IoTwins: Toward Implementation of Distributed Digital Twins in Industry 4.0 Settings

Abstract

:1. Introduction

2. Related Work

3. IoTwins: A Use Case-Driven Project

- Support data transfer to/from the three infrastructure levels in ways that account for the constraints imposed by the specific computation needs (real-time, non-real-time);

- Support several data types and accommodate different data storage needs (short- and long-term storage);

- Support the elaboration of data both on the fly (streamed-data elaboration) and at rest (batch-data elaboration).

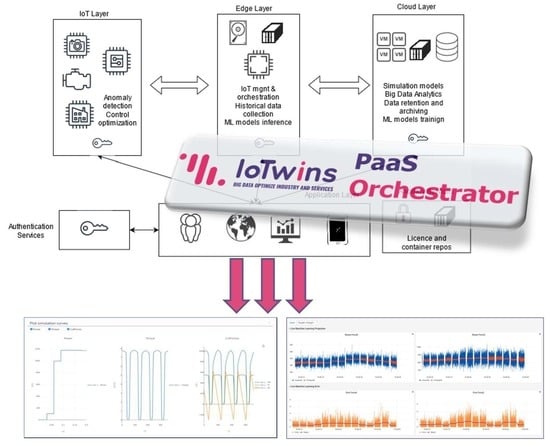

4. Design of an Open Platform for Digital Twins

- Data handling: this refers to the process of gathering, recording and presenting information in a way that is helpful to the final user. It includes three different consecutive steps: data gathering, data transportation and data storage. Data gathering is performed by the sensing devices from the field. Data transportation provides the protocols to implement communication among the three layers (IoT, edge, cloud). Currently, data transportation leverages standard (or de facto standard) technologies to maintain compatibility among the services. Data storage solutions (data models and databases) are used either as preliminary storage or as long-term storage for the testbeds;

- Computation: this is requested at all layers. At the IoT layer, a few computation tools are needed, such as those suited for light and quick calculations enabled on some types of devices. At the edge layer, filtering, data aggregation and big data analytics can be activated. At the cloud layer, heavy simulations and ML training are mainly carried out;

- Anonymization: this consists of replacing/obfuscating/removing data that can identify individuals, both directly and indirectly. This is an important issue for industry, where data need to be kept under strict confidentiality;

- Encryption: this is used to encrypt channels for data transfers. Due to the heavy computational cost of this service, it is provided in the edge and cloud layers.

5. IoTwins Platform’s Components and Functionalities

5.1. Authentication and Authorization

- Normal users: they can login to the INDIGO-IAM service, register client applications that use the INDIGO-IAM for authentication and link external accounts to their account;

- Administrators: they have administrative privileges within the INDIGO-IAM organization.

5.2. Cloud Service Components

- The INDIGO Orchestrator [39] is the core component of the PaaS orchestration. It accepts deployment requests expressed in OASIS’s Topology and Orchestration Specification for Cloud Application (TOSCA) [40] format. From the received TOSCA-compliant request, the orchestrator implements a complex provisioning workflow aimed at fulfilling the request using information about the health status and capabilities of underlying IaaS and their resource availability, QoS/SLA constraints, the status of the data files and the storage resources needed by the service/application. This process allows for achieving the best allocation of the resources among multiple IaaS sites;

- The Managed Service/Application (MSA) deployment service [41] is in charge of scheduling, spawning, executing and monitoring applications and services on top of one or more Mesos clusters;

- The Infrastructure Manager (IM) [42] is in charge of deploying complex and customized virtual infrastructures on different IaaS cloud infrastructures. The IM eases the access and the usability of IaaS clouds by automating the VMI (virtual machine image) selection, deployment, configuration, software installation, monitoring and updating of the virtual infrastructure;

