Vibration-Assisted Roll-Type Polishing System Based on Compliant Micro-Motion Stage

Abstract

:1. Introduction

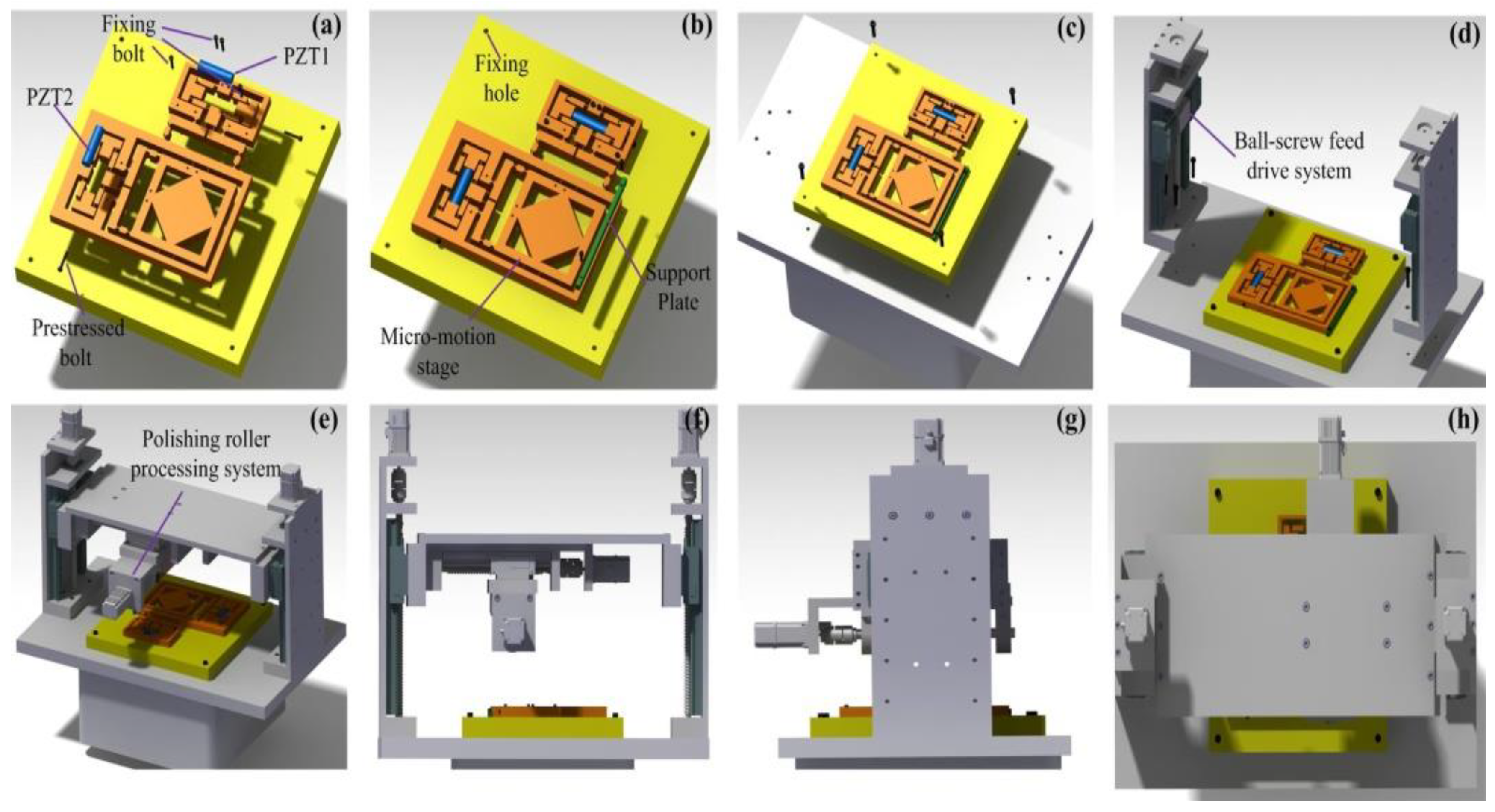

2. Structural Design and Prototype Development

2.1. Assembly of the EARP System

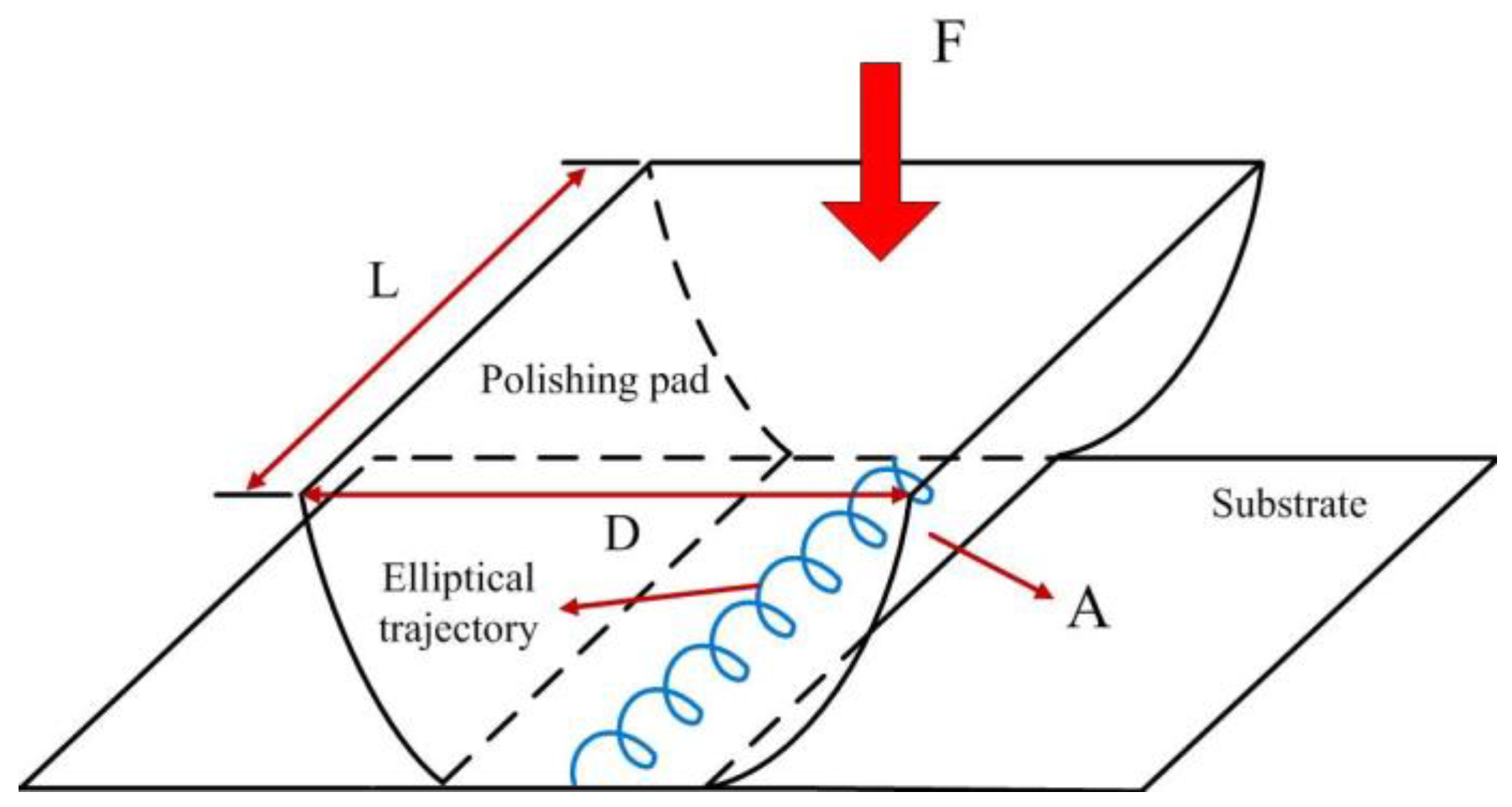

