Commercial Gold Complexes Supported on Functionalised Carbon Materials as Efficient Catalysts for the Direct Oxidation of Ethane to Acetic Acid

Abstract

:1. Introduction

2. Results and Discussion

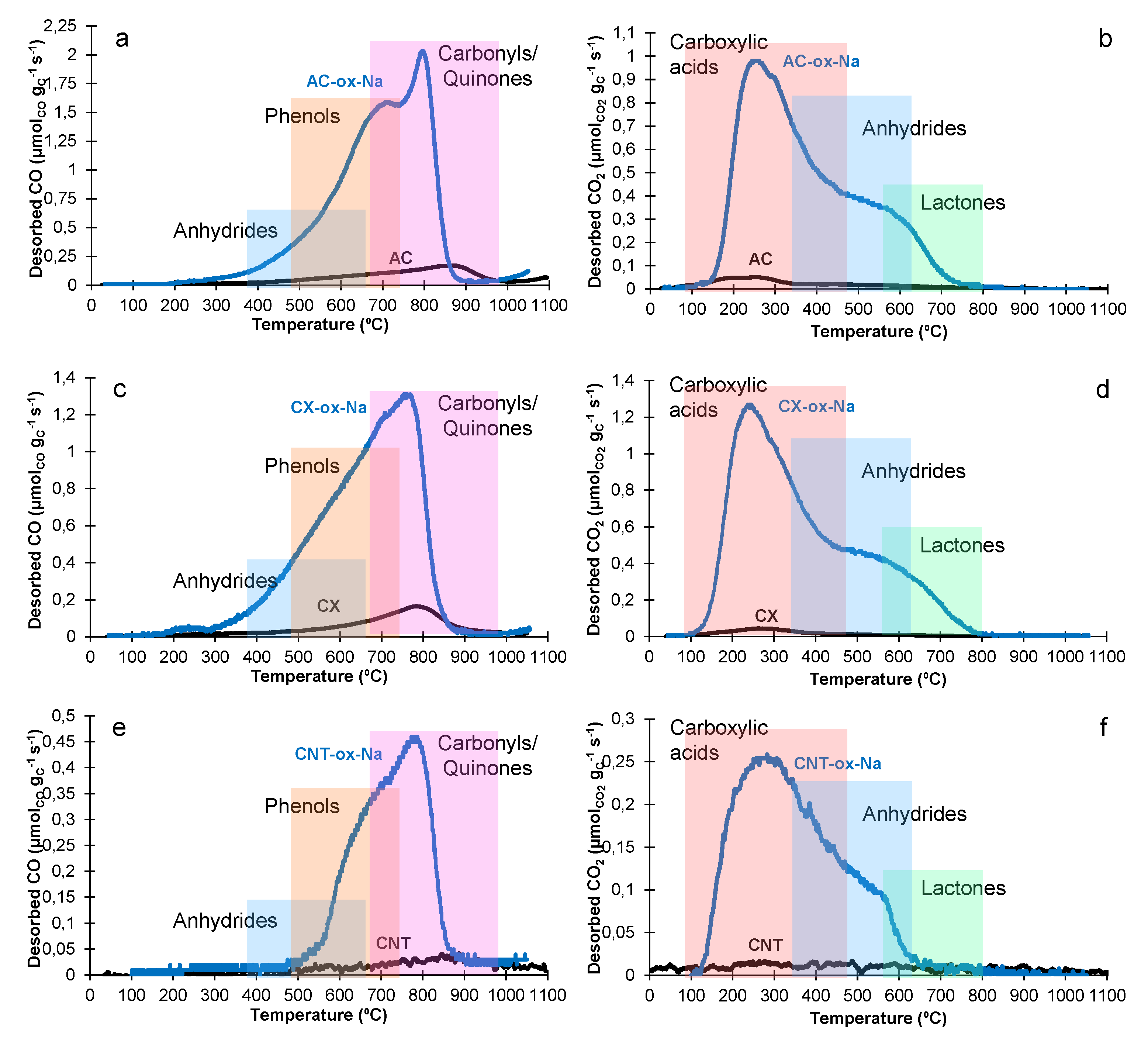

2.1. Carbon Supports Characterisation

| Sample | SBET (m2/g) | Vp (cm3/g) | L (nm) | Vmic (cm3/g) | CO (µmol/g) | CO2 (µmol/g) |

