Custom-Designed Glassy Carbon Tips for Atomic Force Microscopy

Abstract

:1. Introduction

2. Materials and Methods

2.1. 2PP Fabrication

2.2. Pyrolysis

2.3. AFM

2.4. SEM

2.5. TEM

2.6. Raman Spectroscopy

3. Results and Discussion

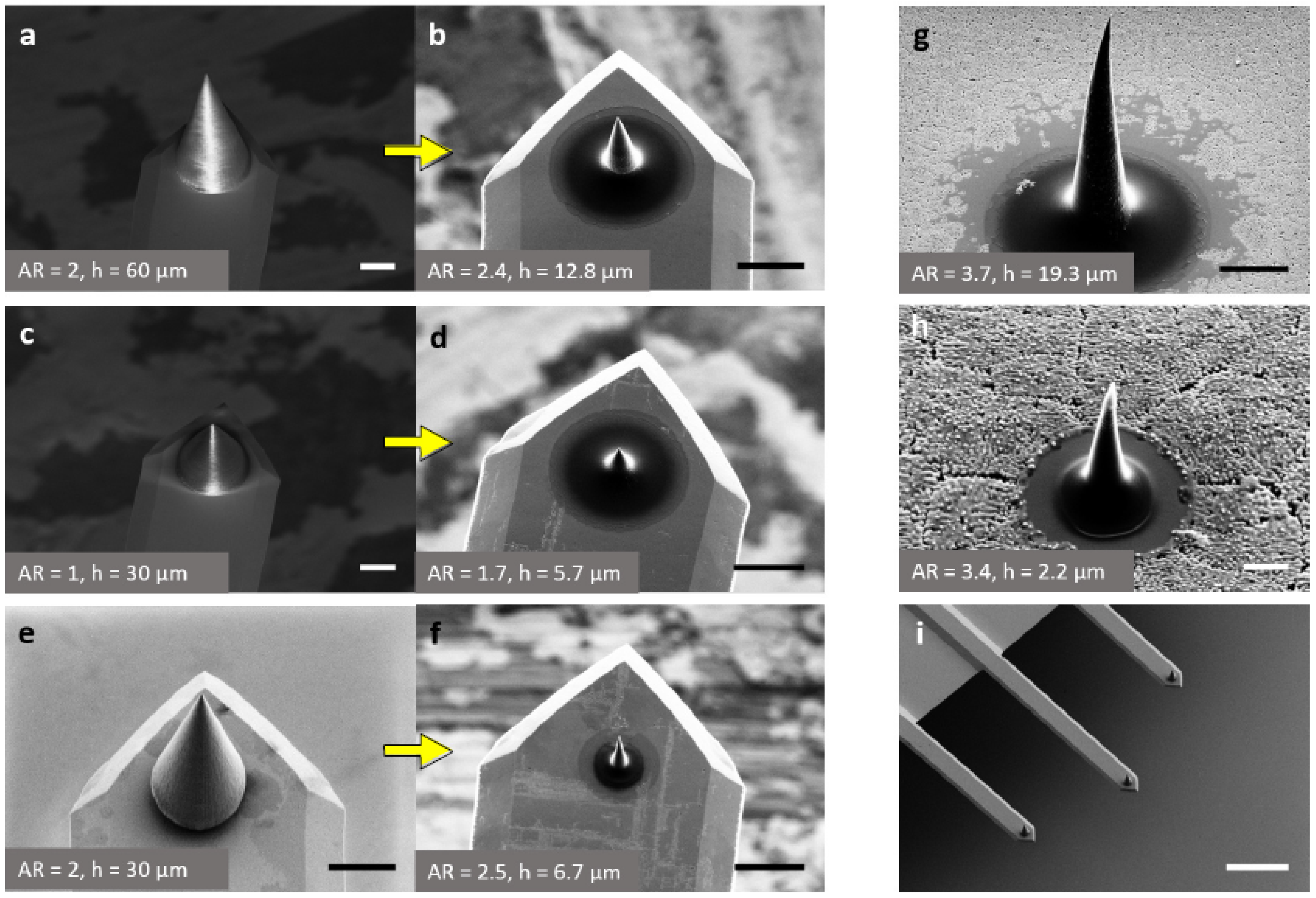

3.1. Tip Design and Fabrication

3.2. AFM Measurements

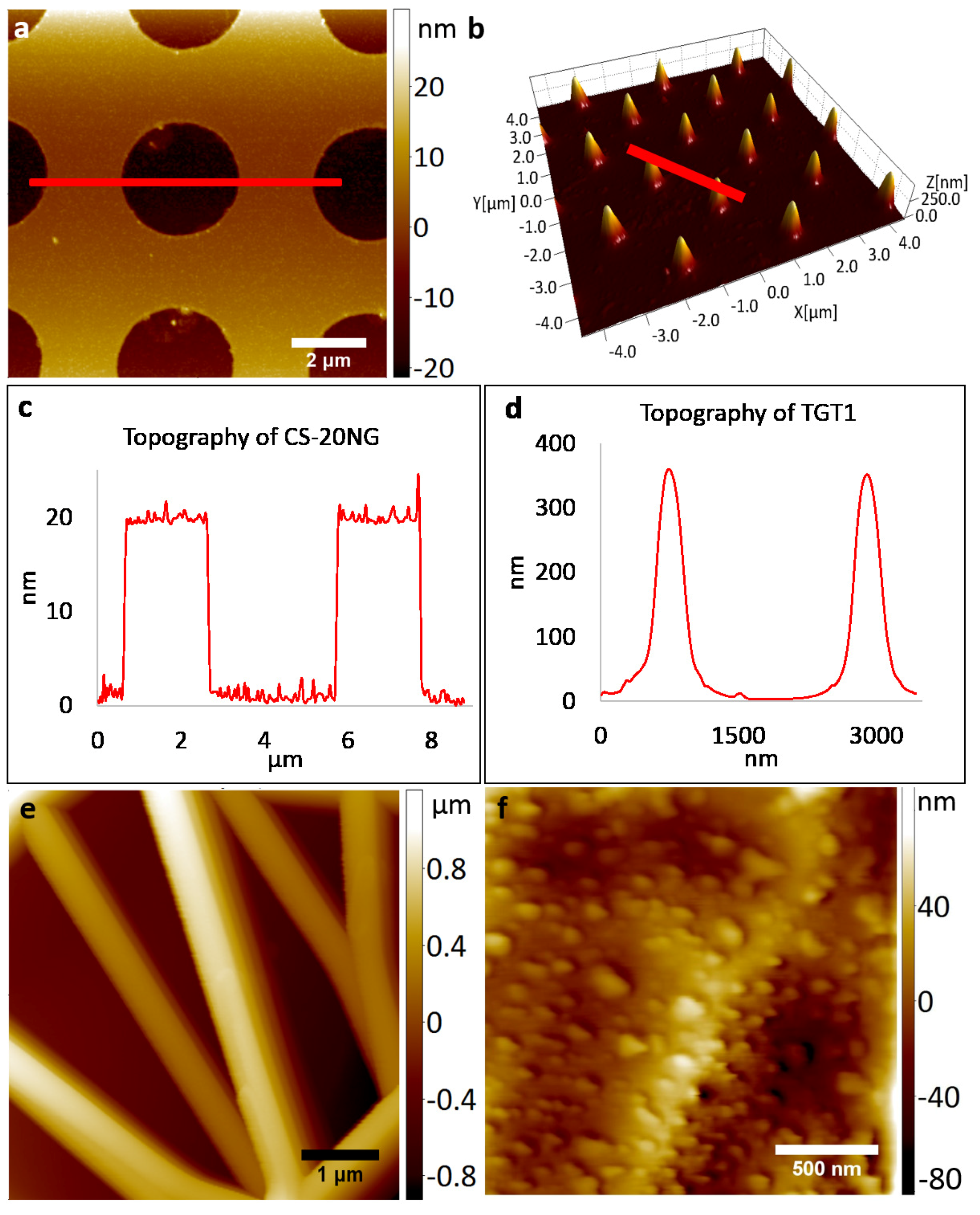

3.2.1. Surface Morphology Tests

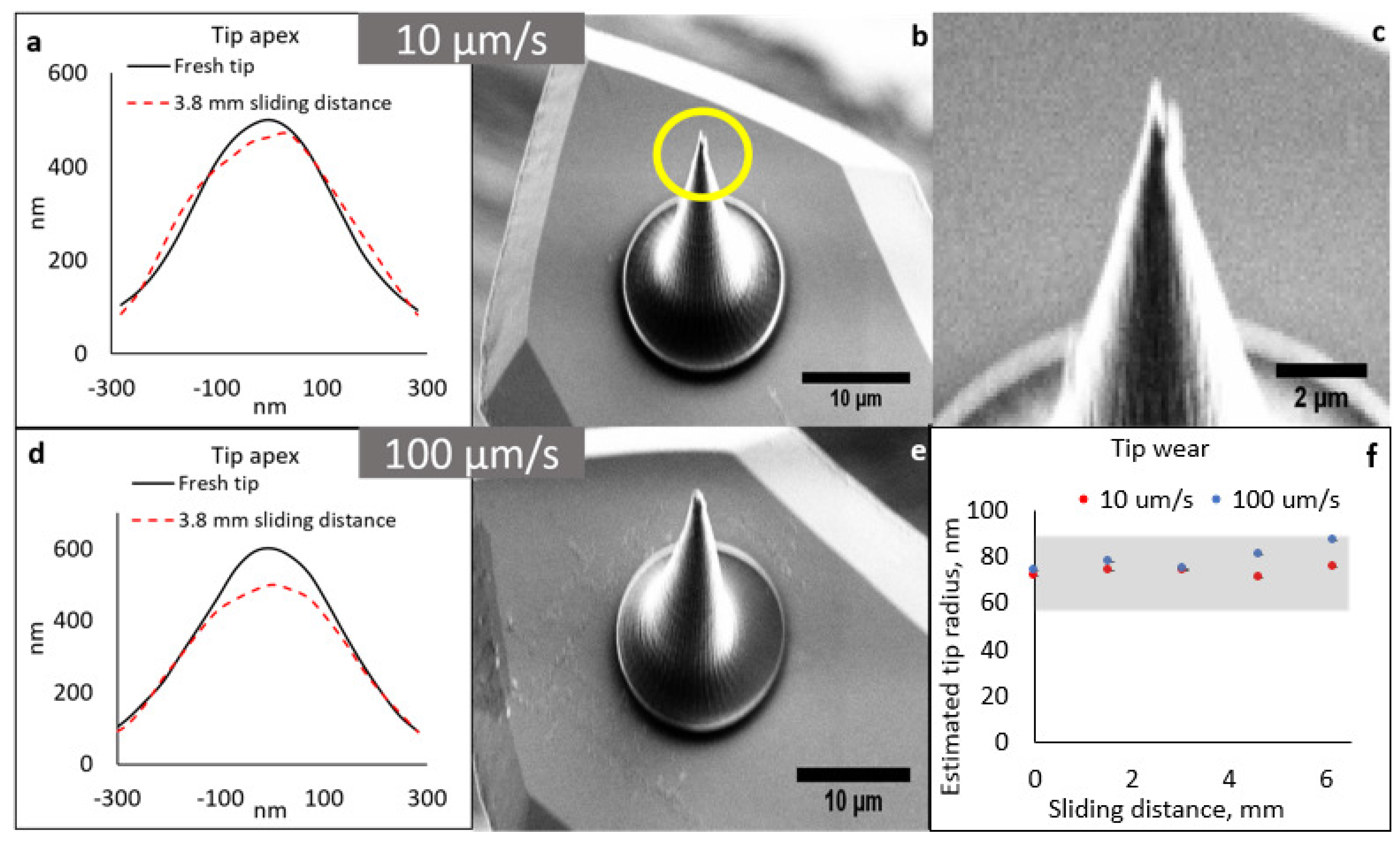

3.2.2. Wear Tests

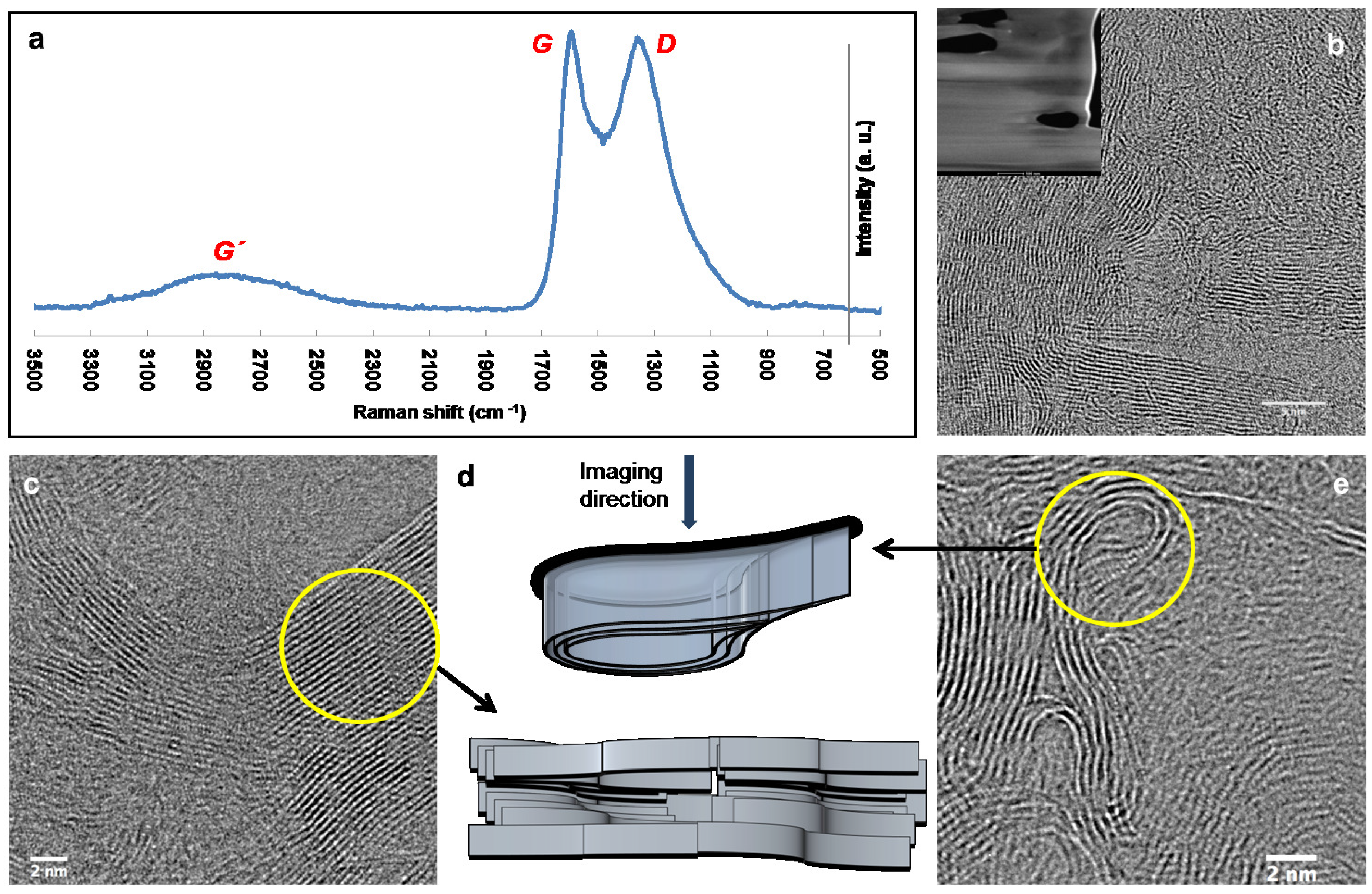

