The Polypyrrole/Multiwalled Carbon Nanotube Modified Au Microelectrode for Sensitive Electrochemical Detection of Trace Levels of Pb2+

Abstract

:1. Introduction

2. Experimental

2.1. Reagents and Apparatus

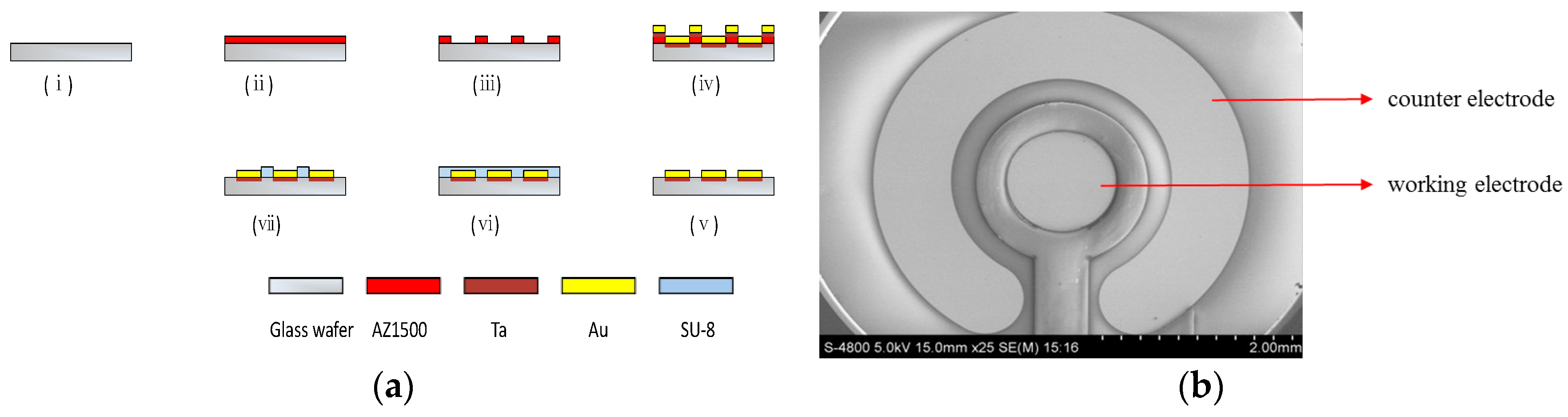

2.2. Microelectrode Fabrication

2.3. Preparation of PPy/MWCNT-Modified Microelectrode

2.4. Electrochemical Measurements

3. Results and Discussion

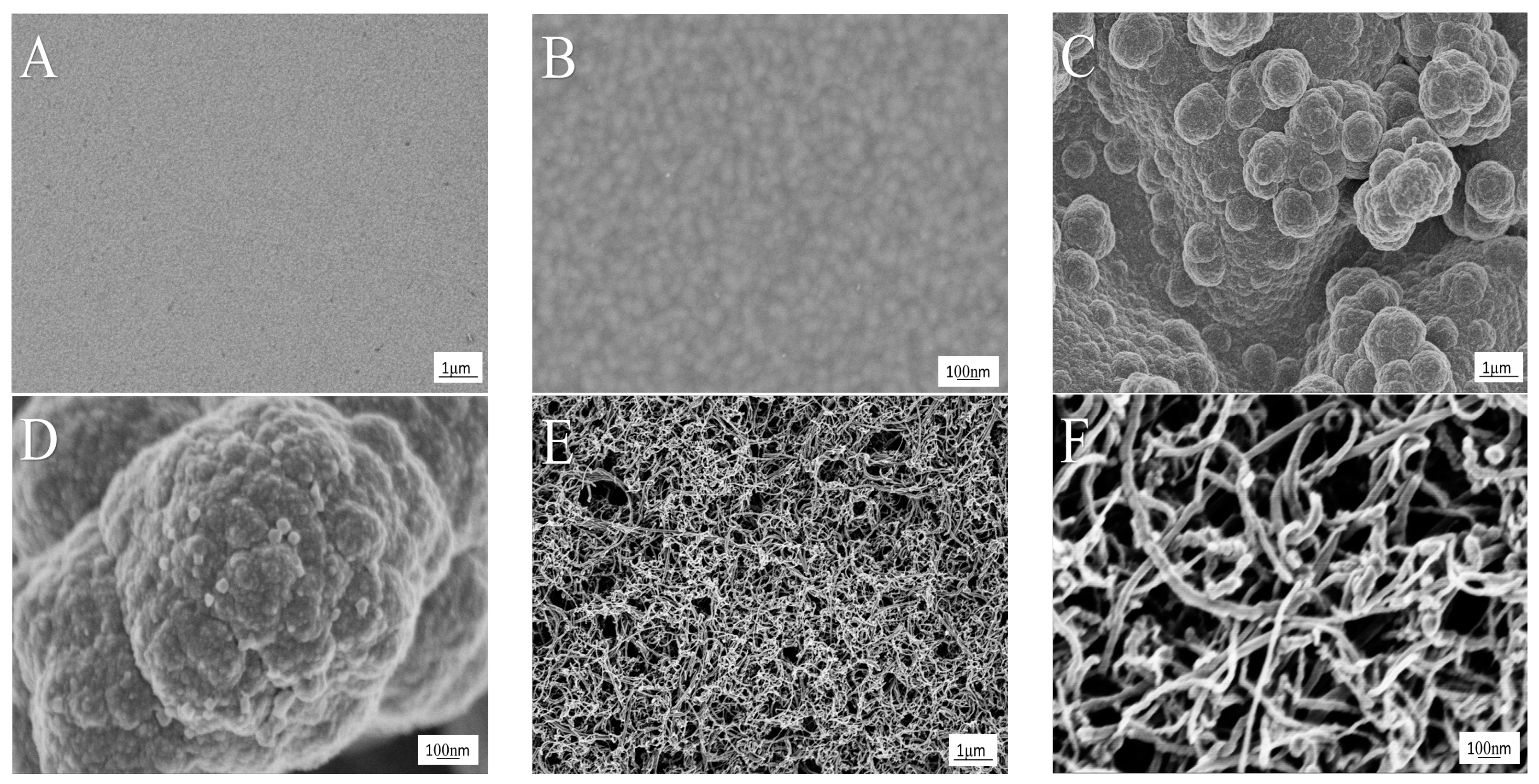