|---|---|---|---|---|---|---|

| AC | 974 | 0.67 | - | 0.34 | 643 | 179 |

| AC-ox-Na | 610 | 0.35 | - | 0.251 | 5012 | 2883 |

| CNT | 257 | 2.89 | ~0 | 142 | 89 | |

| CNT-ox-Na | 350 | 1.45 | - | ~0 | 1079 | 838 |

| CX | 604 | 0.91 | 13.7 | ~0 | 492 | 135 |

| CX-ox-Na | 560 | 0.75 | 17.6 | 0.036 | 3720 | 3793 |

2.2. Heterogenisation Efficiency

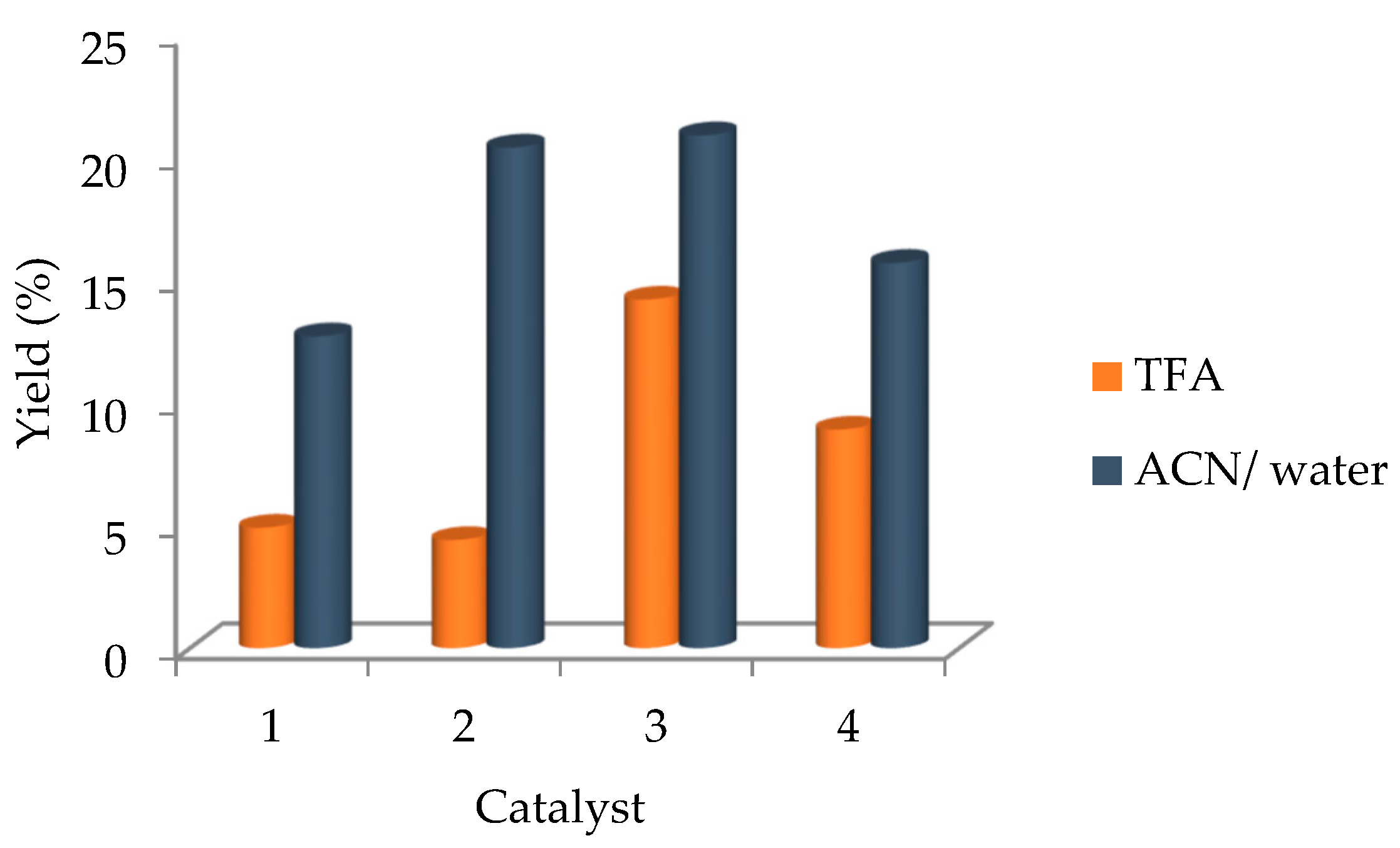

2.3. Oxidation of Ethane to Acetic Acid

3. Materials and Methods

3.1. General Reagents

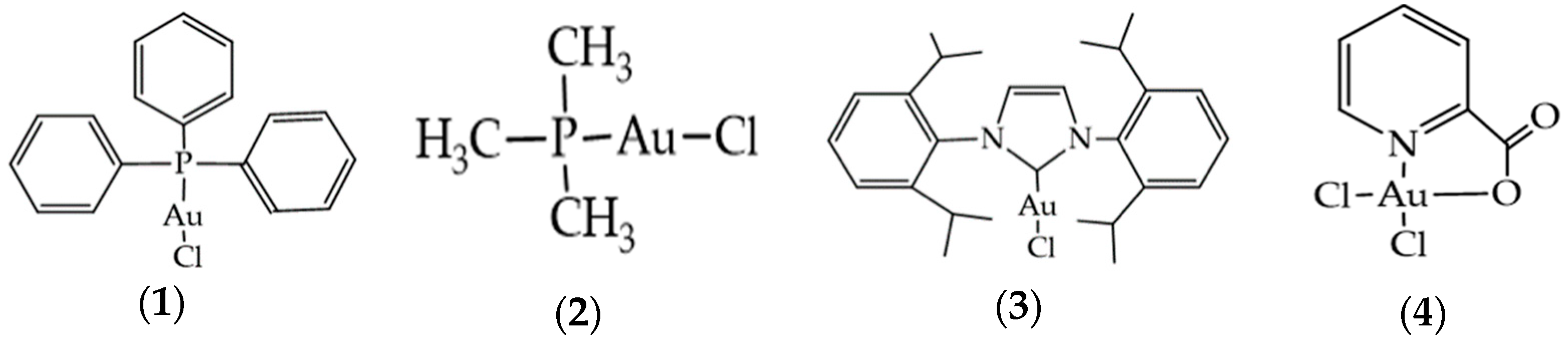

3.2. Gold Complexes

3.3. Carbon Supports

3.4. Supports Characterisation

3.5. Heterogenisation Procedure

3.6. Catalytic Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martins, L.M.D.R.S. Alkanes: Properties, Production and Applications; Nova Science Publishers, Inc.: New York, NY, USA, 2019. [Google Scholar]

- Global Acetic Acid Market to Reach 24.51 Million Tons by 2025. Available online: https://www.expertmarketresearch.com/pressrelease/global-acetic-acid-market (accessed on 24 May 2021).

- Bohnet, M. Ullmann’s Encyclopedia of Industrial Chemistry, 6th ed.; Wiley-VCH: Weinheim, Germany, 2002. [Google Scholar]

- Soliman, M.; Al-Zeghayera, Y.; Al-Awadi, A.S.; Al-Mayman, S. Economics of Acetic Acid Production by Partial Oxidation of Ethane. APCBEE Procedia 2012, 3, 200–208. [Google Scholar] [CrossRef] [Green Version]

- Armstrong, R.D.; Hutchings, G.J.; Taylor, S.H. An Overview of Recent Advances of the Catalytic Selective Oxidation of Ethane to Oxygenates. Catalysts 2016, 6, 71. [Google Scholar] [CrossRef] [Green Version]

- Vedrine, J.C. Heterogeneous catalytic partial oxidation of lower alkanes (C-1-C-6) on mixed metal oxides. J. Energy Chem. 2016, 25, 936–946. [Google Scholar] [CrossRef]

- Bordes-Richard, E. Application of concepts in heterogeneous oxidation of hydrocarbons: Mo, V-based oxide catalysts for oxidation of ethane and of n- and i-butanes. Catal. Today 2021, 363, 15–26. [Google Scholar] [CrossRef]

