One-Step Preparation of Biochar Electrodes and Their Applications in Sediment Microbial Electrochemical Systems

Abstract

:1. Introduction

2. Results and Discussion

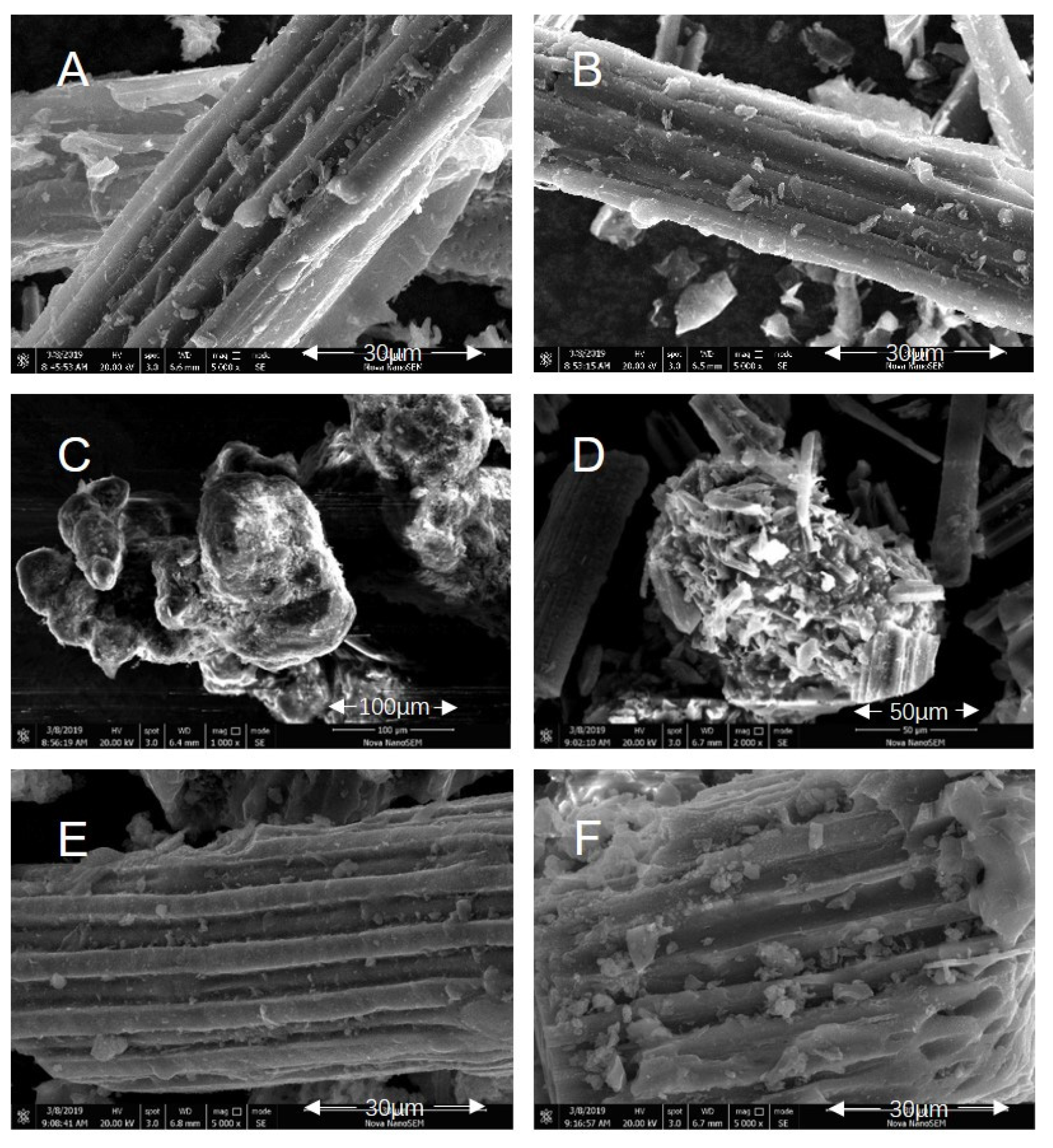

2.1. Analysis of the Biochar Materials

2.2. Analysis of Electrochemical Properties of Biochar-Based Electrode

2.3. Performance of Sediment Microbial Electrochemical Reactors with Different Biochar-Based Materials as the Cathodes

3. Materials and Methods

3.1. Biochar Electrodes Preparation

3.2. Determination of Physical and Electrochemical Properties of Materials

3.3. Construction and Operation of Sediment Microbial Electrochemical Reactors

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Watanabe, K. Recent Developments in Microbial Fuel Cell Technologies for Sustainable Bioenergy. J. Biosci. Bioeng. 2008, 106, 528–536. [Google Scholar] [CrossRef]

- Moon, H.; Chang, I.S.; Kim, B.H. Continuous electricity production from artificial wastewater using a mediator-less microbial fuel cell. Bioresour. Technol. 2006, 97, 621–627. [Google Scholar] [CrossRef]

- You, S.; Zhao, Q.; Zhang, J.; Jiang, J.; Wan, C.; Du, M.; Zhao, S. A graphite-granule membrane-less tubular air-cathode microbial fuel cell for power generation under continuously operational conditions. J. Power Sources 2007, 173, 172–177. [Google Scholar] [CrossRef]

- Jiang, D.; Li, B. Granular activated carbon single-chamber microbial fuel cells (GAC-SCMFCs): A design suitable for large-scale wastewater treatment processes. Biochem. Eng. J. 2009, 47, 31–37. [Google Scholar] [CrossRef]

- Sohi, S.P. Agriculture. Carbon storage with benefits. Science 2012, 338, 1034–1035. [Google Scholar] [CrossRef]

