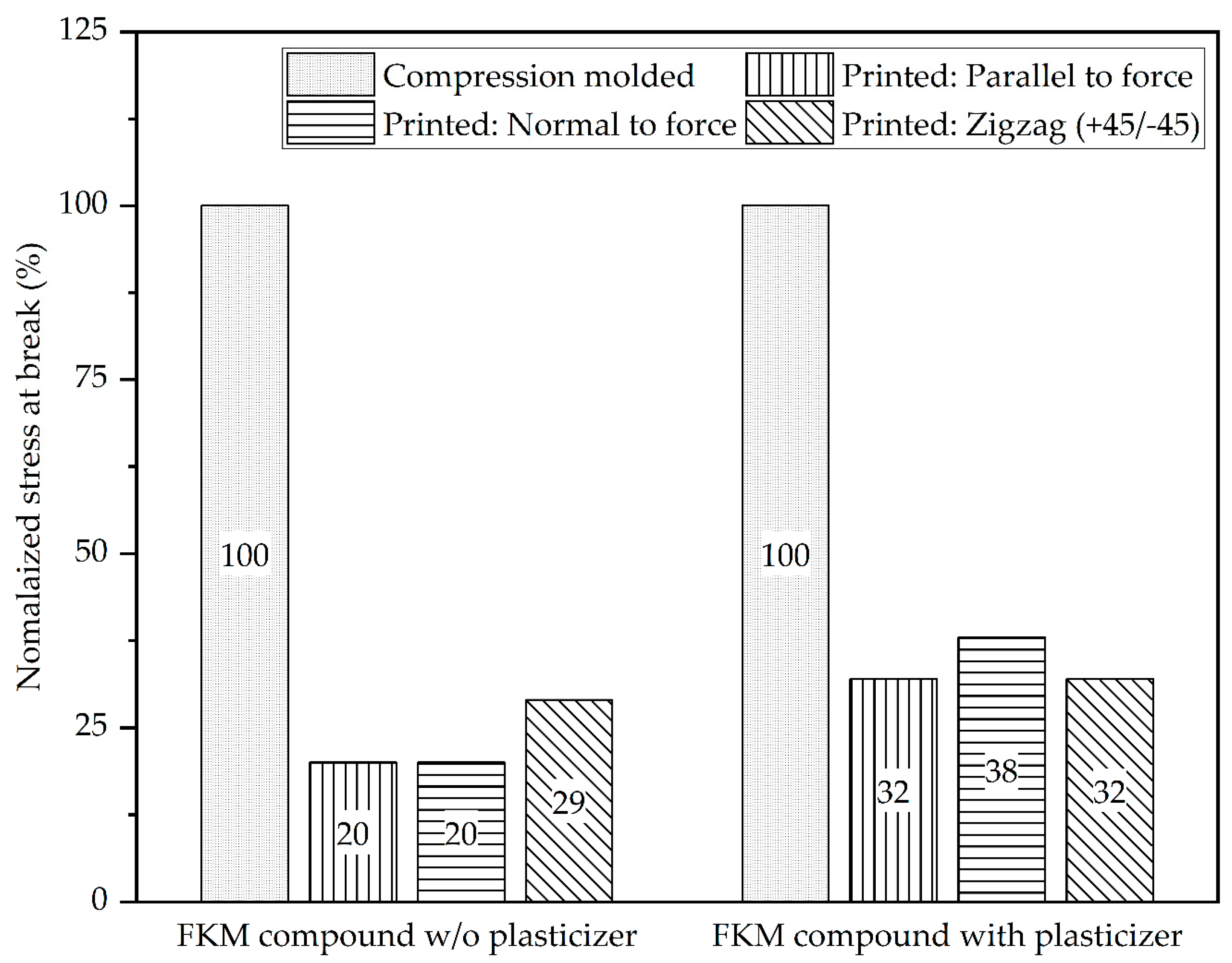

3.1.3. Tensile Behavior and Interlayer Adhesion

3.2. Different Approaches for Additive Manufacturing of FKM Seals

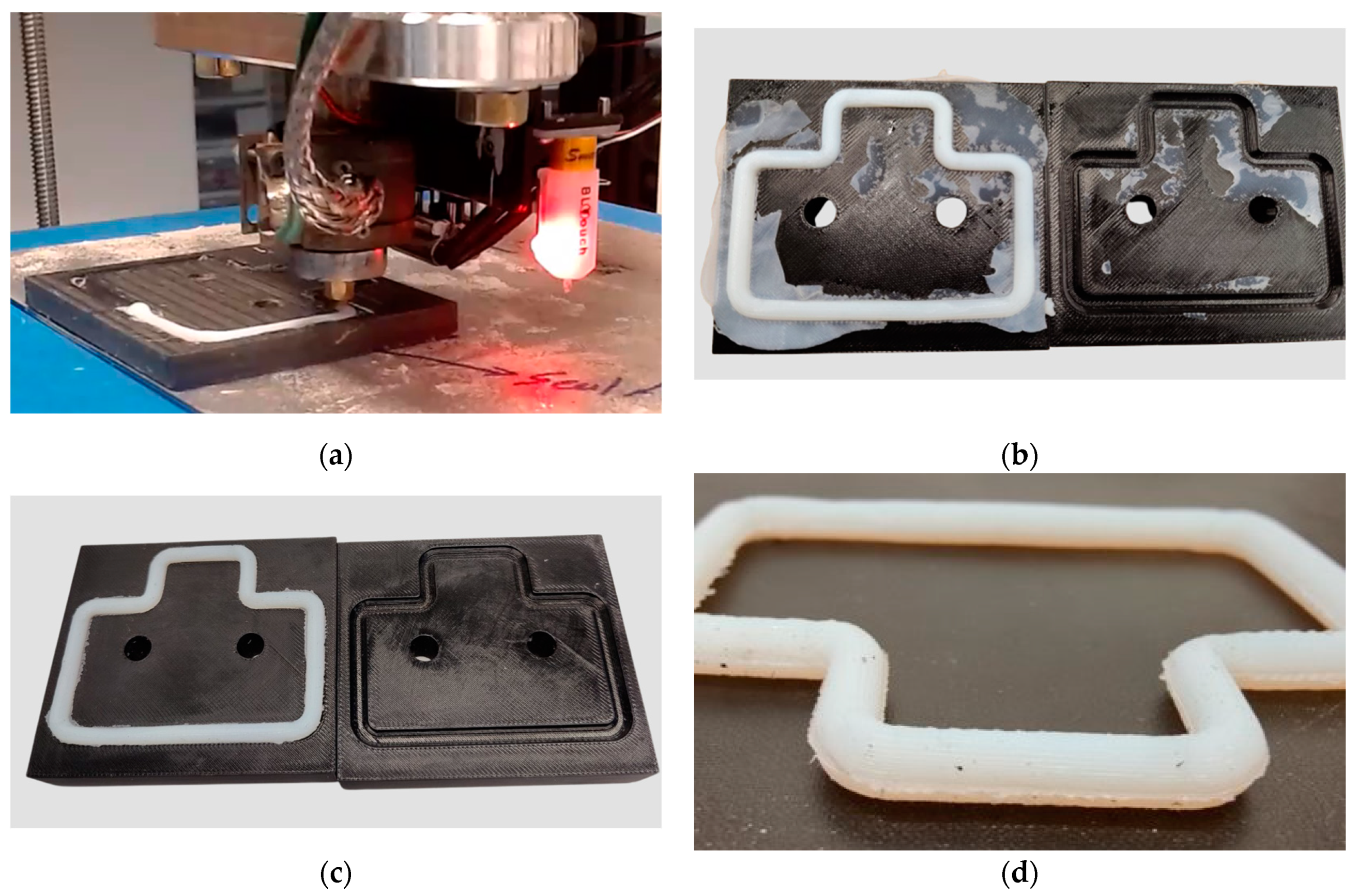

