2.1. Actuation Theory of the In-Plane Micropump

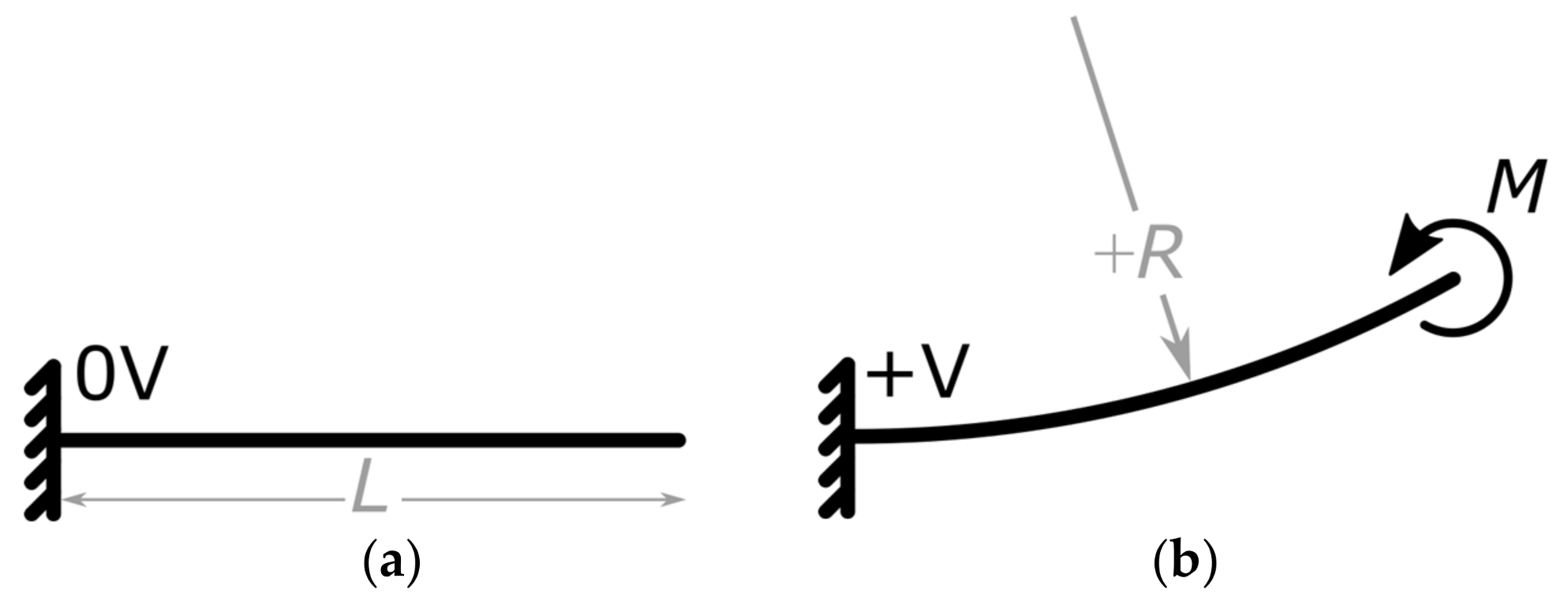

When the NED cantilever is arranged in a clamped-free (c-f) configuration, it deforms cylindrically, with a curvature

, upon actuation [

15]. Following this, the actuator is approximated by a solid cantilever beam, which, under the Euler Bernoulli hypothesis, is associated with small deflections [

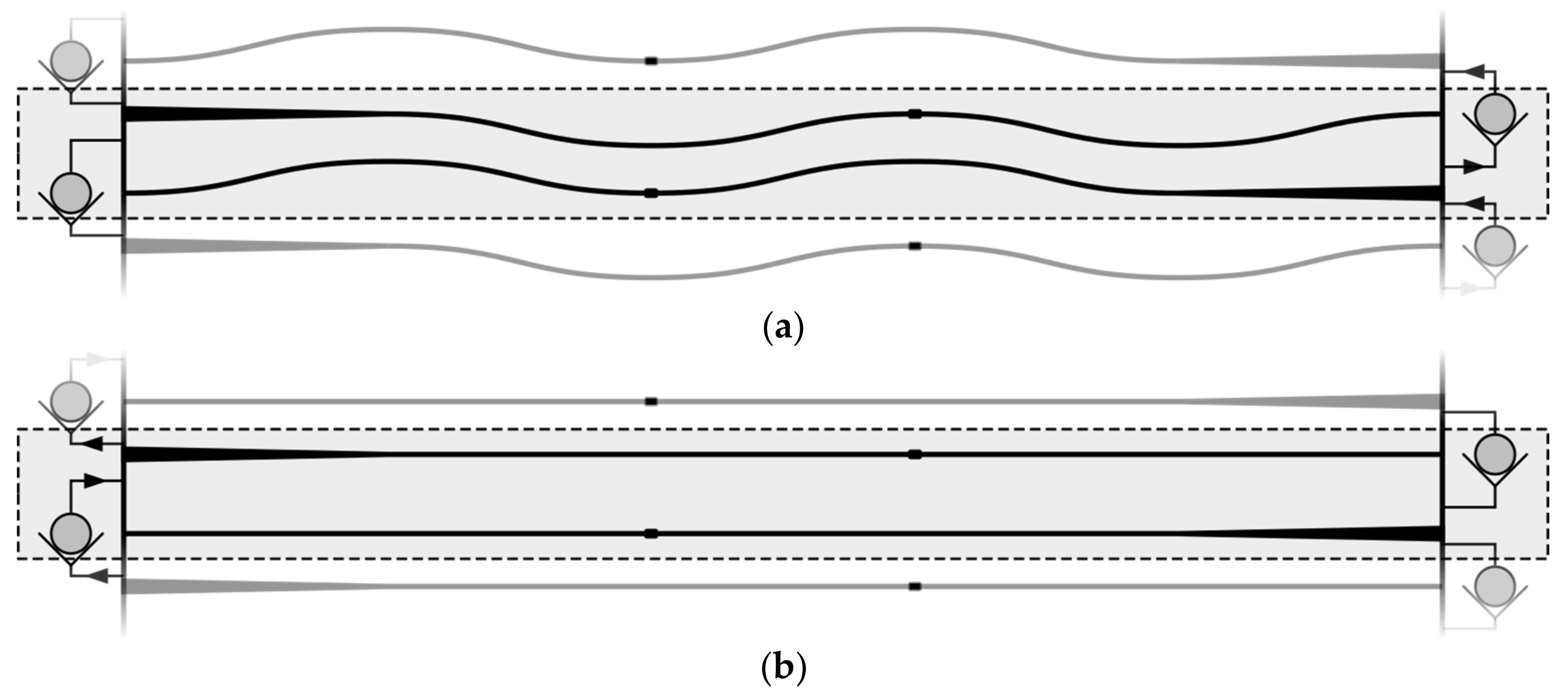

19], as shown in

Figure 1. In an actuated state, the cantilever beam exhibits a curvature

, generating a constant bending moment

along the beam.