- The Data Management Services, a collection of services that provide an abstraction layer for accessing data storage in a unified and federated way, provide a unified view of the storage resources, along with the capabilities of importing data, and schedule transfers of data from different sources. The support of high-level storage requirements, such as flexible allocation of disk or tape storage space and support for the data life cycle, is achieved by the adoption of the INDIGO CDMI server [43]. The CDMI server has been extended in the INDIGO project to support quality-of-Ssrvice (QoS) and data life-cycle (DLC) operations for multiple storage back-ends, such as dCache [44], Ceph [45], IBM Spectrum Scale [46], TSM [47], StoRM [48] and HPSS [49];

- The Monitoring Service [50] is in charge of collecting and monitoring data from the targeted clouds and analyzing and transforming them into information to be consumed by the orchestrator;

- The CloudProviderRanker [51] is a rule-based engine that allows for managing the ranking of the resources eligible to fulfil the requested services. The engine uses the list of IaaS instances and their properties, provided by the orchestrator, to choose the best provider that can support the user requirements;

- The Cloud Information Provider [52] generates a representation of a site’s cloud resources to be published inside the INDIGO Configuration Management Database (CMDB);

- The Configuration Management Database [53] is a REST service storing all the information about the cloud sites that is available and providing details such as the images and containers they support. It is used as an authoritative source of information for matchmaking and the orchestration of VM and containers;

- The QoS/SLA Management Service [54] allows for the handshake between users and resource providers on a given service-level agreement (SLA). The SLA describes the quality of service (QoS) for a group or a specific user, both in the PaaS as a whole or over a given provider.

5.3. Edge Service Components

6. Use Case Scenario

- Measurements and testing;

- Expert analysis;

- Consultancy and training;

- Systems engineering;

- Innovation.

- Model-driven twin, essentially based on simulation tools, that will provide decision support to product planning departments on how to explore optimal ways of implementing production;

- Data-driven twin, built on top of sensor data. Basically, it consists of a ML model trained with historical data in the cloud and then used in the edge to monitor production;

- Hybrid twin, which combines the benefits of the model-driven and data-driven twins. The MOR-based simulator used in online operations shows a very low response time, which makes it compatible with the real-time constraints of the process. In spite of this, the gap between the simulated and real values is still unacceptable. The output of the data-driven model is then used to support the simulator designers to fill that gap.

6.1. Testbed Description and Initial Requirements

- Simulation capabilities were missing. A machining simulation software able to easily compute forces and spindle power would be a plus. Output of simulation could be used to define machine features and limitations;

- During the process setup (pre-production phase), the operator requires the support of software advisors and data analysis tools. The objective is to reduce the new production setup time from 1/2 day to 30 min, and to improve the trial/error phase;

- Need of an optimized operator schedule (calling the operator only when needed for tool changing, typically scheduling the control of the machining process every two hours instead of every hour);

- Need of process monitoring and capitalizing on the events during production time;

- Improvements of part quality (reduce the production of bad parts by detection/prediction using sensor signals and models);

- Need for more accurate and improvable predictions over time (capitalization and fine-tuning of prediction models).

- Visualization of data;

- Local storage;

- Monitoring and follow-up of production (later on, “notifier”), whose purpose is to issue alerts when necessary.

6.2. Requirements of the IoTwins Platform

- Edge computing environment: edge resources are virtualized by means of the software environment provided by the IoTwins edge service runtime. The latter hosts a Mesos cluster to run jobs as containers, which are managed and orchestrated by the Marathon and Chronos frameworks. All containers are hosted at Harbor [61], the open-source registry made available by the IoTwins platform to the IoTwins testbeds;

- Visualization: data visualization is performed through Grafana [66], which displays live sensor data fetched from the MQTT broker deployed at the edge machine. Additional dashboards, developed in the scope of the IoTwins projects, display views combining raw data and training model information. The simulation also requires specific tools to manage visualizations of the results;

- Simulation: the simulation capabilities for machining processes virtually simulate the reality and provide quantitative and qualitative information about the processes and the machine parts. Several decisions may be impacted by such information. Power consumption information may be used to select the most appropriate production machine. Forces predict the the behavior of the tools during the part fabrication and may be used to anticipate breaks and failures. Vibrations are correlated to the tools’ wear. Altogether, this information supports the user to design the process, set the process parameters and define the production strategy;

