Tunnel Junction with Perpendicular Magnetic Anisotropy: Status and Challenges

Abstract

:1. Introduction

2. Perpendicular Magnetic Anisotropy Principles

3. Spin Transfer Torque: Fundamental and Memory Operation

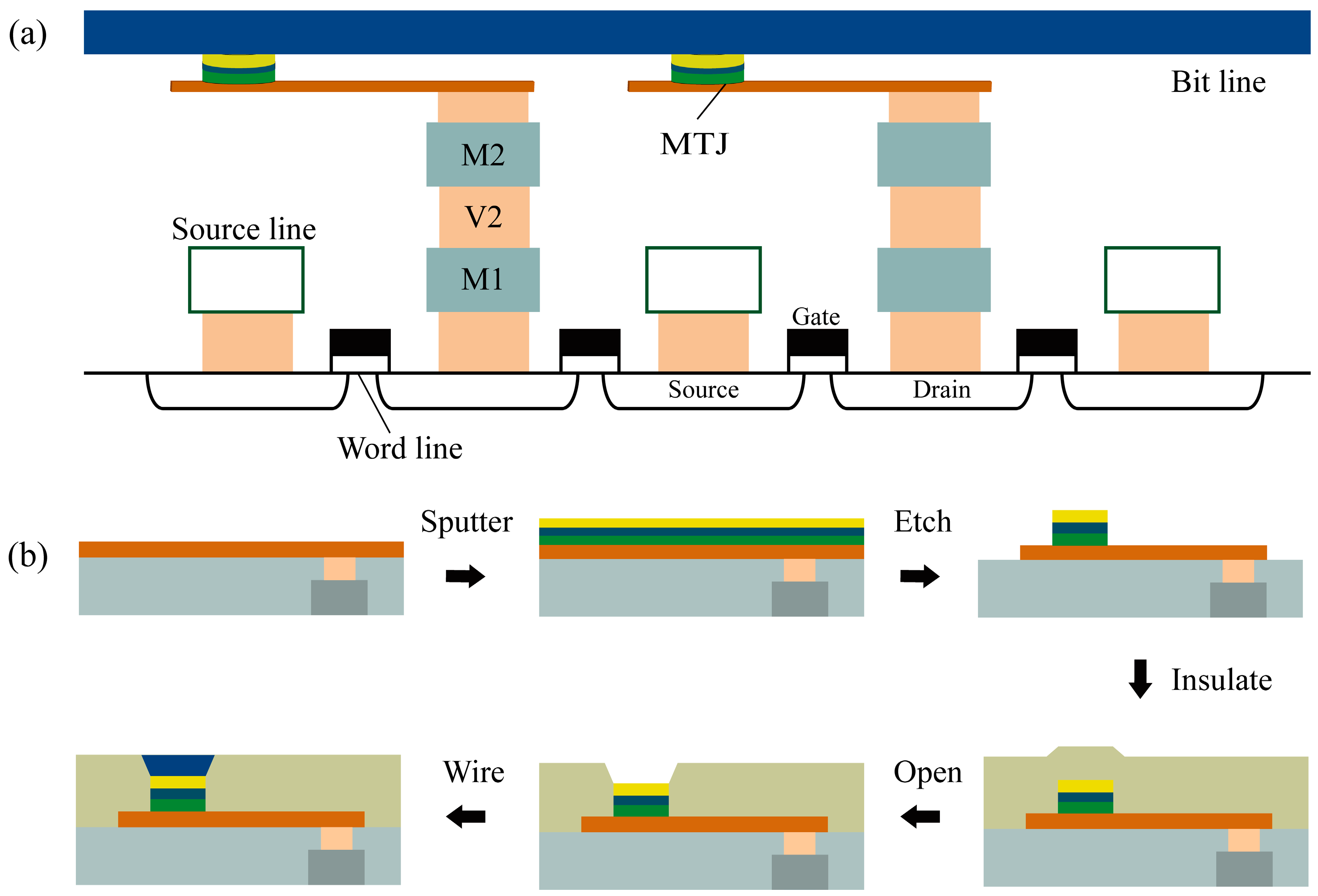

4. Fabrications and Measurements of STT-MRAM Device

4.1. Magnetic Tunnel Junction Device Process Technology

4.1.1. Substrate Preparation

4.1.2. Stack Deposition

4.1.3. Post-Deposition Annealing

4.1.4. Device Etching

4.1.5. Dielectric Encapsulation

4.1.6. Wiring

4.2. Property and Morphology Characterization

Magnetic Measuring Method

5. Challenges and Enhancements towards Interfacial PMA

5.1. Material Engineering

5.1.1. CoFeB Behavior and Composition

5.1.2. Capping or Buffer Layer Material

5.2. Structure Optimization: Double CoFeB/MgO Interfaces

6. Recent Progress and Future Applications

6.1. Spin Orbit Coupling Induced Magnetization Reversal

6.2. Perpendicular Magnetic Anisotropy for Magnetic Field Sensor

6.3. Perpendicular Magnetic Anisotropy for Logic Circuits

7. Conclusion and Perspective

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Technology Roadmap for Semiconductor (ITRS), 2010 Update. Available online: http://www.itrs.net (accessed on 27 March 2014).

- Chappert, C.; Fert, A.; Van Dau, F.N. The emergence of spin electronics in data storage. Nat. Mater. 2007, 6, 813–823. [Google Scholar]

- Nikonov, D.E.; Young, I. Overview of beyond-CMOS devices and a uniform methodology for their benchmarking. Proc. IEEE 2013, 101, 2498–2533. [Google Scholar]

- Wang, D.; Nordman, C.; Daughton, J.M.; Qian, Z.; Fink, J. 70% TMR at room temperature for SDT sandwich junctions with CoFeB as free and reference layers. IEEE Trans. Magn. 2004, 40, 2269–2271. [Google Scholar]

- Yuasa, S.; Nagahama, T.; Fukushima, A.; Suzuki, Y.; Ando, K. Giant room-temperature magnetoresistance in single-crystal Fe/MgO/Fe magnetic tunnel junctions. Nat. Mater. 2004, 3, 868–871. [Google Scholar] [PubMed]