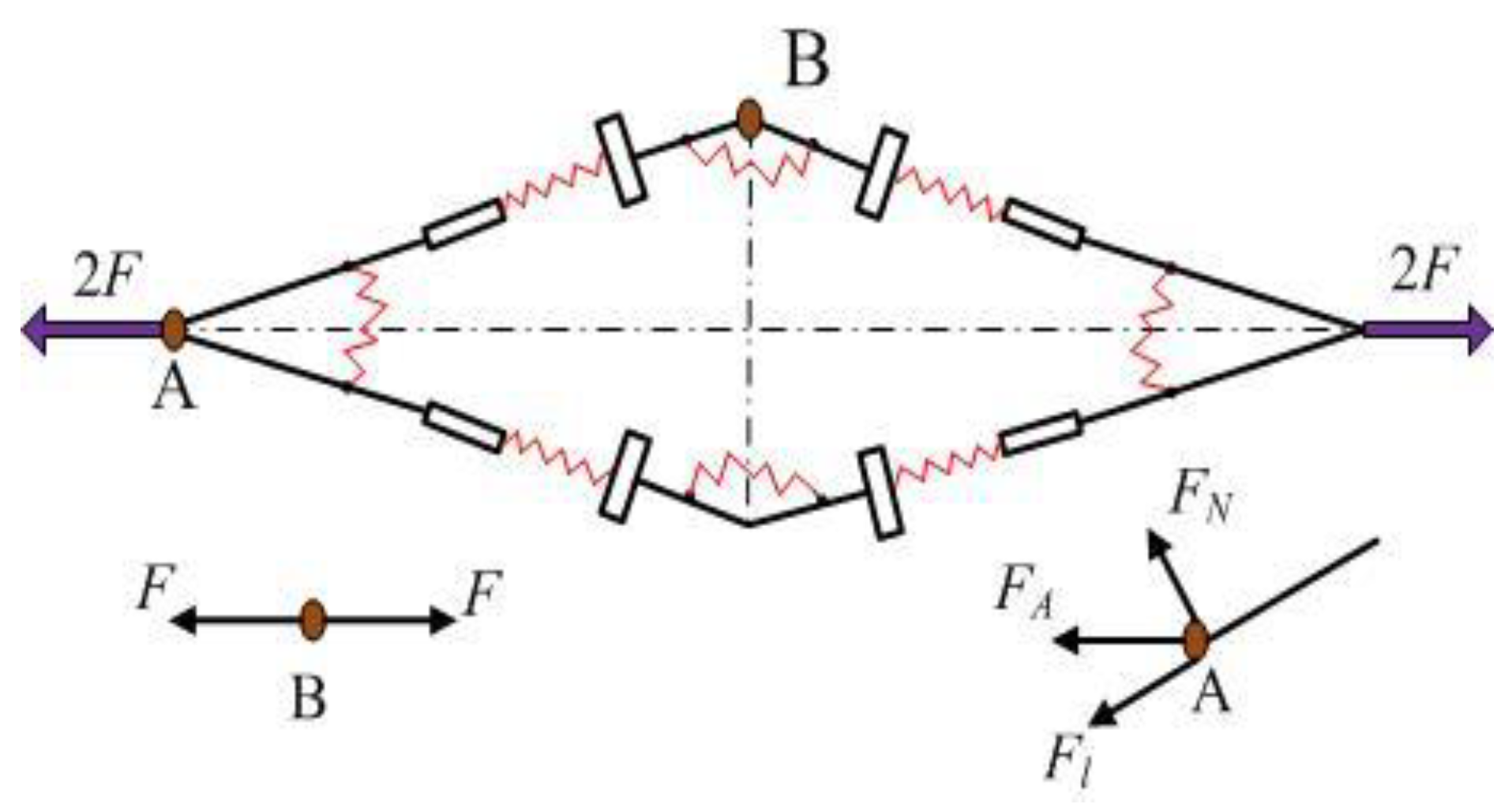

2.2. Vibration Trajectory of the XY Micro-Motion Stage

2.3. Design of the EARP System

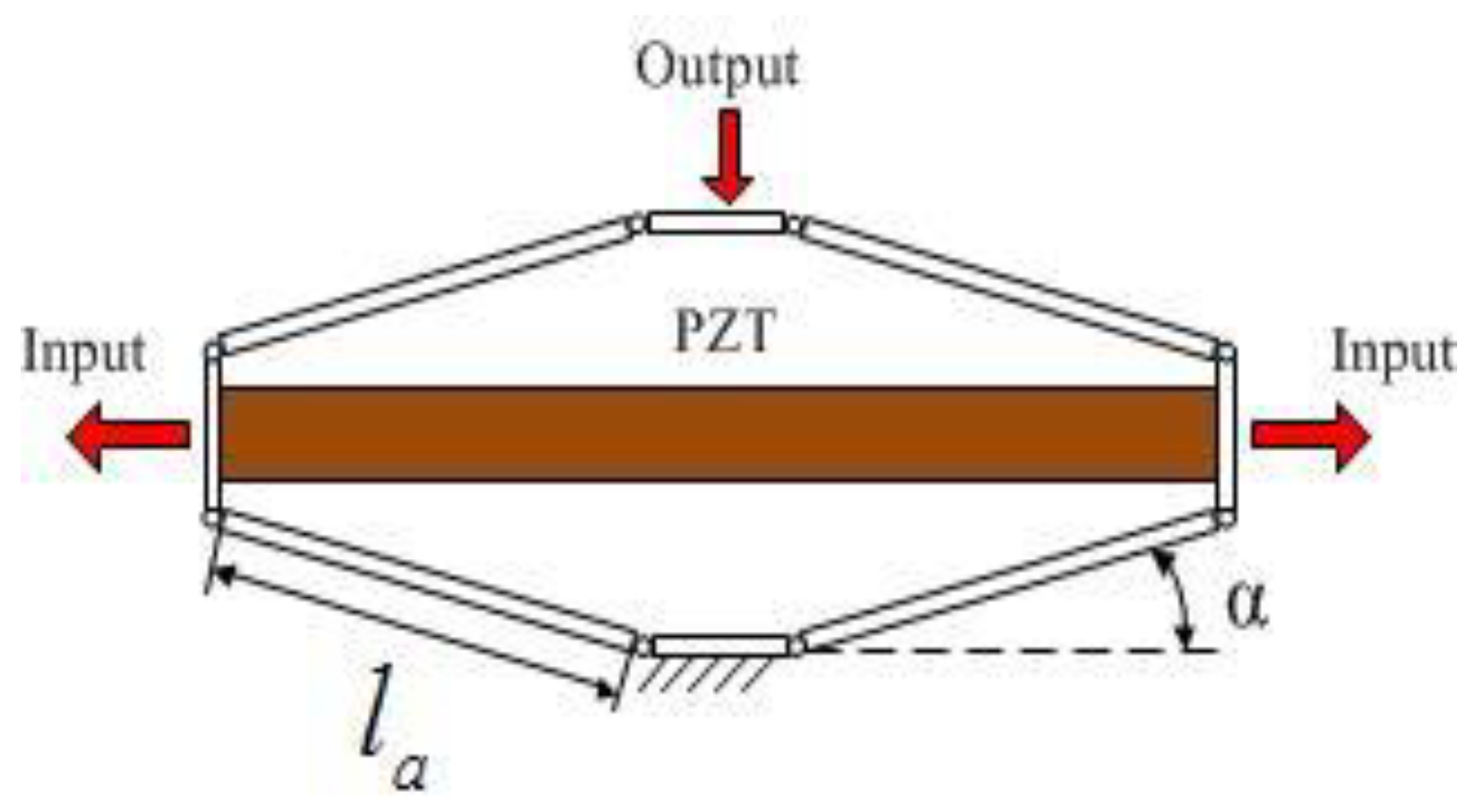

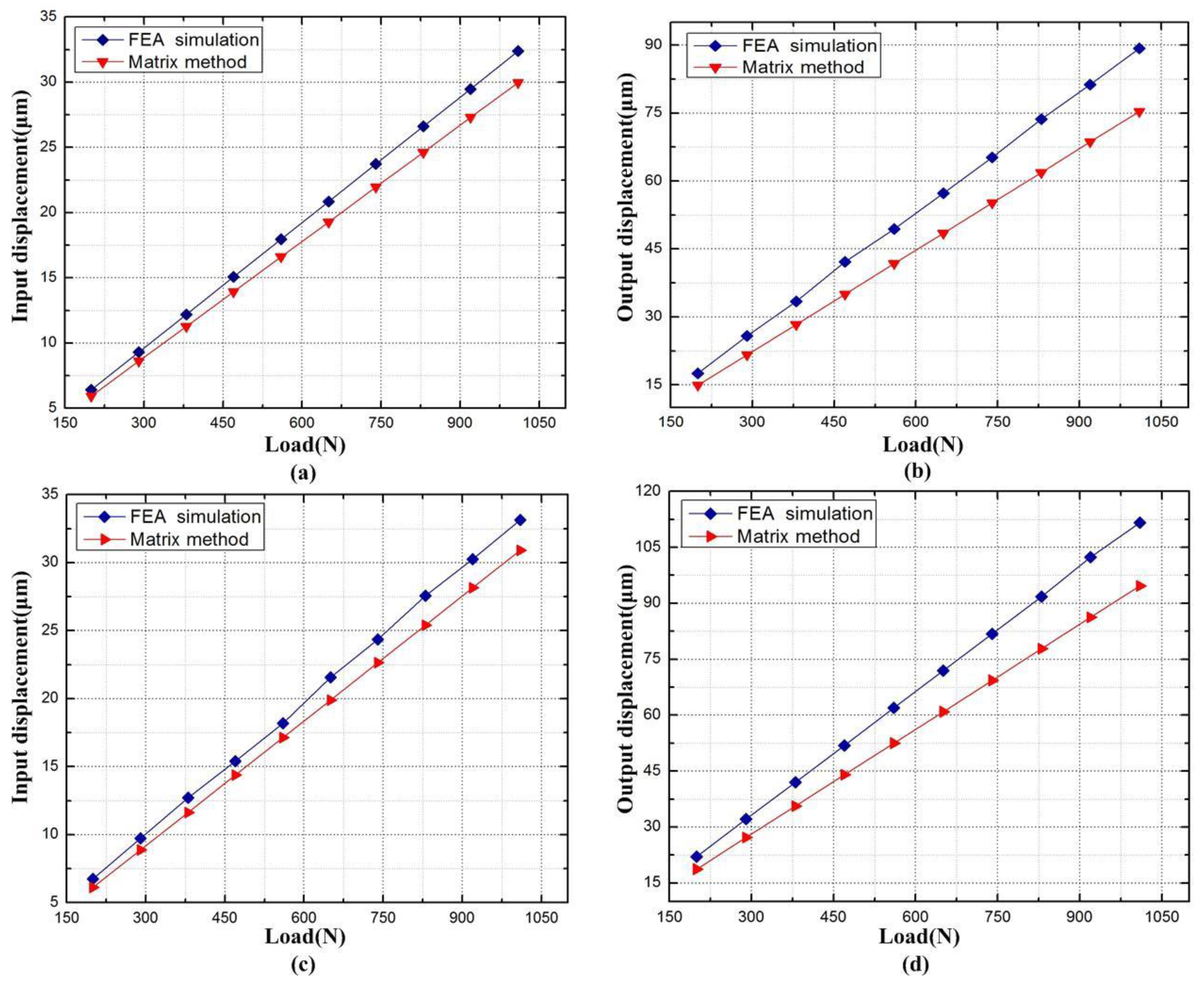

3. Determination of Amplification Ratio and Compliance Matrix Modeling