3.2.1. Traditional Additive Manufacturing of FKM Seals

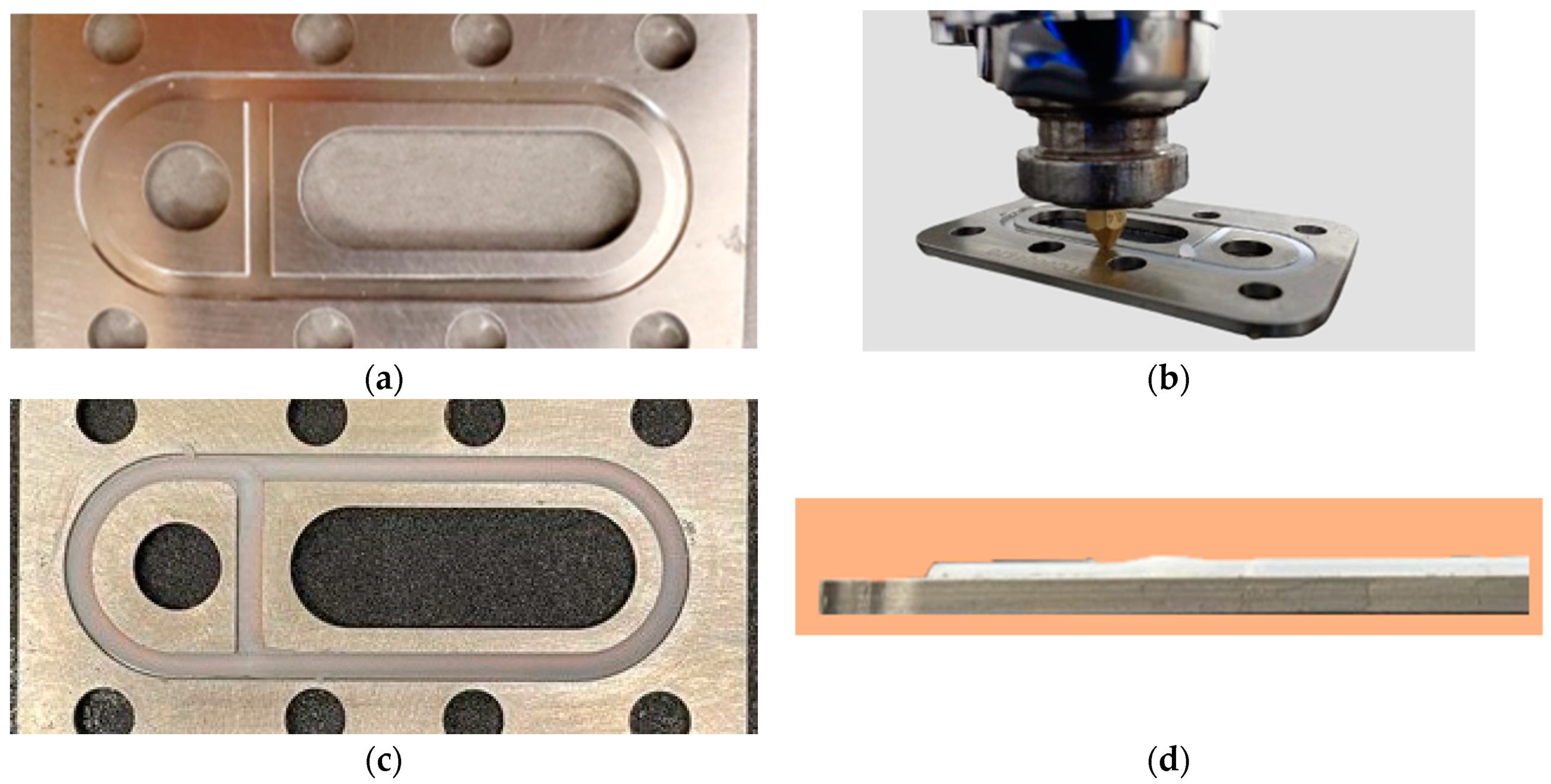

3.2.2. Soft Tooling Approach for FKM Seal Fabrication

3.2.3. Direct Printing of Molded-in-Place (MIP) Seals

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maclachlan, J.D. Fluorocarbon Elastomers: A Technical Review. Polym.-Plast. Technol. Eng. 1978, 11, 41–53. [Google Scholar] [CrossRef]

