Temperature Frequency Characteristics of Hexamethyldisiloxane (HMDSO) Polymer Coated Rayleigh Surface Acoustic Wave (SAW) Resonators for Gas-Phase Sensor Applications

Abstract

:1. Introduction

2. Operation Principle of Polymer Coated RSAW Based Resonant Sensors

3. The Temperature Sensitivity Problem

4. Experimental Work

4.1. The RSAW Sensor Resonators

4.2. The HMDSO Deposition System

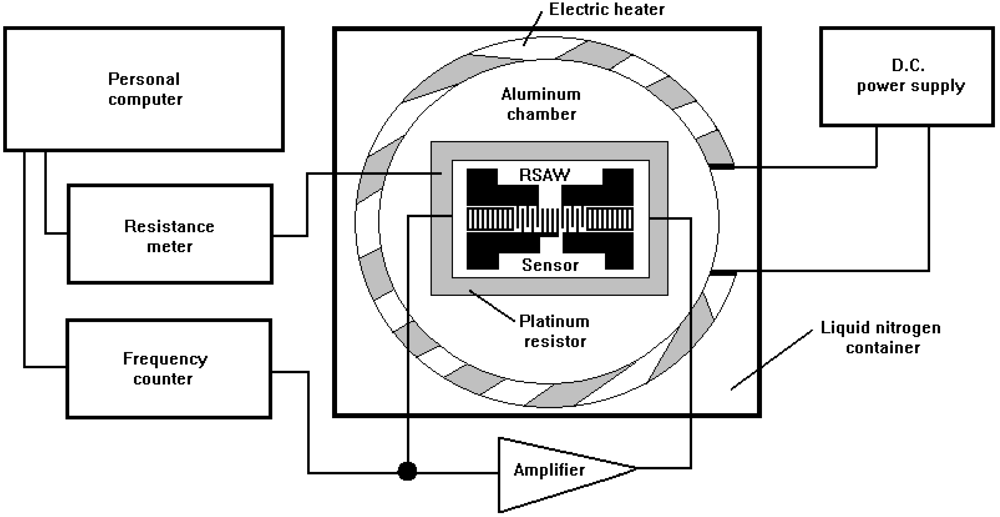

4.3. The TFC Measurement Setup

5. Results and Discussion

5.1. Influence of the HMDSO Polymer Thickness on the Resonance Frequency and the Turn-Over Temperature in RSAW Resonant Sensors

5.2. Temperature Coefficients of the TFC Dependencies

| Thichness [nm] | a | b [K−1] | c [K−2] |

|---|---|---|---|

| 0 | 3.76864 | −0.04955 | −0.03143 |

| 50 | −12.8912 | −1.24357 | −0.03153 |

| 100 | −21.41928 | −1.56463 | −0.03161 |

| 150 | −28.29861 | −1.72997 | −0.03167 |

| 250 | −63.55321 | −2.79867 | −0.03435 |

| Thichness [nm] | a | b [K−1] | c [K−2] | d [K−3] |

|---|---|---|---|---|

| 0 | 4.418 | 0.04149 | −0.0318 | −1.76656E-5 |

| 50 | −10.6505 | −1.27397 | −0.03304 | 2.4608E-5 |

| 100 | −20.26231 | −1.62035 | −0.03232 | 1.32147E-5 |

| 150 | −27.49848 | −1.88854 | −0.0321 | 2.90786E-5 |

| 250 | −65.73898 | −3.00826 | −0.033 | 4.49081E-5 |

6. Conclusions

Acknowledgments

References

- White, R.M. Surface acoustic wave sensors. In Proceedings of IEEE 1985 Ultrasonics Symposium, San Francisco, CA, USA, 16–18 October 1985; pp. 490–494.

- White, R.M. Acoustic sensors for physical, chemical and biochemical applications. In Proceedings of IEEE 1998 International Frequency Control Symposium, Pasadena, CA, USA, 27–29 May 1998; pp. 587–594.

- Barie, N.; Rapp, M.; Ache, H.J. UV crosslinked polysiloxanes as new coatingmaterials for SAW devices with high long-term stability. Sens. Actuat. B Chem. 1998, B46, 97–103. [Google Scholar]

- Bender, F.; Waechter, L.; Voigt, A.; Rapp, M. Deposition of high-quality coatings on SAW sensors using electrospray. In Proceedings of IEEE Sensors Conference, Toronto, ON, Canada, 22–24 October 2003; 1, pp. 115–119.

- Rapp, M.; Reibel, J.; Stier, S.; Voigt, A.; Bahlo, J. SAGAS: Gas Analyzing sensor systems based on surface acoustic wave devices—An issue of commercialization of SAW sensor technology. In Proceedings of IEEE International Frequency Control Symposium, Orlando, FL, USA, 28–30 May 1997; pp. 129–132.

- Staples, E.J. Dioxin/furan detection and analysis using a saw based electronic nose. In Proceedings of IEEE 1998 Ultrasonics Symposium, Sendai, Japan, 5–8 October 1998; 1, pp. 521–524.

- Staples, E.J.; Matsuda, T.; Viswanathan, S. Real time environmental screening of air, water and soil matrices using a novel field portable GC/SAW system. In Proceedings of the Environmental Strategies for the 21st Century Asia Pacific Conference, Singapore, April 1998; pp. 8–10.

- Frye, G.C.; Martin, S.J. Dual output acoustic wave sensor for molecular identification. In Proceedings of 1991 International Conference on Solid-State Sensors and ActuatorsTRANSDUCERS ’91, San Francisco, CA, USA, 24–27 June1991; pp. 566–569.

