Design, Fabrication, and Implementation of an Array-Type MEMS Piezoresistive Intelligent Pressure Sensor System

Abstract

:1. Introduction

2. Design Optimization of the Array-Type Piezoresistive Pressure Sensor and Basic Theory

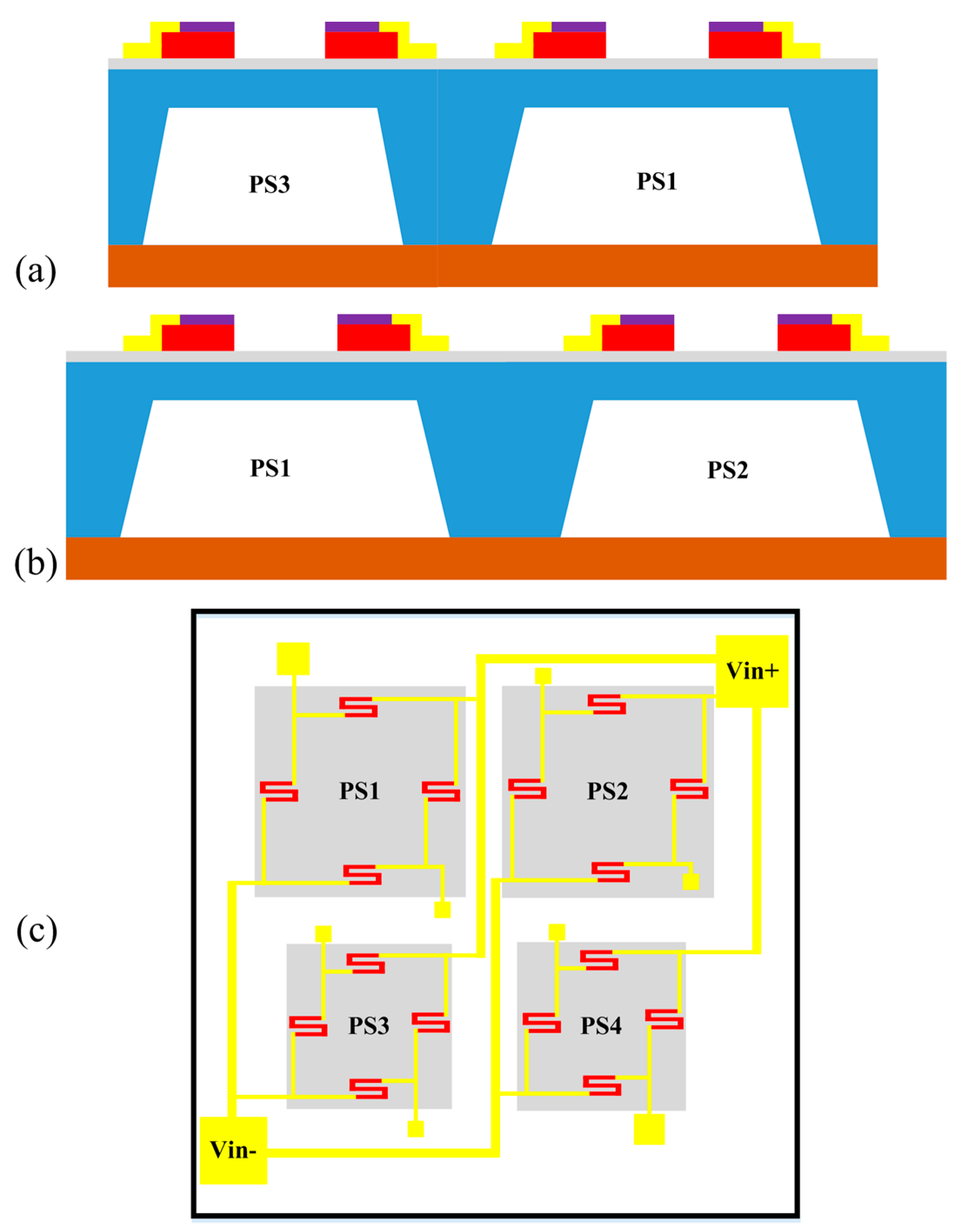

2.1. Configuration of the Array-Type MEMS Pressure Sensor

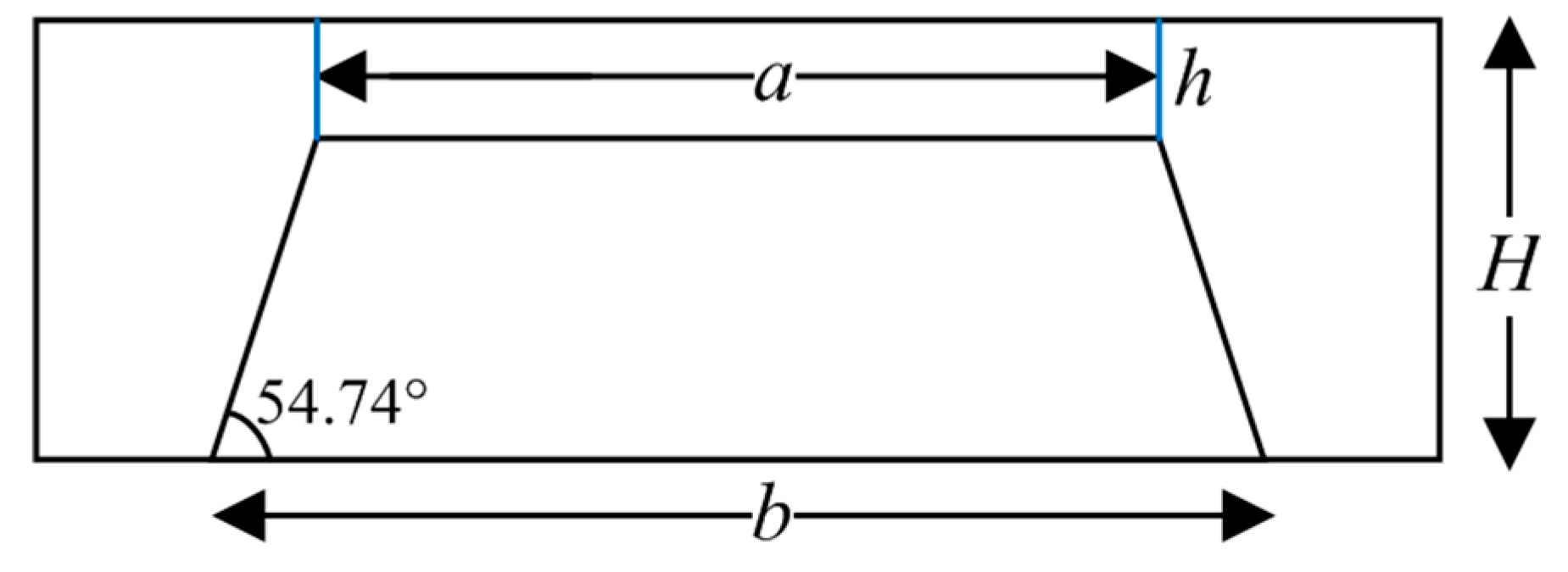

2.1.1. Diaphragm Design

2.1.2. Design of Mask Window of the Silicon Cup

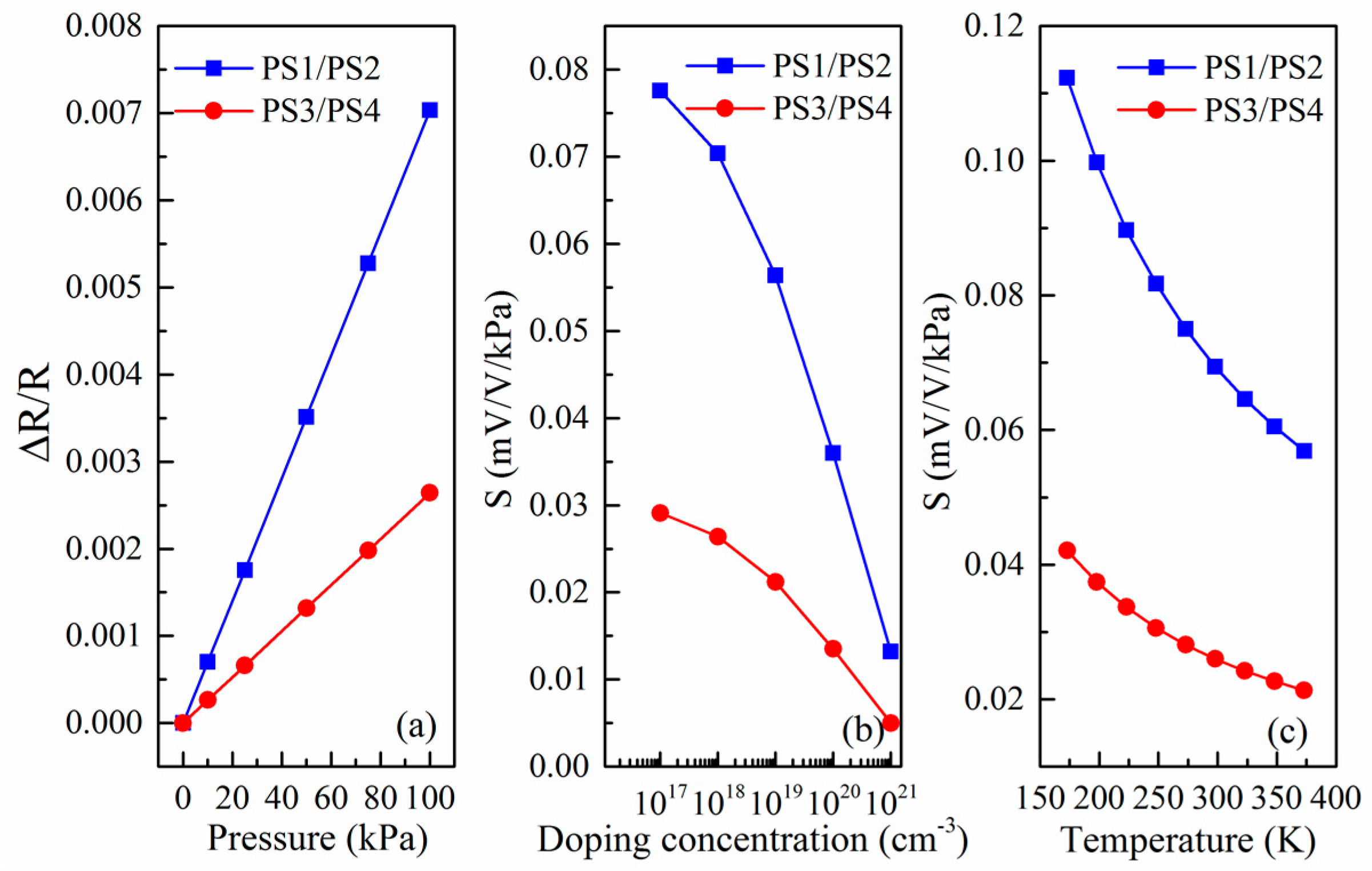

2.1.3. Design of the Piezoresistor

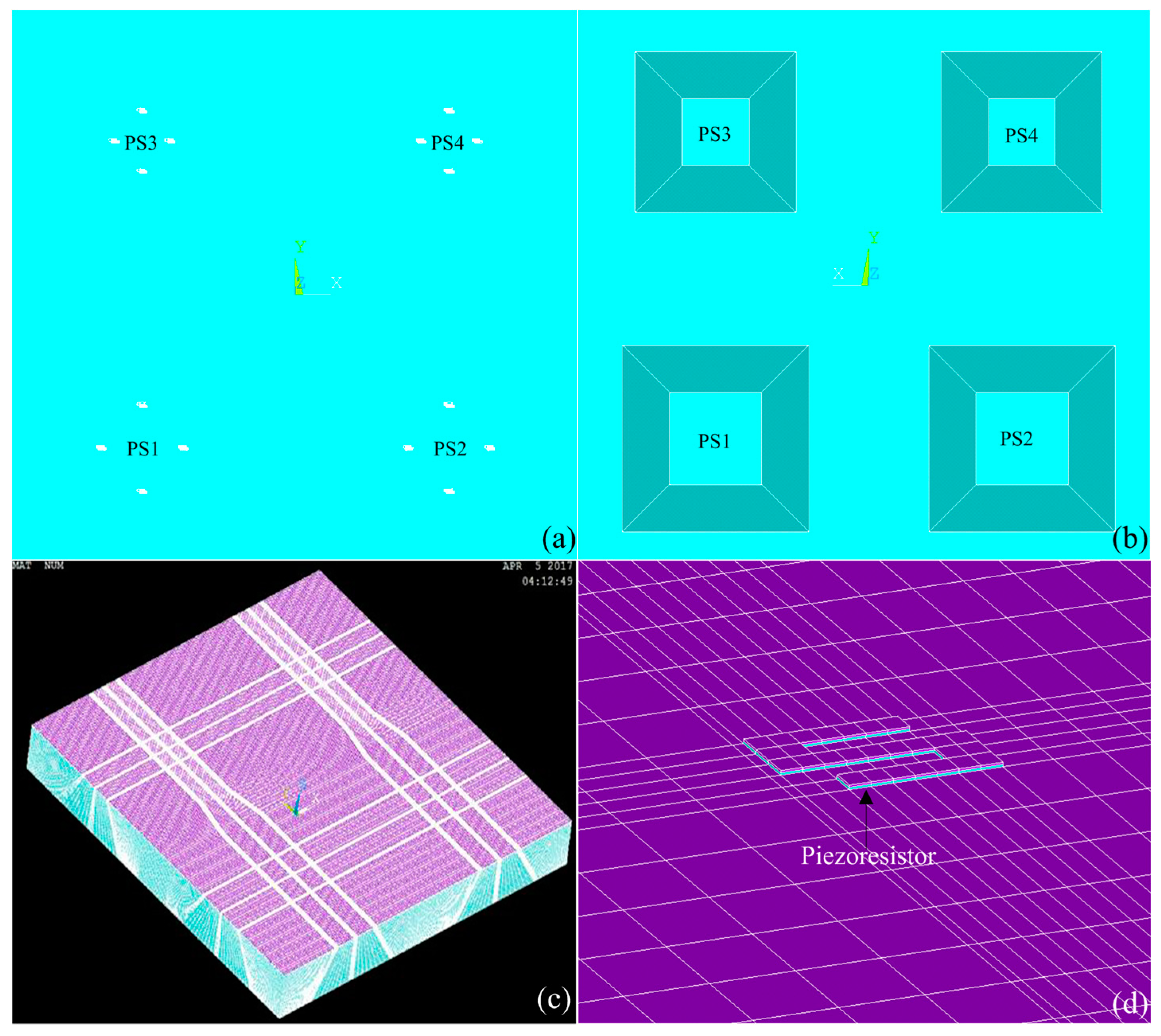

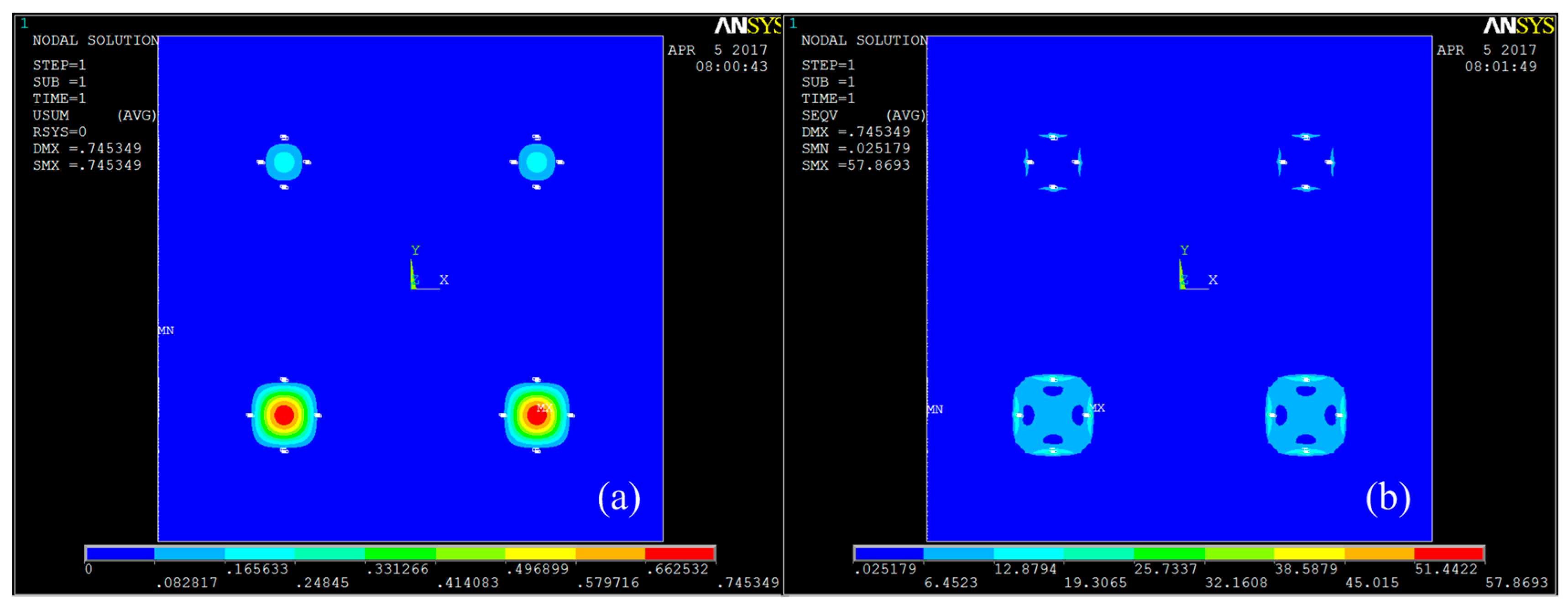

2.2. Finite Element Analysis of the Array-Type MEMS Piezoresistive Pressure Sensor

2.2.1. Structure Modeling and Simulation

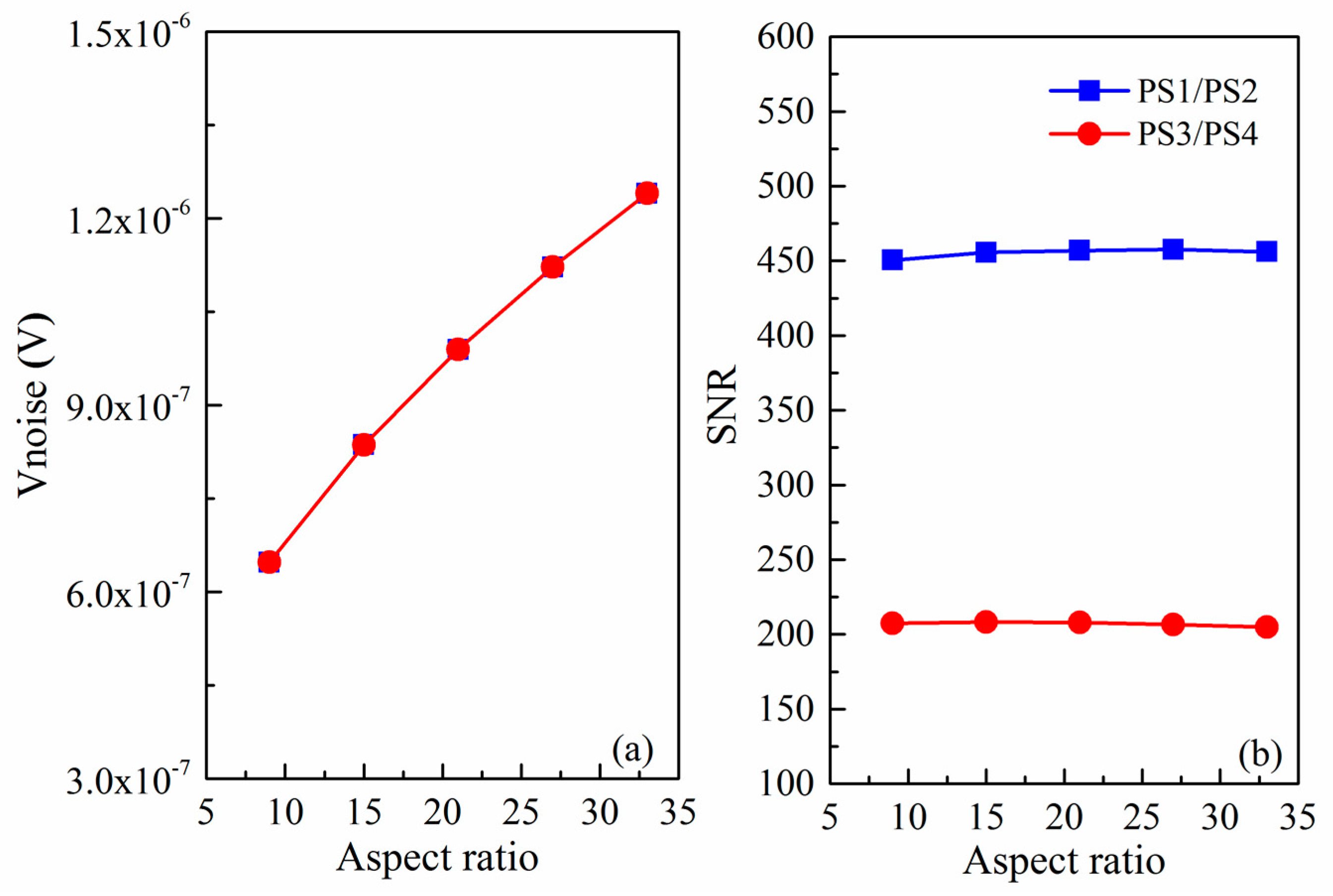

2.2.2. Theoretical Analysis of Sensitivity and SNR of Array-Type Pressure Sensors

3. Fabrication Process of Array-Type MEMS Piezoresistive Sensor

3.1. Process Flow

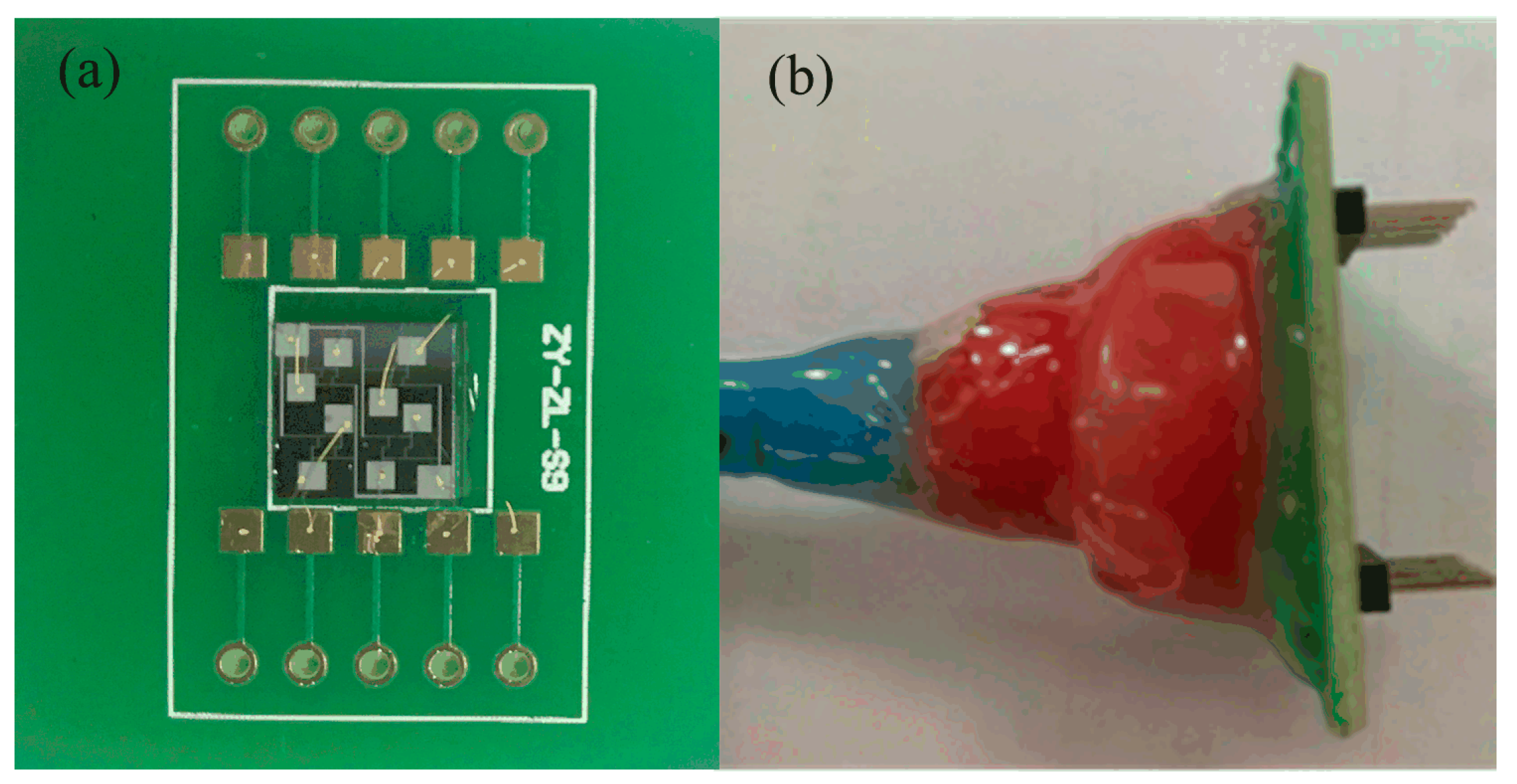

3.2. Sensor Chip Package

4. Hardware Design and Software Design