3.1. Determination of Amplification Ratio and Compliance Matrix Modelling

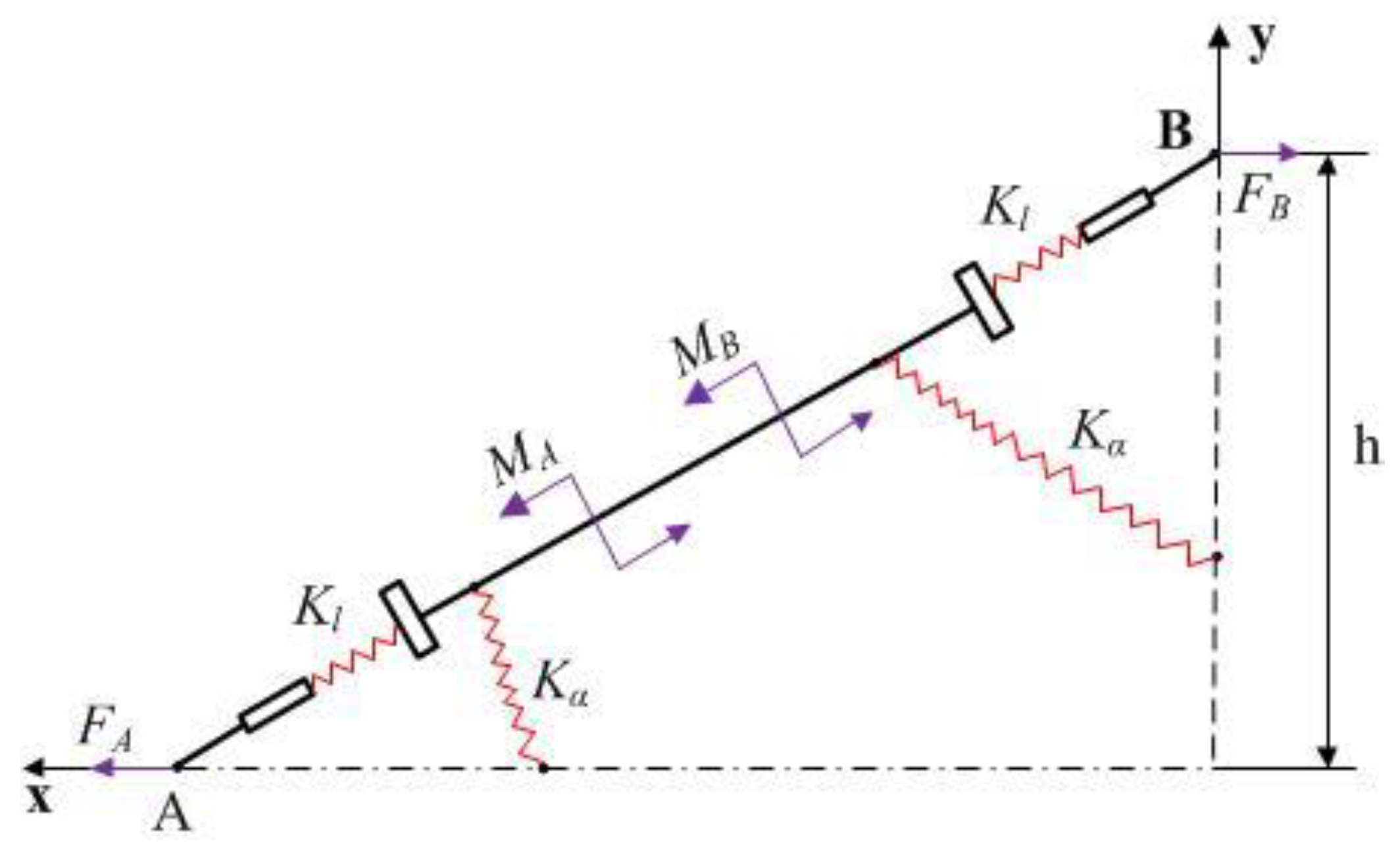

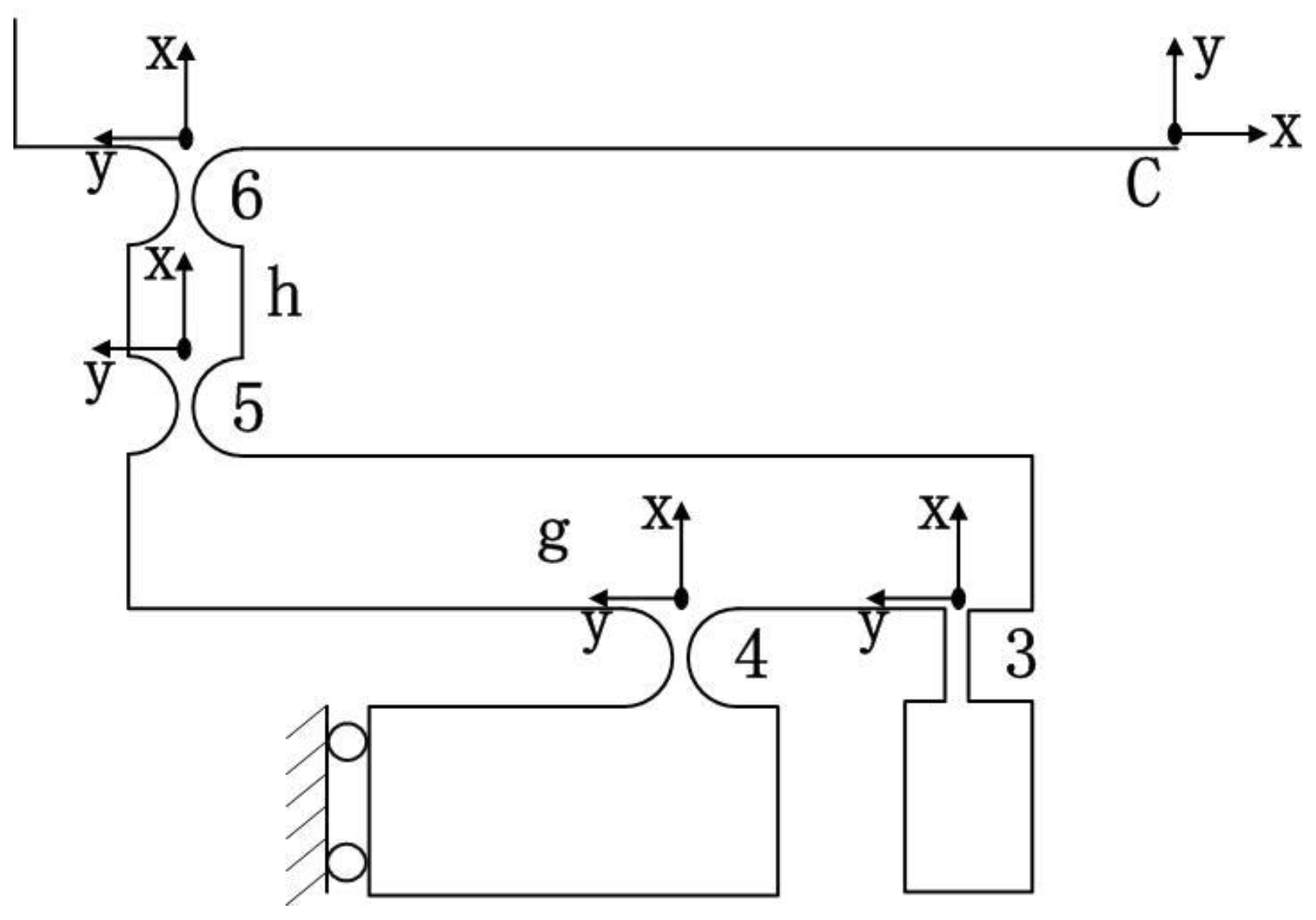

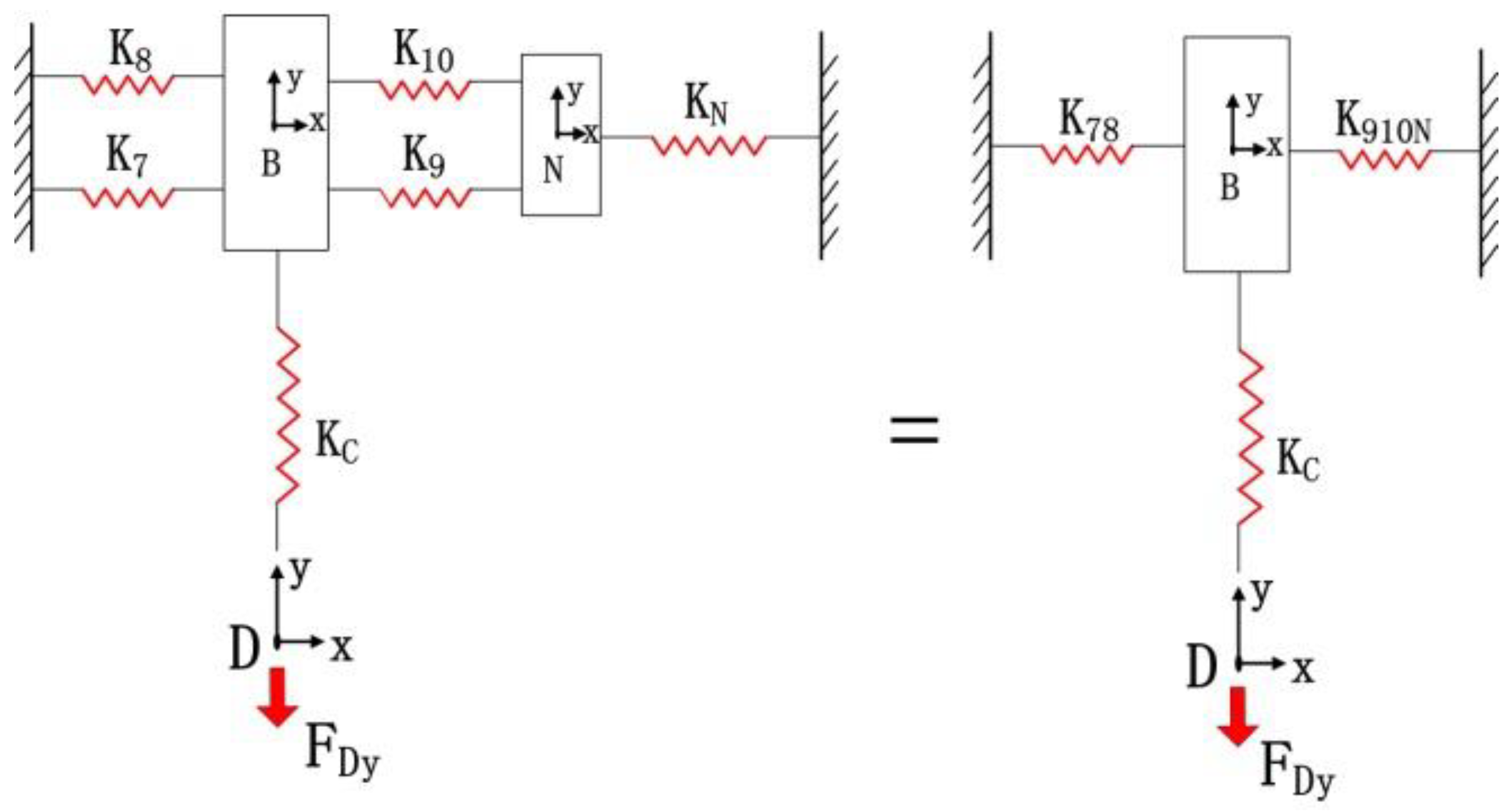

3.2. Compliance Matrix Modelling of XY Micro-Motion Stage

3.2.1. Compliance Matrix Method

3.2.2. Output Compliance Modelling