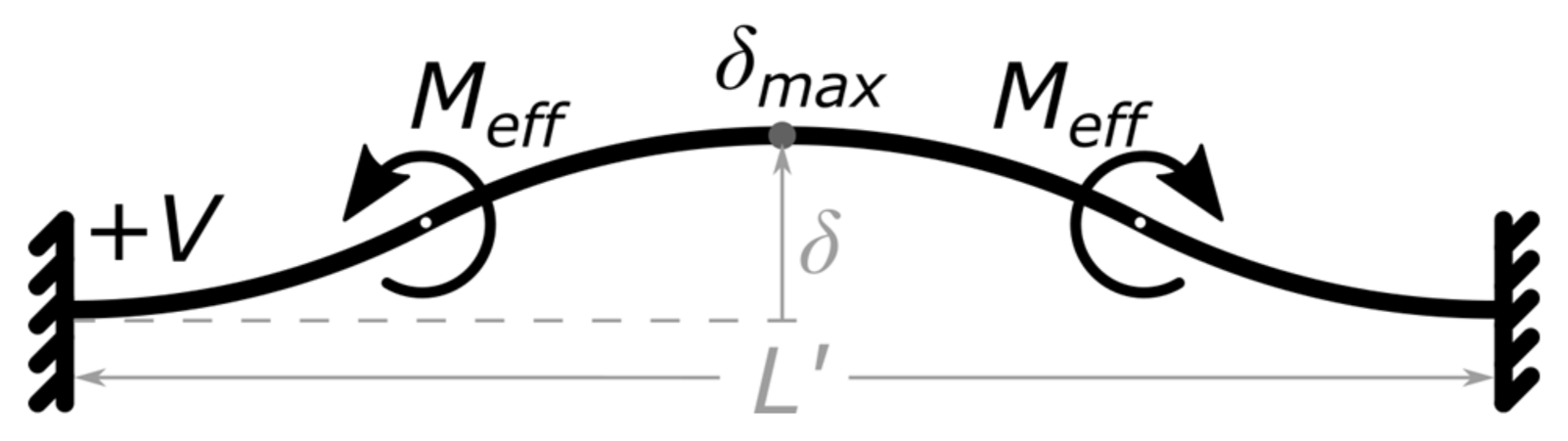

The bending moment thereby depends on the geometrical and material parameters of the NED actuator beam, as well as on the applied control voltage and dielectric permittivity of the fluid between the electrodes [

15,

18]. By interconnecting four NED actuator beams and arranging them to a clamped-clamped (c-c) configuration under the use of an alternating radius scheme

the effective bending Moment

is increased to

. This can be associated to mechanical moments applied at

and

, compared with the (c-f) case in

Figure 1a, where

applied at

. The total length in (c-c) configuration adds up to

.

The maximum deflection

occurs at the center of the clamped-clamped beam and can be derived for the case of pure bending (constant moment, i.e., no shear-forces) to:

Here,

is the equivalent bending stiffness of the physical actuator. The advantage of this configuration is that the two sides of the NED actuator beams (meaning schematically above and below the sketched actuator beam bending line in

Figure 2), are fluidically separated and can act as force-applying moving walls, generating a volume variation during the operation. The stroke volume

is the area passed over by the actuator beam multiplied by its height

(in

Figure 2 perpendicular to the paper plane):

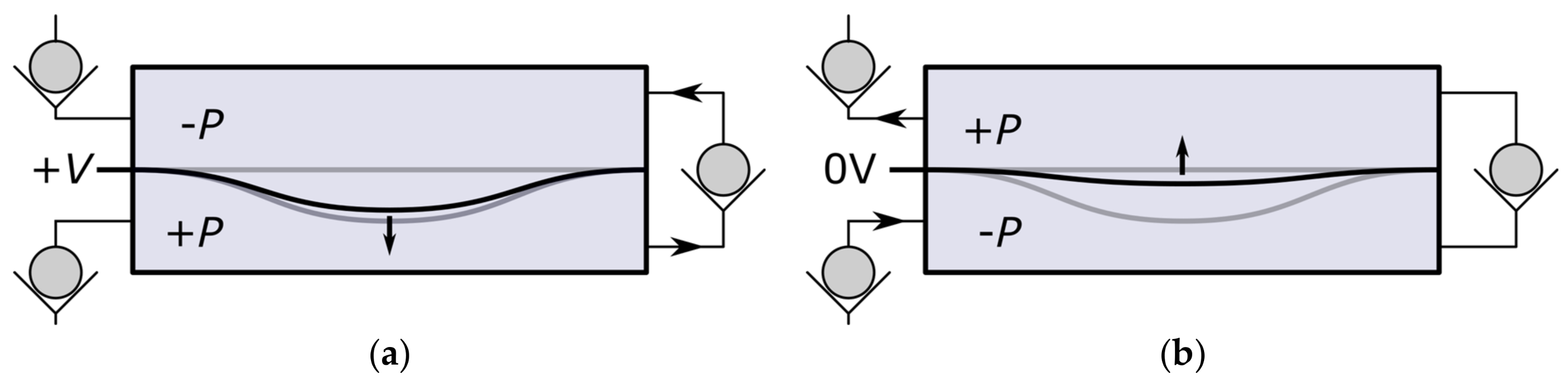

By placing one NED actuator beam in (c-c) configuration with both sides fluidically separated by three ideally rectifying check-valves, a simple pumping effect can be achieved. This situation is shown in

Figure 3. Assuming an ideal incompressible fluid, a gauge overpressure

is created in the cavity compressed by the actuator, while an associated gauge underpressure

, is created in the expanded cavity (

Figure 3a). This gives a total differential pressure of twice the absolute gauge pressure

, between the two cavities, resulting in a pressure-driven flow.