- Wessa, T.; Kueppers, S.; Mann, G.; Rapp, M.; Reibel, J. On-line monitoring of process HPLC by sensors. Organ. Process Res. Dev. 2000, 4, 102–106. [Google Scholar]

- Frye, G.C.; Martin, S.J.; Cerenosek, R.W.; Pfeifer, K.B.; Anderson, J.S. Portable acoustic wave sensor systems. In Proceedings of IEEE Ultrasonics Symposium, Lake Buena Vista, FL, USA, 8–11 December 1991; pp. 311–316.

- Zhang, P.; Chen, M.; He, P.; Ma, R. Study on surface acoustic wave CO gas sensor based on electroactive polymers. Yadian yu Shengguang/Piezoelectrics and Acoustooptics 2010, 32, 709–712. [Google Scholar]

- Wang, W.; He, S.; Li, S.; Liu, M.; Pan, Y. Advances in SXFA-coated SAW chemical sensors for organophosphorous compound detection. Sensors 2011, 11, 1526–1541. [Google Scholar]

- Ayala, V.C.; Eisele, D.; Reindl, L.; Josse, F. Temperature stability analysis of LGS for SH-SAW sensor applications. In Proceedings of 2010 IEEE International Frequency Control Symposium, Newport Beach, CA, USA, 1–4 June 2010; pp. 142–145.

- Shimizu, Y.; Terazaki, A.; Sakaue, T. Temperature dependence of SAW velocity for metal film on α-quartz. In Proceedings of IEEE Ultrasonics Symposium, Annapolis, MD, USA, 29 September–1 October 1976; pp. 519–522.

- Henry, E.; Ballandras, S.; Bigler, E.; Marianneau, G.; Martin, G.; Camou, S. Influence of metallization on temperature stability of SAW devices. In Proceedings of IEEE Ultrasonics Symposium, Toronto, ON, Canada, 5–8 October 1997; 1, pp. 221–225.

- Chung, M.-H.; Wang, S.T.; Huang, A.C.S. Study of frequency-temperature characteristics of quartz with various cut angle and metal thickness of electrode. In Proceedings of the 2004 IEEE International Frequency Control Symposium and Exposition, Montreal, QC, Canada, 23–27 August 2004; pp. 617–620.

- Avramov, I.D. Polymer coated rayleigh SAW and STW resonators for gas sensor applications. In Acoustic Waves—From Microdevices to Helioseismology; Beghi, M.G., Ed.; 2011; pp. 521–546, Chapter 23. [Google Scholar]

- Avramov, I.D.; Voigt, A.; Rapp, M. Rayleigh SAW resonators using gold electrode structure for gas sensor applications in chemically reactive environments. IEE Electron. Lett. 2005, 41, 450–452. [Google Scholar]

- Parker, T.E. SiO2 film overlays for temperature stable surface acoustic wave devices. Appl. Phys. Lett. 1975, 26, 75–77. [Google Scholar] [CrossRef]

- Yin, J.H.; Wu, W.Q.; Zhang, D.; Shu, Y.A. Temperature characteristics of rayleigh wave in SiO2/128" Y-X LiNbO3 structure. In Proceedings of IEEE Ultrasonics Symposium, Denver, Co, USA, 14–16 October 1987; 1, pp. 237–240.

- Cheng, C.-C.; Chung, C.-J.; Chen, Y.-C.; Kao, K.-S. Temperature effect on the characteristics of surface acoustic wave on SiO2 thin films. In Proceedings of 2004 IEEE Ultrasonics Symposium, Montreal, QC, Canada, 23–27 August 2004; 3, pp. 1884–1887.

- Hawkes, P.W. Sensitivity to external perturbations and the design of detectors. In Advances in Electronics and Electron Physics; Academic Press, Inc.: Sand Diego, CA, USA, 1990; Volume 77, pp. 125–127. [Google Scholar]

- Parker, T.E.; Montress, G.K. Precision surface-acoustic-wave (SAW) oscillators. In Proceedings of Transaction on UltrasonicsFerroelectrics and Frequency Control, Chicago, IL, USA, May 1988; 35, pp. 342–364.

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Esmeryan, K.D.; Avramov, I.D.; Radeva, E.I. Temperature Frequency Characteristics of Hexamethyldisiloxane (HMDSO) Polymer Coated Rayleigh Surface Acoustic Wave (SAW) Resonators for Gas-Phase Sensor Applications. Micromachines 2012, 3, 413-426. https://doi.org/10.3390/mi3020413

Esmeryan KD, Avramov ID, Radeva EI. Temperature Frequency Characteristics of Hexamethyldisiloxane (HMDSO) Polymer Coated Rayleigh Surface Acoustic Wave (SAW) Resonators for Gas-Phase Sensor Applications. Micromachines. 2012; 3(2):413-426. https://doi.org/10.3390/mi3020413

Chicago/Turabian StyleEsmeryan, Karekin D., Ivan D. Avramov, and Ekaterina I. Radeva. 2012. "Temperature Frequency Characteristics of Hexamethyldisiloxane (HMDSO) Polymer Coated Rayleigh Surface Acoustic Wave (SAW) Resonators for Gas-Phase Sensor Applications" Micromachines 3, no. 2: 413-426. https://doi.org/10.3390/mi3020413

APA StyleEsmeryan, K. D., Avramov, I. D., & Radeva, E. I. (2012). Temperature Frequency Characteristics of Hexamethyldisiloxane (HMDSO) Polymer Coated Rayleigh Surface Acoustic Wave (SAW) Resonators for Gas-Phase Sensor Applications. Micromachines, 3(2), 413-426. https://doi.org/10.3390/mi3020413