- Thorsteinson, E.M.; Wilson, T.P.; Young, F.G.; Kasai, P.H. The oxidative dehydrogenation of ethane over catalysts containing mixed oxides of molybdenum and vanadium. J. Catal. 1978, 52, 116–132. [Google Scholar] [CrossRef]

- McCain, J.H.; Manyik, R.M.; Naumann, A.W. Ethane oxidation to ethylene and acetic-acid over molybdenium-vanadium oxide catalysts. Abstr. Pap. Am. Chem. Soc. 1987, 194, 416-INOR. [Google Scholar]

- Rahman, F.; Loughlin, K.F.; Al-Saleh, M.A.; Saeed, M.R.; Tukur, N.M.; Hossain, M.M.; Karim, K.; Mamedov, A. Kinetics and mechanism of partial oxidation of ethane to ethylene and acetic acid over MoV type catalysts. Appl. Catal. A Gen. 2010, 375, 17–25. [Google Scholar] [CrossRef]

- Chen, N.F.; Oshihara, K.; Ueda, W. Selective oxidation of ethane over hydrothermally synthesized Mo-V-Al-Ti oxide catalyst. Catal. Today 2001, 64, 121–128. [Google Scholar] [CrossRef]

- Sankaranarayanan, T.M.; Ingle, R.H.; Gaikwad, T.B.; Lokhande, S.K.; Raja, T.; Devi, R.N.; Ramaswamy, V.; Manikandan, P. Selective oxidation of ethane over Mo-V-Al-O oxide catalysts: Insight to the factors affecting the selectivity of ethylene and acetic acid and structure-activity correlation studies. Catal. Lett. 2008, 121, 39–51. [Google Scholar] [CrossRef]

- Merzouki, M.; Taouk, B.; Tessier, L.; Bordes, E.; Courtine, P.; Grasselli, R.K.; Shymanska, M.; Trifiro, F.; Bhasin, M.M.; Kallo, D.; et al. Correlation between catalytic and structural-properties of modified molybdenum and vanadium-oxides in the oxidation of ethane in acetic-acid or ethylene. St. Surf. Sci. Catal. 1993, 75, 753–764. [Google Scholar]

- Ruth, K.; Burch, R.; Kieffer, R. Mo-V-Nb oxide catalysts for the partial oxidation of ethane - II. Chemical and catalytic properties and structure function relationships. J. Catal. 1998, 175, 27–39. [Google Scholar] [CrossRef]

- Roussel, M.; Bouchard, M.; Bordes-Richard, E.; Karim, K.; Al-Sayari, S. Oxidation of ethane to ethylene and acetic acid by MoVNbO catalysts. Catal. Today 2005, 99, 77–87. [Google Scholar] [CrossRef] [Green Version]

- Roussel, M.; Bouchard, M.; Karim, K.; Al-Sayari, S.; Bordes-Richard, E. MoVO-based catalysts for the oxidation of ethane to ethylene and acetic acid - Influence of niobium and/or palladium on physicochemical and catalytic properties. Appl. Catal. A: Gen. 2006, 308, 62–74. [Google Scholar] [CrossRef] [Green Version]

- Li, X.B.; Iglesia, E. Kinetics and mechanism of ethane oxidation to acetic acid on catalysts based on Mo-V-Nb oxides. J. Phys. Chem. C 2008, 112, 15001–15008. [Google Scholar] [CrossRef] [Green Version]

- Li, X.B.; Iglesia, E. Support and promoter effects in the selective oxidation of ethane to acetic acid catalyzed by Mo-V-Nb oxides. Appl. Catal. A: Gen. 2008, 334, 339–347. [Google Scholar] [CrossRef]

- Roussel, M.; Barama, S.; Lofberg, A.; Al-Sayari, S.; Karim, K.; Bordes-Richard, E. MoV-based catalysts in ethane oxidation to acetic acid: Influence of additives on redox chemistry. Catal. Today 2009, 141, 288–293. [Google Scholar] [CrossRef]

- Linke, D.; Wolf, D.; Baerns, M.; Timpe, O.; Schlogl, R.; Zeyss, S.; Dingerdissen, U. Catalytic partial oxidation of ethane to acetic acid over Mo1V0.25Nb0.12Pd0.0005OxI. Catalyst performance and reaction mechanism. J. Catal. 2002, 205, 16–31. [Google Scholar] [CrossRef] [Green Version]

- Bergh, S.; Guan, S.H.; Hagemeyer, A.; Lugmair, C.; Turner, H.; Volpe, A.F.; Weinberg, W.H.; Mott, G. Gas phase oxidation of ethane to acetic acid using high-throughput screening in a massively parallel microfluidic reactor system. Appl. Catal. A Gen. 2003, 254, 67–76. [Google Scholar] [CrossRef]

- Jimenez, J.D.; Mingle, K.; Bureerug, T.; Wen, C.; Lauterbach, J. Statistically Guided Synthesis of MoV-Based Mixed-Oxide Catalysts for Ethane Partial Oxidation. Catalysts 2018, 8, 370. [Google Scholar] [CrossRef] [Green Version]

- Ueda, W.; Chen, N.F.; Oshihara, K. Hydrothermal synthesis of Mo-V-M-O complex metal oxide catalysts active for partial oxidation of ethane. Chem. Commun. 1999, 517–518. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Zhong, S.H. Silica-supported MoVNbO complex oxide catalyst for low-temperature oxidation of ethane to acetic acid. Chin. J. Catal. 2005, 26, 719–723. [Google Scholar]

- Roy, M.; GubelmannBonneau, M.; Ponceblanc, H.; Volta, J.C. Vanadium-molybdenum phosphates supported by TiO2-anatase as new catalysts for selective oxidation of ethane to acetic acid. Catal. Lett. 1996, 42, 93–97. [Google Scholar] [CrossRef]

- Al-Zeghayer, Y.S.; Al-Awadi, A.S.; Jibril, B.Y.; Soliman, M.A.; Al-Mayman, S. Partial Oxidation of Ethane to Acetic Acid on Titania Supported MoVNbPd Catalyst. Asian J. Chem. 2013, 25, 7979–7985. [Google Scholar] [CrossRef]