The maximum generated pressure difference

, during this operation, can be obtained by calculating the maximum gauge pressure in one cavity. It depends on the maximum generated force of the actuator in relation to the surface facing the fluid of the cavity. The so called “blocking force”

is achieved when at applied voltage +

V the displacement is completely blocked [

20]. It is calculated by setting the maximum deflection of the NED beam, given by Equation (1), to the equal maximum deflection of a clamped-clamped (c-c) beam, of equal stiffness and length, under a point-load at the center:

Solving for

F yields

Equation (5) states that the actuators effective bending moment gets transferred into a point-load at the center of the beam. By relating that point-load to the area facing the fluid

, in the cavity being compressed and multiplied by two, the corresponding maximum differential pressure can be obtained:

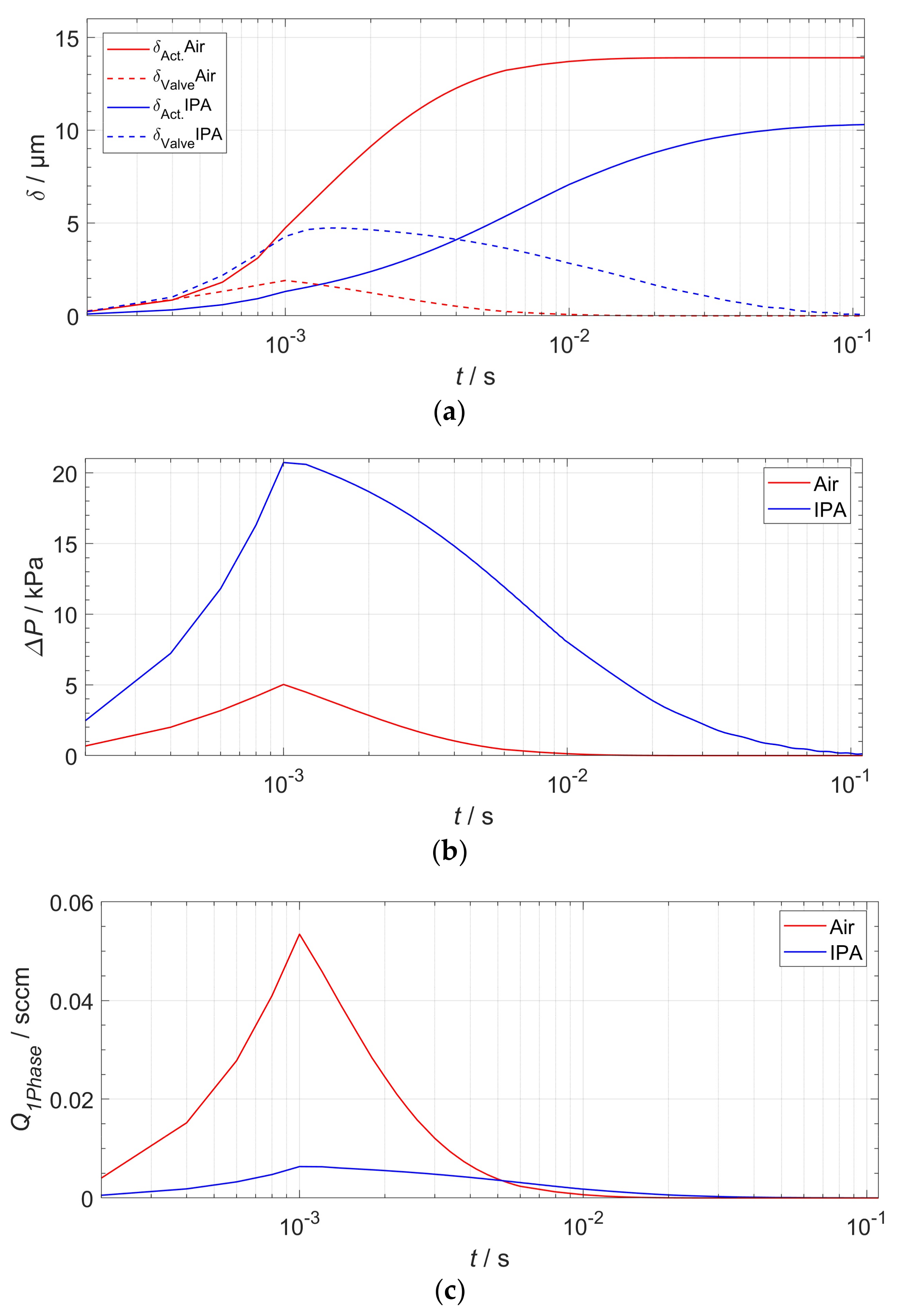

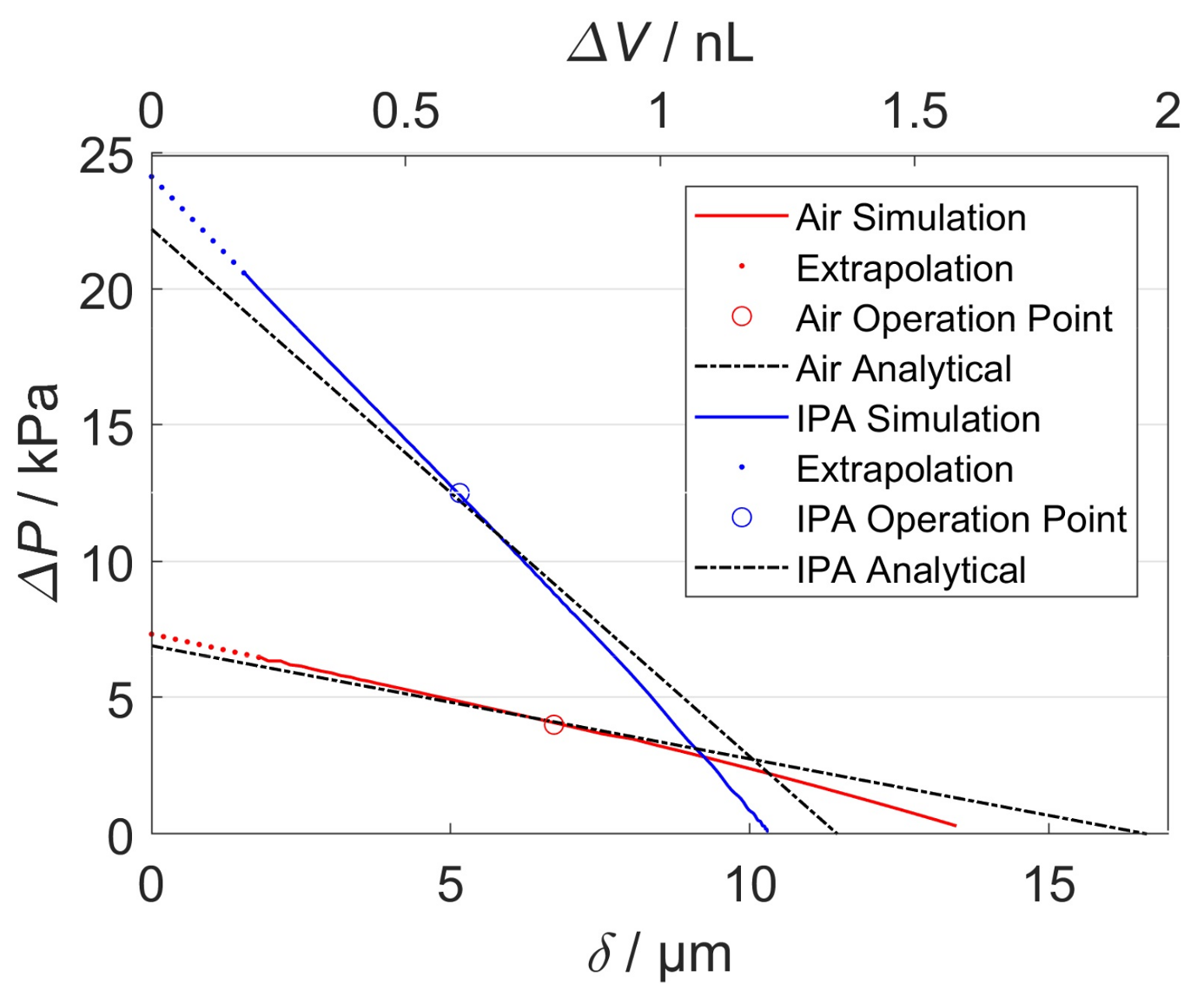

Such kinds of bending actuators follow a characteristic actuator curve, as shown in

Figure 4. At each position of the active displacement, the actuator delivers a specific gauge overpressure in the cavity being compressed, as shown in the upper part of the graph. In the same manner, canceling the applied moment, i.e., switching off the control voltage, will allow the deformed