- Montermoso, J.C. Fluorine-Containing Elastomers. Rubber Chem. Technol. 1961, 34, 1521–1552. [Google Scholar] [CrossRef]

- Logothetis, A.L. Chemistry of fluorocarbon elastomers. Prog. Polym. Sci. 2003, 14, 251–296. [Google Scholar] [CrossRef]

- Francis, L.F. Materials Processing: A Unified Approach to Processing of Metals, Ceramics and Polymers; Academic Press: New York, NY, USA, 2016. [Google Scholar]

- Rodgers, B. Rubber Compounding: Chemistry and Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- ASTM D1418-22; Standard Practice for Rubber and Rubber Latices—Nomenclature. ASTM: Philadelphia, PA, USA, 2022. [CrossRef]

- Singh, D.D.; Mahender, T.; Reddy, A.R. Powder bed fusion process: A brief review. Mater. Today Proc. 2021, 46, 350–355. [Google Scholar] [CrossRef]

- Dejene, N.D.; Lemu, H.G. Status, and Challenges of powder bed fusion-based metal additive manufacturing: Literature review. Metals 2021, 13, 424. [Google Scholar] [CrossRef]

- Wasti, S.; Adhikari, S. Use of biomaterials for 3D printing by fused deposition modeling technique: A review. Front. Chem. 2020, 8, 315. [Google Scholar] [CrossRef] [PubMed]

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Ubaidillah; Arifin, Z. A review on the fused deposition modeling (FDM) 3D printing. Filament processing, materials and printing parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Justino Netto, J.M.; Idogava, H.T.; Frezzatto Santos, L.E.; Silveira ZD, C.; Romio, P.; Alves, J.L. Screw assisted 3D Printing with granulated materials: A systematic review. Int. J. Adv. Manuf. Technol. 2021, 115, 2711–2727. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Mohan Pandey, P. 3D Printing of Flexible Parts Using EVA Material. Mater. Phys. Mech. 2018, 37, 124–132. [Google Scholar] [CrossRef]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Additive Manufacturing of Flexible Electrically Conductive Polymer Compositions Using CNC-Assisted Fused Layer Modeling Process. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 175. [Google Scholar] [CrossRef]

- Elkins, K.; Nordby, H.; Janak, C.; Gray, R.W., IV; Helge Bohn, J.; Baird, D.G. Soft Elastomers for Fused Deposition Modeling; presented in the International Solid Freeform Fabrication Symposium; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 1997. [Google Scholar]

- Herzberger, J.; Sirrine, J.M.; Williams, C.B.; Long, T.E. Polymer Design for 3D Printing Elastomers: Recent Advances in Structure, Properties, and Printing. Prog. Polym. Sci. 2019, 97, 101144. [Google Scholar] [CrossRef]

- Kazmer, D.; Kodra, S.; Mubasshir, A.A.; Keaney, E.E.; Mead, J.L. Additive RAM extrusion and diddling of fully compounded thermoset nitrile rubber. Polym. Compos. 2021, 42, 5237–5248. [Google Scholar] [CrossRef]

- Leineweber, S.; Sundermann, L.; Bindszus, L.; Overmeyer, L.; Klie, B.; Wittek, H.; Giese, U. Additive manufacturing and vulcanization of natural and synthetic rubbers. Logist. J. Proc. 2022, 2022, 2192–9084. [Google Scholar] [CrossRef]

- Periyasamy, M.; Campbell, R.R.; Sassano, E.; Mead, J.; Kazmer, D.; Banerjee, S.; Burbine, S.; Keaney, E.E.; Phaen, L. Articles Formed from Fluorine-Containing Elastomer Compositions Using an Additive Manufacturing Method and Additive Manufacturing Methods for Thermoset Elastomer Compositions. US20210395405A1, 23 December 2021. [Google Scholar]