- Che-Galicia, G.; Ruiz-Martinez, R.S.; Lopez-Isunza, F.; Castillo-Araiza, C.O. Modeling of oxidative dehydrogenation of ethane to ethylene on a MoVTeNbO/TiO2 catalyst in an industrial-scale packed bed catalytic reactor. Chem. Eng. J. 2015, 280, 682–694. [Google Scholar] [CrossRef]

- Al-Mayman, S.I.; Al-Awadi, A.S.; Al-Zeghayer, Y.A.; Soliman, M.A. Partial Oxidation of Ethane to Acetic Acid using a Metallic Pd Promoted MoVNb Catalyst Supported on Titania. J. Chem. Soc. Pakistan 2018, 40, 76–88. [Google Scholar]

- Al-Mayman, S.I.; Soliman, M.A.; Al-Awadi, A.S.; Al-Zeghayer, Y.S. Reaction kinetics of ethane partial oxidation to acetic acid. Appl. Petrochem. Res. 2018, 8, 29–38. [Google Scholar] [CrossRef] [Green Version]

- Roy, M.; Ponceblanc, H.; Volta, J.C. Vanadium-molybdenum phosphates supported by TiO2 for ethane oxidation to acetic acid: A correlation between the local environment of vanadium and the reactivity. Top. Catal. 2000, 11, 101–109. [Google Scholar] [CrossRef]

- Sopa, A.; Waclaw-Held, A.; Grossy, M.; Pijanka, J.; Nowinska, K. Ethane to acetic acid oxidation over supported heteropoly acids. Appl. Catal. A: Gen. 2005, 285, 119–125. [Google Scholar] [CrossRef]

- Fakeeha, A.H.; Fahmy, Y.M.; Soliman, M.A.; Alwahabi, S.M. A kinetic model for partial oxidation of ethane to acetic acid on promoted VPO catalyst. J. Chem. Technol. Biotechnol. 2000, 75, 1160–1168. [Google Scholar] [CrossRef]

- Tessier, L.; Bordes, E.; Gubelmannbonneau, M. Active specie on vanadium-contaning catalysts for the selective oxidation of ethane to acetic-acid. Catal. Today 1995, 24, 335–340. [Google Scholar] [CrossRef]

- Enache, D.I.; Bordes, E.; Ensuque, A.; Bozon-Verduraz, F. Vanadium oxide catalysts supported on titania and zirconia II. Selective oxidation of ethane to acetic acid and ethylene. Appl. Catal. A Gen. 2004, 278, 103–110. [Google Scholar]

- Rahmana, A.; Indo, R.; Hagiwara, H.; Ishihara, T. Direct conversion of ethane to acetic acid over H-ZSM-5 using H2O2 in aqueous phase. Appl. Catal. A Gen. 2013, 456, 82–87. [Google Scholar] [CrossRef]

- Forde, M.M.; Armstrong, R.D.; Hammond, C.; He, Q.; Jenkins, R.L.; Kondrat, S.A.; Dimitratos, N.; Lopez-Sanchez, J.A.; Taylor, S.H.; Willock, D.; et al. Partial Oxidation of Ethane to Oxygenates Using Fe- and Cu-Containing ZSM-5. J. Am. Chem. Soc. 2013, 135, 11087–11099. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, R.D.; Freakley, S.J.; Forde, M.M.; Peneau, V.; Jenkins, R.L.; Taylor, S.H.; Moulijn, J.A.; Morgan, D.J.; Hutchings, G.J. Low temperature catalytic partial oxidation of ethane to oxygenates by Fe- and Cu-ZSM-5 in a continuous flow reactor. J. Catal. 2015, 330, 84–92. [Google Scholar] [CrossRef]

- Forde, M.M.; Armstrong, R.D.; McVicker, R.; Wells, P.P.; Dimitratos, N.; He, Q.; Lu, L.; Jenkins, R.L.; Hammond, C.; Lopez-Sanchez, J.A.; et al. Light alkane oxidation using catalysts prepared by chemical vapour impregnation: Tuning alcohol selectivity through catalyst pre-treatment. Chem. Sci. 2014, 5, 3603–3616. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.T.; Tang, Y.; Nguyen, L.; Tao, F.F. Catalytic Oxidation of Ethane to Carboxylic Acids in the Liquid Phase at Near Room Temperature at Ambient Pressure. ACS Sust. Chem. Eng. 2019, 7, 4707–4715. [Google Scholar] [CrossRef]

- Liu, B.Y.; Oh, S.C.; Chen, H.Y.; Liu, D.X. The effect of oxidation of ethane to oxygenates on Pt- and Zn-containing LTA zeolites with tunable selectivity. J. Energy Chem. 2019, 30, 42–48. [Google Scholar] [CrossRef] [Green Version]

- Jin, R.X.; Peng, M.; Li, A.; Deng, Y.C.; Jia, Z.M.; Huang, F.; Ling, Y.J.; Yang, F.; Fu, H.; Xie, J.L.; et al. Low Temperature Oxidation of Ethane to Oxygenates by Oxygen over Iridium-Cluster Catalysts. J. Am. Chem. Soc. 2019, 141, 18921–18925. [Google Scholar] [CrossRef]

- Alegria, E.C.B.; Kirillova, M.V.; Martins, L.; Pombeiro, A.J.L. Pyrazole and trispyrazolylmethane rhenium complexes as catalysts for ethane and cyclohexane oxidations. Appl. Catal. A: Gen. 2007, 317, 43–52. [Google Scholar] [CrossRef]

- Alegria, E.C.B.A.; Martins, L.M.D.R.S.; Guedes da Silva, M.F.C.; Pombeiro, A.J.L. Syntheses and Properties of Re(III) Complexes Derived from Hydrotris(1-pyrazolyl)methanes. Molecular Structure of [ReCl2(HCpz3)(PPh3)][BF4]. J. Organomet. Chem. 2005, 690, 1947–1958. [Google Scholar] [CrossRef]

- Alvarez, L.X.; Sorokin, A.B. Mild oxidation of ethane to acetic acid by H2O2 catalyzed by supported mu-nitrido diiron phthalocyanines. J. Organomet. Chem. 2015, 793, 139–144. [Google Scholar] [CrossRef]