actuator to release the elastic bending energy and move back to its original position. As a result, the previously compressed cavity is expanded, generating a gauge underpressure. This is shown schematically in

Figure 3b and represented in the lower part of the graph in

Figure 4.

During a full cycle, both cavities (on the lower and the upper side of the beam; see

Figure 3) experience a compression and a subsequent expansion, which can be associated to a pump and intake stroke, correspondingly. The resulting flow rate during the cycle thereby depends on the generated differential pressure, flow channel geometry, and fluid properties [

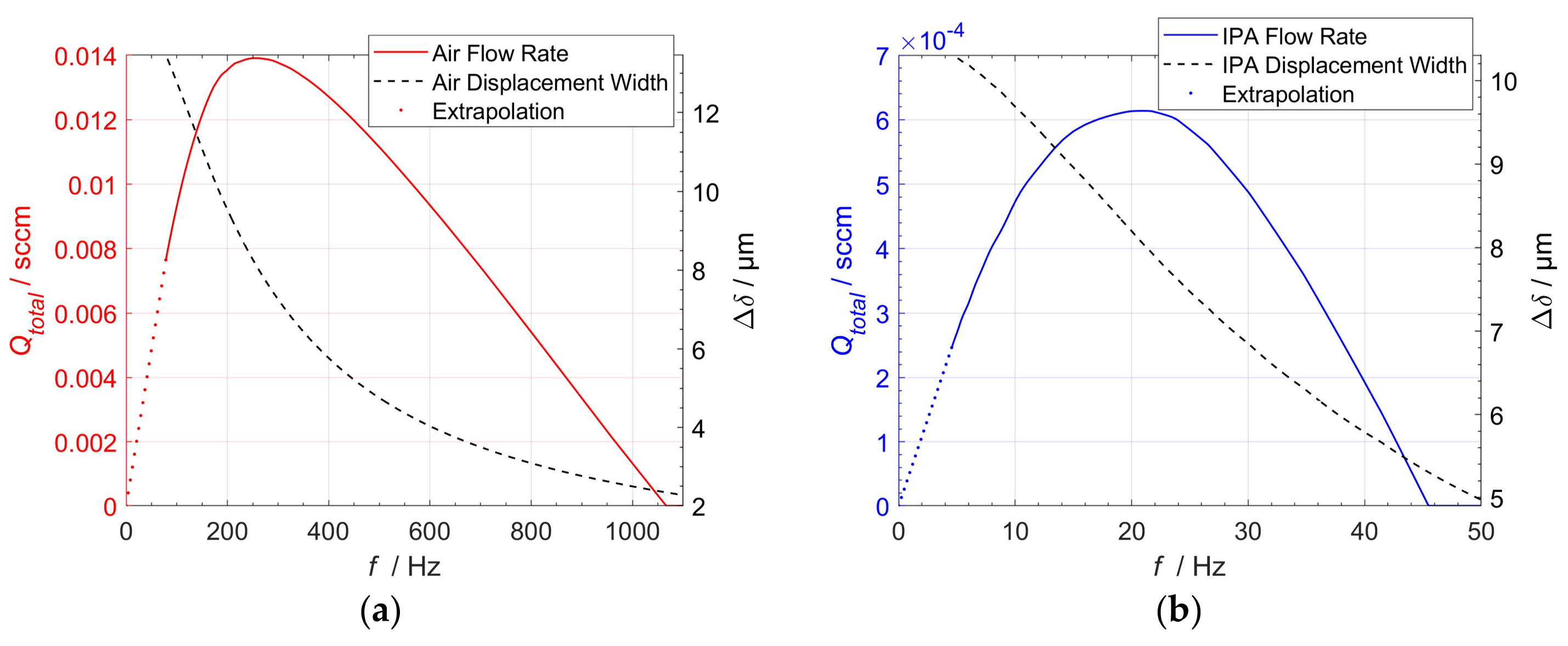

21]. By letting the NED actuator beam displace over its full range and back to the initial position, a flow rate is to be expected which is lower than the maximum achievable flow rate of the set-up. This is due to the fact that at displacements near

in the active stroke, and

in the passive stroke, the generated gauge pressure tends to zero. Hence, the stroke volume takes a longer time duration to be pumped. On the other hand, switching off the driving voltage at a too small displacement results in a smaller generated gauge pressure in the cavities (i.e., smaller differential pressure), and thus, unequal stroke durations. This consequently leads to a reduced output flow rate, as well.