- ML training: data analytics is deployed to detect the default in a machining process. For simplicity, the parts are labelled as damaged (1) or good (0). According to the level of error, three zones are defined to access the quality of the part and an appropriate alert is notified: green zone (good parts), when the error value is 2%, orange zone (average parts), when the error value is between 2% and 5%; and red zone (bad parts), when the error value is above 5% (percentages are expressed in absolute values). The first machined parts are used to extract the features (modes), via the proper orthogonal decomposition [67] (POD) methodology, which is similar to the singular value decomposition (SVD) method, of what are qualified as “good parts”. The extraction of the data is performed on the sensors’ data, measured on the tool. The forces of the tool are used as indicators of the state of the machined part. Trained models (modes), built offline and stored, will be sent to the edge machine in the production phase. Measured sensor data are projected on the (stored) modes (describing the good parts). The projection error helps to define the state of the current machined part. According to the level of error, an alert notification may be issued.

6.3. UML Sequence Diagram of a Digital Twin Deployment

6.4. The Application and Development Context

- build the sequence manufacturing process operations;

- identify potential issues that may come during the production phase;

- select the most appropriates machines for the production based on the computed forces and the machine power.

7. Conclusions and Future Work

- data transfer to/from the different infrastructure levels;

- data types to accommodate different data storage needs;

- elaboration of data both for streamed-data and batch-data elaboration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Reference Architecture Model Industrie 4.0 (RAMI 4.0). Available online: https://www.isa.org/intech-home/2019/march-april/features/rami-4-0-reference-architectural-model-for-industr (accessed on 13 March 2022).

- Wübbeke, J.; Meissner, M.; Zenglein, M.J.; Ives, J.; Conrad, B. MADE IN CHINA 2025: The Making of a High-Tech Superpower and Its Implications for Industrial Countries in Handout for Hamburg Summit, Mercator Institute for China Studies. 2017. Available online: https://merics.org/en/report/made-china-2025 (accessed on 27 April 2022).

- Internet Industrial Reference Architecture (IIRA), Journal of Industrial IoT Consortium Releases Reference Architecture. Available online: https://www.iiconsortium.org/press-room/06-17-15.htm (accessed on 13 March 2022).

- European Open Science Cloud Hub. Available online: https://www.eosc-hub.eu/ (accessed on 13 March 2022).

- H2020 IoTwins Project. Available online: https://www.iotwins.eu/ (accessed on 13 March 2022).

- Costantini, A.; Duma Doina, C.; Martelli, B.; Antonacci, M.; Galletti, M.; Tisbeni Rossi, S.; Bellavista, P.; Di Modica, G.; Nehls, D.; Ahouangonou, J.C.; et al. A Cloud-Edge Orchestration Platform for the Innovative Industrial Scenarios of the IoTwins Project. In Computational Science and Its Applications–ICCSA 2021; Gervasi, O., Murgante, B., Misra, S., Garau, C., Blečić, I., Taniar, D., Apduhan, B.O., Rocha, A.M.A.C., Tarantino, E., Torre, C.M., Eds.; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2021; Volume 12950. [Google Scholar] [CrossRef]

- Bittighofer, D.; Dust, M.; Irslinger, A.; Liebich, M.; Martin, L. State of Industry 4.0 Across German Companies. In Proceedings of the in 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–8. [Google Scholar]

- Trotta, D.; Garengo, P. Assessing Industry 4.0 Maturity: An Essential Scale for SMEs. In Proceedings of the 8th International Conference on Industrial Technology and Management (ICITM), Cambridge, UK, 2–4 March 2019; pp. 69–74. [Google Scholar]

- Yang, L. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inform. Integr. 2017, 6, 1–10. [Google Scholar]