- Matias, I.A.S.; Ribeiro, A.P.C.; Martins, L.M.D.R.S. Selective oxidation of ethane to acetic acid catalyzed by a C-scorpionate iron(II) complex: Homogeneous vs. heterogeneous. Molecules 2020, 25, 5642. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, S.A.; Sajid, M.A.; Khan, Z.A.; Canseco-Gonzalez, D. Gold catalysis in organic transformations: A review. Synth. Commun. 2017, 47, 735–755. [Google Scholar] [CrossRef]

- Scurrell, M.S. Thoughts on the use of gold-based catalysts in environmental protection catalysis. Gold Bull. 2017, 50, 77–84. [Google Scholar] [CrossRef]

- Pflasterer, D.; Hashmi, A.S.K. Gold catalysis in total synthesis-recent achievements. Chem. Soc. Rev. 2016, 45, 1331–1367. [Google Scholar] [CrossRef] [PubMed]

- Carabineiro, S.A.C. Supported Gold Nanoparticles as Catalysts for the Oxidation of Alcohols and Alkanes. Front. Chem. 2019, 7, 702. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.L.; Gurses, S.; Felvey, N.; Kronawitter, C.X. Room temperature and atmospheric pressure aqueous partial oxidation of ethane to oxygenates over AuPd catalysts. Catal. Sci. Technol. 2020, 10, 6679–6686. [Google Scholar] [CrossRef]

- Ribeiro, A.P.C.; Matias, I.A.S.; Zargaran, P.; Hashmi, A.S.K.; Martins, L.M.D.R.S. Unprecedented Use of NHC Gold (I) Complexes as Catalysts for the Selective Oxidation of Ethane to Acetic Acid. Materials 2021, 14, 4294. [Google Scholar] [CrossRef]

- Carabineiro, S.A.C.; Martins, L.M.D.R.S.; Pombeiro, A.J.L.; Figueiredo, J.L. Commercial Gold(I) and Gold(III) Compounds Supported on Carbon Materials as Greener Catalysts for the Oxidation of Alkanes and Alcohols. ChemCatChem 2018, 10, 1804–1813. [Google Scholar] [CrossRef]

- Figueiredo, J.L.; Pereira, M.F.R.; Freitas, M.M.A.; Órfão, J.J.M. Modification of the surface chemistry of activated carbons. Carbon 1999, 37, 1379–1389. [Google Scholar] [CrossRef]

- Figueiredo, J.L.; Pereira, M.F.R.; Freitas, M.M.A.; Órfão, J.J.M. Characterization of active sites on carbon catalysts. Ind. Eng. Chem. Res. 2007, 46, 4110–4115. [Google Scholar] [CrossRef] [Green Version]

- Carabineiro, S.A.C.; Pereira, M.F.R.; Órfão, J.J.M.; Figueiredo, J.L. Surface Chemistry of Activated Carbons. In Activated Carbon: Classifications, Properties and Applications; Kwiatkowski, J.F., Ed.; Nova Science Pub Inc.: New York, NY, USA, 2011; pp. 125–168. [Google Scholar]

- Carabineiro, S.A.C.; Thavorn-Amornsri, T.; Pereira, M.F.R.; Figueiredo, J.L. Adsorption of ciprofloxacin on surface-modified carbon materials. Water Res. 2011, 45, 4583–4591. [Google Scholar] [CrossRef] [PubMed]

- Carabineiro, S.A.C.; Thavorn-Amornsri, T.; Pereira, M.F.R.; Serp, P.; Figueiredo, J.L. Comparison between activated carbon, carbon xerogel and carbon nanotubes for the adsorption of the antibiotic ciprofloxacin. Catal. Today 2012, 186, 29–34. [Google Scholar] [CrossRef]

- Figueiredo, J.L. Functionalization of porous carbons for catalytic applications. J. Mater. Chem. A 2013, 1, 9351–9364. [Google Scholar] [CrossRef]

- Maia, F.; Mahata, N.; Jarrais, B.; Silva, A.R.; Pereira, M.F.R.; Freire, C.; Figueiredo, J.L. Jacobsen catalyst anchored onto modified carbon xerogel as enantioselective heterogeneous catalyst for alkene epoxidation. J. Mol. Catal. A Chem. 2009, 305, 135–141. [Google Scholar] [CrossRef]

- Figueiredo, J.L.; Pereira, M.F.R. The role of surface chemistry in catalysis with carbons. Catal. Today 2010, 150, 2–7. [Google Scholar] [CrossRef]

- Sutradhar, M.; Martins, L.M.D.R.S.; Carabineiro, S.A.C.; Guedes da Silva, M.F.C.; Buijnsters, J.G.; Figueiredo, J.L.; Pombeiro, A.J.L. Oxidovanadium(V) complexes anchored on carbon materials as catalysts for the oxidation of 1-phenylethanol. ChemCatChem 2016, 8, 2254–2266. [Google Scholar] [CrossRef]

- Peixoto de Almeida, M.; Martins, L.M.D.R.S.; Carabineiro, S.A.C.; Lauterbach, T.; Rominger, F.; Hashmi, A.S.K.; Pombeiro, A.J.L.; Figueiredo, J.L. Homogeneous and Heterogenised New Gold C-Scorpionate Complexes as Catalysts for Cyclohexane Oxidation. Catal. Sci. Technol. 2013, 3, 3056–3069. [Google Scholar] [CrossRef] [Green Version]

- Martins, L.M.D.R.S.; Ribeiro, A.P.C.; Carabineiro, S.A.C.; Figueiredo, J.L.; Pombeiro, A.J.L. Highly efficient and reusable CNT supported iron(ii) catalyst for microwave assisted alcohol oxidation. Dalton Trans. 2016, 45, 6816–6819. [Google Scholar] [CrossRef] [Green Version]

- Kirillov, A.M.; Haukka, M.; Kirillova, M.V.; Pombeiro, A.J.L. Single-Pot Ethane Carboxylation Catalyzed by New Oxorhenium(V) Complexes with N,O Ligands. Adv. Synth. Catal. 2005, 347, 1435–1446. [Google Scholar] [CrossRef]