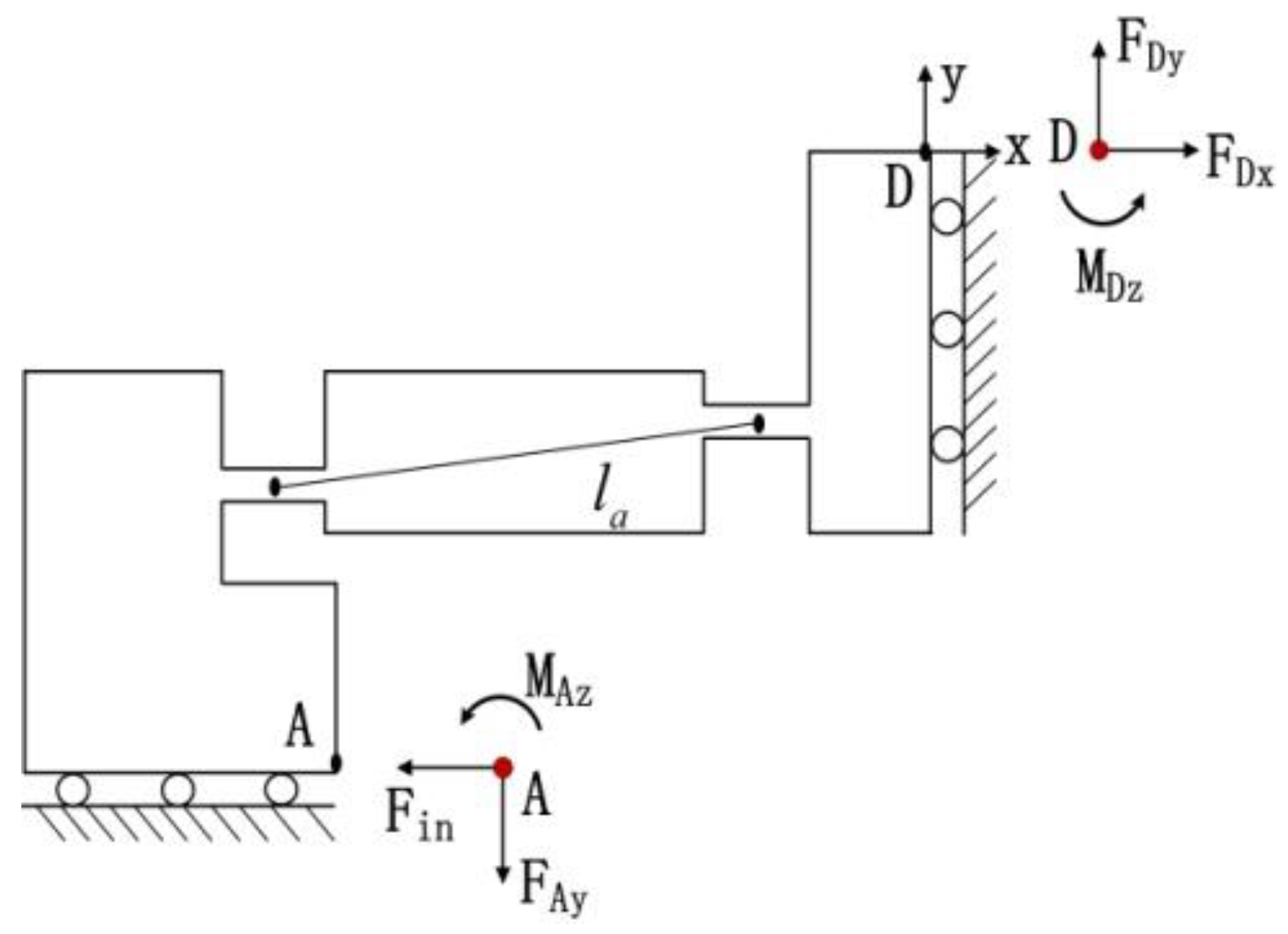

3.2.3. Input Compliance Modelling

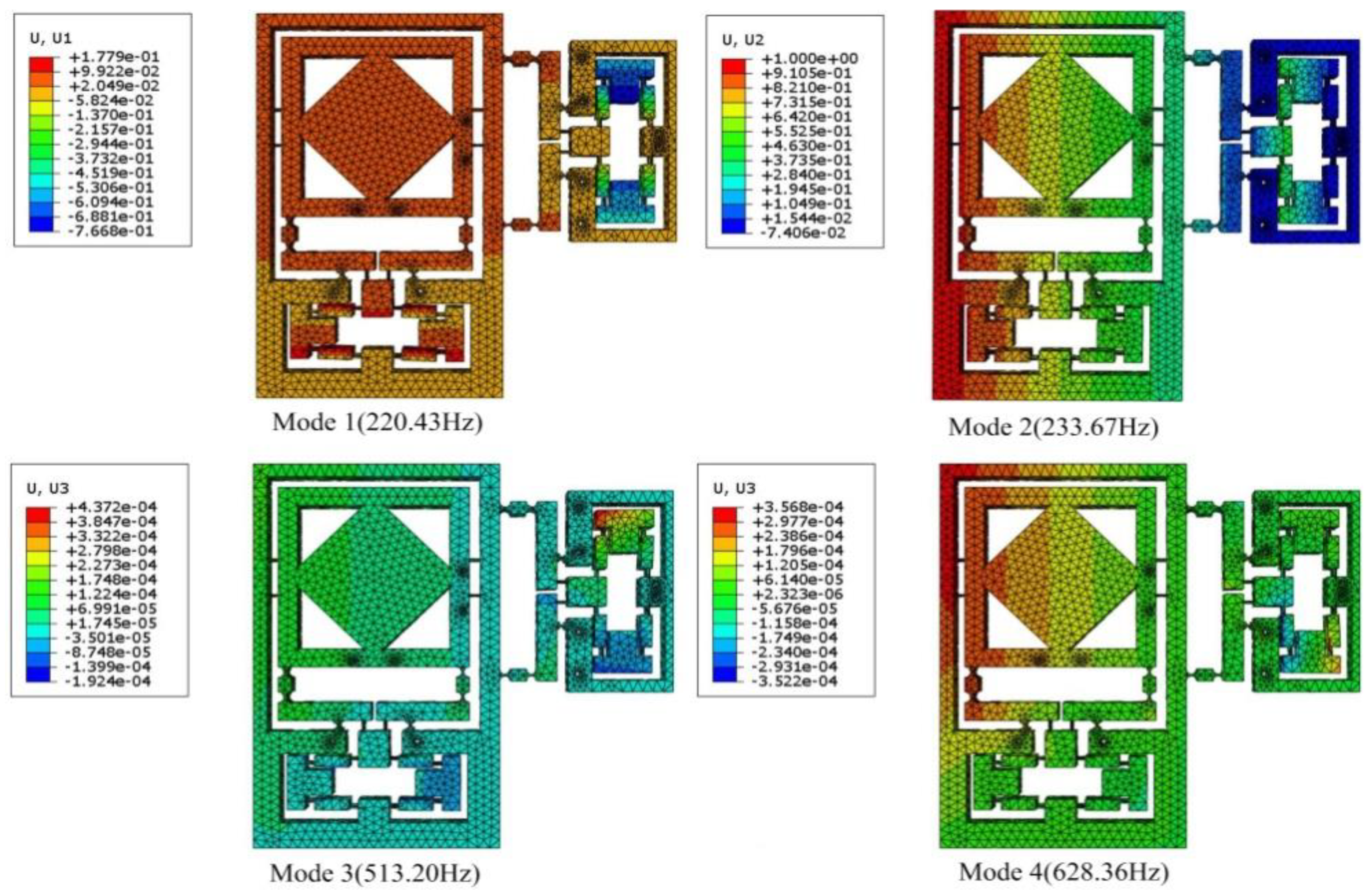

4. Dynamics Model

5. Workspace and Material Analysis

5.1. Maximum Stress Subject to Rotation

5.2. Maximum Tensile Stress Calculation

6. Dimension Optimization

- (1)

- Objective: maximize the natural frequency (f)

- (2)

- Related parameters: r, t, w, ta1, ta2, la, and lb

- (3)

- Constraints: parameters of right-circular flexure hinge: ; amplification ratio:; constraint Equations (54), (56), and (58); ranges of parameters: , , , , , , and .