4.1. Hardware Design of Array-Type Intelligent Pressure Sensor System

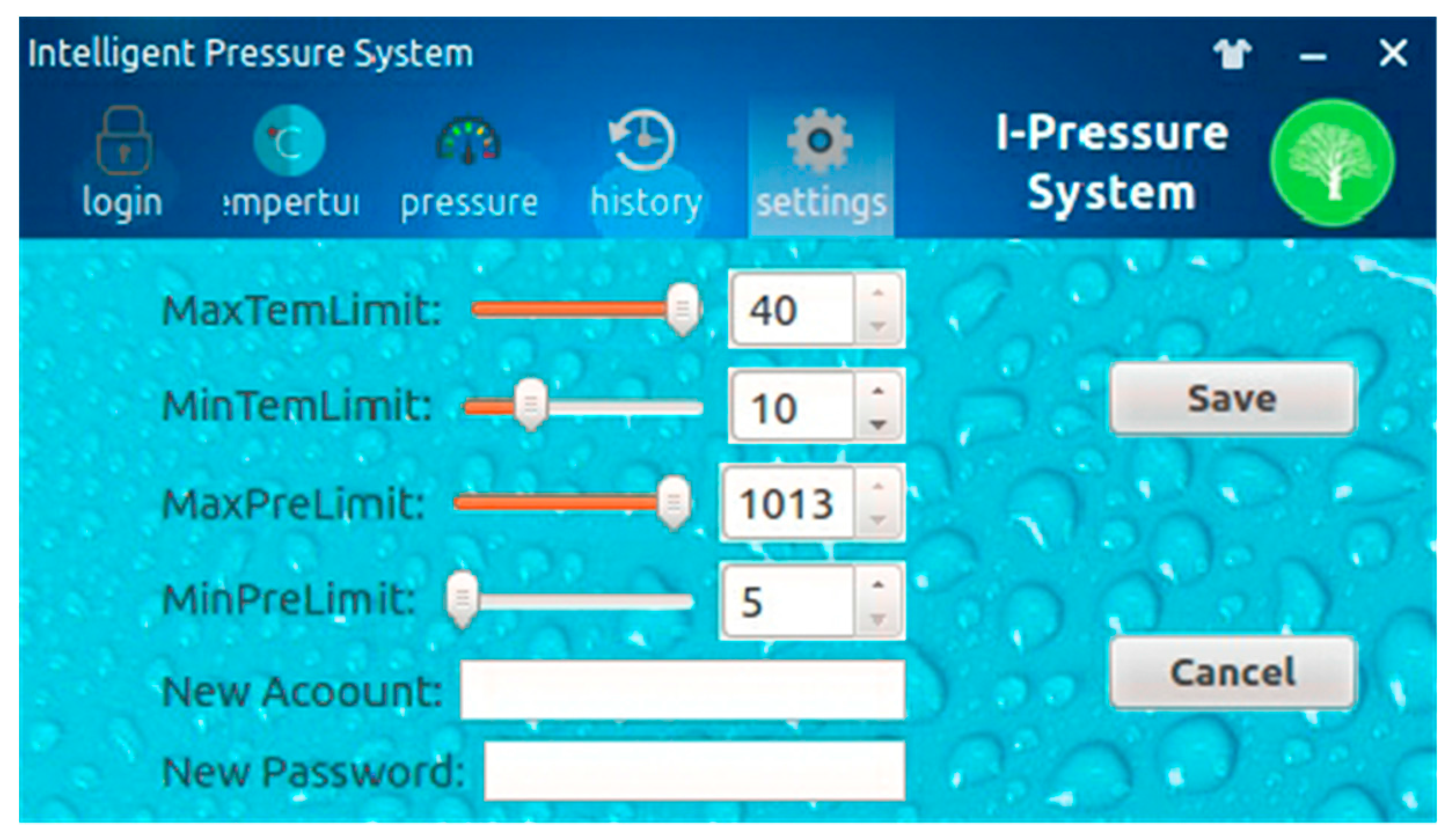

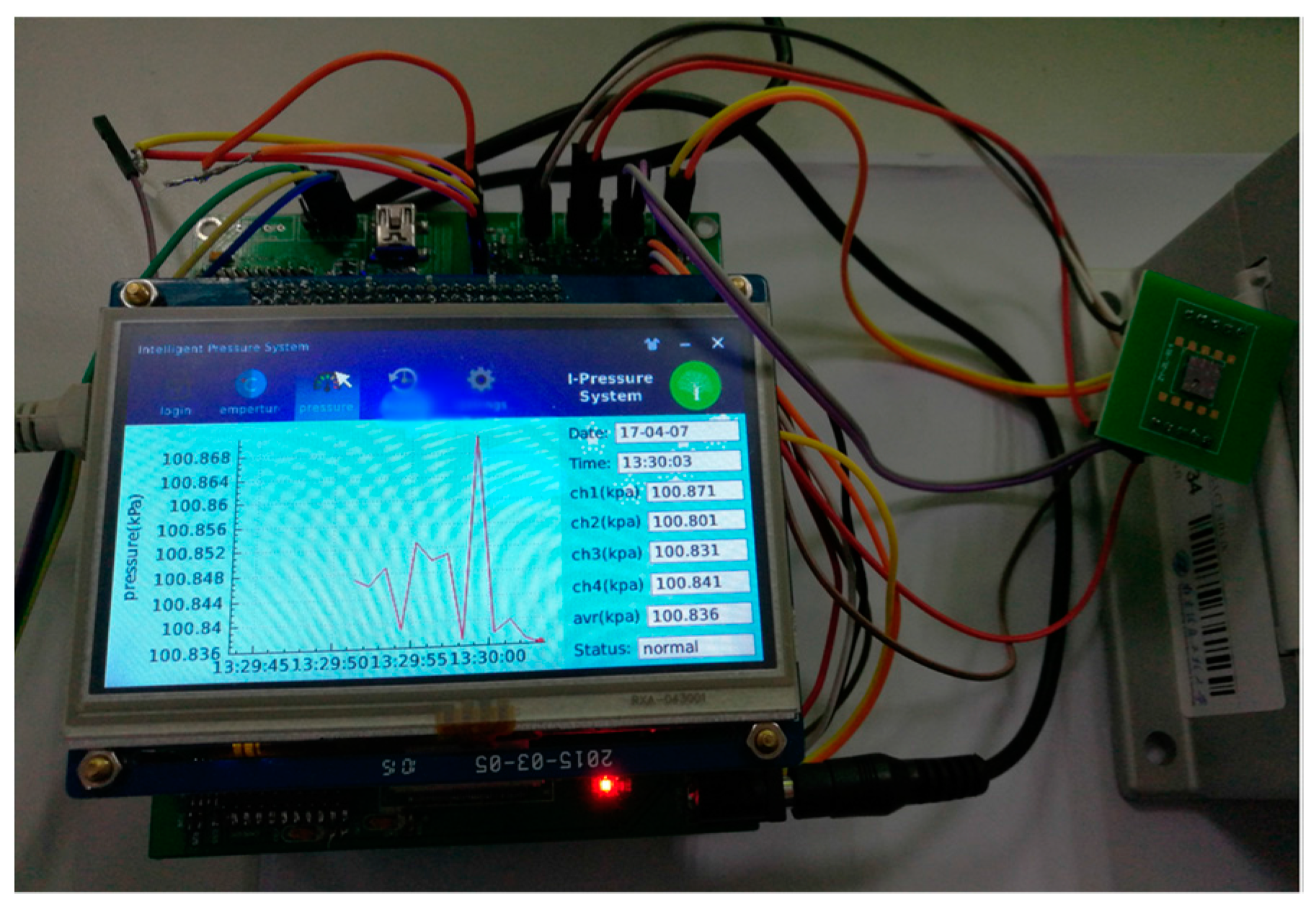

4.2. Software Design of Array-Type Intelligent Pressure Sensor System

5. Experimental Section and Discussion

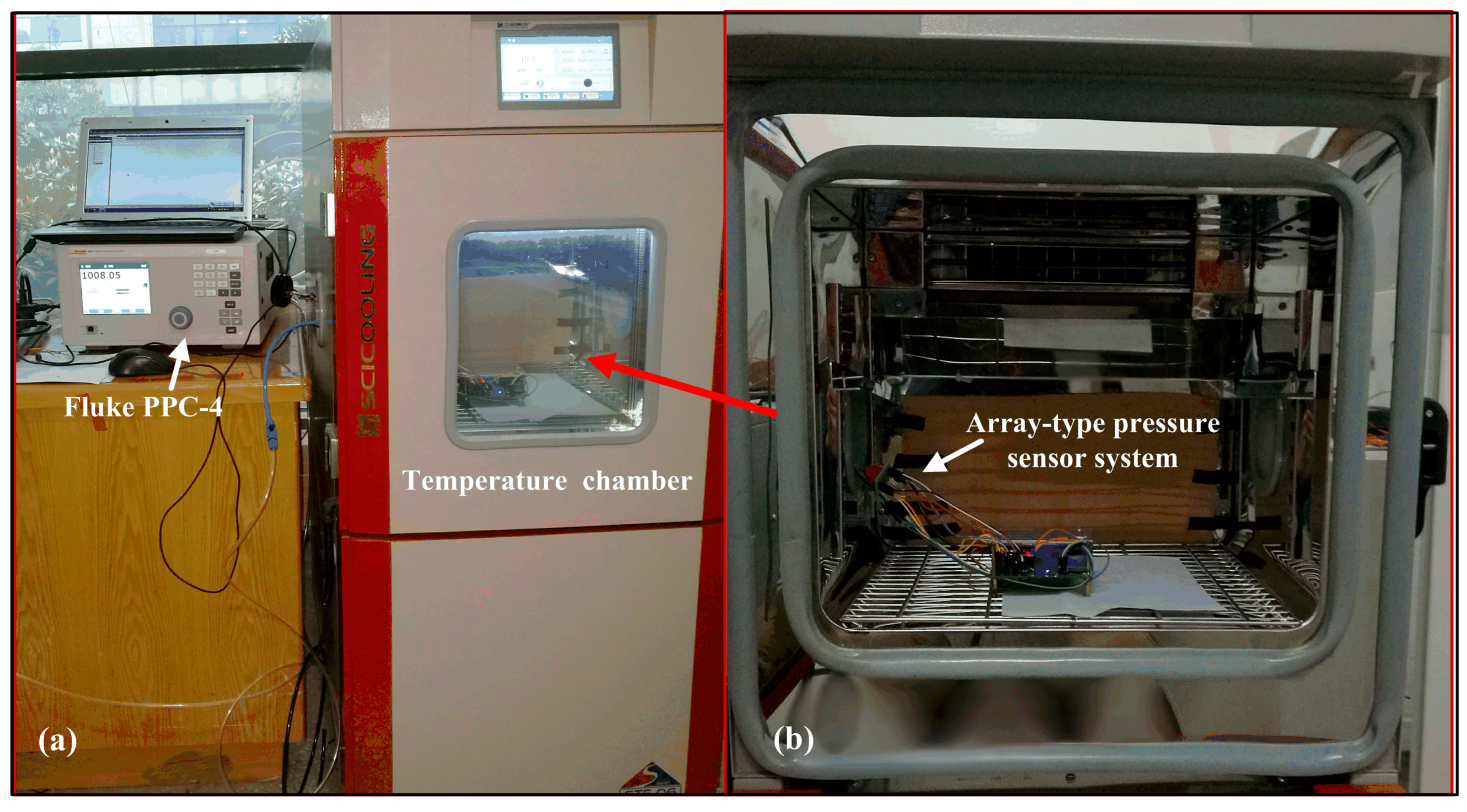

5.1. Experimental Setup

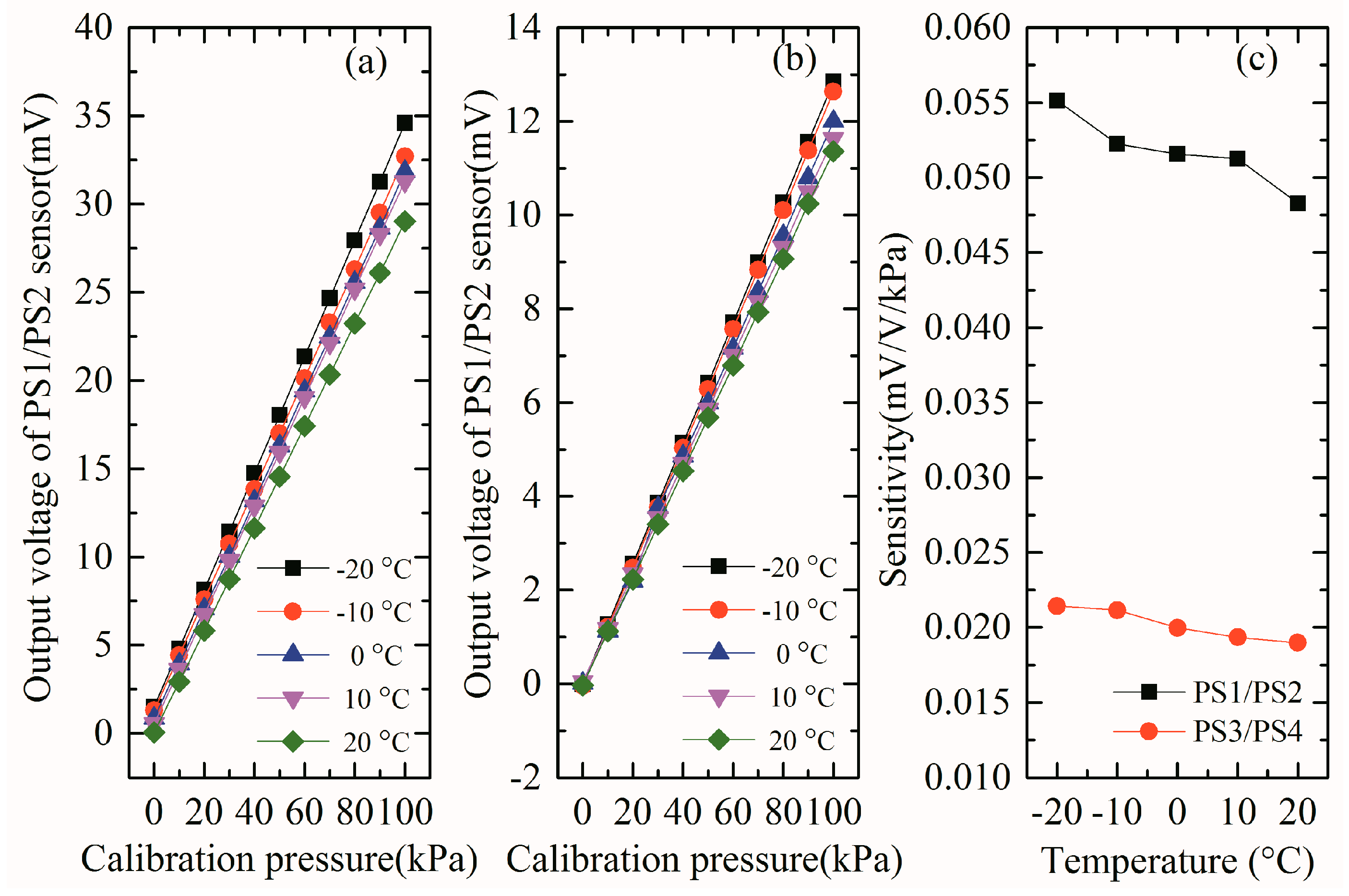

5.2. Array-Type Sensor Output Result

5.3. Data Fusion Using GA-WNN Compensation Algorithm

5.3.1. GA-WNN Algorithm Overview

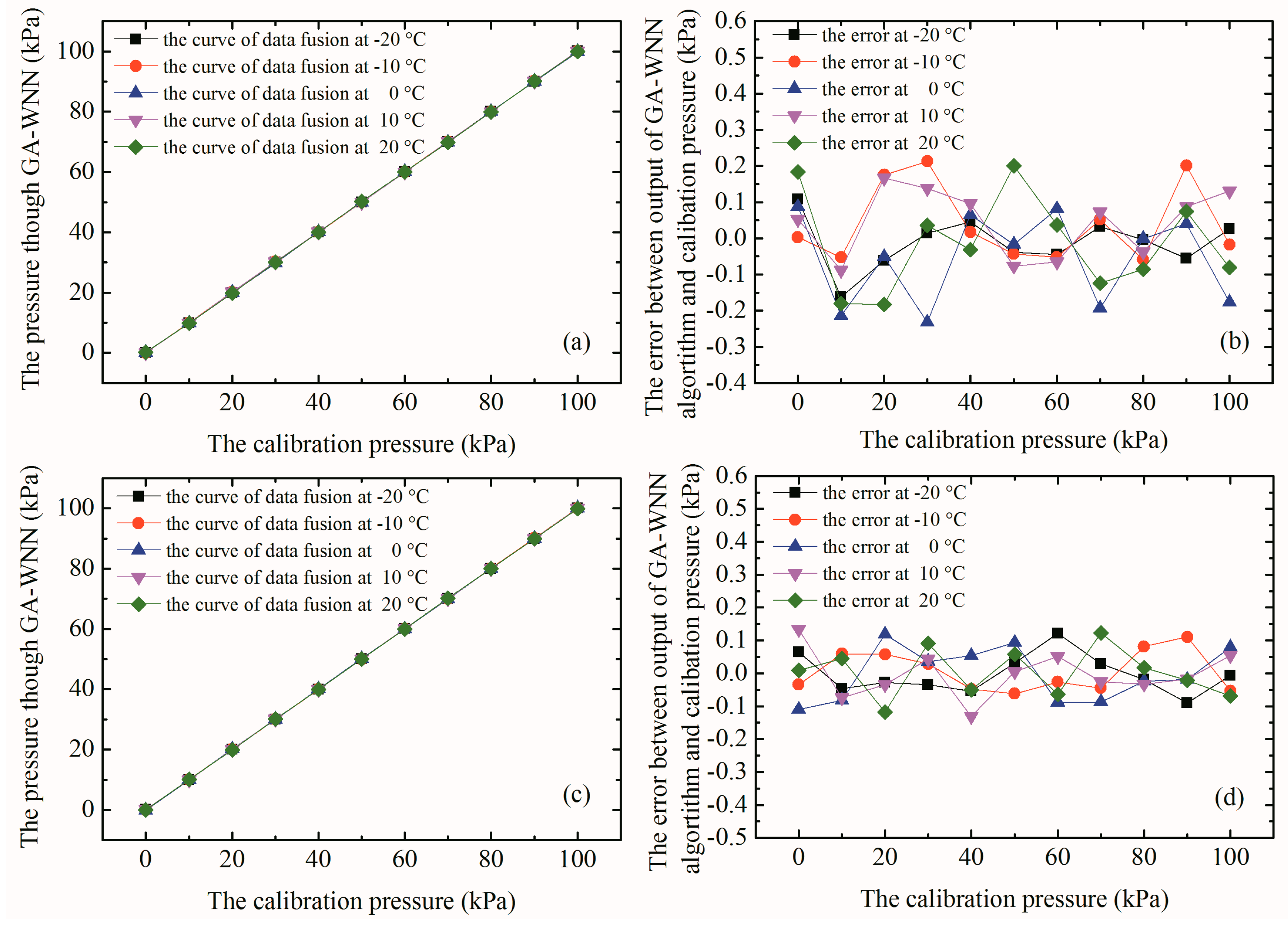

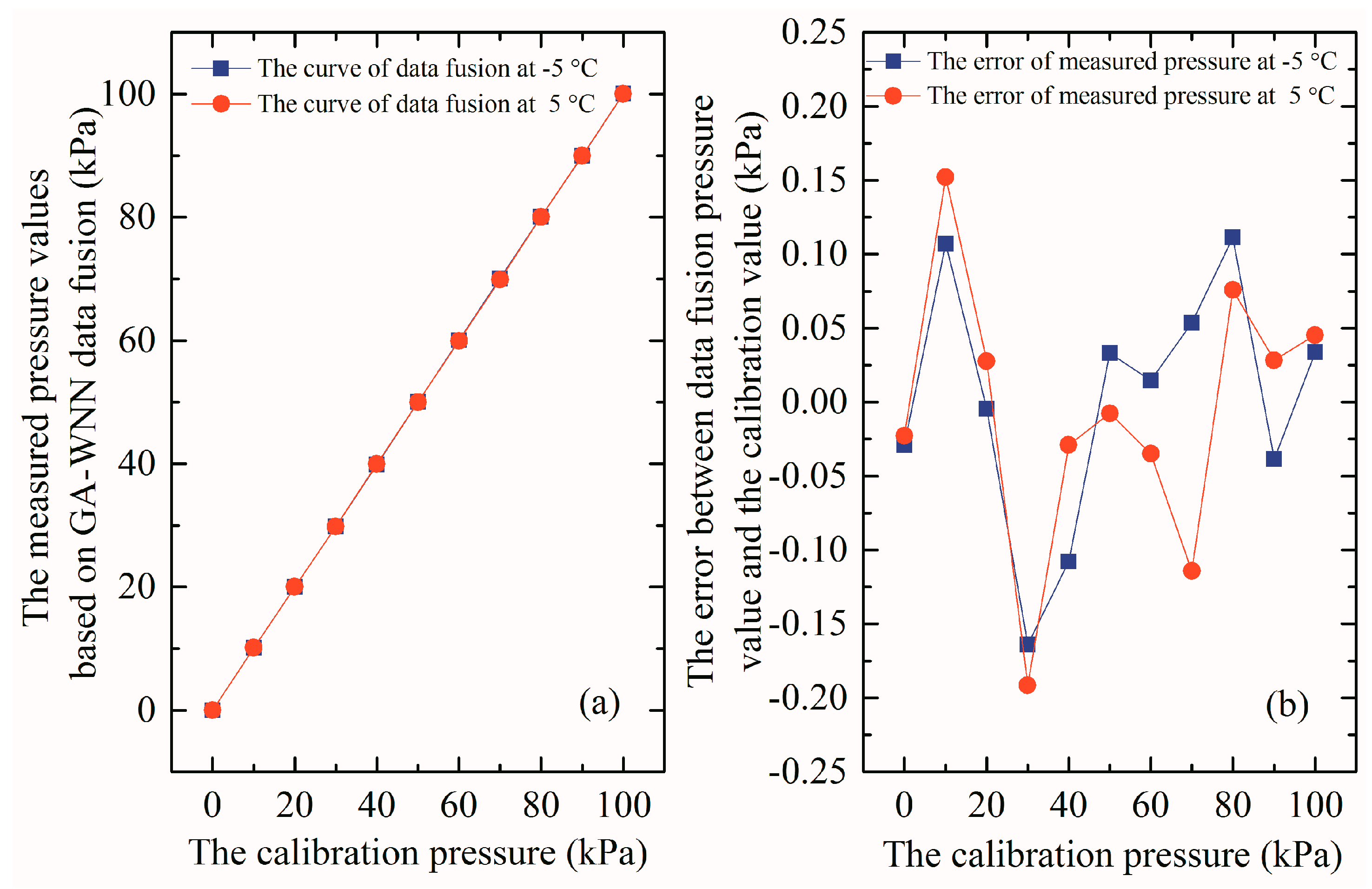

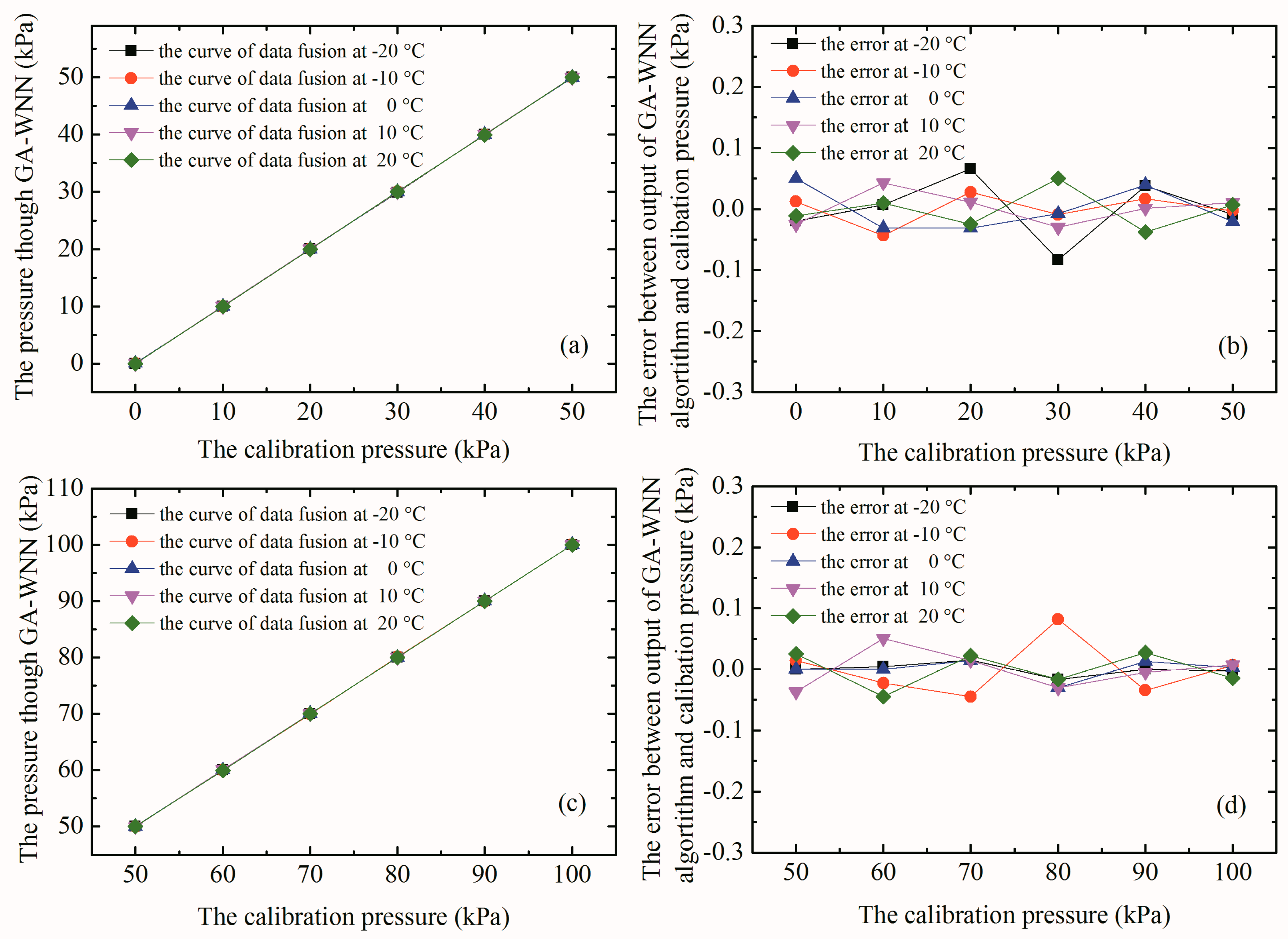

5.3.2. Analysis of Compensation Results Based on GA-WNN Algorithm

6. Conclusions and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Eaton, W.P.; Smith, J.H. Micromachined pressure sensors: Review and recent developments. Smart Mater. Struct. 1997, 6, 530–539. [Google Scholar] [CrossRef]

- Barlian, A.A.; Park, W.T.; Mallon, J.R.; Rastegar, A.J.; Pruitt, B.L. Review: Semiconductor piezoresistance for microsystems. Proc. IEEE 2009, 97, 513–552. [Google Scholar] [CrossRef] [PubMed]