- Parkin, S.S.P.; Kaiser, C.; Panchula, A.; Rice, P.M.; Hughes, B.; Samant, M.; Yang, S.H. Giant tunnelling magnetoresistance at room temperature with MgO (100) tunnel barriers. Nat. Mater. 2004, 3, 862–867. [Google Scholar] [PubMed]

- Ikeda, S.; Hayakawa, J.; Ashizawa, Y.; Lee, Y.M.; Miura, K.; Hasegawa, H.; Tsunoda, M.; Matsukura, F.; Ohno, H. Tunnel magnetoresistance of 604% at 300 K by suppression of Ta diffusion in CoFeB/MgO/CoFeB pseudo-spin-valves annealed at high temperature. Appl. Phys. Lett. 2008, 93, 082508. [Google Scholar] [CrossRef]

- Thomas, L.; Jan, G.; Zhu, J.; Liu, H.; Lee, Y.J.; Le, S.; Tong, R.Y.; Pi, K.; Wang, Y.J.; Shen, D.; et al. Perpendicular spin transfer torque magnetic random access memories with high spin torque efficiency and thermal stability for embedded applications. J. Appl. Phys. 2014, 115, 172615. [Google Scholar] [CrossRef]

- Kent, A.D.; Worledge, D.C. A new spin on magnetic memories. Nat. Nanotech. 2015, 10, 187–191. [Google Scholar] [CrossRef]

- Carcia, P.F.; Meinhaldt, A.D.; Suna, A. Perpendicular magnetic anisotropy in Pd/Co thin film layered structures. Appl. Phys. Lett. 1985, 47, 178–180. [Google Scholar] [CrossRef]

- Carcia, P.F. Perpendicular magnetic anisotropy in Pd/Co and Pt/Co thin-film layered structures. J. Appl. Phys. 1988, 63, 5066–5073. [Google Scholar] [CrossRef]

- Hashimoto, S.; Ochiai, Y.; Aso, K. Perpendicular magnetic anisotropy and magnetostriction of sputtered Co/Pd and Co/Pt multilayered films. J. Appl. Phys. 1989, 66, 4909–4916. [Google Scholar] [CrossRef]

- Park, J.H.; Park, C.; Jeong, T.; Moneck, M.T.; Nufer, N.T.; Zhu, J.G. Co/Pt multilayer based magnetic tunnel junctions using perpendicular magnetic anisotropy. J. Appl. Phys. 2008, 103, 07A917. [Google Scholar] [CrossRef]