- Maddox, N. The promise [and uncertainties] of Biochar. CSA News Mag. 2013, 58, 4–9. [Google Scholar] [CrossRef]

- Lehmann, J.; Gaunt, J.; Rondon, M. Bio-char Sequestration in Terrestrial Ecosystems—A Review. Mitig. Adapt. Strateg. Glob. Chang. 2006, 11, 403–427. [Google Scholar] [CrossRef]

- Brosse, N.; Dufour, A.; Meng, X.; Sun, Q.; Ragauskas, A. Miscanthus: A fast-growing crop for biofuels and chemicals production. Biofuels Bioprod. Biorefining 2012, 6, 580–598. [Google Scholar] [CrossRef]

- Kookana, R.S.; Sarmah, A.K.; Zwieten, L.V.; Krull, E.V.; Singh, B. Biochar Application to Soil: Agronomic and Environmental Benefits and Unintended Consequences. Adv. Agron. 2011, 112, 103–143. [Google Scholar]

- Yan, L.; Guo, Y.; Wei, G.; Zhuo, W.; Ma, Y.; Wang, Z. Simultaneous preparation of silica and activated carbon from rice husk ash. J. Clean. Prod. 2012, 32, 204–209. [Google Scholar]

- Uchimiya, M.; Wartelle, L.H.; Klasson, K.T.; Fortier, C.A.; Lima, I.M. Influence of Pyrolysis Temperature on Biochar Property and Function as a Heavy Metal Sorbent in Soil. J. Agric. Food Chem. 2011, 59, 2501–2510. [Google Scholar] [CrossRef]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Ok, Y.S. Biochar as a sorbent for contaminant management in soil and water: A review. Chemosphere 2014, 99, 19–33. [Google Scholar] [CrossRef]

- Wu, P.; Cui, P.; Fang, G.; Gao, J.; Zhou, D.; Wang, Y. Sorption mechanism of zinc on reed, lignin, and reed- and lignin-derived biochars: Kinetics, equilibrium, and spectroscopic studies. J. Soils Sediments 2018, 18, 2535–2543. [Google Scholar] [CrossRef]

- Liu, X.-J.; Li, M.-F.; Singh, S.K. Manganese-modified lignin biochar as adsorbent for removal of methylene blue. J. Mater. Res. Technol. 2021, 12, 1434–1445. [Google Scholar] [CrossRef]