An optimum flow rate can be achieved if the generated gauge pressure, at the beginning of active and passive stroke is the same, resulting in equal time durations of pump and intake phase. With the exception of the extreme case of a full displacement range operation, which takes a longer stroke time, this is also the case for a reduced symmetric zone operation around the actuators’ half displacement, with significantly shorter stroke durations. Here, the shorter stroke durations also mean smaller stroke volume, but the stroke durations will have higher influence on the flow rate. For that reason, it is of interest to actuate in a defined displacement interval around a working point, chosen to be at the actuators half displacement. This is shown schematically in

Figure 4. The electrical excitation of the actuator is chosen as a periodic step function rather than a sinusoidal function, in order to have the generated pressure instantly available, and not building up following the characteristic pressure/displacement graph.

2.2. Base Unit Design of the Micropump

The advantage of the NED actuator is that its maximum generated bending moment (i.e., its maximum generated differential pressure) can be optimized for a specific fluid with dielectric permittivity at a targeted control voltage. With that in mind, two micropump test structures were designed with two different actuator design points. Design point A for pumping air is operated at +300 V, and design point B for Isopropanol (IPA) is operated at +100 V. The design consists of multiple identical pumping units: the so-called “base units”. A base unit is composed of 4 NED actuators in (c-c) configuration, as displayed in

Figure 2, with two actuators placed in series and another two facing each other with shift of

.

Figure 5 shows an illustration of a base unit with adjacent units indicated above and underneath.

During the active stroke, the actuators inside the base unit deflect in opposite directions. Thereby, the flow channel inside the base unit is compressed, while the flow channel between two neighboring base units is expanded. The generated differential pressure by the actuators between the flow channel cavities establishes a flow from one base unit to the next through the passive valves, indicated as check valves in

Figure 5. The base units are periodically stacked, which increases the total length of the flow channel. This increases the differential pressure drop for an imposed backpressure from the outlet to the inlet of the micropump. The advantage of this is that each base unit acts only as an

N-th part of the back pressure, with

N being the number of periodically stacked units. Thereby, the generated differential pressure is added to the fluid in each of the pump unit stages. This creates a stage-like structure of the micropump. As a result, a larger pressure difference between the inlet and outlet can be overcome.

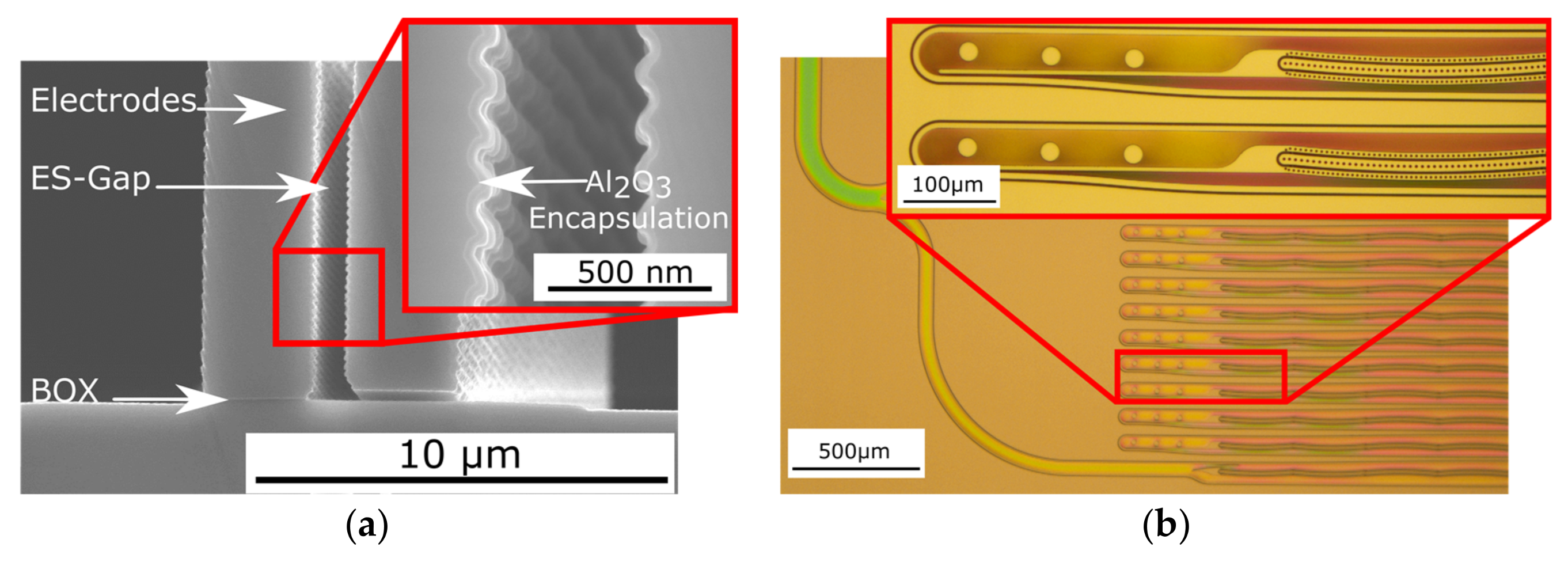

2.4. Micropump Test Structure Setup and Fabrication

The micropump test structure chip is composed of a standard wafer, which is bonded on a bonded Silicon On Insulator (SOI) wafer, with 1 µm Buried-Oxide (BOX). The bond interface between the top cover and the SOI is thermal grown Silicon-Dioxide (SiO

2) of 1 µm as well. The active device layer has a height of 75 μm and contains the driving NED actuator beams as well as passive valves and fluidic channels. It is processed by standard bulk-micromachining technologies, such as Deep Reactive Ion Etching (DRIE).

Figure 7a shows the result of a test etching of the electrostatic gap of the NED electrodes. The fluidic inlet and outlet are located on the top cover, while the electrical connections are located on the bottom cover (SOI-handle), making up a total chip thickness of approximately 900 μm. This enables an easy integration of the chip into a measurement system. The entire fabrication process is compatible with CMOS-technologies, using crystalline silicon, silicon-dioxide, and aluminumoxid only.