- Lim, D.; Kim, K.; Kim, S.; Jeung, W.Y.; Lee, S.R. Study on exchange-biased perpendicular magnetic tunnel junction. IEEE Trans. Magn. 2009, 45, 2407–2409. [Google Scholar]

- Yakushiji, K.; Saruya, T.; Kubota, H.; Fukushima, A.; Nagahama, T.; Yuasa, S.; Ando, K. Ultrathin Co/Pt and Co/Pd superlattice films for MgO-based perpendicular magnetic tunnel junctions. Appl. Phys. Lett. 2010, 97, 232508. [Google Scholar] [CrossRef]

- Ishikawa, S.; Sato, H.; Yamanouchi, M.; Ikeda, S.; Fukami, S.; Matsukura, F.; Ohno, H. Magnetic properties of MgO-[Co/Pt] multilayers with a CoFeB insertion layer. J. Appl. Phys. 2013, 113, 17C721. [Google Scholar] [CrossRef]

- Mizunuma, K.; Ikeda, S.; Park, J.H.; Yamamoto, H.; Gan, H.; Miura, K.; Hasegawa, H.; Hayakawa, J.; Matsukura, F.; Ohno, H. MgO barrier-perpendicular magnetic tunnel junctions with CoFe/Pd multilayers and ferromagnetic insertion layers. Appl. Phys. Lett. 2009, 95, 232516. [Google Scholar] [CrossRef]

- Lee, C.M.; Ye, L.X.; Hsieh, T.H.; Huang, C.Y.; Wu, T.H. Magnetic properties of TbFeCo-based perpendicular magnetic tunnel junctions. J. Appl. Phys. 2010, 107, 09C712. [Google Scholar] [CrossRef]

- Ikeda, S.; Miura, K.; Yamamoto, H.; Mizunuma, K.; Gan, H.D.; Endo, M.; Kanai, S.; Hayakawa, J.; Matsukura, F.; Ohno, H. A perpendicular-anisotropy CoFeB–MgO magnetic tunnel junction. Nat. Mater. 2010, 9, 721–724. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.S.; Zhang, Y.; Devolder, T.; Klein, J.O.; Ravelosona, D.; Chappert, C.; Mazoyer, P. Failure and reliability analysis of STT-MRAM. Microelectron. Reliab. 2012, 52, 1848–1852. [Google Scholar] [CrossRef]

- Shimabukuro, R.; Nakamura, K.; Akiyama, T.; Ito, T. Electric field effects on magnetocrystalline anisotropy in ferromagnetic Fe monolayers. Physica E Low-Dimens. Syst. Nanostruct. 2010, 42, 1014–1017. [Google Scholar] [CrossRef]

- Yang, H.X.; Chshiev, M.; Dieny, B.; Lee, J.H.; Manchon, A.; Shin, K.H. First-principles investigation of the very large perpendicular magnetic anisotropy at Fe|MgO and Co|MgO interfaces. Phys. Rev. B 2011, 84, 054401. [Google Scholar] [CrossRef]

- Slonczewski, J.C. Current-driven excitation of magnetic multilayers. J. Magn. Magn. Mater. 1996, 159, L1–L7. [Google Scholar] [CrossRef]

- Huai, Y.; Albert, F.; Nguyen, P.; Pakala, M.; Valet, T. Observation of spin-transfer switching in deep submicron-sized and low-resistance magnetic tunnel junctions. Appl. Phys. Lett. 2004, 84, 3118–3120. [Google Scholar] [CrossRef]

- Ikeda, S.; Sato, H.; Yamanouchi, M.; Gan, H.; Miura, K.; Mizunuma, K.; Kana, N.; Fukami, S.; Matsukura, F.; Kasai, N.; Ohno, H. Recent progress of perpendicular anisotropy magnetic tunnel junctions for nonvolatile VLSI. Spin 2012, 2, 1240003. [Google Scholar] [CrossRef]

- Nakayama, M.; Kai, T.; Shimomura, N.; Amano, M.; Kitagawa, E.; Nagase, T.; Yoshikawa, M.; Kishi, T.; Ikegawa, S.; Yoda, H. Spin transfer switching in TbCoFe/CoFeB/MgO/CoFeB/TbCoFe magnetic tunnel junctions with perpendicular magnetic anisotropy. J. Appl. Phys. 2008, 103, 07A710. [Google Scholar] [CrossRef]