3.3. Material Characterization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Schwarz, U.D.; Haefke, H.; Reimann, P.; Güntherodt, H.J. Tip artefacts in scanning force microscopy. J. Microsc. 1994, 173, 183–197. [Google Scholar] [CrossRef]

- Eaton, P.; West, P. Atomic Force Microscopy; Oxford University Press: Oxford, UK, 2010. [Google Scholar]

- Boisen, A.; Hansen, O.; Bouwstra, S. AFM probes with directly fabricated tips. J. Micromech. Microeng. 1996, 6, 58. [Google Scholar] [CrossRef]

- Mesa, B.; Magonov, S. Novel diamond/sapphire probes for scanning probe microscopy applications. J. Phys. Conf. Ser. 2007, 61, 770–774. [Google Scholar] [CrossRef]

- Neuzil, P.; Nagarajan, R. The formation of sharp AFM tips by single step etching. J. Micromech. Microeng. 2006, 16, 1298. [Google Scholar] [CrossRef]

- Lee, J.S.; Song, J.; Kim, S.O.; Kim, S.; Lee, W.; Jackman, J.A.; Kim, D.; Cho, N.J.; Lee, J. Multifunctional hydrogel nano-probes for atomic force microscopy. Nat. Commun. 2016, 7, 11566. [Google Scholar] [CrossRef] [PubMed]

- Göring, G.; Dietrich, P.I.; Blaicher, M.; Sharma, S.; Korvink, J.G.; Schimmel, T.; Koos, C.; Hölscher, H. Tailored probes for atomic force microscopy fabricated by two-photon polymerization. Appl. Phys. Lett. 2016, 109, 063101. [Google Scholar] [CrossRef]