- Mubasshir, A.A.; Kodra, S.; David, K.; Mead, J. 3D Printing of Fully Compounded Thermoset Elastomer: Effects of Compound Formulation. In Proceedings of the 2023 Technical Meeting, International Elastomer Conference, Cleveland, OH, USA, 16–19 October 2023. [Google Scholar]

- Štěpek, J.; Daoust, H. Additives for Plastics; Springer Science+Business Media, LLC: New York, NY, USA, 1983. [Google Scholar]

- Bajwa, D.; Eichers, M.; Shojaeiarani, J.; Kallmeyer, A. Influence of biobased plasticizers on 3D printed polylactic acid composites filled with sustainable biofiller. Ind. Crops Prod. 2021, 173, 114132. [Google Scholar] [CrossRef]

- Oz, O.; Ozturk, F.H.; Gulec, C. Effect of fiber content and plasticizer on mechanical and joint properties of carbon fiber powder reinforced PLA manufactured by 3D printing process. J. Adhes. Sci. Technol. 2023, 37, 2208–2231. [Google Scholar] [CrossRef]

- Menčík, P.; Přikryl, R.; Stehnová, I.; Melčová, V.; Kontárová, S.; Figalla, S.; Alexy, P.; Bočkaj, J. Effect of Selected Commercial Plasticizers on Mechanical, Thermal, and Morphological Properties of Poly(3-hydroxybutyrate)/Poly(lactic acid)/Plasticizer Biodegradable Blends for Three-Dimensional (3D). Print. Mater. 2018, 11, 1893. [Google Scholar] [CrossRef] [PubMed]

- Wasti, S.; Triggs, E.; Farag, R.; Auad, M.; Adhikari, S.; Bajwa, D.; Li, M.; Ragauskas, A.J. Influence of plasticizers on thermal and mechanical properties of biocomposite filaments made from lignin and polylactic acid for 3D printing. Compos. Part B 2020, 205, 108483. [Google Scholar] [CrossRef]

- Campbell, R.; Periyasamy, M. Fluid Plasticizers Including Fluorinated Organic Compounds for Use in Curable Fluoropolymer Compositions and Fluoroelastomer Compositions, and Methods for Improving. USPTO Patent US8906821B2, 14 December 2023. [Google Scholar]

- ASTM D2084-19a; Standard Test Method for Rubber Property—Vulcanization Using Oscillating Disk Cure Meter. ASTM: Philadelphia, PA, USA, 2019. [CrossRef]

- ASTM D412-16(2021); Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM: Philadelphia, PA, USA, 2021. [CrossRef]

- Mageli, O.L.; Sheppard, C.S. Organic Peroxides; Swern, D., Ed.; Wiley Interscience: New York, NY, USA, 1979. [Google Scholar]

- Ostromislenskiy, J. New method for production of 1,3-Butadiene. J. Russ. Phys. Chem. Soc. 1915, 47, 1467. [Google Scholar]

- Fisher, H.L.; Gray, A.E. Chemical Unsaturation of Rubbers Vulcanized with Polynitro Compounds and Benzoyl Peroxide, and Its Possible Bearing on Vulcanization. Ind. Eng. Chem. 1928, 20, 294–295. [Google Scholar] [CrossRef]

- Baranwal, K.C.; Stephens, H.L. Basic Elastomer Technology; The Rubber Division, American Chemical Society: Washington, DC, USA, 2001. [Google Scholar]

- Roland, C.M. Science and Technology of Rubber; Erman, B., Mark, J.E., Roland, C.M., Eds.; Elsevier Academic Press: Cambridge, MA, USA, 2013; p. 285. [Google Scholar]

- Ebnesajjad, S.; Morgan, R.A. Fluoropolymer Additives; William Andrew: Norwich, NY, USA, 2012. [Google Scholar] [CrossRef]

- Malac, J. Viscosity, Relaxation and Stability of Natural Rubber. Open Macromol. J. 2009, 3, 41–44. [Google Scholar] [CrossRef]