3.1. Morphologies of Modified Microelectrode

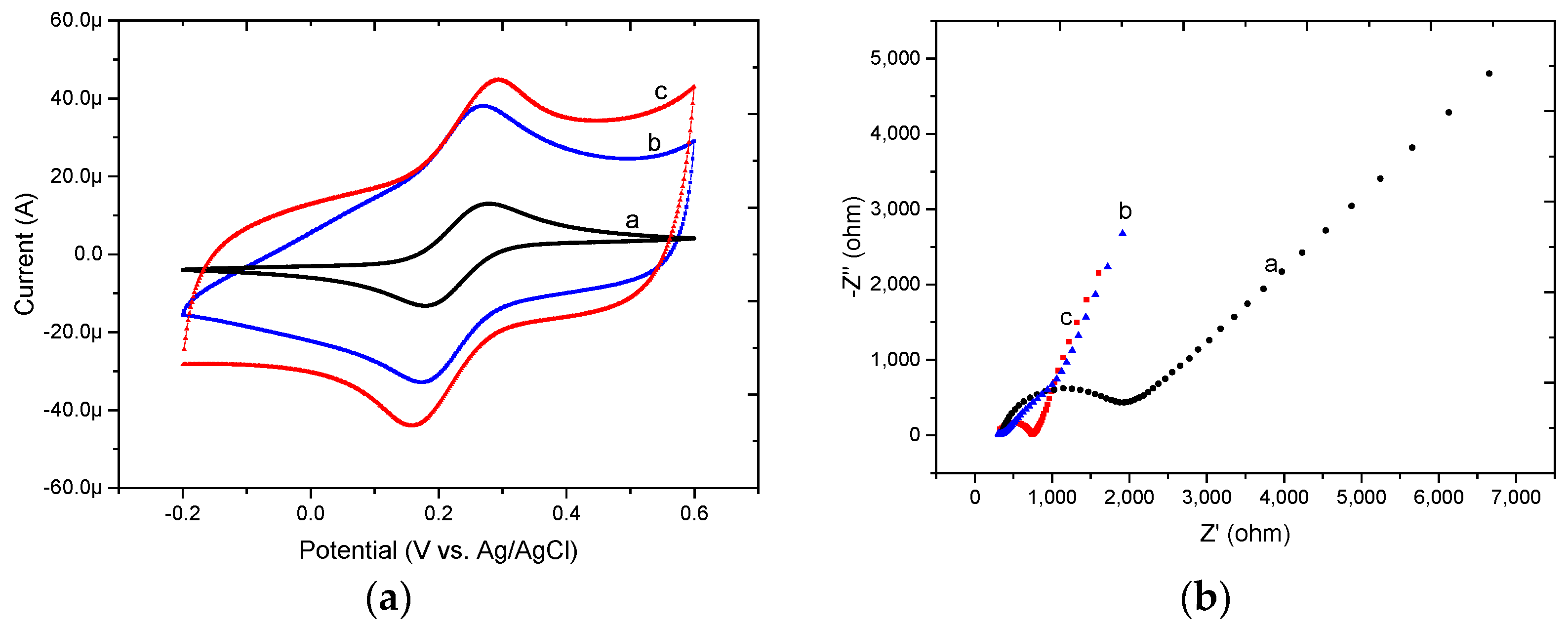

3.2. Characterization of Modified Microelectrode

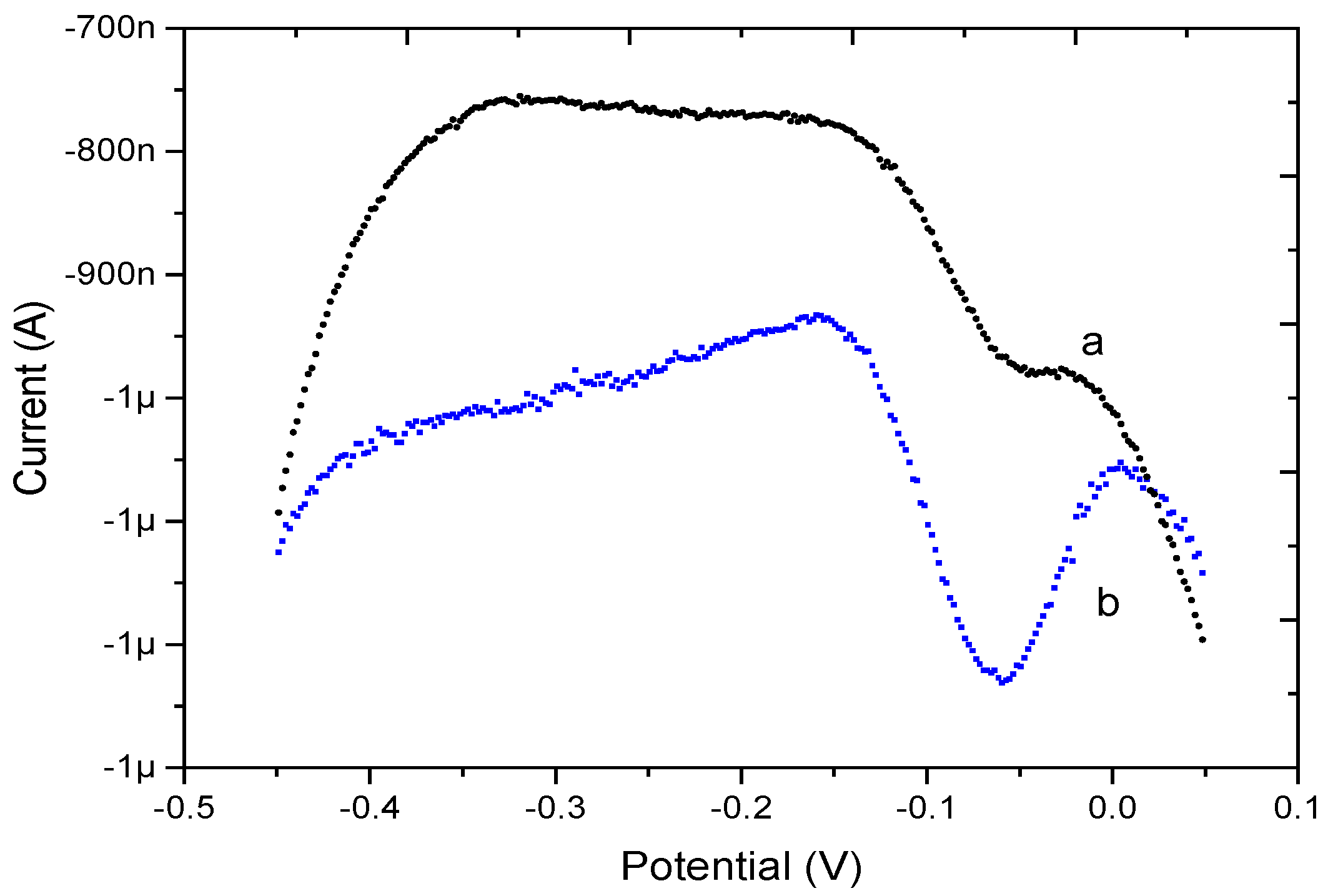

3.3. Electrochemical Behaviors of Pb2+ at Various Microelectrodes