- Wilson, N.R.; Macpherson, J.V. Carbon nanotube tips for atomic force microscopy. Nat. Nanotechnol. 2009, 4, 483–491. [Google Scholar] [CrossRef] [PubMed]

- Drew, M.E.; Konicek, A.R.; Jaroenapibal, P.; Carpick, R.W.; Yamakoshi, Y. Nanocrystalline diamond AFM tips for chemical force spectroscopy: Fabrication and photochemical functionalization. J. Mater. Chem. 2012, 22, 12682–12688. [Google Scholar] [CrossRef]

- Schueller, O.J.A.; Brittain, S.T.; Marzolin, C.; Whitesides, G.M. Fabrication and Characterization of Glassy Carbon MEMS. Chem. Mater. 1997, 9, 1399–1406. [Google Scholar] [CrossRef]

- Bauer, J.; Schroer, A.; Schwaiger, R.; Kraft, O. Approaching theoretical strength in glassy carbon nanolattices. Nat. Mater. 2016, 15, 438–443. [Google Scholar] [CrossRef] [PubMed]

- Kinoshita, K. Carbon: Electrochemical and Physicochemical Properties; Wiley: Hoboken, NJ, USA, 1988. [Google Scholar]

- Sharma, S.; Madou, M. Micro and nano patterning of carbon electrodes for bioMEMS. Bioinspired Biomim. Nanobiomater. 2012, 1, 252–265. [Google Scholar] [CrossRef]

- Jenkins, G.M. Polymeric Carbons—Carbon Fibre, Glass and Char; Cambridge University Press: Cambridge, UK, 1976. [Google Scholar]