- Xu, H.; Yu, W.; Griffith, D.; Golmie, N. A Survey on Industrial Internet of Things: A Cyber-Physical Systems Perspective. IEEE Access 2018, 6, 78238–78259. [Google Scholar] [CrossRef]

- Halenar, I.; Juhas, M.; Juhasova, B.; Borkin, D. Virtualization of Production Using Digital Twin Technology. In Proceedings of the 2019 20th International Carpathian Control Conference (ICCC), Kraków, Poland, 26–29 May 2019. [Google Scholar] [CrossRef]

- Jaensch, F.; Csiszar, A.; Scheifele, C.; Verl, A. Digital twins of manufacturing systems as a base for machine learning. In Proceedings of the in 2018 25th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Stuttgart, Germany, 20–22 November 2018. [Google Scholar] [CrossRef]

- Perzylo, A.; Profanter, S.; Rickert, M.; Knoll, A. Opc ua nodeset ontologies as a pillar of representing semantic digital twins of manufacturing resources. In Proceedings of the 2019 IEEE 24th International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019. [Google Scholar] [CrossRef] [Green Version]

- Preuveneers, D.; Joosen, W.; Ilie-Zudor, E. Robust digital twin compositions for industry 4.0 smart manufacturing systems. In Proceedings of the 2018 IEEE 22nd International Enterprise Distributed Object Computing Workshop (EDOCW), Stockholm, Sweden, 16–19 October 2018. [Google Scholar] [CrossRef] [Green Version]

- SPARTA Cybersecurity. 20 January 2022. Available online: https://www.sparta.eu (accessed on 13 March 2022).

- Europe’s AI-on-Demand Platform. Available online: https://www.ai4europe.eu/ (accessed on 13 March 2022).

- Fortissimo: Enabling Manufacturing SMEs to Benefit from High Performance, Computer-based Simulations. Available online: https://www.fortissimo-project.eu/ (accessed on 13 March 2022).

- Amazon Web Services (AWS). Available online: https://aws.amazon.com/iot/ (accessed on 13 March 2022).

- Microsoft Azure. Available online: https://azure.microsoft.com/overview/iot/ (accessed on 13 March 2022).

- Google Cloud Platform (GCP). Available online: https://cloud.google.com/solutions/iot (accessed on 13 March 2022).

- Bringing Fog Technlogy into Manufacturing Industry. Available online: https://www.autoware-eu.org/ (accessed on 13 March 2022).

- Real-Time Machine to Machine Communication. Available online: http://www.beincpps.eu/ (accessed on 13 March 2022).

- European Initiative that Applies Big Data in Manufacturing Applications through Fog/Edge Technology. Available online: https://boost40.eu/ (accessed on 13 March 2022).

- AWS IoT Greengrass Cloud-Edge Architectures. Available online: https://aws.amazon.com/greengrass/ (accessed on 13 March 2022).

- Cejka, S.; Knorr, F.; Kintzler, F. Edge device security for critical cyber-physical systems. In Proceedings of the 2nd Workshop on Cyber-Physical Systems Security and Resilience (CPS-SR), Pittsburgh, PA, USA, 21 April 2017. [Google Scholar]

- AWS IoT SiteWise: Collect, Store, Organize, and Monitor Data from Industrial Facilities at Large Scale. Available online: https://aws.amazon.com/iot-sitewise/ (accessed on 13 March 2022).

- DEEP-Hybrid-DataCloud (DEEP-HDC) EU Funded Project. Available online: https://deep-hybrid-datacloud.eu/ (accessed on 13 March 2022).

- eXtreme-DataCloud (XDC) EU Funded Project. Available online: http://www.extreme-datacloud.eu/ (accessed on 13 March 2022).

- INDIGO-DataCloud EU Funded Project, Web Site, Last view March 2022. Available online: https://repo.indigo-datacloud.eu/ (accessed on 13 March 2022).

- INDIGO Identity and Access Management (IAM) Service. Available online: https://github.com/indigo-iam/iam (accessed on 13 March 2022).