A micrograph of a processed device layer of the micropump test structure is presented in

Figure 7b, where the feed channels from the inlet and the left part of the periodically arranged pumping base units are shown. The inset shows the magnified passive valves of two base units and the beginning of the defined shaped electrodes of the NED electrostatic-bending actuators. The currently fabricated design points of the micropump test structures are chosen to test the working principle with non-conductive fluids. However, in terms of perspective, the intention is to pump conductive fluids, as well. In order to avoid electrical short-circuiting, the electrodes are additionally encapsulated by either a layer of 60 nm Al

2O

3 (

Figure 7a), deposited by Atomic Layer Deposition (ALD), or in another split by a 200 nm layer of Parylene.

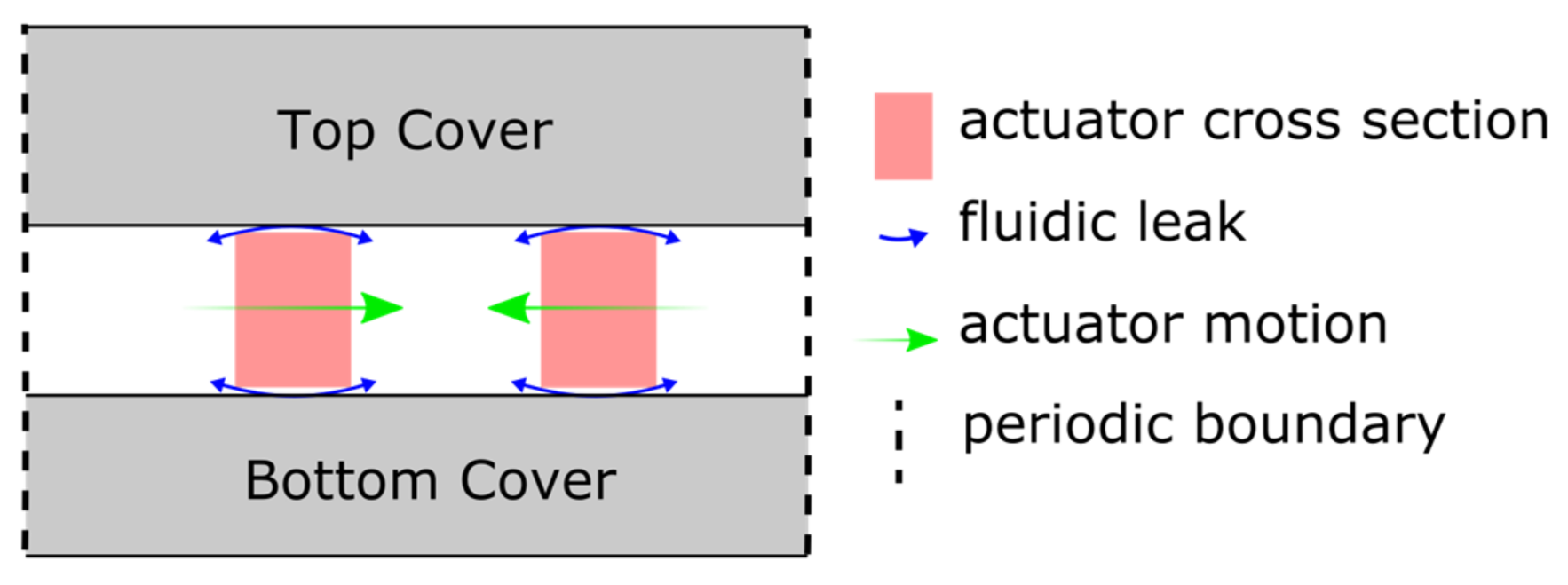

Figure 8 shows a sketch of a cross-section of a fabricated wafer stack going through the middle of a base unit. To ensure that the actuators and the valves can move laterally in the wafer stack, the 1 µm oxide layer is locally removed. The remaining clearance presents a fluidic leak that is small compared to the fluid transfer in the channels (cf.

Figure 7b). It manifests itself as a dead volume during the operation. The additional encapsulation of the actuators by Parylene or Al

2O

3 further reduces this clearance.