- Harris, P.J.F. New Perspectives on the Structure of Graphitic Carbons. Crit. Rev. Solid State Mater. Sci. 2005, 30, 235–253. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, A.; Cho, Y.K.; Madou, M. Increased Graphitization in Electrospun Single Suspended Carbon Nanowires Integrated with Carbon-MEMS and Carbon-NEMS Platforms. ACS Appl. Mater. Interfaces 2012, 4, 34–39. [Google Scholar] [CrossRef] [PubMed]

- Lewis, J.; Redfern, B.; Cowlard, F. Vitreous carbon as a crucible material for semiconductors. Solid-State Electron. 1963, 6, 251–254. [Google Scholar] [CrossRef]

- Biryukova, G.; Shablygin, M.; Mikhailov, N.; Andrianov, K. Relationship between the conditions of pyrolysis and the structural and chemical transformation of cellulose hydrate. Polym. Sci. USSR 1973, 15, 1762–1766. [Google Scholar] [CrossRef]

- Litvinov, I.; Kargin, V. Effect of heat treatment on the supermolecular structure of polyacrylonitrile. Polym. Sci. USSR 1973, 15, 1811–1819. [Google Scholar] [CrossRef]

- Sharma, S.; Kamath, R.; Madou, M. Porous glassy carbon formed by rapid pyrolysis of phenol-formaldehyde resins and its performance as electrode material for electrochemical double layer capacitors. J. Anal. Appl. Pyrolysis 2014, 108, 12–18. [Google Scholar] [CrossRef]

- Sharma, S. Microstructural Tuning of Glassy Carbon for Electrical and Electrochemical Sensor Applications. Ph.D. Thesis, University of California, Irvine, CA, USA, 2013. [Google Scholar]

- Nathan, M.I.; Smith, J.E., Jr.; Tu, K.N. Raman spectra of glassy carbon. J. Appl. Phys. 1974, 45, 2370. [Google Scholar] [CrossRef]

- Ferrari, A.C. Raman spectroscopy of graphene and graphite: Disorder, electron-phonon coupling, doping and nonadiabatic effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Franklin, R.E. Crystallite Growth in Graphitizing and Non-Graphitizing Carbons. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. 1951, 209, 196–218. [Google Scholar] [CrossRef]

- Ugarte, D. Morphology and structure of graphitic soot particles generated in arc-discharge C60 production. Chem. Phys. Lett. 1992, 198, 596–602. [Google Scholar] [CrossRef]

- Yu, J.; Liu, J.; Zhang, J.; Wu, J. TEM investigation of FIB induced damages in preparation of metal material TEM specimens by FIB. Mater. Lett. 2006, 60, 206–209. [Google Scholar] [CrossRef]

- Giannuzzi, L.; Stevie, F. A review of focused ion beam milling techniques for TEM specimen preparation. Micron 1999, 30, 197–204. [Google Scholar] [CrossRef]

- Endo, T.; Yamada, H.; Sumomogi, T.; Kuwahara, K.; Morita, S.; Kino, T. Atomic-resolution images of structural defects on microcrystalline graphite. Ultramicroscopy 1992, 42, 674–678. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zakhurdaeva, A.; Dietrich, P.-I.; Hölscher, H.; Koos, C.; Korvink, J.G.; Sharma, S. Custom-Designed Glassy Carbon Tips for Atomic Force Microscopy. Micromachines 2017, 8, 285. https://doi.org/10.3390/mi8090285

Zakhurdaeva A, Dietrich P-I, Hölscher H, Koos C, Korvink JG, Sharma S. Custom-Designed Glassy Carbon Tips for Atomic Force Microscopy. Micromachines. 2017; 8(9):285. https://doi.org/10.3390/mi8090285

Chicago/Turabian StyleZakhurdaeva, Anna, Philipp-Immanuel Dietrich, Hendrik Hölscher, Christian Koos, Jan G. Korvink, and Swati Sharma. 2017. "Custom-Designed Glassy Carbon Tips for Atomic Force Microscopy" Micromachines 8, no. 9: 285. https://doi.org/10.3390/mi8090285