- Security Assertion Markup Language. Available online: http://docs.oasis-open.org/security/saml/Post2.0/sstc-saml-tech-overview-2.0.html (accessed on 13 March 2022).

- OpenID Connect. Available online: https://openid.net/connect/ (accessed on 13 March 2022).

- X.509. Available online: https://www.itu.int/rec/T-REC-X.509/en (accessed on 13 March 2022).

- IDEM Federation. Available online: https://idem.garr.it/en/federazione-idem-en/idem-federation (accessed on 13 March 2022).

- eduGAIN Interfederation Service. Available online: https://edugain.org/ (accessed on 13 March 2022).

- Salomoni, D.; Campos, I.; Gaido, L.; Marco de Lucas, J.; Solagna, P.; Gomes, J.; Matyska, L.; Fuhrman, P.; Hardt, M.; Donvito, G.; et al. INDIGO-DataCloud: A platform to facilitate seamless access to e-infrastructures. J. Grid Comput. 2018, 16, 381–408. [Google Scholar] [CrossRef] [Green Version]

- Cesini, D.; Costantini, A.; Fuhrmann, P.; Aguilar, F.; Duma, C.; Ohmann, C.; Lemrani, R.; Keeble, O.; Battaglia, S.; Poireau, V.; et al. The eXtreme-DataCloud project: Data management services for the next generation distributed e-infrastructures. In Proceedings of the 2018 Conference Grid, Cloud & High Performance Computing in Science (ROLCG), Cluj-Napoca, Romania, 17–19 October 2018; pp. 1–4. [Google Scholar] [CrossRef]

- López García, Á.; de Lucas, J.M.; Antonacci, M.; Castell, W.Z.; David, M.; Hardt, M.; Iglesias, L.L.; Molto, F.; Plociennik, M.; Tran, V.; et al. A Cloud-Based Framework for Machine Learning Workloads and Applications. IEEE Access 2020, 8, 18681–18692. [Google Scholar] [CrossRef]

- INDIGO Orchestrator Component. Available online: https://github.com/indigo-dc/orchestrator (accessed on 13 March 2022).

- TOSCA—Topology and Orchestration Specification for Cloud Applications. Available online: https://docs.oasis-open.org/tosca/TOSCA-Simple-Profile-YAML/v1.3/os/TOSCA-Simple-Profile-YAML-v1.3-os.html (accessed on 13 March 2022).

- Managed Service/Application Service. Available online: https://github.com/indigo-dc/mesos-cluster (accessed on 13 March 2022).

- Infrastructure Manager Service. Available online: https://indigo-dc.gitbook.io/im/ (accessed on 13 March 2022).

- INDIGO Cloud Data Management Interface. Available online: https://www.snia.org/cdmi (accessed on 13 March 2022).

- dCache Storage Service. Available online: https://www.dcache.org (accessed on 13 March 2022).

- CEPH Distributed Storage System. Available online: https://ceph.io (accessed on 13 March 2022).

- IBM Spectrum Scale Distributed Storage System. Available online: https://www.ibm.com/docs/en/spectrum-scale/5.0.4?topic=overview-spectrum-scale (accessed on 13 March 2022).

- IBM Spectrum Protect. Available online: http://www-03.ibm.com/software/products/it/spectrum-protect (accessed on 13 March 2022).

- Storage Resource Manager Service. Available online: http://italiangrid.github.io/storm/documentation/functional-description/1.11.2/ (accessed on 13 March 2022).

- High Performance Storage Systems. Available online: https://www.hpss-collaboration.org (accessed on 13 March 2022).

- High Performance Storage Systems. Available online: https://github.com/indigo-dc/Monitoring (accessed on 13 March 2022).

- CloudProviderRanker Cloud Service. Available online: https://github.com/indigo-dc/CloudProviderRanker (accessed on 13 March 2022).

- Cloud Info Provider Cloud Service. Available online: https://github.com/EGI-Federation/cloud-info-provider (accessed on 13 March 2022).