- Nie, S.; Ratzsch, K.-F.; Grage, S.L.; Keller, J.; Ulrich, A.S.; Lacayo-Pineda, J.; Wilhelm, M. Correlation between Macroscopic Elasticity and Chain Dynamics of Natural Rubber during Vulcanization as Determined by a Unique Rheo-NMR Combination. Macromolecules 2021, 54, 6090–6100. [Google Scholar] [CrossRef]

- Maxwell, J.C. On the Dynamical Theory of Gases. Philos. Trans. R. Soc. Lond. 1867, 157, 49–88. [Google Scholar]

- Coogan, T.J.; Kazmer, D.O. Prediction of interlayer strength in material extrusion additive manufacturing. J. Addit. Manuf. 2020, 35, 101368. [Google Scholar] [CrossRef]

- Coogan, T.J.; Kazmer, D.O. Modeling of interlayer contact and contact pressure during fused filament fabrication. J. Rheol. 2019, 63, 655–672. [Google Scholar] [CrossRef]

- Aliheidari, N.; Christ, J.; Tripuraneni, R.; Nadimpalli, S.; Ameli, A. Interlayer adhesion and fracture resistance of polymers printed through melt extrusion additive manufacturing process. Mater. Des. 2018, 156, 351–361. [Google Scholar] [CrossRef]

- Drossel, W.-G.; Ihlemann, J.; Landgraf, R.; Oelsch, E.; Schmidt, M. Media for Dimensional Stabilization of Rubber Compounds during Additive Manufacturing and Vulcanization. Materials 2021, 14, 1337. [Google Scholar] [CrossRef]

- Pham, D.; Dimov, S.S. Rapid Manufacturing: The Technologies and Applications of Rapid Prototyping and Rapid Tooling; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Schjølberg-Henriksen, K.; Tvedt, L.G.W.; Moe, S.; Poppe, E.; Wang, D.; Gjelstad, S.A.; Mork, C.; Imenes, K. Bond strength of conductive Si-Si fusion bonded seals. In Proceedings of the 2014 Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS (DTIP), Cannes, France, 1–4 April 2014. [Google Scholar] [CrossRef]

- Bralla, J. Handbook of Manufacturing Processes: How Products, Components and Materials Are Made; Industrial Press, Inc.: New York, NY, USA, 2007; ISBN 9780831131791. [Google Scholar]

| Compound/Recipe | Parts per Hundred Rubber (PHR) | |

|---|---|---|

| FKM-1 (FKM w/o Plasticizer) | FKM-2 (FKM with Plasticizer) | |

| Tecnoflon FKM (Tecnoflon VPL 45535-25 Mooney) | 100 | 100 |

| Filler and cure package for FKM | 39 | 39 |

| Plasticizer (Fomblin M60) | 0 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Periyasamy, M.; Mubasshir, A.; Kodra, S.; Chandramouli, S.; Campbell, R.; Kazmer, D.O.; Mead, J.L. From Formulation to Application: Effects of Plasticizer on the Printability of Fluoro Elastomer Compounds and Additive Manufacturing of Specialized Seals. Micromachines 2024, 15, 622. https://doi.org/10.3390/mi15050622

Periyasamy M, Mubasshir A, Kodra S, Chandramouli S, Campbell R, Kazmer DO, Mead JL. From Formulation to Application: Effects of Plasticizer on the Printability of Fluoro Elastomer Compounds and Additive Manufacturing of Specialized Seals. Micromachines. 2024; 15(5):622. https://doi.org/10.3390/mi15050622

Chicago/Turabian StylePeriyasamy, Mookkan, AA Mubasshir, Stiven Kodra, Sangeetham Chandramouli, Ronald Campbell, David O. Kazmer, and Joey L. Mead. 2024. "From Formulation to Application: Effects of Plasticizer on the Printability of Fluoro Elastomer Compounds and Additive Manufacturing of Specialized Seals" Micromachines 15, no. 5: 622. https://doi.org/10.3390/mi15050622