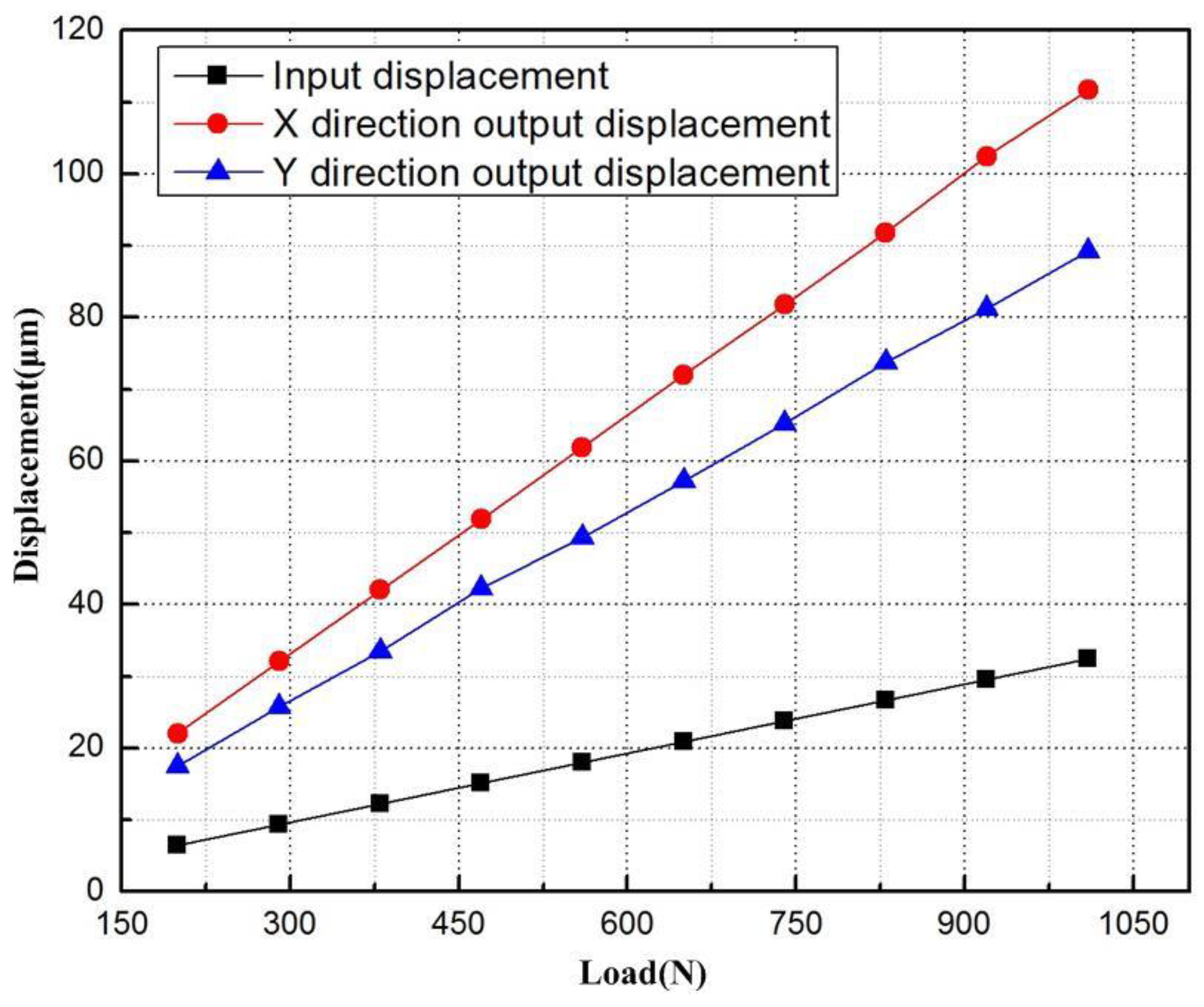

7. Performance Evaluation with Finite-Element Analysis

8. Testing Experiments

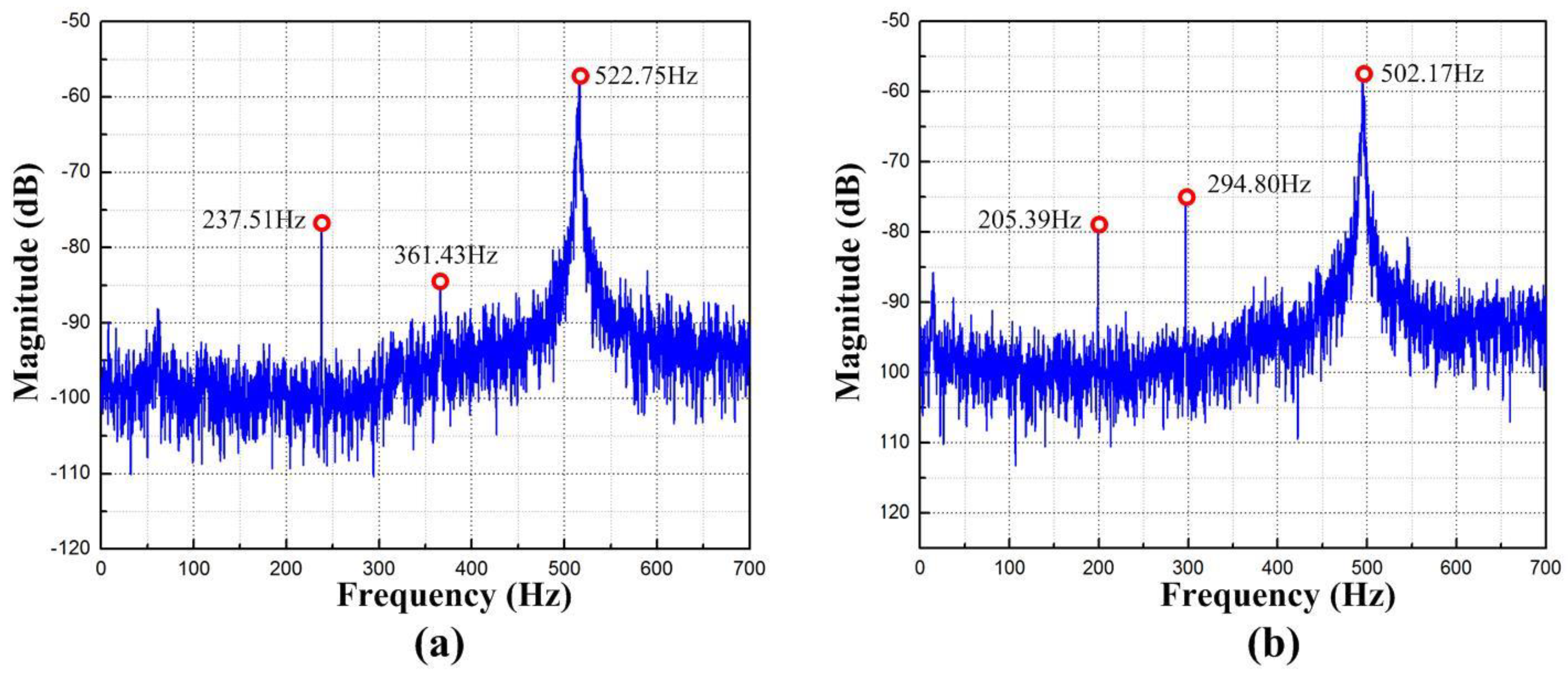

8.1. Sine Sweep Response

8.2. Stroke and Resolution Test

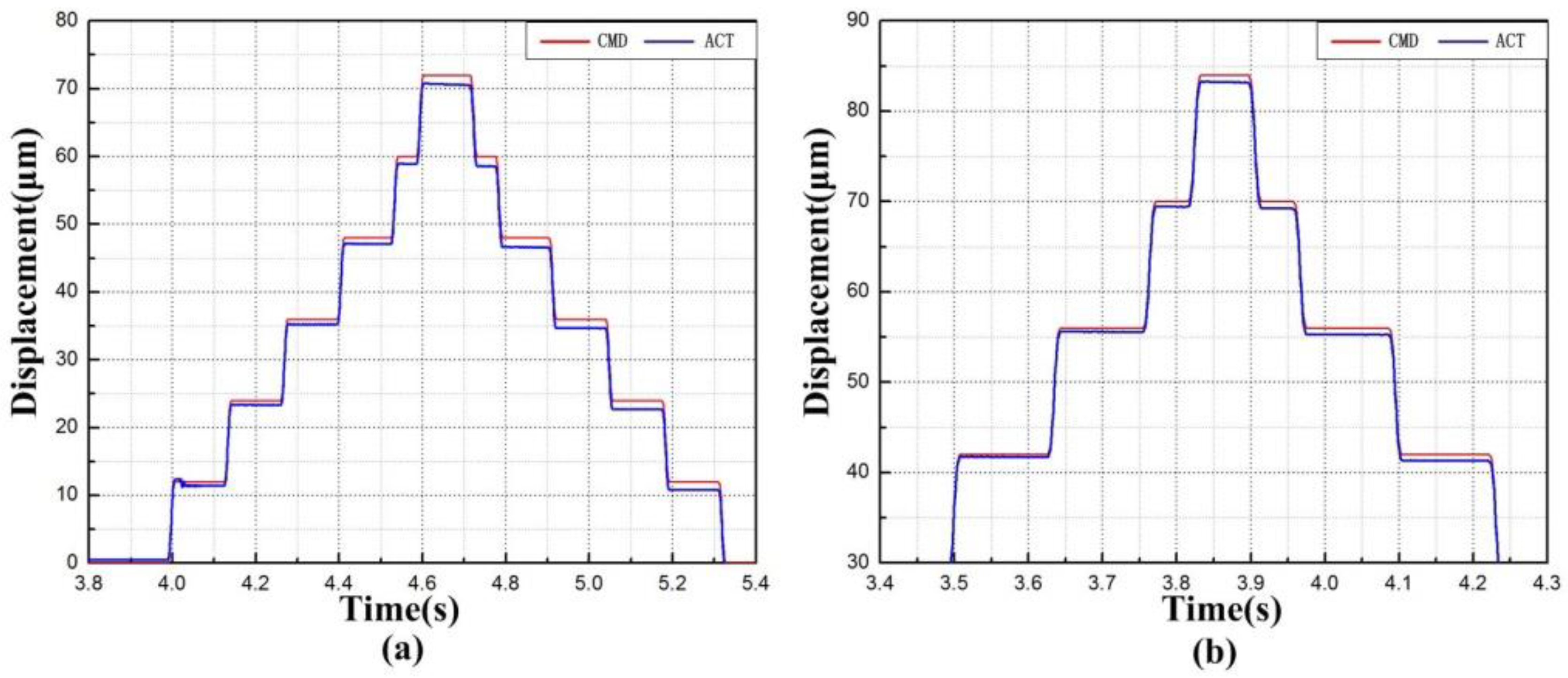

8.3. Step Response and Sine Response Test

9. Polishing Experiment

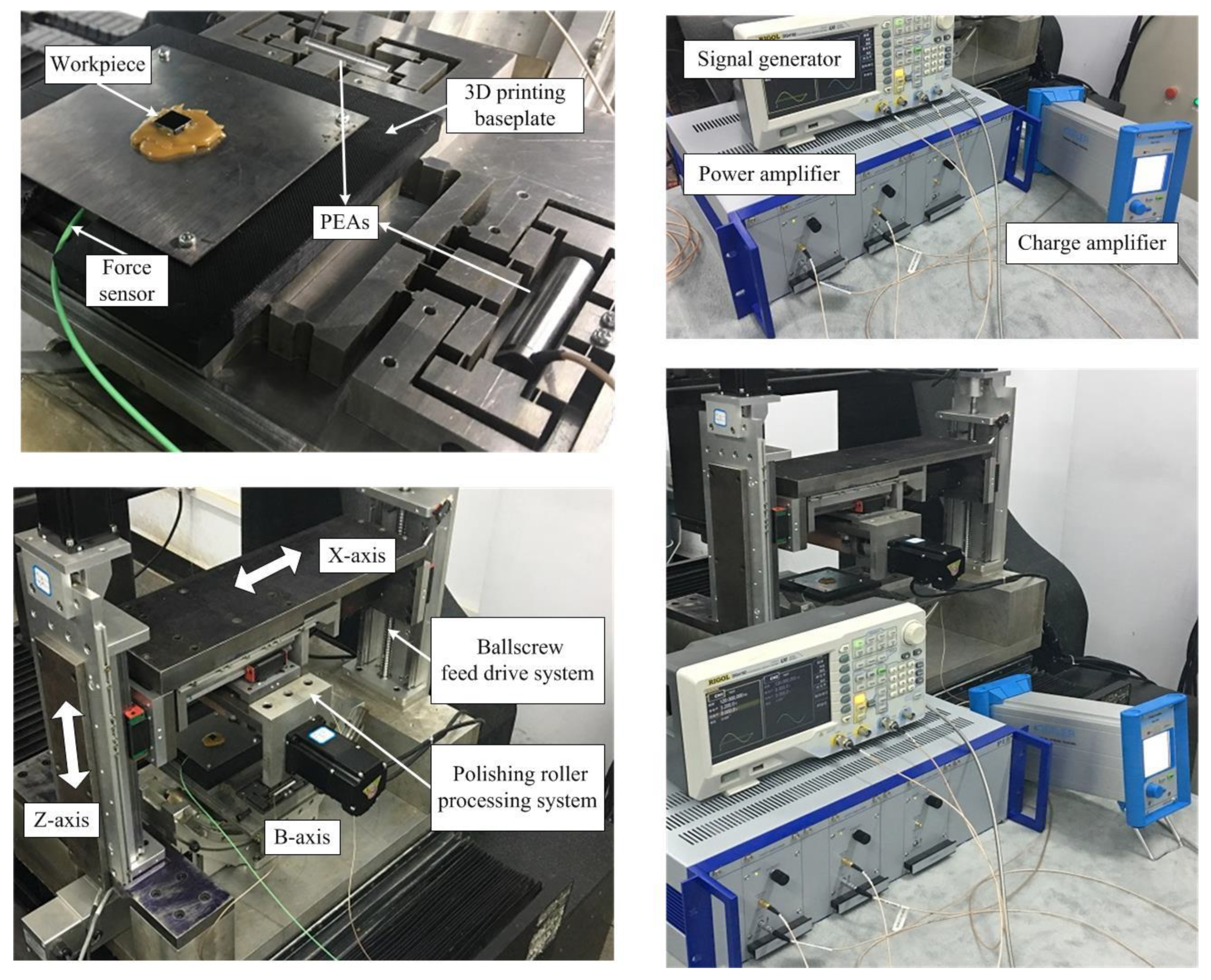

9.1. Experiment Setup

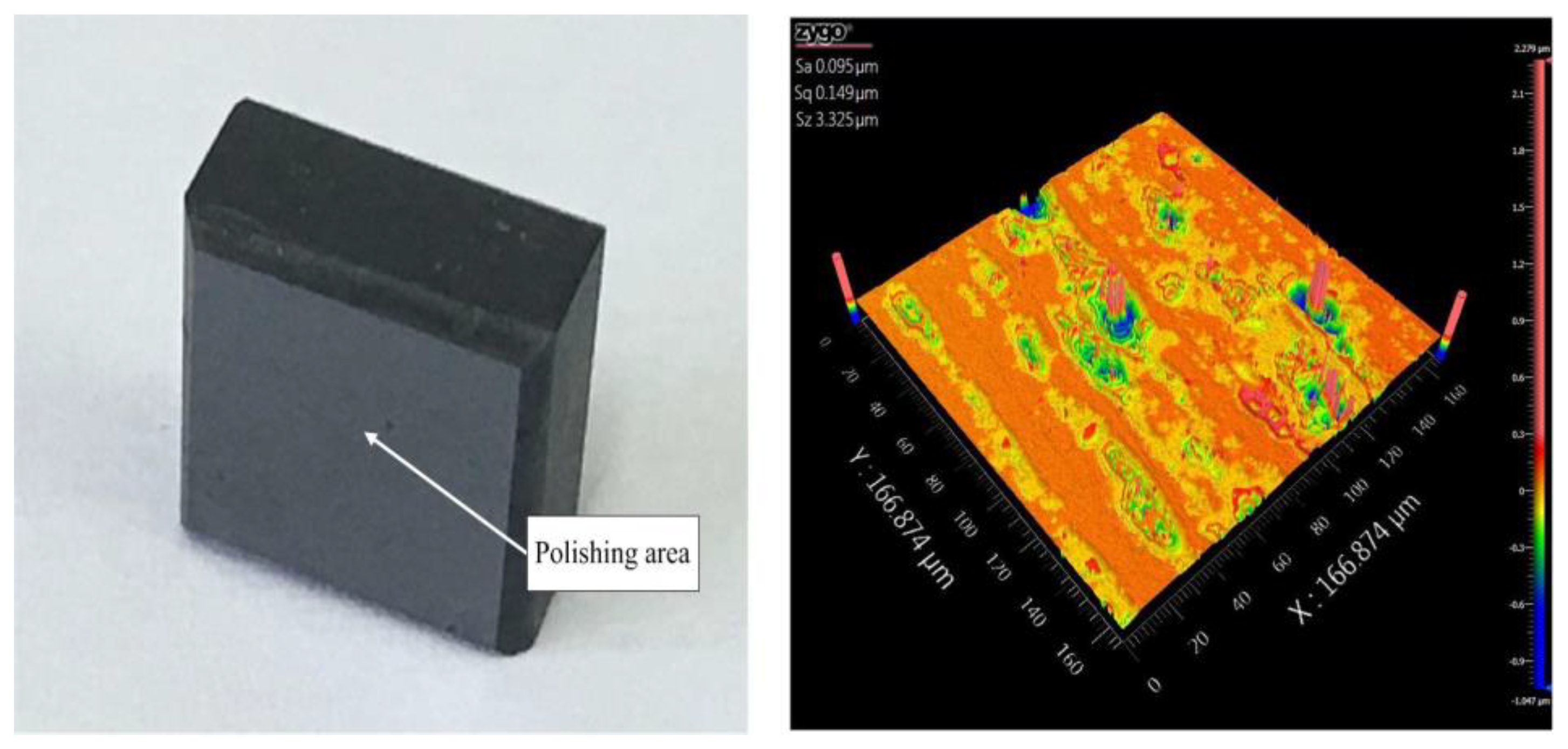

9.2. Results and Discussions

10. Conclusions

- (1)

- It is capable to deliver large 2D vibration amplitudes, while maintaining favourable resolution. Experimental tests performed show that the vibration strokes in the x- and y-directions can reach 71 μm and 83 μm, respectively, while the resolution at points B and C of the micro-motion stage are 70 nm and 56 nm, respctively.

- (2)

- Because of the high stiffness of the proposed flexure-based stage, natural frequencies that meet the requirements are also achieved, which were examined to be 205.39 Hz and 237.51 Hz in the x- and y-directions, respectively.

- (3)

- Compared with the non-vibration roll-type polishing system, 44 nm Sa and 856 nm Sz are improved by proposed EARP system used independently developed polishing machine. Accordingly, the micro-motion stage could increase the number of abrasive particles involved in polishing.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.; Zhang, J.; Han, J.; He, X.; Yao, W. Large-scale fabrication of lightweight Si/SiC ceramic composite optical mirror. Mater. Lett. 2004, 58, 1204–1208. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, X.; Zheng, L.; Xue, D. High-performance grinding of a 2-m scale silicon carbide mirror blank for the space-based telescope. Int. J. Adv. Manuf. Technol. 2017, 89, 463–473. [Google Scholar] [CrossRef]

