Fluid-Mediated Stochastic Self-Assembly at Centimetric and Sub-Millimetric Scales: Design, Modeling, and Control

Abstract

:1. Introduction

2. Related Work

2.1. Self-Assembly of Miniaturized Robots

2.2. Self-Assembly of Micro-/Nano-Systems

3. Fluidic Self-Assembly of Passive Modules

3.1. Centimetric Scale

3.1.1. Module Design

3.1.2. Experimental System Design

3.1.3. Modeling and Control

3.1.4. Results and Discussion

3.2. Sub-Millimetric Scale

3.2.1. Module Design

3.2.2. Experimental System Design

3.2.3. Modeling and Control

4. Fluidic Self-Assembly of Active Modules

4.1. Module Design

4.2. Experimental System Design

4.3. Modeling and Control

4.4. Results and Discussion

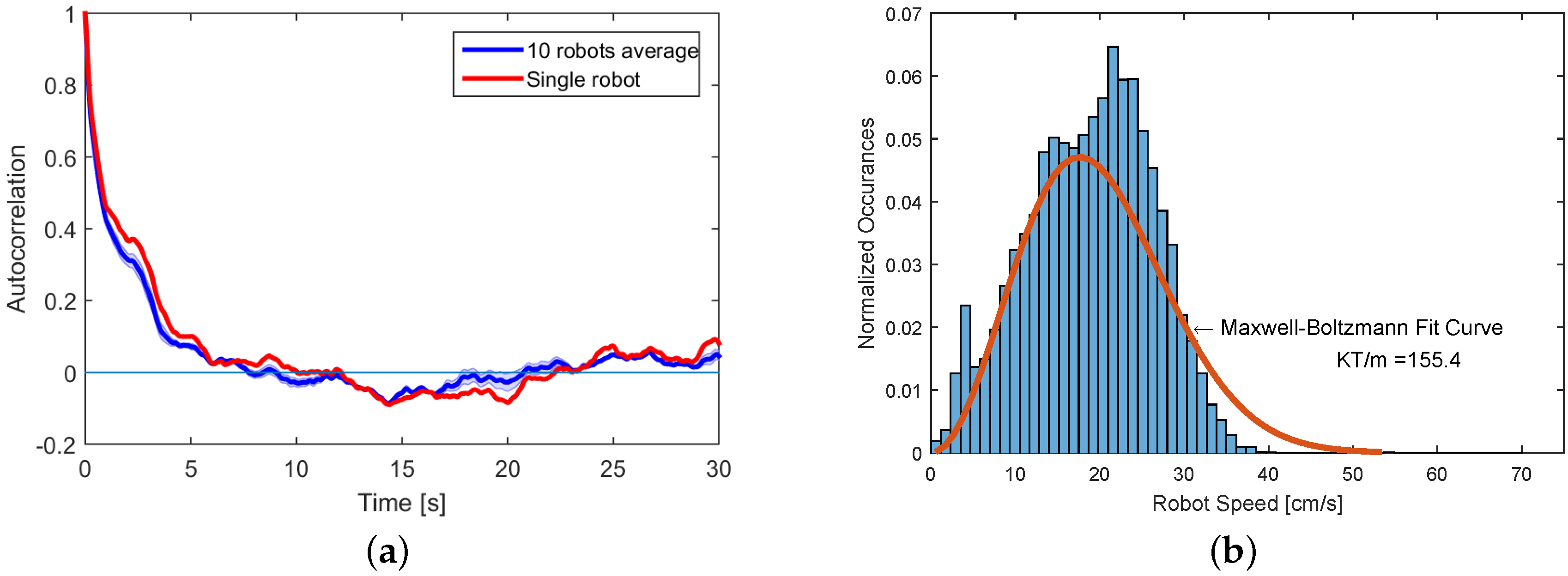

4.4.1. Experimental Set A: Macroscopic Kinetics

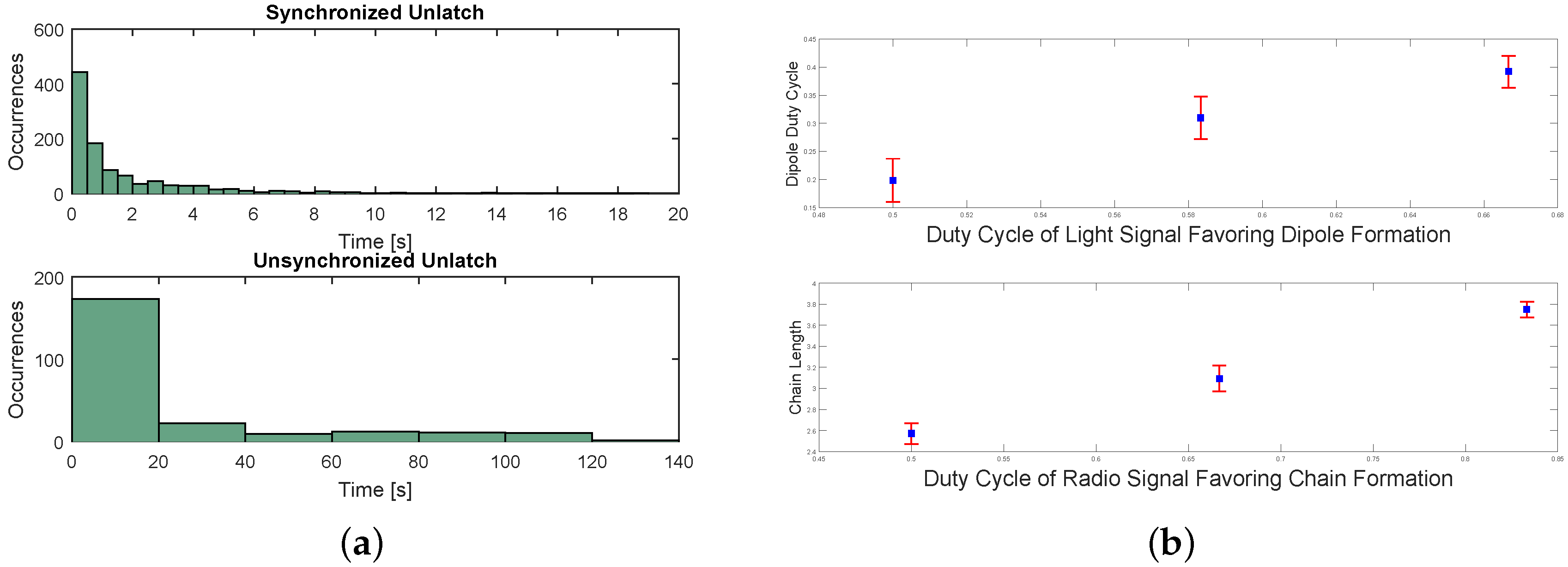

4.4.2. Experimental Set B: Demonstrating Lily Robots’ Capabilities

5. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mastrangeli, M.; Mermoud, G.; Martinoli, A. Modeling Self-Assembly Across Scales: The Unifying Perspective of Smart Minimal Particles. Micromachines 2011, 2, 82–115. [Google Scholar]

- Mastrangeli, M.; Abbasi, S.; Varel, C.; Van Hoof, C.; Celis, J.P.; Böhringer, K.F. Self-Assembly from milli-to nanoscales: Methods and applications. J. Micromech. Microeng. 2009, 19, 083001. [Google Scholar] [CrossRef] [PubMed]

- Lavine, M.S. Large-Scale robotic self-assembly. Science 2014, 345, 782. [Google Scholar] [CrossRef]

- Mermoud, G.; Prorok, A.; Matthey, L.; Cianci, C.M.; Correll, N.; Martinoli, A. Self-Organized Robotic Systems: Large-Scale Experiments in Aggregation and Self-Assembly using Miniature Robots. In Handbook of Collective Robotics; Pan Stanford Publishing: Singapore, Singapore, 2013; pp. 229–259. [Google Scholar]

- Sitti, M.; Ceylan, H.; Hu, W.; Giltinan, J.; Turan, M.; Yim, S.; Diller, E. Biomedical applications of untethered mobile milli/microrobots. Proc. IEEE 2015, 103, 205–224. [Google Scholar] [CrossRef]