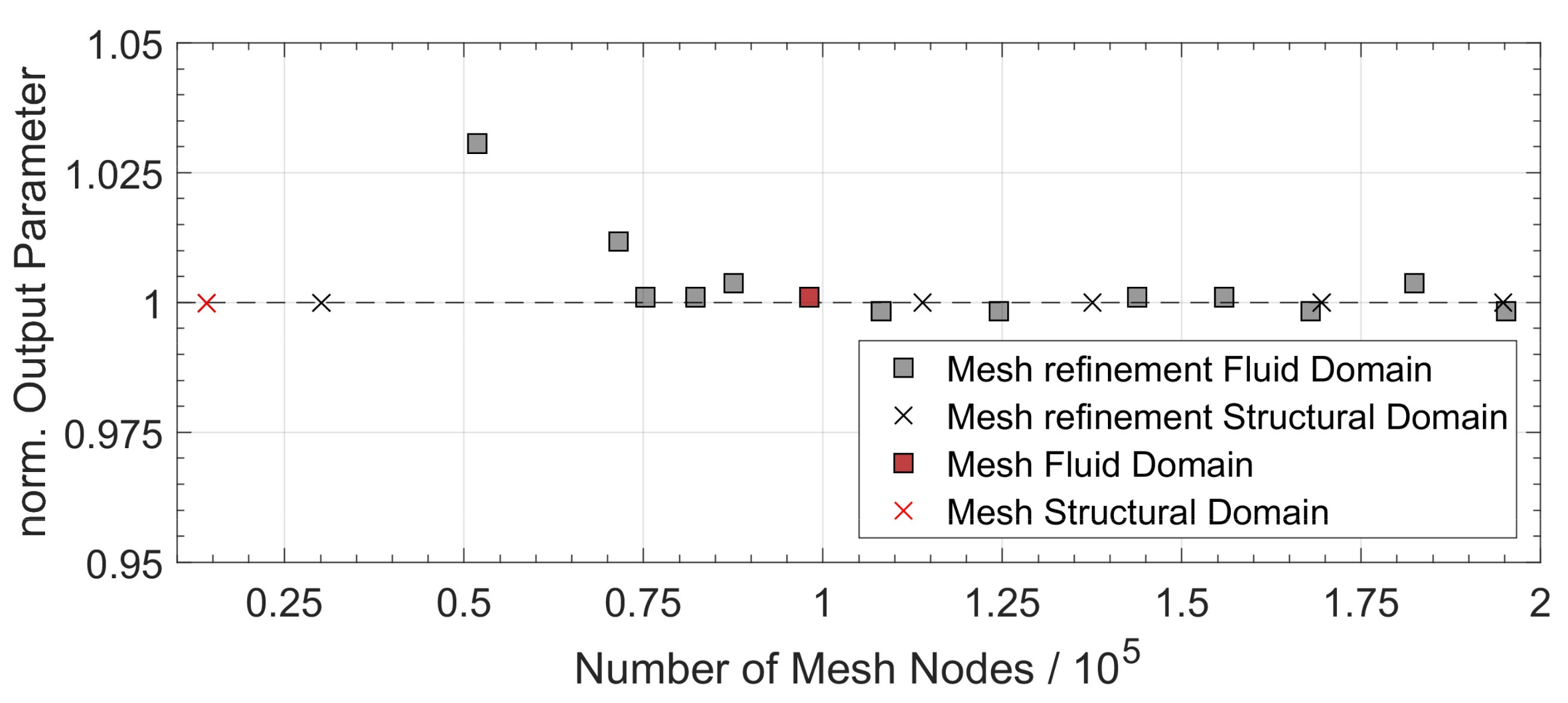

2.5. Simulation Setup of the Micropump

In order to validate the concept and the behavior of the NED in-plane micropump test structures, a transient two-way Fluid-Structure Interaction (FSI) simulation [

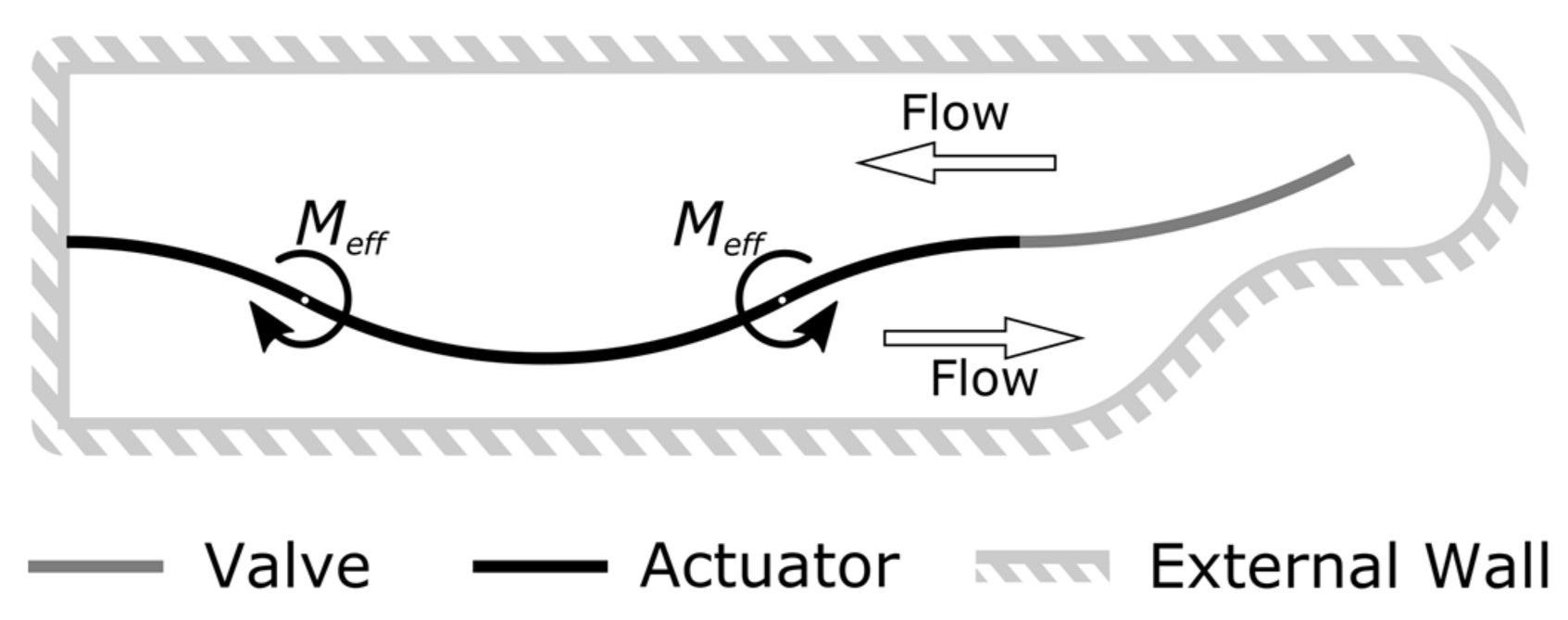

22] using an ANSYS Workbench was carried out. The multiphysics problem is thereby treated in a partitioned approach. This means that the governing equations of the structural and fluid domain are solved separately, and their resulting data (i.e., displacement and pressure, respectively) is exchanged in a coupling application between the individual solvers. This was achieved by combining the toolboxes “transient mechanical” and “FLUENT” via the “system coupling” toolbox, which controlled the data transfer and the number of coupling steps used. The two-way FSI simulation therefore takes into account the effect of the structural domain on the fluid, as well as the subsequent reaction of the fluid on the structural part. To reduce the computational complexity, a simplified model of the described base unit was created. The FSI model consists of a cavity of one NED actuator beam in (c-c) configuration of length

and one passive flap valve, with the same dimension as the designed base unit of the micropump test structures. This model is sufficient to cover the behavior of pumping the fluid through the structure of the micropump to the outlet, since each stage works equivalently and transfers the fluid from underneath to above the actuator through the separating passive valve. The clearance was not considered in this model. A 2D sketch of the FSI model’s geometry is shown in

Figure 9.

Because of the anisotropic DRIE fabrication process, the device layer of the micropump can be seen as an extrusion of the 2D geometry into the 3rd dimension. Thus, only a thin 2.5D slice, (extrusion of 2D geometry into 3D) of one finite-volume height of 4 µm was simulated, instead of the entire 3D structure of the pump. This simplification further reduces the computational complexity. As a result, in this model the choice of a 4 µm 2.5D-slice height ensured finite volumes with a high mesh quality (skewness of 0.6, orthogonal quality of 0.7). The top and bottom plane of the 2.5D model slice (the paper plane in

Figure 9) were set up as symmetric boundary conditions, consequently neglecting the influence of the top and bottom walls of the fluid channel. This approach is valid due to the high aspect ratio of channel height and channel width of more than 15, as can be seen in

Figure 7b [

23].