3.4. Optimization of Experimental Conditions

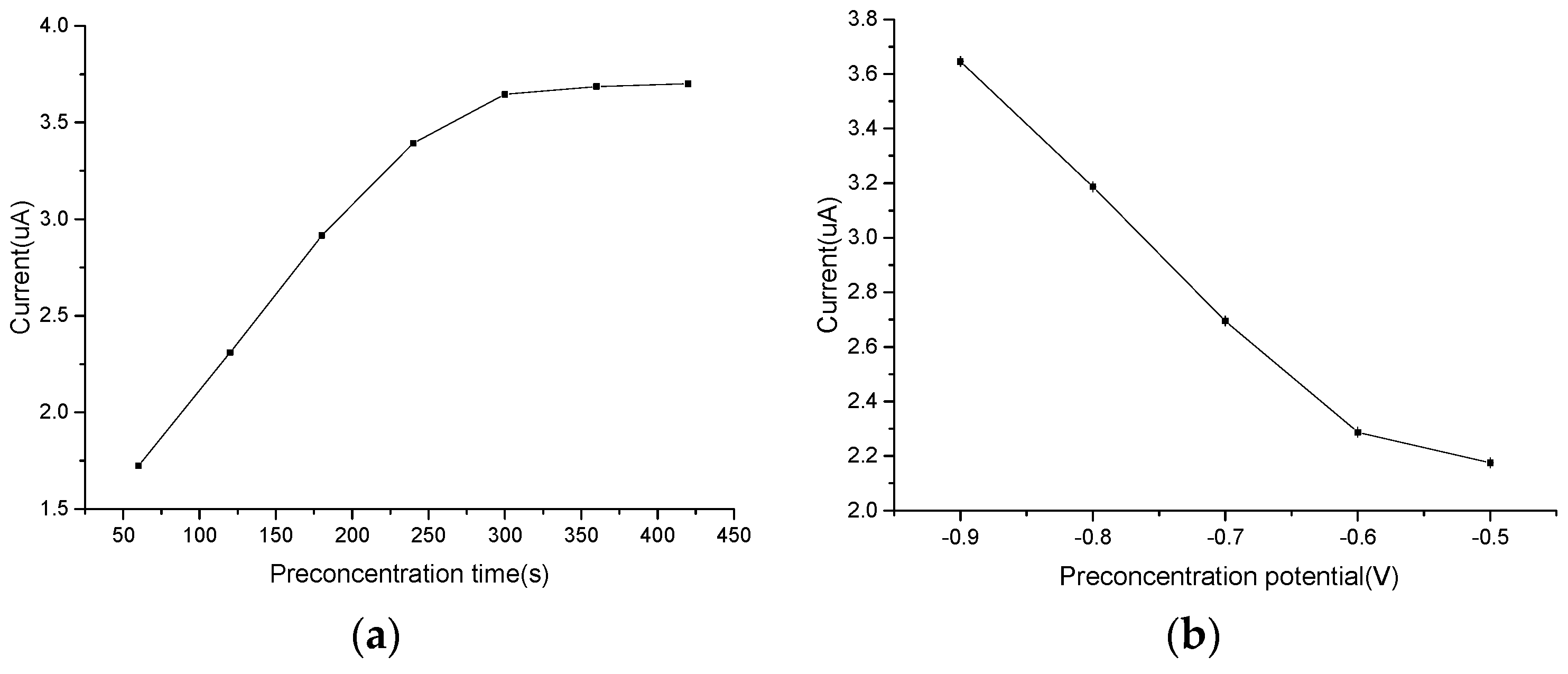

3.4.1. Optimization of Accumulation Time

3.4.2. Optimization of Deposition Potential

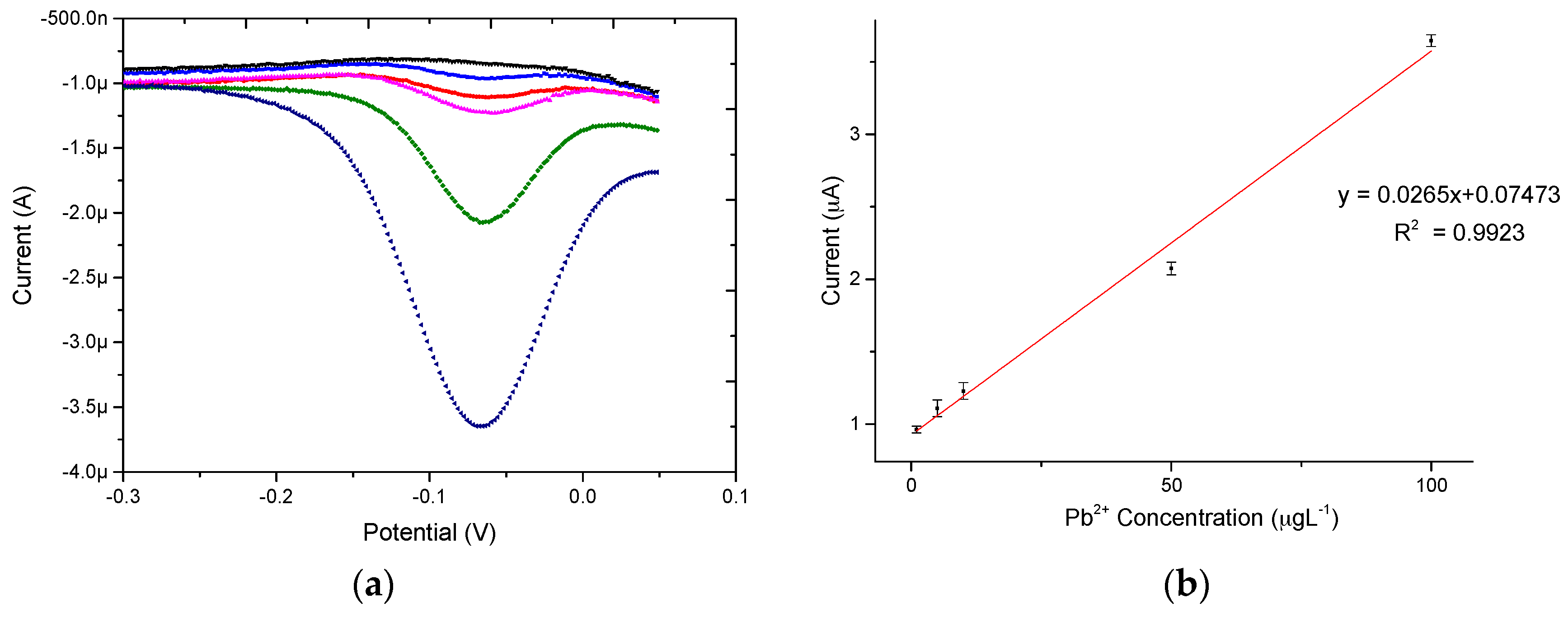

3.5. Electrochemical Determination of Pb2+

3.6. Interference Study

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lars, J. Hazards of heavy metal contamination. Br. Med. Bull. 2003, 68, 167–182. [Google Scholar]