- Worledge, D.C.; Hu, G.; Abraham, D.W.; Sun, J.Z.; Trouilloud, P.L.; Nowak, J.; Brown, S.; Gaidis, M.C.; O’Sullivan, E.J.; Robertazzi, R.P. Spin torque switching of perpendicular Ta/CoFeB/MgO-based magnetic tunnel junctions. Appl. Phys. Lett. 2011, 98, 022501. [Google Scholar] [CrossRef]

- Zhao, H.; Glass, B.; Amiri, P.K.; Lyle, A.; Zhang, Y.; Chen, Y.J.; Rowlands, G.; Upadhyaya, P.; Zeng, Z.; Katine, J.A.; et al. Sub-200 ps spin transfer torque switching in in-plane magnetic tunnel junctions with interface perpendicular anisotropy. J. Phys. D Appl. Phys. 2012, 45, 025001. [Google Scholar] [CrossRef]

- Choi, Y.S.; Nagamine, Y.; Tsunekawa, K.; Maehara, H.; Djayaprawira, D.D.; Yuasa, S.; Ando, K. Effect of Ta getter on the quality of MgO tunnel barrier in the polycrystalline CoFeB/MgO/CoFeB magnetic tunnel junction. Appl. Phys. Lett. 2007, 90, 012505. [Google Scholar] [CrossRef]

- Sinha, J.; Gruber, M.; Kodzuka, M.; Ohkubo, T.; Mitani, S.; Hono, K.; Hayashi, M. Influence of boron diffusion on the perpendicular magnetic anisotropy in Ta|CoFeB|MgO ultrathin films. J. Appl. Phys. 2015, 117, 043913. [Google Scholar] [CrossRef]

- Gokan, H.; Esho, S. Pattern fabrication by oblique incidence ion-beam etching. J. Vac. Sci. Technol. 1981, 18, 23–27. [Google Scholar] [CrossRef]

- Kinoshita, K.; Utsumi, H.; Suemitsu, K.; Hada, H.; Sugibayashi, T. Etching magnetic tunnel junction with metal etchers. Jpn. J. Appl. Phys. 2010, 49, 08JB02. [Google Scholar] [CrossRef]

- Kinoshita, K.; Yamamoto, T.; Honjo, H.; Kasai, N.; Ikeda, S.; Ohno, H. Damage recovery by reductive chemistry after methanol-based plasma etch to fabricate magnetic tunnel junctions. Jpn. J. Appl. Phys. 2012, 51, 08HA01. [Google Scholar] [CrossRef]

- Vasile, M.J.; Mogab, C.J. Chemically assisted sputter-etching of permalloy using CO or Cl2. J. Vac. Sci. Technol. A 1986, 4, 1841–1849. [Google Scholar] [CrossRef]

- Kinoshita, K.; Yamada, K.; Matsutera, H. Reactive ion etching of Fe-Si-Al alloy for thin film head. IEEE Trans. Magn. 1991, 27, 4888–4890. [Google Scholar] [CrossRef]

- Nakatani, I. Ultramicro fabrications on Fe-Ni alloys using electron-beam writing and reactive-ion etching. IEEE Trans. Magn. 1996, 32, 4448–4451. [Google Scholar] [CrossRef]

- Osada, T.; Doi, M.; Sakamoto, K.; Maehara, H.; Kodaira, Y. Dry etching of magnetic thin film stacks using CO/NH3 and CH3OH gases for tunneling magneto-resistance devices. In Proceedings of 4th International Symposium on Dry Process, Tokyo, Japan, 30 November–1 December 2004; pp. 127–131.

- Kinoshita, K.; Honjo, H.; Fukami, S.; Sato, H.; Mizunuma, K.; Tokutome, K.; Murahata, M.; Ikeda, S.; Miura, S.; Kasai, N.; Ohno, H. Process-induced damage and its recovery for a CoFeB–MgO magnetic tunnel junction with perpendicular magnetic easy axis. Jpn. J. Appl. Phys. 2014, 53, 103001. [Google Scholar] [CrossRef]

- Greer, A.A.; Gray, A.X.; Kanai, S.; Kaiser, A.M.; Ueda, S.; Yamashita, Y.; Bordel, C.; Palsson, G.; Maejima, N.; Yang, S.H.; et al. Observation of boron diffusion in an annealed Ta/CoFeB/MgO magnetic tunnel junction with standing-wave hard x-ray photoemission. Appl. Phys. Lett. 2012, 101, 202402. [Google Scholar] [CrossRef]