- Niu, Z.; Zhao, Y.L.; Tian, B. Design optimization of high pressure and high temperature piezoresistive pressure sensor for high sensitivity. Rev. Sci. Instrum. 2014, 85. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Kim, J.K.; Patil, S.J.; Park, J.K.; Park, S.; Lee, D.W. A wireless pressure sensor integrated with a biodegradable polymer stent for biomedical applications. Sensors 2016, 16, 809. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.H.; Wu, Y.S.; Liu, Q.Q.; Gu, F.; Mao, X.L.; Li, M. Research on high-precision, low cost piezoresistive MEMS-array pressure transmitters based on genetic wavelet neural networks for meteorological measurements. Micromachines 2015, 6, 554–573. [Google Scholar] [CrossRef]

- Brancato, L.; Keulemans, G.; Verbelen, T.; Meyns, B.; Puers, R. An implantable intravascular pressure sensor for a ventricular assist device. Micromachines 2016, 7, 135. [Google Scholar] [CrossRef]

- Soon, B.W.; Neuzil, P.; Wong, C.C.; Reboud, J.; Feng, H.H.; Lee, C. Ultrasensitive nanowire pressure sensor makes its debut. Procedia Eng. 2010, 5, 1127–1130. [Google Scholar] [CrossRef]

- Kumar, S.S.; Pant, B.D. Design principles and considerations for the ‘ideal’ silicon piezoresistive pressure sensor: A focused review. Microsyst. Technol. 2014, 20, 1213–1247. [Google Scholar] [CrossRef]

- Kumar, S.S.; Ojha, A.K.; Pant, B.D. Experimental evaluation of sensitivity and non-linearity in polysilicon piezoresistive pressure sensors with different diaphragm sizes. Microsyst. Technol. 2016, 22, 83–91. [Google Scholar] [CrossRef]

- Voorthuyzen, J.A.; Bergveld, P. The influence of tensile forces on the deflection of circular diaphragms in pressure sensors. Sens. Actuators 1984, 6, 201–213. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Yang, C.; Zhang, Z.H.; Lin, H.W.; Liu, L.T.; Ren, T.L. A novel pressure microsensor with 30-μm-thick diaphragm and meander-shaped piezoresistors partially distributed on high-stress bulk silicon region. IEEE Sens. J. 2008, 7, 1742–1748. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, D. A high sensitivity and high linearity pressure sensor based on a peninsula-structured diaphragm for low-pressure ranges. Sens. Actuators A 2014, 216, 176–189. [Google Scholar] [CrossRef]