- Agarwal, S.; Rao, P.V. Grinding characteristics, material removal and damage formation mechanisms in high removal rate grinding of silicon carbide. Int. J. Mach. Tools Manuf. 2010, 50, 1077–1087. [Google Scholar] [CrossRef]

- Gu, Y.; Zhu, W.; Lin, J.; Lu, M.; Kang, M. Subsurface Damage in Polishing Process of Silicon Carbide Ceramic. Materials 2018, 11, 506. [Google Scholar] [CrossRef] [PubMed]

- López de Lacalle, L.N.; Rodriguez, A.; Lamikiz, A.; Celaya, A.; Alberdi, R. Five-axis machining and burnishing of complex parts for the improvement of surface roughness. Mater. Manuf. Process. 2011, 26, 997–1003. [Google Scholar] [CrossRef]

- Becker, K. M400 and P400-A pair of machines for computer-controlled fine correction of optical surfaces. In Proceedings of the International Congress for Ultraprecision Technology, Aachen, Germany, 19 May 1988; p. 212. [Google Scholar]

- Jones, R.A. Computer-controlled optical surfacing with orbital tool motion. Opt. Eng. 1986, 25, 256–785. [Google Scholar] [CrossRef]

- Mori, Y.; Ikawa, N.; Okuda, T.; Yamagata, K. Numerically controlled elastic emission machining. Technol. Rep. Osaka Univ. 1976, 26, 283–294. [Google Scholar]

- Mori, Y.; Yamauchi, K.; Endo, K. Elastic emission machining. Precis. Eng. 1987, 9, 123–128. [Google Scholar] [CrossRef]

- Suzuki, H.; Moriwaki, T.; Okino, T.; Ando, Y. Development of ultrasonic vibration assisted polishing machine for micro aspheric die and mold. CIRP. Ann.-Manuf. Technol. 2006, 55, 385–388. [Google Scholar] [CrossRef]