- Kurt, H.; Rode, K.; Oguz, K.; Boese, M.; Faulkner, C.C.; Coey, J.M.D. Boron diffusion in magnetic tunnel junctions with MgO (001) barriers and CoFeB electrodes. Appl. Phys. Lett. 2010, 96, 262501. [Google Scholar] [CrossRef]

- Mukherjee, S.; Knut, R.; Mohseni, S.M.; Nguyen, T.A.; Chung, S.; Le, Q.T.; Akerman, J.; Persson, J.; Sahoo, A.; Hazarika, A.; et al. Role of boron diffusion in CoFeB/MgO magnetic tunnel junctions. Phys. Rev. B 2015, 91, 085311. [Google Scholar] [CrossRef]

- Ikeda, S.; Koizumi, R.; Sato, H.; Yamanouchi, M.; Miura, K.; Mizunuma, K.; Gan, H.; Matsukura, F.; Ohno, H. Boron composition dependence of magnetic anisotropy and tunnel magnetoresistance in MgO/CoFe (B) based stack structures. IEEE Trans. Magn. 2012, 48, 3829–3832. [Google Scholar] [CrossRef]

- Cheng, C.W.; Feng, W.; Chern, G.; Lee, C.M.; Wu, T.H. Effect of cap layer thickness on the perpendicular magnetic anisotropy in top MgO/CoFeB/Ta structures. J. Appl. Phys. 2011, 110, 033916. [Google Scholar] [CrossRef]

- Miura, Y.; Tsujikawa, M.; Shirai, M. A first-principles study on magnetocrystalline anisotropy at interfaces of Fe with non-magnetic metals. J. Appl. Phys. 2013, 113, 233908. [Google Scholar] [CrossRef]

- Liu, T.; Cai, J.W.; Sun, L. Large enhanced perpendicular magnetic anisotropy in CoFeB/MgO system with the typical Ta buffer replaced by an Hf layer. Aip Adv. 2012, 2, 032151. [Google Scholar] [CrossRef]

- Lee, D.S.; Chang, H.T.; Cheng, C.W.; Chern, G. Perpendicular magnetic anisotropy in MgO/CoFeB/Nb and a comparison of the cap layer effect. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, Y.; Cai, J.W.; Pan, H.Y. Thermally robust Mo/CoFeB/MgO trilayers with strong perpendicular magnetic anisotropy. Sci. Rep. 2014, 4. [Google Scholar] [CrossRef] [PubMed]

- An, G.G.; Lee, J.B.; Yang, S.M.; Kim, J.H.; Chung, W.S.; Hong, J.P. Highly stable perpendicular magnetic anisotropies of CoFeB/MgO frames employing W buffer and capping layers. Acta Mater. 2015, 87, 259–265. [Google Scholar] [CrossRef]

- Wang, M.; Peng, S.; Zhang, Y.; Zhang, Y.; Zhang, Y.; Zhang, Q.; Ravelosona, D.; Zhao, W. A Multi-Level Cell for STT-MRAM Realized by Capping Layer Adjustment. In Proceedings of the IEEE Magnetics Conference, Beijing, China, 11–15 May 2015.

- Jan, G.; Wang, Y.J.; Moriyama, T.; Lee, Y.J.; Lin, M.; Zhong, T.; Tong, R.Y.; Torng, T.; Wang, P.K. High spin torque efficiency of magnetic tunnel junctions with MgO/CoFeB/MgO free layer. Appl. Phys. Express 2012, 5, 093008. [Google Scholar] [CrossRef]

- Sato, H.; Yamanouchi, M.; Ikeda, S.; Fukami, S.; Matsukura, F.; Ohno, H. Perpendicular-anisotropy CoFeB-MgO magnetic tunnel junctions with a MgO/CoFeB/Ta/CoFeB/MgO recording structure. Appl. Phys. Lett. 2012, 101, 022414. [Google Scholar] [CrossRef]

- Sato, H.; Yamanouchi, M.; Ikeda, S.; Fukami, S.; Matsukura, F.; Ohno, H. MgO/CoFeB/Ta/CoFeB/MgO recording structure in magnetic tunnel junctions with perpendicular easy axis. IEEE Trans. Magn. 2013, 49, 4437–4440. [Google Scholar] [CrossRef]

- Ikeda, S.; Sato, H.; Honjo, H.; Enobio, E.C.I.; Ishikawa, S.; Yamanouchi, M.; Fukami, S.; Kanai, S.; Matsukura, F.; Endoh, T.; Ohno, H. Perpendicular-anisotropy CoFeB-MgO based magnetic tunnel junctions scaling down to 1X nm. In Proceedings of the IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2014; pp. 3321–3324.