- Kirillova, M.V.; Kirillov, A.M.; Reis, P.M.; Silva, J.A.L.; Fraústo da Silva, J.J.R.; Pombeiro, A.J.L. Group 5–7 transition metal oxides as efficient catalysts for oxidative functionalization of alkanes under mild conditions. J. Catal. 2007, 248, 130–136. [Google Scholar] [CrossRef]

- Hashmi, A.S.K.; Weyrauch, J.P.; Rudolph, M.; Kurpejović, E. Gold Catalysis: The Benefits of N and N,O Ligands. Angew. Chem. Int. Ed. 2004, 43, 6545–6547. [Google Scholar] [CrossRef] [PubMed]

- Mahata, N.; Silva, A.R.; Pereira, M.F.R.; Freire, C.; de Castro, B.; Figueiredo, J.L. Anchoring of a [Mn(salen)Cl] complex onto mesoporous carbon xerogels. J. Coll. Interf. Sci. 2007, 311, 152–158. [Google Scholar] [CrossRef] [PubMed]

- Mahata, N.; Pereira, M.F.R.; Suárez-García, F.; Martínez-Alonso, A.; Tascón, J.M.D.; Figueiredo, J.L. Tuning of texture and surface chemistry of carbon xerogels. J. Coll. Interf. Sci. 2008, 324, 150–155. [Google Scholar] [CrossRef]

- Martins, L.M.D.R.S.; Peixoto de Almeida, M.; Carabineiro, S.A.C.; Figueiredo, J.L.; Pombeiro, A.J.L. Heterogenisation of a C-scorpionate Fe(II) complex in carbon materials for cyclohexane oxidation. ChemCatChem 2013, 5, 3847–3856. [Google Scholar] [CrossRef]

- Ribeiro, A.P.C.; Martins, L.M.D.R.S.; Carabineiro, S.A.C.; Figueiredo, J.L.; Pombeiro, A.J.L. Gold Nanoparticles Deposited on Surface Modified Carbon Xerogels as Reusable Catalysts for Cyclohexane C-H Activation in the Presence of CO and Water. Molecules 2017, 22, 603. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, A.P.C.; Martins, L.M.D.R.S.; Carabineiro, S.A.C.; Figueiredo, J.L.; Pombeiro, A.J.L. Gold nanoparticles deposited on surface modified carbon materials as reusable catalysts for hydrocarboxylation of cyclohexane. Appl. Catal. A Gen. 2017, 547, 124–131. [Google Scholar] [CrossRef]

- Wang, J.; Martins, L.M.D.R.S.; Ribeiro, A.P.C.; Carabineiro, S.A.C.; Figueiredo, J.L.; Pombeiro, A.J.L. Supported C-Scorpionate Vanadium(IV) Complexes as Reusable Catalysts for Xylene Oxidation. Chem. Asian J. 2017, 12, 1915–1919. [Google Scholar] [CrossRef]

- Nakata, K.; Yamaoka, Y.; Miyata, T.; Taniguchi, Y.; Takaki, K.; Fujiwara, Y. Palladium(II) and/or copper(II)-catalyzed carboxylation of small alkanes such as methane and ethane with carbon monoxide. J. Organomet. Chem. 1994, 473, 329–334. [Google Scholar] [CrossRef]