- Tatiane, M.A.; André, S.; Mauricio, R.B.; Fernando, H.C.; Neidenei, G.F. Lead detection using micro/nanocrystalline boron-doped diamond by square-wave anodic stripping voltammetry. Talanta 2014, 128, 132–140. [Google Scholar]

- Pan, D.W.; Wang, Y.E.; Chen, Z.P.; Lou, T.T.; Qin, W. Nanomaterial/ionophore-based electrode for anodic stripping voltammetric determination of lead: An electro chemical sensing platform toward heavy metals. Anal. Chem. 2009, 81, 5088–5094. [Google Scholar] [CrossRef] [PubMed]

- Salaun, P.; van den Berg, C.M. Voltammetric detection of mercury and copperin seawater using a gold microwire electrode. Anal. Chem. 2006, 78, 5052–5060. [Google Scholar] [CrossRef] [PubMed]

- Dresselhaus, M.S. Nanotechnology: New tricks with nanotubes. Nature 1998, 391, 19–20. [Google Scholar] [CrossRef]

- De Heer, W.A.; Bonard, J.M.; Kai, F.; André, C.; Daniel, U.; László, F. Electron field emitters based on carbon nanotube films. Adv. Mater. 1997, 9, 87–89. [Google Scholar] [CrossRef]

- Sander, J.; Alwin, R.M.; Cees, D. Room-temperature transistor based on a single carbon nanotube. Nature 1998, 393, 49–52. [Google Scholar]

- Dresselhaus, M.S. Down the straight and narrow. Nature 1992, 358, 195–196. [Google Scholar] [CrossRef]

- Luo, H.X.; Shi, Z.J.; Li, N.Q.; Gu, Z.N.; Zhuang, Q.K. Investigation of the electrochemical and electrocatalytic behavior of single-wall carbon nanotube film on a glassy carbon electrode. Anal. Chem. 2001, 73, 915–920. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.H.; Zhao, G.C.; Wei, X.W. Electrocatalytic oxidation of nitric oxide at multi-walled carbon nanotubes modified electrode. Electrochem. Commun. 2002, 4, 690–694. [Google Scholar] [CrossRef]

- Musameh, M.; Lawrence, N.S.; Wang, J. Electrochemical activation of carbon nanotubes. Electrochem. Commun. 2005, 7, 14–18. [Google Scholar] [CrossRef]

- Rouse, J.H.; Lillehei, P.T. Electrostatic assembly of polymer/single walled carbon nanotube multilayer films. Nano Lett. 2003, 3, 59–62. [Google Scholar] [CrossRef]

- Li, Q.W.; Wang, Y.M.; Luo, G.A. Voltammetric separation of dopamine and ascorbic acid with graphite electrodes modified with ultrafine TiO2. Mater. Sci. Eng. C 2000, 11, 71–74. [Google Scholar] [CrossRef]

- Nardes, A.M.; Kemerink, M.; Janssen, R.A.; Bastiaansen, J.A.; Kiggen, N.M.; Langeveld, B.M.; Van Breemen, A.J.; de Kok, M.M. Microscopic understanding of the anisotropic conductivity of PEDOT/PSS thin films. Adv. Mater. 2007, 19, 1196–1200. [Google Scholar] [CrossRef]

- Pernaut, J.M.; Reynolds, J.R. Use of conducting electroactive polymers for drug delivery and sensing of bioactive molecules. A redox chemistry approach. J. Phys. Chem. 2000, 104, 4080–4090. [Google Scholar] [CrossRef]

- Malitesta, C.; Palmisano, F.; Torsi, L.; Zambonin, P.G. Glucose fast-response amperometric sensor based on glucose oxidase immobilized in an electropolymerized poly(o-phenylenediamine) film. Anal. Chem. 1990, 62, 2735–2740. [Google Scholar] [CrossRef] [PubMed]

- Girifalco, L.A.; Hodak, M.; Lee, R.S. Carbon nanotubes, buckyballs, ropes, and a universal graphitic potential. Phys. Rev. B 2000, 62, 13104–13110. [Google Scholar] [CrossRef]