- Amara-Dababi, S.; Sousa, R.C.; Chshiev, M.; Béa, H.; Alvarez-Hérault, J.; Lombard, L.; Prejbeanu, I.L.; Mackay, K.; Dieny, B. Charge trapping-detrapping mechanism of barrier breakdown in MgO magnetic tunnel junctions. Appl. Phys. Lett. 2011, 99, 083501. [Google Scholar] [CrossRef]

- Liu, L.; Moriyama, T.; Ralph, D.C.; Buhrman, R.A. Spin-torque ferromagnetic resonance induced by the spin Hall effect. Phys. Rev. Lett. 2011, 106, 036601. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Pai, C.F.; Li, Y.; Tseng, H.W.; Ralph, D.C.; Buhrman, R.A. Spin-torque switching with the giant spin Hall effect of tantalum. Science 2012, 336, 555–558. [Google Scholar] [CrossRef] [PubMed]

- Pai, C.F.; Liu, L.; Li, Y.; Tseng, H.W.; Ralph, D.C.; Buhrman, R.A. Spin transfer torque devices utilizing the giant spin Hall effect of tungsten. Appl. Phys. Lett. 2012, 101, 122404. [Google Scholar] [CrossRef]

- Cubukcu, M.; Boulle, O.; Drouard, M.; Garello, K.; Avci, C.O.; Miron, I.M.; Langer, J.; Ocker, B.; Gambardella, P.; Gaudin, G. Spin-orbit torque magnetization switching of a three-terminal perpendicular magnetic tunnel junction. Appl. Phys. Lett. 2014, 104, 042406. [Google Scholar] [CrossRef]

- Yu, G.; Upadhyaya, P.; Fan, Y.; Alzate, J.G.; Jiang, W.; Wong, K.L.; Takei, S.; Bender, S.A.; Chang, L.T.; Jiang, Y.; Lang, M.; Tang, J.; Wang, Y.; Tserkovnyak, Y.; Amiri, P.K.; Wang, K.L. Switching of perpendicular magnetization by spin-orbit torques in the absence of external magnetic fields. Nat. Nanotech. 2014, 9, 548–554. [Google Scholar] [CrossRef] [PubMed]

- Van den Brink, A.; Cosemans, S.; Cornelissen, S.; Manfrini, M.; Vaysset, A.; Van Roy, W.; Min, T.; Swagten, H.J.M.; Koopmans, B. Spin-Hall-assisted magnetic random access memory. Appl. Phys. Lett. 2014, 104, 012403. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, W.; Deng, E.; Klein, J.O.; Chappert, C. Perpendicular-anisotropy magnetic tunnel junction switched by spin-Hall-assisted spin-transfer torque. J. Phys. D Appl. Phys. 2015, 48, 065001. [Google Scholar] [CrossRef]

- Pai, C.F.; Nguyen, M.H.; Belvin, C.; Vilela-Leão, L.H.; Ralph, D.C.; Buhrman, R.A. Enhancement of perpendicular magnetic anisotropy and transmission of spin-Hall-effect-induced spin currents by a Hf spacer layer in W/Hf/CoFeB/MgO layer structures. Appl. Phys. Lett. 2014, 104, 082407. [Google Scholar] [CrossRef]

- Negulescu, B.; Lacour, D.; Montaigne, F.; Gerken, A.; Paul, J.; Spetter, V.; Marienb, J.; Duret, C.; Hehn, M. Wide range and tunable linear magnetic tunnel junction sensor using two exchange pinned electrodes. Appl. Phys. Lett. 2009, 95, 112502. [Google Scholar] [CrossRef]

- Chen, J.Y.; Feng, J.F.; Coey, J.M.D. Tunable linear magnetoresistance in MgO magnetic tunnel junction sensors using two pinned CoFeB electrodes. Appl. Phys. Lett. 2012, 100, 142407. [Google Scholar] [CrossRef]

- Ding, Y.; Judy, J.H.; Wang, J.P. Magneto-resistive sensors with perpendicular magnetic anisotropy. IEEE Trans. Magn. 2005, 41, 707–712. [Google Scholar] [CrossRef]