- Spanu, D.; Binda, G.; Dossi, C.; Monticelli, D. Biochar as an alternative sustainable platform for sensing applications: A review. Microchem. J. 2020, 159, 105506. [Google Scholar] [CrossRef]

- Mian, M.M.; Liu, G. Recent progress in biochar-supported photocatalysts: Synthesis, role of biochar, and applications. Rsc. Adv. 2018, 8, 14237–14248. [Google Scholar] [CrossRef] [Green Version]

- Jiang, J.; Zhang, L.; Wang, X.; Holm, N.; Rajagopalan, K.; Chen, F.; Ma, S. Highly ordered macroporous woody biochar with ultra-high carbon content as supercapacitor electrodes—ScienceDirect. Electrochim. Acta 2013, 113, 481–489. [Google Scholar] [CrossRef]

- Kouchachvili, L.; Entchev, E. Ag/Biochar composite for supercapacitor electrodes. Mater. Today Energy 2017, 6, 136–145. [Google Scholar] [CrossRef]

- Ayyappan, C.S.; Bhalambaal, V.M.; Kumar, S. Effect of biochar on bio-electrochemical dye degradation and energy production. Bioresour. Technol. 2018, 251, 165–170. [Google Scholar] [CrossRef]

- Huggins, T.; Wang, H.; Kearns, J.; Jenkins, P.; Ren, Z.J. Biochar as a sustainable electrode material for electricity production in microbial fuel cells. Bioresour. Technol. 2014, 157, 114–119. [Google Scholar] [CrossRef]

- Marzorati, S.; Goglio, A.; Fest-Santini, S.; Mombelli, D.; Villa, F.; Cristiani, P.; Schievano, A. Air-breathing bio-cathodes based on electro-active biochar from pyrolysis of Giant Cane stalks. Int. J. Hydrogen Energy 2019, 44, 4496–4507. [Google Scholar] [CrossRef]

- Jin, C.; Nai, J.; Sheng, O.; Yuan, H.; Zhang, W.; Tao, X.; Lou, X.W. Biomass-based materials for green lithium secondary batteries. Energy Environ. Sci. 2021, 14, 1326–1379. [Google Scholar] [CrossRef]

- Caguiat, J.N.; Arpino, G.; Krigstin, S.G.; Kirk, D.W.; Jia, C.Q. Dependence of supercapacitor performance on macro-structure of monolithic biochar electrodes. Biomass Bioenergy 2018, 118, 126–132. [Google Scholar] [CrossRef]

- Salimi, P.; Norouzi, O.; Pourhoseini, S.; Bartocci, P.; Tavasoli, A.; Maria, F.D.; Pirbazari, S.M.; Bidini, G.; Fantozzi, F. Magnetic biochar obtained through catalytic pyrolysis of macroalgae: A promising anode material for Li-ion Batteries. Renew. Energy 2019, 140, 704–714. [Google Scholar] [CrossRef]

- Thines, K.R.; Abdullah, E.C.; Ruthiraan, M.; Mubarak, N.M.; Tripathi, M. A new route of magnetic biochar based polyaniline composites for supercapacitor electrode materials. J. Anal. Appl. Pyrolysis 2016, 121, 240–257. [Google Scholar] [CrossRef]

- Chang, H.C.; Gustave, W.; Yuan, Z.F.; Xiao, Y.; Chen, Z. One-step fabrication of binder-free air cathode for microbial fuel cells by using balsa wood biochar. Environ. Technol. Innov. 2020, 18, 100615. [Google Scholar] [CrossRef]

- Liu, Z.; Niu, W.; Chu, H.; Zhou, T.; Niu, Z. Effect of the Carbonization Temperature on the Properties of Biochar Produced from the Pyrolysis of Crop Residues. Bioresources 2018, 13, 3429–3446. [Google Scholar] [CrossRef] [Green Version]

- Shen, Z.; Hou, D.; Jin, F.; Shi, J.; Fan, X.; Tsang, D.; Alessi, D.S. Effect of production temperature on lead removal mechanisms by rice straw biochars. Sci. Total Environ. 2019, 655, 751–758. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Khajavi-Shojaei, S.; Moezzi, A.; Norouzi Masir, M.; Taghavi, M. Characteristics of conocarpus wastes and common reed biochars as a predictor of potential environmental and agronomic applications. In Energy Sources, Part A: Recovery, Utilization, and Environmental Effects; Taylor & Francis Group: Abingdon, UK, 2020; pp. 1–18. [Google Scholar]