- Suzuki, H.; Hamada, S.; Okino, T.; Kondo, M.; Yamagata, Y. Ultraprecision finishing of micro-aspheric surface by ultrasonic two-axis vibration assisted polishing. CIRP Ann. 2010, 59, 347–350. [Google Scholar] [CrossRef]

- Zhao, Q.; Sun, Z.; Guo, B. Material removal mechanism in ultrasonic vibration assisted polishing of micro cylindrical surface on SiC. Int. J. Mach. Tools Manuf. 2016, 103, 28–39. [Google Scholar] [CrossRef]

- Liang, Z.; Wang, X.; Wu, Y.; Xie, L.; Jiao, L.; Zhao, W. Experimental study on brittle–ductile transition in elliptical ultrasonic assisted grinding (EUAG) of monocrystal sapphire using single diamond abrasive grain. Int. J. Mach. Tools Manuf. 2013, 71, 41–51. [Google Scholar] [CrossRef]

- Yu, T.; Yang, X.; An, J.; Yu, X.; Zhao, J. Material removal mechanism of two-dimensional ultrasonic vibration assisted polishing Inconel718 nickel-based alloy. Int. J. Adv. Manuf. Techol. 2018, 96, 657–667. [Google Scholar] [CrossRef]

- Chern, G.L.; Chang, Y.C. Using two-dimensional vibration cutting for micro-milling. Int. J. Mach. Tools Manuf. 2006, 46, 659–666. [Google Scholar] [CrossRef]

- Chen, W.; Huo, D.; Shi, Y.; Hale, J.M. State-of-the-art review on vibration-assisted milling: Principle, system design, and application. Int. J. Adv. Manuf. Technol. 2018, 97, 2033–2049. [Google Scholar] [CrossRef]

- Chee, S.K.; Suzuki, H.; Uehara, J.; Yano, T.; Higuchi, T.; Lin, W. A Low Contact Force Polishing System for Micro Molds that Utilizes 2-Dimensional Low Frequency Vibrations (2DLFV) with Piezoelectric Actuators (PZT) and a Mechanical Transformer Mechanism. IJAT 2013, 7, 71–82. [Google Scholar] [CrossRef]

- Martínez, S.; Lamikiz, A.; Ukar, E.; Calleja, A.; Arrizubieta, J.A.; de Lacalle, L.L. Analysis of the regimes in the scanner-based laser hardening process. Opt. Laser Eng. 2017, 90, 72–80. [Google Scholar] [CrossRef]

- Chen, W.; Zheng, L.; Huo, D.; Chen, Y. Surface texture formation by non-resonant vibration assisted micro milling. J. Micromech. Microeng. 2018, 28, 025006. [Google Scholar] [CrossRef] [Green Version]

- Gu, Y.; Zhou, Y.; Lin, J.; Lu, M.; Zhang, C.; Chen, X. Design, analysis, and testing of a flexure-based vibration-assisted polishing device. AIP Adv. 2018, 8, 055113. [Google Scholar] [CrossRef]

- Wang, H.; Lee, H.; Jeong, H. Statistical Analysis on Process Variables in Linear Roll-CMP. J. Korean Soc. Tribol. Lubr. Eng. 2014, 30, 139–145. [Google Scholar] [Green Version]

- Lee, H.; Wang, H.; Park, J.; Jeong, H. Experimental investigation of process parameters for roll-type linear chemical mechanical polishing (Roll-CMP) system. Precis. Eng. 2014, 38, 928–934. [Google Scholar] [CrossRef]

- Lee, H. Mathematical modelling of material removal rate in roll-type linear CMP (roll-CMP) process: Effect of polishing pad. Int. J. Precis. Eng. Manuf. 2016, 17, 495–501. [Google Scholar] [CrossRef]

- Tabernero, I.; Lamikiz, A.; Martinez, S.; Ukar, E.; De Lacalle, L.L. Modelling of energy attenuation due to powder flow-laser beam interaction during laser cladding process. J. Mater. Process. Technol. 2012, 212, 516–522. [Google Scholar] [CrossRef]

- Ma, H.W.; Yao, S.M.; Wang, L.Q.; Zhong, Z. Analysis of the displacement amplification ratio of bridge-type flexure hinge. Sens. Actuator A Phys. 2006, 132, 730–736. [Google Scholar] [CrossRef]

- Qi, K.Q.; Xiang, Y.; Fang, C.; Zhang, Y.; Yu, C.S. Analysis of the displacement amplification ratio of bridge-type mechanism. Mech. Mach. Theory 2015, 87, 45–56. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.H.; Kim, S.H.; Kwak, Y.K. Development and optimization of 3-D bridge-type hinge mechanisms. Sens. Actuator A Phys. 2004, 116, 530–538. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, Z. Design calculations for flexure hinges. Rev. Sci. Instrum. 2002, 73, 3101–3106. [Google Scholar] [CrossRef]

- Pham, H.H.; Chen, I.M. Stiffness modelling of flexure parallel mechanism. Precis. Eng. 2005, 29, 467–478. [Google Scholar] [CrossRef]

- Li, Y.; Huang, J.; Tang, H. A compliant parallel XY micromotion stage with complete kinematic decoupling. IEEE. Trans. Autom. Sci. Eng. 2012, 9, 538–553. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Q. Design and analysis of a totally decoupled flexure-based XY parallel micromanipulator. IEEE Trans. Robot. 2009, 25, 645–657. [Google Scholar]

- Olvera, D.; De Lacalle, L.L.; Compeán, F.I.; Fz-Valdivielso, A.; Lamikiz, A.; Campa, F.J. Analysis of the tool tip radial stiffness of turn-milling centers. Int. J. Adv. Manuf. Technol. 2012, 60, 883–891. [Google Scholar] [CrossRef]

- Xiao, S.; Li, Y. Optimal Design, Fabrication, and Control of an XY Micropositioning Stage Driven by Electromagnetic Actuators. IEEE. Trans. Ind. Electron. 2013, 60, 4613–4626. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Q. A totally decoupled piezo-driven XYZ flexure parallel micropositioning stage for micro/nanomanipulation. IEEE. Trans. Autom. Sci. Eng. 2011, 8, 265–279. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Q. A novel piezoactuated XY stage with parallel, decoupled, and stacked flexure structure for micro-/nanopositioning. IEEE. Trans. Ind. Electron. 2011, 58, 3601–3615. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey wolf optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Mirjalili, S. How effective is the Grey Wolf optimizer in training multi-layer perceptrons. Appl. Intell. 2015, 43, 150–161. [Google Scholar] [CrossRef]

- Jia, S.; Yuan, Q.; Cai, W.; Li, M.; Li, Z. Energy modeling method of machine-operator system for sustainable machining. Energy Convers. Manag. 2018, 172, 265–276. [Google Scholar] [CrossRef]

- Cai, K.; Tian, Y.; Wang, F.; Zhang, D.; Shirinzadeh, B. Development of a piezo-driven 3-DOF stage with T-shape flexible hinge mechanism. Robot. Comput.-Intergr. Manuf. 2016, 37, 125–138. [Google Scholar] [CrossRef] [Green Version]

| r | b | t | w | ta1 | ta2 |

| 3 mm | 15 mm | 0.6 mm | 0.6 mm | 0.6 mm | 0.4 mm |

| la | lb | E | σ | μ | ρ |

| 20.88 mm | 8 mm | 69,000 MPa | 228 MPa | 0.3 | 2700 kg/m3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Y.; Chen, X.; Lin, J.; Lu, M.; Lu, F.; Zhang, Z.; Yang, H. Vibration-Assisted Roll-Type Polishing System Based on Compliant Micro-Motion Stage. Micromachines 2018, 9, 499. https://doi.org/10.3390/mi9100499

Gu Y, Chen X, Lin J, Lu M, Lu F, Zhang Z, Yang H. Vibration-Assisted Roll-Type Polishing System Based on Compliant Micro-Motion Stage. Micromachines. 2018; 9(10):499. https://doi.org/10.3390/mi9100499

Chicago/Turabian StyleGu, Yan, Xiuyuan Chen, Jieqiong Lin, Mingming Lu, Faxiang Lu, Zheming Zhang, and Hao Yang. 2018. "Vibration-Assisted Roll-Type Polishing System Based on Compliant Micro-Motion Stage" Micromachines 9, no. 10: 499. https://doi.org/10.3390/mi9100499

APA StyleGu, Y., Chen, X., Lin, J., Lu, M., Lu, F., Zhang, Z., & Yang, H. (2018). Vibration-Assisted Roll-Type Polishing System Based on Compliant Micro-Motion Stage. Micromachines, 9(10), 499. https://doi.org/10.3390/mi9100499