- Lee, Y.C.; Chao, C.T.; Li, L.C.; Suen, Y.W.; Horng, L.; Wu, T.H.; Chang, C.R.; Wu, J.C. Magnetic tunnel junction based out-of-plane field sensor with perpendicular magnetic anisotropy in reference layer. J. Appl. Phys. 2015, 117, 17A320. [Google Scholar] [CrossRef]

- Matsunaga, S.; Hayakawa, J.; Ikeda, S.; Miura, K.; Hasegawa, H.; Endoh, T.; Ohno, H.; Hanyu, T. Fabrication of a nonvolatile full adder based on logic-in-memory architecture using magnetic tunnel junctions. Appl. Phys. Express 2008, 1, 091301. [Google Scholar] [CrossRef]

- Zhao, W.; Torres, L.; Cargnini, L.V.; Brum, R.M.; Zhang, Y.; Guillemenet, Y.; Guillemenet, Y.; Sassatelli, G.; Lakys, Y.; Klein, J.O.; Etiemble, D.; Ravelosona, D.; Chappert, C. High performance SoC design using magnetic logic and memory. In Proceedings of the IEEE International Conference on Very Large Scale Integration, Hong Kong, China, 3–5 October 2011; pp. 10–33.

- Zhao, W.; Belhaire, E.; Chappert, C. Spin-MTJ based non-volatile flip-flop. In Nanotechnology, Proceedings of the IEEE conference, Hong Kong, China, 2–5 August 2007; pp. 399–402.

- Zhang, Y.; Zhao, W.; Lakys, Y.; Klein, J.O.; Kim, J.V.; Ravelosona, D.; Chappert, C. Compact modeling of perpendicular-anisotropy CoFeB/MgO magnetic tunnel junctions. IEEE Trans. Electron Devices 2012, 59, 819–826. [Google Scholar] [CrossRef]

- Mahmoudi, H.; Sverdlov, V.; Selberherr, S. MTJ-based implication logic gates and circuit architecture for large-scale spintronic stateful logic systems. In Proceedings of the European Solid-State Device Research Conference, Brodeaux, France, 17–21 September 2012; pp. 254–257.

- Yao, X.; Harms, J.; Lyle, A.; Ebrahimi, F.; Zhang, Y.; Wang, J.P. Magnetic tunnel junction-based spintronic logic units operated by spin transfer torque. IEEE Trans. Nanotechnol. 2012, 11, 120–126. [Google Scholar] [CrossRef]

- Behin-Aein, B.; Datta, D.; Salahuddin, S.; Datta, S. Proposal for an all-spin logic device with built-in memory. Nat. Nanotech. 2010, 5, 266–270. [Google Scholar] [CrossRef] [PubMed]

- Dlubak, B.; Martin, M.B.; Deranlot, C.; Servet, B.; Xavier, S.; Mattana, R.; Sprinkle, M.; Berger, C.; De Heer, W.A.; Petroff, F.; et al. Highly efficient spin transport in epitaxial graphene on SiC. Nat. Phys. 2012, 8, 557–561. [Google Scholar] [CrossRef]

- Su, L.; Zhao, W.; Zhang, Y.; Querlioz, D.; Zhang, Y.; Klein, J.O.; Dollfus, P.; Bournel, A. Proposal for a graphene-based all-spin logic gate. Appl. Phys. Lett. 2015, 106, 072407. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Zhang, Y.; Zhao, X.; Zhao, W. Tunnel Junction with Perpendicular Magnetic Anisotropy: Status and Challenges. Micromachines 2015, 6, 1023-1045. https://doi.org/10.3390/mi6081023

Wang M, Zhang Y, Zhao X, Zhao W. Tunnel Junction with Perpendicular Magnetic Anisotropy: Status and Challenges. Micromachines. 2015; 6(8):1023-1045. https://doi.org/10.3390/mi6081023

Chicago/Turabian StyleWang, Mengxing, Yue Zhang, Xiaoxuan Zhao, and Weisheng Zhao. 2015. "Tunnel Junction with Perpendicular Magnetic Anisotropy: Status and Challenges" Micromachines 6, no. 8: 1023-1045. https://doi.org/10.3390/mi6081023

APA StyleWang, M., Zhang, Y., Zhao, X., & Zhao, W. (2015). Tunnel Junction with Perpendicular Magnetic Anisotropy: Status and Challenges. Micromachines, 6(8), 1023-1045. https://doi.org/10.3390/mi6081023