| @AC-ox-Na | @CX-ox-Na | @CNT-ox-Na | |

|---|---|---|---|

| 1 | 0.20 | 0.01 | 0.17 |

| 2 | 0.05 | 0.06 | 0.04 |

| 3 | 0.03 | 0.02 | 0.03 |

| 4 | 0.10 | 0.10 | 0.10 |

| Entry | Catalyst | Temperature (°C) | Solvent | Yield b (%) | TON c | TOF d |

|---|---|---|---|---|---|---|

| 1 | 1 | 80 | TFA | 4.9 | 54 | 3 |

| 2 | 80 | ACN/H2O | 12.7 | 141 | 7 | |

| 3 | 50 | TFA | 0 | 0 | 0 | |

| 4 | 50 | ACN/H2O | 0.1 | 0 | 0 | |

| 5 | 2 | 80 | TFA | 4.4 | 49 | 3 |

| 6 | 80 | ACN/H2O | 20.4 | 226 | 11 | |

| 7 | 50 | TFA | 3.2 | 35 | 2 | |

| 8 | 50 | ACN/H2O | 5.3 | 59 | 3 | |

| 9 | 3 | 80 | TFA | 14.2 | 157 | 8 |

| 10 | 80 | ACN/H2O | 20.9 | 231 | 12 | |

| 11 | 50 | TFA | 0 | 0 | 0 | |

| 12 | 50 | ACN/H2O | 0.2 | 0 | 0 | |

| 13 | 4 | 80 | TFA | 8.9 | 98 | 5 |

| 14 | 80 | ACN/H2O | 15.7 | 174 | 9 | |

| 15 | 50 | TFA | 3.1 | 34 | 2 | |

| 16 | 50 | ACN/H2O | 5.2 | 58 | 3 |

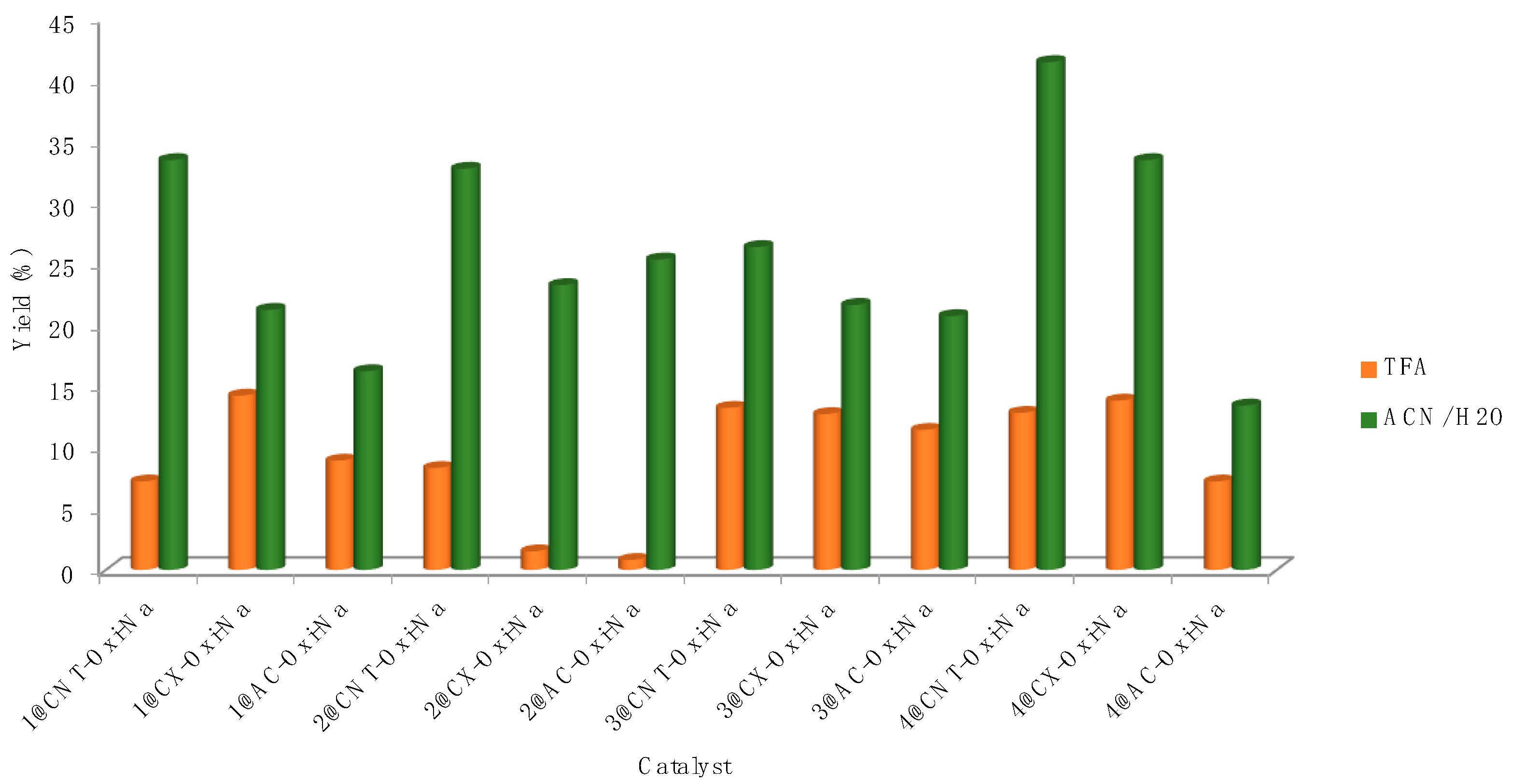

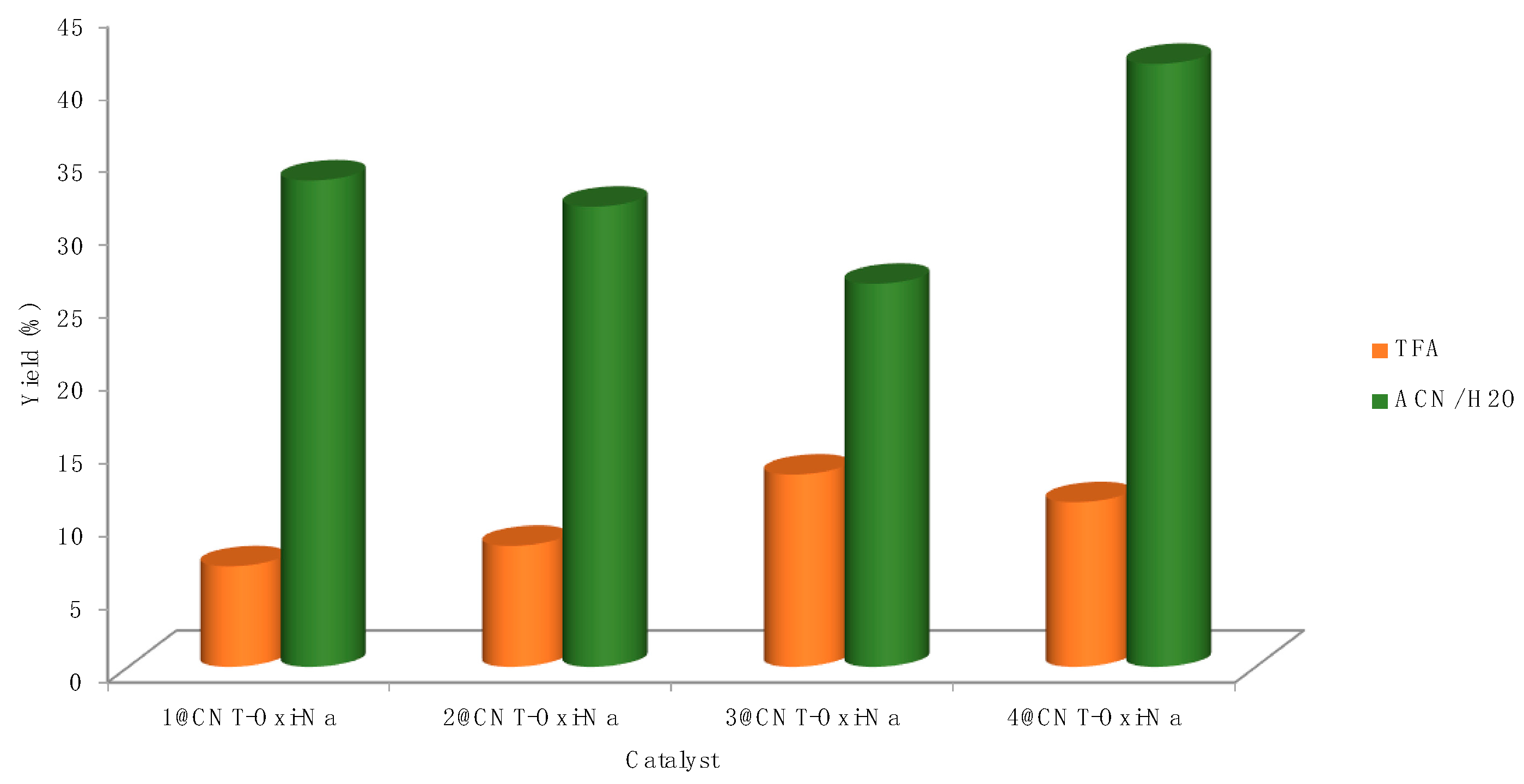

| Entry | Catalyst | Catalyst Amount (μmol Au) | Temperature (°C) | Solvent | Yield b (%) | TON c | TOF d |