- Dunbabin, M.; Marques, L. Robots for environmental monitoring: Significant advancements and applications. IEEE Robot. Autom. Mag. 2012, 19, 24–39. [Google Scholar] [CrossRef]

- Rubenstein, M.; Cornejo, A.; Nagpal, R. Programmable self-assembly in a thousand-robot swarm. Science 2014, 345, 795–799. [Google Scholar] [CrossRef] [PubMed]

- Gilpin, K.; Koyanagi, K.; Rus, D. Making self-disassembling objects with multiple components in the robot pebbles system. In Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 3614–3621.

- Mermoud, G.; Mastrangeli, M.; Upadhyay, U.; Martinoli, A. Real-Time automated modeling and control of self-assembling systems. In Proceedings of the IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 4266–4273.

- Mastrangeli, M.; Schill, F.; Goldowsky, J.; Knapp, H.; Brugger, J.; Martinoli, A. Automated real-time control of fluidic self-assembly of microparticles. In Proceedings of the IEEE International Conference on Robotics and Automation, Hong Kong, China, 31 May–7 June 2014; pp. 5860–5865.

- Romanishin, J.W.; Gilpin, K.; Claici, S.; Rus, D. 3D M-Blocks: Self-Reconfiguring robots capable of locomotion via pivoting in three dimensions. In Proceedings of the IEEE International Conference on Robotics and Automation, Seattle, WA, USA, 26–30 May 2015; pp. 1925–1932.

- O’Hara, I.; Paulos, J.; Davey, J.; Eckenstein, N.; Doshi, N.; Tosun, T.; Greco, J.; Seo, J.; Turpin, M.; Kumar, V.; et al. Self-Assembly of a swarm of autonomous boats into floating structures. In Proceedings of the IEEE International Conference on Robotics and Automation, Hong Kong, China, 31 May–7 June 2014; pp. 1234–1240.

- Tolley, M.; Lipson, H. Programmable 3D Stochastic Fluidic Assembly of cm-scale modules. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 4366–4371.

- Miyashita, S.; Kessler, M.; Lungarella, M. How morphology affects self-assembly in a stochastic modular robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 3533–3538.

- Klavins, E. Programmable self-assembly. IEEE Control Syst. 2007, 27, 43–56. [Google Scholar] [CrossRef]

- Freitas, R.A., Jr.; Merkle, R.C. Kinematic Self-Replicating Machines; Landes Bioscience: Georgetown, TX, USA, 2004. [Google Scholar]

- Hogg, T. Robust self-assembly using highly designable structures. Nanotechnology 1999, 10, 300. [Google Scholar] [CrossRef]

- Sariola, V.; Zhou, Q.; Koivo, H.N. Hybrid microhandling: A unified view of robotic handling and self-assembly. J. Micro-Nano Mechatron. 2008, 4, 5–16. [Google Scholar] [CrossRef]

- Hsieh, M.A.; Kumar, V.; Chaimowicz, L. Decentralized controllers for shape generation with robotic swarms. Robotica 2008, 26, 691–701. [Google Scholar] [CrossRef]

- Gilpin, K.; Rus, D. Modular robot systems. IEEE Robot. Autom. Mag. 2010, 17, 38–55. [Google Scholar] [CrossRef]

- Yim, M.; Shen, W.; Salemi, B.; Rus, D.; Moll, M.; Lipson, H.; Klavins, E.; Chirikjian, G. Modular self-reconfigurable robot systems [grand challenges of robotics]. IEEE Robot. Autom. Mag. 2007, 14, 43–52. [Google Scholar] [CrossRef]

- Tolley, M.; Lipson, H. Fluidic manipulation for scalable stochastic 3D assembly of modular robots. In Proceedings of the IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 2473–2478.

- White, P.; Zykov, V.; Bongard, J.; Lipson, H. Three Dimensional Stochastic Reconfiguration of Modular Robots. In Proceedings of the Robotics: Science and Systems, Cambridge, MA, USA, 8–11 June 2005; pp. 161–168.