In the structural domain, the entities’ actuator and valve were meshed using higher-order SOLID186 elements. The actuator itself was modelled as a solid beam, with equivalent bending stiffness

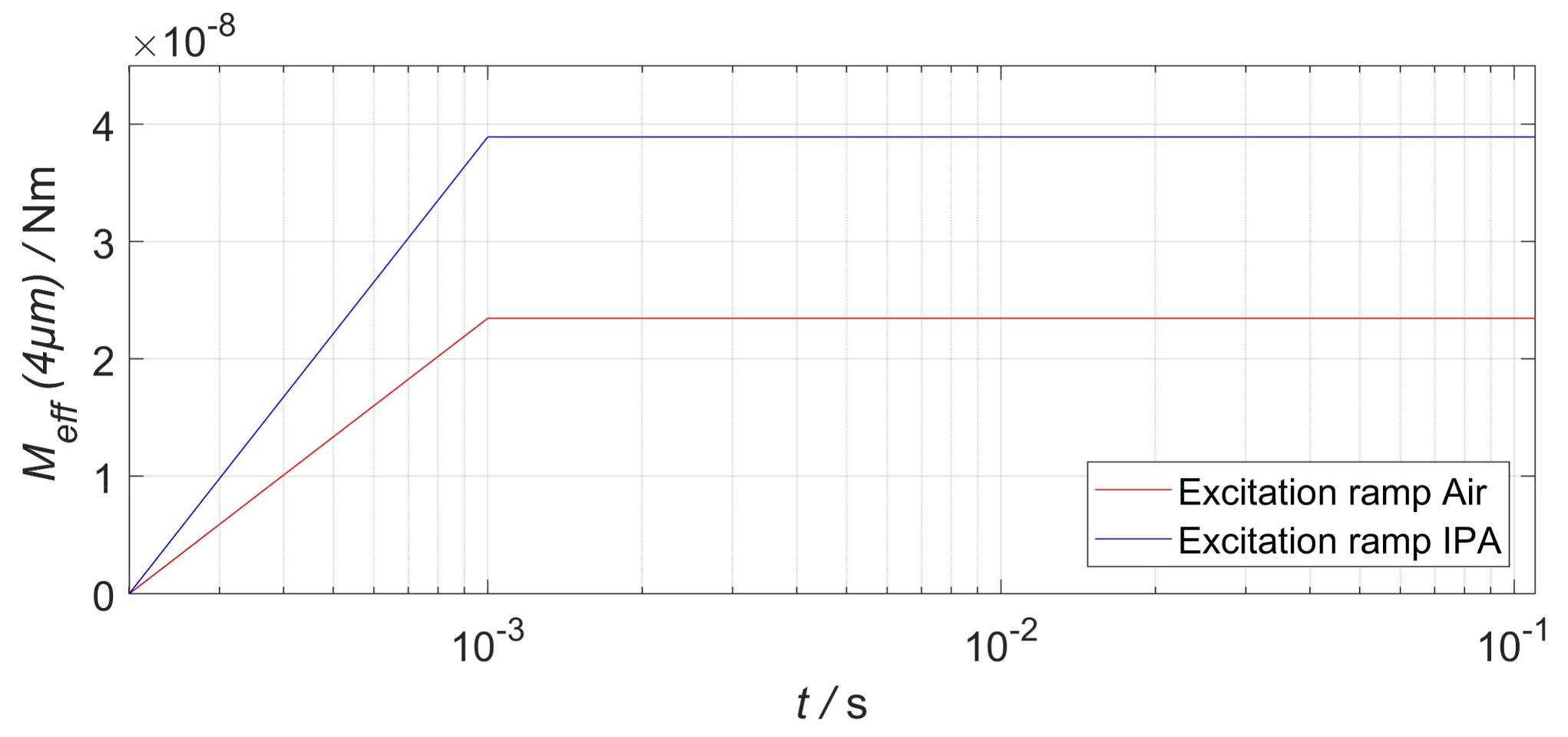

, and equal footprint of the physical NED actuator beam. The effective moments

were scaled to the 2.5D model height and applied at the positions of

and

via a step excitation. In order to ensure convergence of the model during the pressure buildup, the moment step was ramped with a time constant of

s, as shown in

Figure 10. The generated pressure of the 2.5D slice model remains the same as for a full 3D structure, since the force (i.e., applied beam moment) and area facing the fluid is scaled down equivalently. Further boundary conditions in “ANSYS mechanical” included the fixed supports and the fluid–solid interfaces (actuator and valves sides facing the fluid). During the simulation, the fluid reaction data is mapped as a load onto these interfaces. Additionally, nonlinear stiffening effects were considered in the structural model.

The fluid domain was setup in “FLUENT”. For lengths scales

, the fluid can be considered as a continuum of fluid particles, meaning that no significant fluctuation of the viscosity is expected in the physical case [

23,

24]. The viscosity and density values used in the simulation are based on a reference temperature of

. The small microchannel dimensions in the geometry (channel widths ranging from 3–30 µm) and a differential pressure drop in the kPa range generate flow velocities of a few m/s, leading to low Reynolds numbers (

). At values lower than 2300, the flow can be considered as laminar in the system. Consequently, the model for laminar flows with constant viscosity in “FLUENT” was selected. In the material properties, air was modelled as ideal gas, while IPA was modelled as a compressible fluid, with a maximum allowable change in density of ±2%. This is of high importance, because in a closed volume system with deforming boundaries, as modelled above, a constant density would imply an infinite wave speed and result in a non-converging model [

25]. Because of large structural deformations (i.e., valve and actuator deflection), relative to the finite-volume mesh size, the option deforming mesh in combination with mesh smoothing was applied. For the remeshing, the 2.5D option was selected, while the mesh smoothing was based on the spring-layer boundary method.

The computational fluid dynamic (CFD) solution was obtained by using the pressure-based solver with the SIMPLE algorithm. Furthermore, the solution was stabilized by using the coefficient-based stabilization factors with the declared fluid–solid interfaces.

The time step used in the FSI simulation was declared in the “system coupling” toolbox, as well as in the “mechanical” toolbox, and was chosen to reach a proper convergence of the flow field and data transfers between the solvers in the “mechanical” and “FLUENT” toolboxes. A complete list of solver settings and convergence criteria is given in

Appendix A of

Table A1, while an error analysis is presented in

Appendix B. The corresponding actuator and valve design point values used in the simulation are summarized in

Table 1.