- Ahmad, M.; Lee, S.S.; Dou, X.; Mohan, D.; Sung, J.K.; Yang, J.E.; Ok, Y.S. Effects of pyrolysis temperature on soybean stover- and peanut shell-derived biochar properties and TCE adsorption in water. Bioresour. Technol. 2012, 118, 536–544. [Google Scholar] [CrossRef]

- Ma, Y.; Yao, D.; Liang, H.; Yin, J.; Xia, Y.; Zuo, K.; Zeng, Y.-P. Ultra-thick wood biochar monoliths with hierarchically porous structure from cotton rose for electrochemical capacitor electrodes. Electrochim. Acta 2020, 352, 136452. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, H.; Wang, X.; Zhang, S.; Chen, H. Biomass-based pyrolytic polygeneration system on cotton stalk pyrolysis: Influence of temperature. Bioresour. Technol. 2012, 107, 411–418. [Google Scholar] [CrossRef]

- Zhang, Q.; Khan, M.U.; Lin, X.; Cai, H.; Lei, H. Temperature varied biochar as a reinforcing filler for high-density polyethylene composites. Compos. Part B Eng. 2019, 175, 107151. [Google Scholar] [CrossRef]

- Das, O.; Bhattacharyya, D.; Hui, D.; Lau, K.-T. Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos. Part B Eng. 2016, 106, 120–128. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.; Jiang, Y.; Tan, G.; Xu, N.; Xu, Y. Enhanced power generation and wastewater treatment in sustainable biochar electrodes based bioelectrochemical system. Bioresour. Technol. 2017, 241, 841–848. [Google Scholar] [CrossRef]

- Cuong, D.V.; Wu, P.-C.; Liu, N.-L.; Hou, C.-H. Hierarchical porous carbon derived from activated biochar as an eco-friendly electrode for the electrosorption of inorganic ions. Sep. Purif. Technol. 2020, 242, 116813. [Google Scholar] [CrossRef]

- Budihardjo, M.A.; Syafrudin Effendi, A.J.; Hidayat, S.; Purnawan, C.; Lantasi, A.I.D.; Muhammad, F.I.; Ramadan, B.S. Waste valorization using solid-phase microbial fuel cells (SMFCs): Recent trends and status. J. Environ. Manag. 2021, 277, 111417. [Google Scholar] [CrossRef]

| Heating Temperature (°C) | Size (L × W × H, ±0.1 mm) | Resistance | Biochar Yield (%) |

|---|---|---|---|

| 400 | 54.0 × 27.0 × 4.3 | Overload | 35.4 |

| 500 | 52.0 × 26.0 × 4.2 | 3.5–30 MΩ | 29.6 |

| 600 | 51.0 × 26.0 × 4.1 | 400–1400 Ω | 28.0 |

| 700 | 50.0 × 25.0 × 4.0 | 300–500 Ω | 27.2 |

| 800 | 50.0 × 25.0 × 3.8 | 30–50 Ω | 25.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, K.; Zhou, Z.; Gao, C.; Yang, Q. One-Step Preparation of Biochar Electrodes and Their Applications in Sediment Microbial Electrochemical Systems. Catalysts 2021, 11, 508. https://doi.org/10.3390/catal11040508

You K, Zhou Z, Gao C, Yang Q. One-Step Preparation of Biochar Electrodes and Their Applications in Sediment Microbial Electrochemical Systems. Catalysts. 2021; 11(4):508. https://doi.org/10.3390/catal11040508

Chicago/Turabian StyleYou, Kui, Zihan Zhou, Chao Gao, and Qiao Yang. 2021. "One-Step Preparation of Biochar Electrodes and Their Applications in Sediment Microbial Electrochemical Systems" Catalysts 11, no. 4: 508. https://doi.org/10.3390/catal11040508