- Ganesan, V.; Chitre, M. On Stochastic Self-Assembly of Underwater Robots. IEEE Robot. Autom. Lett. 2016, 1, 251–258. [Google Scholar] [CrossRef]

- Napp, N.; Burden, S.; Klavins, E. The statistical dynamics of programmed self-assembly. In Proceedings of the IEEE International Conference on Robotics and Automation, Orlando, FL, USA, 15–19 May 2006; pp. 1469–1476.

- Hogg, T. Coordinating microscopic robots in viscous fluids. Auton. Agents Multi-Agent Syst. 2007, 14, 271–305. [Google Scholar] [CrossRef]

- Berman, S.; Halász, Á.; Hsieh, M.A.; Kumar, V. Optimized stochastic policies for task allocation in swarms of robots. IEEE Trans. Robot. 2009, 25, 927–937. [Google Scholar] [CrossRef]

- Gillespie, D.T. Stochastic simulation of chemical kinetics. Annu. Rev. Phys. Chem. 2007, 58, 35–55. [Google Scholar] [CrossRef] [PubMed]

- Matthey, L.; Berman, S.; Kumar, V. Stochastic strategies for a swarm robotic assembly system. In Proceedings of the IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 1953–1958.

- Evans, W.C.; Mermoud, G.; Martinoli, A. Comparing and modeling distributed control strategies for miniature self-assembling robots. In Proceedings of the IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 1438–1445.

- Cohn, M.B.; Kim, C.; Pisano, A.P. Self-Assembling electrical networks: An application of micromachining technology. In Proceedings of the IEEE International Conference on Solid-State Sensors and Actuators, San Francisco, CA, USA, 24–27 June 1991; pp. 490–493.

- Gracias, D.H.; Tien, J.; Breen, T.L.; Hsu, C.; Whitesides, G.M. Forming electrical networks in three dimensions by self-assembly. Science 2000, 289, 1170–1172. [Google Scholar] [CrossRef] [PubMed]

- Stauth, S.A.; Parviz, B.A. Self-Assembled single-crystal silicon circuits on plastic. Proc. Natl. Acad. Sci. USA 2006, 103, 13922–13927. [Google Scholar] [CrossRef] [PubMed]

- Verma, A.K.; Hadley, M.A.; Yeh, H.J.; Smith, J. Fluidic self-assembly of silicon microstructures. In Proceedings of the IEEE 45th Electronic Components and Technology Conference, Las Vegas, NV, USA, 21–24 May 1995; pp. 1263–1268.

- Cohn, M.B.; Boehringer, K.F.; Noworolski, J.M.; Singh, A.; Keller, C.G.; Goldberg, K.A.; Howe, R.T. Microassembly technologies for MEMS. In Proceedings of the International Society for Optics and Photonics Micromachining and Microfabrication, Santa Clara, CA, USA, 20 September 1998; pp. 2–16.

- Bohringer, K.F.; Goldberg, K.; Cohn, M.; Howe, R.; Pisano, A. Parallel microassembly with electrostatic force fields. In Proceedings of the IEEE International Conference on Robotics and Automation, Leuven, Belgium, 16–20 May 1998; Volume 2, pp. 1204–1211.

- Chung, J.; Zheng, W.; Hatch, T.J.; Jacobs, H.O. Programmable reconfigurable self-assembly: Parallel heterogeneous integration of chip-scale components on planar and nonplanar surfaces. J. Microelectromech. Syst. 2006, 15, 457–464. [Google Scholar] [CrossRef]

- Leong, T.G.; Zarafshar, A.M.; Gracias, D.H. Three-Dimensional Fabrication at Small Size Scales. Small 2010, 6, 792–806. [Google Scholar] [CrossRef] [PubMed]

- Knuesel, R.J.; Jacobs, H.O. Self-Assembly of microscopic chiplets at a liquid–liquid–solid interface forming a flexible segmented monocrystalline solar cell. Proc. Natl. Acad. Sci. USA 2010, 107, 993–998. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.S. High density, low parasitic direct integration by fluidic self assembly (FSA). In Proceedings of the IEEE International Technical Digest on Electron Devices Meeting, San Francisco, CA, USA, 10–13 December 2000; pp. 201–204.