- Wu, J.C.; Pawlisayn, J. Preparation and applications of polypyrrole films in solid-phase microextraction. J. Chromatogr. A 2001, 909, 37–52. [Google Scholar] [CrossRef]

- Yan, W.; Yang, R.; Zhang, Y.X.; Wang, L.; Liu, J.H.; Huang, X.J. High adsorptive γ-AlOOH (boehmite) @SiO2/Fe3O4 porous magnetic microspheres for detection of toxic metal ions in drinking water. Chem. Commun. 2011, 47, 11062–11064. [Google Scholar]

- Gao, C.; Huang, X.-J. Voltammetric determination of mercury(II). TrAC Trends Anal. Chem. 2013, 51, 1–12. [Google Scholar] [CrossRef]

- Chira, A.; Bucur, B.; Bucura, M.P.; Radu, G.L. Electrode-modified with nanoparticles composed of 4,40-bipyridine-silver coordination polymer for sensitive determination of Hg(II), Cu(II) and Pb(II). New J. Chem. 2014, 38, 5641–5646. [Google Scholar] [CrossRef]

- Wu, K.; Hu, S.; Fei, J.; Bai, W. Mercury-free simultaneous determination of cadmium and lead at a glassy carbon electrode modified with multi-wall carbon nanotubes. Anal. Chim. Acta 2003, 489, 215–221. [Google Scholar] [CrossRef]

- Serrano, N.; González-Calabuig, A.; del Valle, M. Crown ether-modified electrodes for the simultaneous stripping voltammetric determination of Cd(II), Pb(II) and Cu(II). Talanta 2015, 138, 130–137. [Google Scholar] [CrossRef] [PubMed]

- Ruas de Souza, A.P.; Foster, C.W.; Kolliopoulos, A.V.; Bertotti, M.; Banks, C.E. Screen-printed back-to-back electroanalytical sensors: Heavy metal ion sensing. Analyst 2015, 140, 4130–4136. [Google Scholar] [CrossRef] [PubMed]

| Electrode | Linearity Range (μg·L−1) | Correlation Coefficient | LOD (μg·L−1) | Reference |

|---|---|---|---|---|

| MWCNTs/GCE | 4.14–200 | 0.99 | 0.83 | [22] |

| Crown/GCE | 5.0–186.5 | 0.99 | 1.5 | [23] |

| b2SPE | 5–110 | 0.99 | 1.10 | [24] |

| PPy/MWCNT/Au | 1–100 | 0.9923 | 0.65 | This work |

| Interferences | Signal Change (%) |

|---|---|

| Ca2+ | +4.5 |

| Mg2+ | +3.5 |

| Mn2+ | +2.6 |

| Ni2+ | −3.1 |

| Co2+ | −2.8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Tong, J.; Bian, C.; Gao, C.; Xia, S. The Polypyrrole/Multiwalled Carbon Nanotube Modified Au Microelectrode for Sensitive Electrochemical Detection of Trace Levels of Pb2+. Micromachines 2017, 8, 86. https://doi.org/10.3390/mi8030086

Zhu X, Tong J, Bian C, Gao C, Xia S. The Polypyrrole/Multiwalled Carbon Nanotube Modified Au Microelectrode for Sensitive Electrochemical Detection of Trace Levels of Pb2+. Micromachines. 2017; 8(3):86. https://doi.org/10.3390/mi8030086

Chicago/Turabian StyleZhu, Xuxing, Jianhua Tong, Chao Bian, Chengyao Gao, and Shanhong Xia. 2017. "The Polypyrrole/Multiwalled Carbon Nanotube Modified Au Microelectrode for Sensitive Electrochemical Detection of Trace Levels of Pb2+" Micromachines 8, no. 3: 86. https://doi.org/10.3390/mi8030086

APA StyleZhu, X., Tong, J., Bian, C., Gao, C., & Xia, S. (2017). The Polypyrrole/Multiwalled Carbon Nanotube Modified Au Microelectrode for Sensitive Electrochemical Detection of Trace Levels of Pb2+. Micromachines, 8(3), 86. https://doi.org/10.3390/mi8030086