- Xu, T.; Zhao, L.; Jiang, Z.; Guo, X.; Ding, J.; Xiang, W. A high sensitive pressure sensor with the novel bossed diaphragm combined with peninsula-island structure. Sens. Actuators A 2016, 244, 66–76. [Google Scholar] [CrossRef]

- Li, C.; Cordovilla, F.; Jagdheesh, R.; Ocaña, J.L. Design and optimization of a novel structural MEMS piezoresistive pressure sensor. Microsyst. Technol. 2017, 23, 4531–4541. [Google Scholar] [CrossRef]

- Rajavelu, M.; Sivakumar, D.; Rathnam, J.D.; Sumangala, K. Enhanced sensitivity with extended linearity in MEMS piezoresistive pressure sensor. Micro Nano Lett. 2013, 8, 753–756. [Google Scholar] [CrossRef]

- Lou, L.; Zhang, S.S.; Park, W.T.; Tsai, J.M.; Kwong, D.L.; Lee, C. Optimization of NEMS pressure sensors with a multilayered diaphragm using silicon nanowires as piezoresistive sensing elements. J. Micromech. Microeng. 2012, 22. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Wang, X.F.; Mohammad, M.A.; Bie, Z.; Xie, Q.Y.; Li, C.; Mi, W.T.; Yang, Y.; Ren, T.L. A graphene-based resistive pressure sensor with record-high sensitivity in a wide pressure range. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Sugiyama, S.; Kawahata, K.; Yoneda, M.; Igarashi, I. Tactile image detection using a 1k-element silicon pressure sensor array. Sens. Actuators A 1990, 22, 397–400. [Google Scholar] [CrossRef]

- Berns, A.; Buder, U.; Obermeier, E.; Wolter, A.; Leder, A. AeroMEMS sensor array for high-resolution wall pressure measurements. Sens. Actuators A 2006, 132, 104–111. [Google Scholar] [CrossRef]

- Berns, A.; Buder, U.; Obermeier, E.; Wolter, A.; Leder, A.; Frederich, O.; Thiele, F. Aero-micro-electromechanical system sensor arrays for time resolved wall pressure measurements. AIAA J. 2009, 47, 863–873. [Google Scholar] [CrossRef]

- Xiong, J.J.; Mao, H.Y.; Zhang, W.D.; Xu, D.; Guo, T. Research on multi-ranged micro accelerometer. Chin. J. Sens. Actuators 2006, 19, 2200–2203. (In Chinese) [Google Scholar]