- Srinivasan, U.; Liepmann, D.; Howe, R.T. Microstructure to substrate self-assembly using capillary forces. IEEE J. Microelectromech. Syst. 2001, 10, 17–24. [Google Scholar] [CrossRef]

- Zheng, W.; Chung, J.; Jacobs, H.O. Fluidic heterogeneous microsystems assembly and packaging. J. Microelectromech. Syst. 2006, 15, 864–870. [Google Scholar] [CrossRef]

- Lee, S.W.; Bashir, R. Dielectrophoresis and Chemically Mediated Directed Self-Assembly of Micrometer-Scale Three-Terminal Metal Oxide Semiconductor Field-Effect Transistors. Adv. Mater. 2005, 17, 2671–2677. [Google Scholar] [CrossRef]

- Shetye, S.B.; Eskinazi, I.; Arnold, D.P. Self-assembly of millimeter-scale components using integrated micromagnets. IEEE Trans. Mag. 2008, 44, 4293–4296. [Google Scholar] [CrossRef]

- Bowden, N.; Choi, I.S.; Grzybowski, B.A.; Whitesides, G.M. Mesoscale self-assembly of hexagonal plates using lateral capillary forces: Synthesis using the “capillary bond”. J. Am. Chem. Soc. 1999, 121, 5373–5391. [Google Scholar] [CrossRef]

- Tanemura, T.; Lopez, G.; Sato, R.; Sugano, K.; Tsuchiya, T.; Tabata, O.; Fujita, M.; Maeda, M. Sequential and selective self-assembly of micro components by DNA grafted polymer. In Proceedings of the IEEE 22nd International Conference on Micro Electro Mechanical Systems, Sorrento, Italy, 25–29 January 2009; pp. 184–187.

- Krishnan, M.; Tolley, M.T.; Lipson, H.; Erickson, D. Hydrodynamically tunable affinities for fluidic assembly. Langmuir 2009, 25, 3769–3774. [Google Scholar] [CrossRef] [PubMed]

- Whitesides, G.M.; Boncheva, M. Beyond molecules: Self-Assembly of mesoscopic and macroscopic components. Proc. Natl. Acad. Sci. USA 2002, 99, 4769–4774. [Google Scholar] [CrossRef] [PubMed]

- Bishop, K.J.; Wilmer, C.E.; Soh, S.; Grzybowski, B.A. Nanoscale forces and their uses in self-assembly. Small 2009, 5, 1600–1630. [Google Scholar] [CrossRef] [PubMed]

- Donald, B.R.; Levey, C.G.; Paprotny, I.; Rus, D. Simultaneous control of multiple MEMS microrobots. In Algorithmic Foundation of Robotics VIII; Springer: Berlin/Heidelberg, Germany, 2010; pp. 69–84. [Google Scholar]

- Frutiger, D.R.; Vollmers, K.; Kratochvil, B.E.; Nelson, B.J. Small, fast, and under control: Wireless resonant magnetic micro-agents. Int. J. Robot. Res. 2010, 29, 613–636. [Google Scholar] [CrossRef]

- Chang, S.T.; Paunov, V.N.; Petsev, D.N.; Velev, O.D. Remotely powered self-propelling particles and micropumps based on miniature diodes. Nat. Mater. 2007, 6, 235–240. [Google Scholar] [CrossRef] [PubMed]

- Miyashita, S.; Guitron, S.; Ludersdorfer, M.; Sung, C.R.; Rus, D. An untethered miniature origami robot that self-folds, walks, swims, and degrades. In Proceedings of the IEEE International Conference on Robotics and Automation, Seattle, WA, USA, 26–30 May 2015; pp. 1490–1496.

- Lochmatter, T.; Roduit, P.; Cianci, C.; Correll, N.; Jacot, J.; Martinoli, A. SwisTrack—A flexible open source tracking software for multi-agent systems. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; pp. 4004–4010.