|---|---|---|---|---|---|---|---|

| 1 | 1@CNT-ox-Na | 1.5 | 80 | TFA | 7.2 | 80 | 4 |

| 2 | 1@CNT-ox-Na | 1.5 | 80 | ACN/water | 33.4 | 370 | 19 |

| 3 | 1@CNT-ox-Na | 15 | 80 | TFA | 6.9 | 8 | 0 |

| 4 | 1@CNT-ox-Na | 15 | 80 | ACN/water | 36.5 | 40 | 2 |

| 5 | 1@CNT-ox-Na | 1.5 | 50 | TFA | 0.2 | 2 | 0 |

| 6 | 1@CNT-ox-Na | 1.5 | 50 | ACN/water | 0 | 0 | 0 |

| 7 | 1@CX-ox-Na | 1.5 | 80 | TFA | 14.2 | 157 | 8 |

| 8 | 1@CX-ox-Na | 1.5 | 80 | ACN/water | 21.2 | 235 | 12 |

| 9 | 1@AC-ox-Na | 1.5 | 80 | TFA | 8.9 | 98 | 5 |

| 10 | 1@AC-ox-Na | 1.5 | 80 | ACN/water | 16.2 | 179 | 9 |

| 11 | 2@CNT-ox-Na | 1.5 | 80 | TFA | 8.3 | 92 | 5 |

| 12 | 2@CNT-ox-Na | 1.5 | 80 | ACN/water | 32.7 | 322 | 16 |

| 13 | 2@CNT-ox-Na | 15 | 80 | TFA | 10.1 | 11 | 1 |

| 14 | 2@CNT-ox-Na | 15 | 80 | ACN/water | 31.6 | 35 | 2 |

| 15 | 2@CNT-ox-Na | 1.5 | 50 | TFA | 0.6 | 7 | 0 |

| 16 | 2@CNT-ox-Na | 1.5 | 50 | ACN/water | 1.1 | 12 | 1 |

| 17 | 2@CX-ox-Na | 1.5 | 80 | TFA | 1.5 | 17 | 1 |

| 18 | 2@CX-ox-Na | 1.5 | 80 | ACN/water | 23.2 | 257 | 13 |

| 19 | 2@AC-ox-Na | 1.5 | 80 | TFA | 0.8 | 9 | 0 |

| 20 | 2@AC-ox-Na | 1.5 | 80 | ACN/water | 25.3 | 280 | 14 |

| 21 | 3@CNT-ox-Na | 1.5 | 80 | TFA | 13.2 | 146 | 7 |

| 22 | 3@CNT-ox-Na | 1.5 | 80 | ACN/water | 26.3 | 291 | 15 |

| 23 | 3@CX-ox-Na | 1.5 | 80 | TFA | 12.7 | 362 | 18 |

| 24 | 3@CX-ox-Na | 1.5 | 80 | ACN/water | 21.6 | 239 | 12 |

| 25 | 3@CX-ox-Na | 15 | 80 | TFA | 14.3 | 16 | 1 |

| 26 | 3@CX-ox-Na | 15 | 80 | ACN/water | 29.4 | 33 | 2 |

| 27 | 3@CX-ox-Na | 1.5 | 50 | TFA | 0 | 0 | 0 |

| 28 | 3@CX-ox-Na | 1.5 | 50 | ACN/water | 0 | 0 | 0 |

| 29 | 3@AC-ox-Na | 1.5 | 80 | TFA | 11.4 | 126 | 6 |

| 30 | 3@AC-ox-Na | 1.5 | 80 | ACN/water | 20.7 | 229 | 11 |

| 31 | 4@CNT-ox-Na | 1.5 | 80 | TFA | 12.8 | 142 | 7 |

| 32 | 4@CNT-ox-Na | 1.5 | 80 | ACN/water | 41.4 | 458 | 23 |

| 33 | 4@CNT-ox-Na | 15 | 80 | TFA | 11.3 | 13 | 1 |

| 34 | 4@CNT-ox-Na | 15 | 80 | ACN/water | 39.7 | 44 | 2 |

| 35 | 4@CNT-ox-Na | 1.5 | 50 | TFA | 0.9 | 10 | 1 |

| 36 | 4@CNT-ox-Na | 1.5 | 50 | ACN/water | 1.3 | 14 | 1 |

| 37 | 4@CX-ox-Na | 1.5 | 80 | TFA | 13.8 | 153 | 8 |

| 38 | 4@CX-ox-Na | 1.5 | 80 | ACN/water | 33.4 | 370 | 19 |

| 39 | 4@AC-ox-Na | 1.5 | 80 | TFA | 7.2 | 80 | 4 |

| 40 | 4@AC-ox-Na | 1.5 | 80 | ACN/water | 13.4 | 148 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ribeiro, A.P.C.; Matias, I.A.S.; Carabineiro, S.A.C.; Martins, L.M.D.R.S. Commercial Gold Complexes Supported on Functionalised Carbon Materials as Efficient Catalysts for the Direct Oxidation of Ethane to Acetic Acid. Catalysts 2022, 12, 165. https://doi.org/10.3390/catal12020165

Ribeiro APC, Matias IAS, Carabineiro SAC, Martins LMDRS. Commercial Gold Complexes Supported on Functionalised Carbon Materials as Efficient Catalysts for the Direct Oxidation of Ethane to Acetic Acid. Catalysts. 2022; 12(2):165. https://doi.org/10.3390/catal12020165

Chicago/Turabian StyleRibeiro, Ana P. C., Inês A. S. Matias, Sónia A. C. Carabineiro, and Luísa M. D. R. S. Martins. 2022. "Commercial Gold Complexes Supported on Functionalised Carbon Materials as Efficient Catalysts for the Direct Oxidation of Ethane to Acetic Acid" Catalysts 12, no. 2: 165. https://doi.org/10.3390/catal12020165