- Configuration Management DataBase Cloud Service. Available online: https://github.com/indigo-dc/cmdb (accessed on 13 March 2022).

- QoS/SLA Management Service. Available online: https://github.com/indigo-dc/slam (accessed on 13 March 2022).

- Open Container Initiative. Available online: https://opencontainers.org/ (accessed on 13 March 2022).

- Mesos Project. Available online: http://mesos.apache.org/ (accessed on 13 March 2022).

- Apache Marathon Framework. Available online: https://mesosphere.github.io/marathon/ (accessed on 13 March 2022).

- Apache Chronos Framework. Available online: https://mesos.github.io/chronos/ (accessed on 13 March 2022).

- Cetim—Centre Technique des Industries Mécaniques. Available online: https://www.cetim.fr/ (accessed on 13 March 2022).

- Industry 4.0: Digitalisation for Productivity and Growth, Web Site. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2015/568337/EPRS_BRI(2015)568337_EN.pdf (accessed on 13 March 2022).

- Harbor, Harbor is an Open Source Registry. Available online: https://goharbor.io/ (accessed on 13 March 2022).

- RabbitMQ Open Source Message Broker. Available online: https://www.rabbitmq.com/ (accessed on 13 March 2022).

- MQTT: An OASIS Standard Messaging Protocol for the Internet of Things (IoT). Available online: https://mqtt.org/ (accessed on 13 March 2022).

- PostgreSQL Open Source Object-Relational Database. Available online: https://www.postgresql.org/ (accessed on 13 March 2022).

- InfluxDB Time Series Data Platform. Available online: https://www.influxdata.com/ (accessed on 27 April 2022).

- Grafana Operational Dashboards for Data Visualization. Available online: https://grafana.com/ (accessed on 27 April 2022).

- Chinesta, F.; Huerta, A.; Rozza, G.; Willcox, K. Model Order Reduction, 2nd ed.; Chapter in the Encyclopedia of Computational Mechanics; Stein, E., de Borst, R., Hughes, T., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2015. [Google Scholar]

- Kubernetes Production-Grade Container Orchestration. Available online: https://kubernetes.io/ (accessed on 13 March 2022).

| Referenced Infrastructure | Use Case Flow | Data Processing |

|---|---|---|

| IoT | Configure and run | On-the-fly data processing |

| data processing. | or data processing at rest. | |

| Edge | Configure data processing, | |

| run bulk data and | Data stream processing. | |

| data stream processing, | ||

| run ML model. | ||

| Cloud | Configure data processing, | Data streams from |

| run bulk-data and | either IoT or edge | |

| data stream processing, | or data-at-rest | |

| run ML training | stored in the cloud | |

| and simulation. | data processing. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costantini, A.; Di Modica, G.; Ahouangonou, J.C.; Duma, D.C.; Martelli, B.; Galletti, M.; Antonacci, M.; Nehls, D.; Bellavista, P.; Delamarre, C.; et al. IoTwins: Toward Implementation of Distributed Digital Twins in Industry 4.0 Settings. Computers 2022, 11, 67. https://doi.org/10.3390/computers11050067

Costantini A, Di Modica G, Ahouangonou JC, Duma DC, Martelli B, Galletti M, Antonacci M, Nehls D, Bellavista P, Delamarre C, et al. IoTwins: Toward Implementation of Distributed Digital Twins in Industry 4.0 Settings. Computers. 2022; 11(5):67. https://doi.org/10.3390/computers11050067

Chicago/Turabian StyleCostantini, Alessandro, Giuseppe Di Modica, Jean Christian Ahouangonou, Doina Cristina Duma, Barbara Martelli, Matteo Galletti, Marica Antonacci, Daniel Nehls, Paolo Bellavista, Cedric Delamarre, and et al. 2022. "IoTwins: Toward Implementation of Distributed Digital Twins in Industry 4.0 Settings" Computers 11, no. 5: 67. https://doi.org/10.3390/computers11050067