- Henzinger, T.A. The Theory of Hybrid Automata; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

- Donald, B.R.; Levey, C.G.; Paprotny, I.; Rus, D. Planning and control for microassembly of structures composed of stress-engineered MEMS microrobots. Int. J. Robot. Res. 2013, 32, 218–246. [Google Scholar] [CrossRef] [PubMed]

- Miyashita, S.; Diller, E.; Sitti, M. Two-Dimensional magnetic micro-module reconfigurations based on inter-modular interactions. Int. J. Robot. Res. 2013, 32, 591–613. [Google Scholar] [CrossRef]

- Mastrangeli, M.; Martinoli, A.; Brugger, J. Three-Dimensional polymeric microtiles for optically-tracked fluidic self-assembly. Microelectron. Eng. 2014, 124, 1–7. [Google Scholar] [CrossRef]

- Meyer, E.E.; Rosenberg, K.J.; Israelachvili, J. Recent progress in understanding hydrophobic interactions. Proc. Natl. Acad. Sci. USA 2006, 103, 15739–15746. [Google Scholar] [CrossRef] [PubMed]

- Goldowsky, J.; Mastrangeli, M.; Jacot-Descombes, L.; Gullo, M.R.; Mermoud, G.; Brugger, J.; Martinoli, A.; Nelson, B.J.; Knapp, H.F. Acousto-Fluidic system assisting in-liquid self-assembly of microcomponents. J. Micromech. Microeng. 2013, 23, 125026. [Google Scholar] [CrossRef]

- Haghighat, B.; Droz, E.; Martinoli, A. Lily: A Miniature Floating Robotic Platform for Programmable Stochastic Self-Assembly. In Proceedings of the IEEE International Conference on Robotics and Automation, Seattle, WA, USA, 26–30 May 2015; pp. 1941–1948.

- Knaian, A. Electropermanent Magnetic Connectors and Actuators: Devices and Their Application in Programmable Matter. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2010. [Google Scholar]

- Haghighat, B.; Platerrier, B.; Waegeli, L.; Alcherio, M. Synthesizing Rulesets for Programmable Robotic Self-Assembly: A Case Study using Floating Miniaturized Robots. In Proceedings of the ANTS: International Conference on Swarm Intelligence, Brussels, Belgium, 7 September 2016.

- Fox, M.; Shamma, J. Probabilistic performance guarantees for distributed self-assembly. IEEE Trans. Autom. Control 2015, 60, 3180–3194. [Google Scholar] [CrossRef]

- Forces, M.D. Statistical Thermodynamics in Chemistry and Biology; Garland Science: New York, NY, USA, 2003. [Google Scholar]

- Gillespie, D.T. Exact stochastic simulation of coupled chemical reactions. J. Phys. Chem. 1977, 81, 2340–2361. [Google Scholar] [CrossRef]

- Martinoli, A.; Easton, K.; Agassounon, W. Modeling swarm robotic systems: A case study in collaborative distributed manipulation. Int. J. Robot. Res. 2004, 23, 415–436. [Google Scholar] [CrossRef]

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haghighat, B.; Mastrangeli, M.; Mermoud, G.; Schill, F.; Martinoli, A. Fluid-Mediated Stochastic Self-Assembly at Centimetric and Sub-Millimetric Scales: Design, Modeling, and Control. Micromachines 2016, 7, 138. https://doi.org/10.3390/mi7080138

Haghighat B, Mastrangeli M, Mermoud G, Schill F, Martinoli A. Fluid-Mediated Stochastic Self-Assembly at Centimetric and Sub-Millimetric Scales: Design, Modeling, and Control. Micromachines. 2016; 7(8):138. https://doi.org/10.3390/mi7080138

Chicago/Turabian StyleHaghighat, Bahar, Massimo Mastrangeli, Grégory Mermoud, Felix Schill, and Alcherio Martinoli. 2016. "Fluid-Mediated Stochastic Self-Assembly at Centimetric and Sub-Millimetric Scales: Design, Modeling, and Control" Micromachines 7, no. 8: 138. https://doi.org/10.3390/mi7080138