- Kottapalli, A.G.P.; Tan, C.W.; Olfatnia, M.; Miao, J.M.; Barbastathis, G.; Triantafyllou, M.S. A liquid crystal polymer membrane MEMS sensor for flow rate and flow direction sensing applications. J. Micromech. Microeng. 2011, 21. [Google Scholar] [CrossRef]

- Kottapalli, A.G.P.; Asadnia, M.; Miao, J.M.; Barbastathis, G.; Triantafyllou, M.S. A flexible liquid crystal polymer MEMS pressure sensor array for fish-like underwater sensing. Smart Mater. Struct. 2012, 21. [Google Scholar] [CrossRef]

- Lou, Z.; Chen, S.; Wang, L.L.; Jiang, K.; Shen, G.Z. An ultra-sensitive and rapid response speed graphene pressure sensors for electronic skin and health monitoring. Nano Energy 2016, 23, 7–14. [Google Scholar] [CrossRef]

- Bae, B.; Flachsbart, B.R.; Park, K.; Shannon, M.A. Design optimization of a piezoresistive pressure sensor considering the output signal-to-noise ratio. J. Micromech. Microeng. 2004, 14, 1597–1607. [Google Scholar] [CrossRef]

- Pramanik, C.; Saha, H.; Gangopadhyay, U. Design optimization of a high performance silicon MEMS piezoresistive pressure sensor for biomedical applications. J. Micromech. Microeng. 2006, 16, 2060–2066. [Google Scholar] [CrossRef]

- Jevtiæ, M.M.; Smiljaniæ, M.A. Diagnostic of silicon piezoresistive pressure sensors by low frequency noise measurements. Sens. Actuators A 2008, 144, 267–274. [Google Scholar] [CrossRef]

- Rajan, N.K.; Routenberg, D.A.; Reed, M.A. Optimal signal-to-noise ratio for silicon nanowire biochemical sensors. Appl. Phys. Lett. 2011, 98. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.H.; Zhao, Y.; Ge, Y.X.; Li, M.; Yang, L.J.; Mao, X.L. Design optimization and fabrication of high-sensitivity SOI pressure sensors with high signal-to-noise ratios based on silicon nanowire piezoresistors. Micromachines 2016, 7, 187. [Google Scholar] [CrossRef]

- Zhang, J.H.; Huang, Q.A.; Yu, H.; Lei, S.Y. Effect of temperature and elastic constant on the piezoresistivity of silicon nanobeams. In Proceedings of the 4th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Shenzhen, China, 5–8 January 2009. [Google Scholar]

- Rowe, A.C.H. Piezoresistance in silicon and its nanostructures. J. Mater. Res. 2014, 29, 731–744. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Lu, F.; He, H.D.; Lu, Q.C.; Wang, D.S.; Peng, Z.R. Fine-scale estimation of carbon monoxide and fine particulate matter concentrations in proximity to a road intersection by using wavelet neural network with genetic algorithm. Atmosp. Environ. 2015, 104, 264–272. [Google Scholar] [CrossRef]

- Lu, Y.; Zeng, N.Y.; Liu, Y.R.; Zhang, N. A hybrid wavelet neural network and switching particle swarm optimization algorithm for face direction recognition. Neurocomputing 2015, 155, 219–224. [Google Scholar] [CrossRef]

- Sun, Y.C.; Liu, Y.L.; Meng, Q.H. Design, manufacture and application of pressure sensor. Beijing Metall. Ind. Press 2000, 126–127. (In Chinese) [Google Scholar]

- Kozlovskiy, S.I.; Sharan, N.N. Piezoresistive effect in p-type silicon classical nanowires at high uniaxial strains. J. Comput. Electron. 2011, 10, 258–267. [Google Scholar] [CrossRef]

- Doll, J.C.; Park, S.J.; Pruitt, B.L. Design optimization for piezoresistive cantilevers for force sensing in air and water. J. Appl. Phys. 2009, 106. [Google Scholar] [CrossRef] [PubMed]

- Shin, C.; Jeon, I.; Khim, Z.G.; Hong, J.W.; Nam, H. Study of sensitivity and noise in the piezoelectric self-sensing and self-actuating cantilever with an integrated Wheatstone bridge circuit. Rev. Sci. Instrum. 2010, 81. [Google Scholar] [CrossRef] [PubMed]

- Yu, X.M.; Thaysen, J.; Hansen, O.; Boisen, A. Optimization of sensitivity and noise in piezoresistive cantilever. J. Appl. Phys. 2002, 92, 6296–6301. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.Y.; Huang, J.Q. Design and application of a high sensitivity piezoresistive pressure sensor for low pressure conditions. Sensors 2015, 15, 22692–22704. [Google Scholar] [CrossRef] [PubMed]

| Temperature | P/kPa | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T = −20 °C | Up/mV | 1.506 | 4.804 | 8.128 | 11.433 | 14.745 | 18.036 | 21.348 | 24.670 | 27.956 | 31.265 | 34.597 |

| T = −10 °C | Up/mV | 1.295 | 4.428 | 7.596 | 10.738 | 13.846 | 16.997 | 20.134 | 23.291 | 26.298 | 29.523 | 32.696 |

| T = 0 °C | Up/mV | 0.865 | 3.942 | 7.062 | 10.043 | 13.191 | 16.292 | 19.434 | 22.465 | 25.570 | 28.638 | 31.858 |

| T = 10 °C | Up/mV | 0.564 | 3.632 | 6.732 | 9.790 | 12.862 | 15.943 | 19.037 | 22.126 | 25.179 | 28.285 | 31.276 |

| T = 20 °C | Up/mV | 0.052 | 2.936 | 5.832 | 8.748 | 11.625 | 14.542 | 17.421 | 20.336 | 23.242 | 26.104 | 29.020 |

| Temperature | P/kPa | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T = −20 °C | Up/mV | −0.010 | 1.270 | 2.554 | 3.856 | 5.141 | 6.416 | 7.708 | 8.990 | 10.268 | 11.563 | 12.846 |

| T = −10 °C | Up/mV | −0.050 | 1.211 | 2.474 | 3.765 | 5.031 | 6.288 | 7.568 | 8.830 | 10.103 | 11.377 | 12.638 |

| T = 0 °C | Up/mV | 0.007 | 1.182 | 2.394 | 3.606 | 4.811 | 5.994 | 7.168 | 8.370 | 9.571 | 10.804 | 12.002 |

| T = 10 °C | Up/mV | 0.047 | 1.178 | 2.342 | 3.542 | 4.698 | 5.858 | 7.010 | 8.152 | 9.308 | 10.498 | 11.638 |

| T = 20 °C | Up/mV | −0.034 | 1.122 | 2.230 | 3.404 | 4.540 | 5.684 | 6.794 | 7.933 | 9.064 | 10.240 | 11.357 |

| P/kPa | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| Uinc/mV | 1.123 | 2.229 | 3.401 | 4.538 | 5.669 | 6.795 | 7.933 | 9.064 | 10.222 | 11.342 |

| Udec/mV | 1.140 | 2.246 | 3.422 | 4.556 | 5.692 | 6.811 | 7.954 | 9.080 | 10.231 | 11.346 |

| Uinc/mV | 1.132 | 2.222 | 3.386 | 4.541 | 5.675 | 6.792 | 7.933 | 9.065 | 10.228 | 11.357 |

| Udec/mV | 1.141 | 2.240 | 3.405 | 4.558 | 5.694 | 6.812 | 7.949 | 9.082 | 10.239 | 11.357 |

| Uinc/mV | 1.122 | 2.230 | 3.404 | 4.540 | 5.684 | 6.794 | 7.933 | 9.064 | 10.240 | 11.356 |

| Udec/mV | 1.138 | 2.247 | 3.421 | 4.563 | 5.705 | 6.812 | 7.951 | 9.082 | 10.241 | 11.357 |

| Uinc/mV | 1.125 | 2.230 | 3.402 | 4.539 | 5.680 | 6.794 | 7.934 | 9.064 | 10.233 | 11.351 |

| Udec/mV | 1.140 | 2.246 | 3.422 | 4.561 | 5.701 | 6.811 | 7.952 | 9.081 | 10.236 | 11.353 |

| Temperature | P/kPa | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T = −20 °C | PGW/kPa | −0.02 | 10.01 | 20.07 | 29.92 | 40.04 | 49.99 | 60.00 | 70.02 | 79.98 | 90.00 | 100.00 |

| T = −10 °C | PGW/kPa | 0.01 | 9.96 | 20.03 | 29.99 | 40.02 | 50.00 | 59.98 | 69.96 | 80.08 | 89.97 | 100.01 |

| T = 0 °C | PGW/kPa | 0.05 | 9.97 | 19.97 | 29.99 | 40.04 | 49.98 | 60.00 | 70.01 | 79.97 | 90.01 | 100.00 |

| T = 10 °C | PGW/kPa | −0.02 | 10.04 | 20.01 | 29.97 | 40.00 | 50.01 | 60.05 | 70.01 | 79.97 | 89.99 | 100.01 |

| T = 20 °C | PGW/kPa | −0.01 | 10.01 | 19.98 | 30.05 | 39.96 | 50.01 | 59.96 | 70.02 | 79.98 | 90.03 | 99.99 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Chen, J.; Li, M.; Ge, Y.; Wang, T.; Shan, P.; Mao, X. Design, Fabrication, and Implementation of an Array-Type MEMS Piezoresistive Intelligent Pressure Sensor System. Micromachines 2018, 9, 104. https://doi.org/10.3390/mi9030104

Zhang J, Chen J, Li M, Ge Y, Wang T, Shan P, Mao X. Design, Fabrication, and Implementation of an Array-Type MEMS Piezoresistive Intelligent Pressure Sensor System. Micromachines. 2018; 9(3):104. https://doi.org/10.3390/mi9030104

Chicago/Turabian StyleZhang, Jiahong, Jianxiang Chen, Min Li, Yixian Ge, Tingting Wang, Peng Shan, and Xiaoli Mao. 2018. "Design, Fabrication, and Implementation of an Array-Type MEMS Piezoresistive Intelligent Pressure Sensor System" Micromachines 9, no. 3: 104. https://doi.org/10.3390/mi9030104