Conversion of South African Coal Fly Ash into High-Purity ZSM-5 Zeolite without Additional Source of Silica or Alumina and Its Application as a Methanol-to-Olefins Catalyst

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Synthesis of ZSM-5 from the Acid-Treated Fly Ash (AL)

3.2.2. Synthesis of ZSM-5 from the Fused Fly Ash Extracts (FFAEs)

3.2.3. Methanol-to-Olefins (MTO) Catalytic Reaction over the Fly Ash-Based ZSM-5 Samples

3.2.4. Characterization Techniques

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Holler, H.; Wirsching, G.U. Zeolite formation from fly ash. Fortschr. Miner. 1985, 63, 21–43. [Google Scholar]

- Ojha, K.; Pradhan, N.C.; Samanta, A.N. Zeolite from fly ash: Synthesis and characterization. Bull. Mater. Sci. 2004, 27, 555–564. [Google Scholar] [CrossRef]

- Musyoka, N.M.; Petrik, L.F.; Gitari, W.M.; Balfour, G.; Hums, E. Optimization of hydrothermal synthesis of pure phase zeolite Na-P1 from South African coal fly ashes. J. Environ. Sci. Health A 2012, 47, 337–350. [Google Scholar] [CrossRef] [PubMed]

- Belviso, C.; Cavalcante, F.; Lettino, A.; Fiore, S. Zeolite synthesized from fused coal fly ash at low temperature using seawater for crystallization. CCGP 2009, 1, 7–13. [Google Scholar] [CrossRef]

- Chigondo, M.; Guyo, U.; Shumba, M.; Chigondo, F.; Nyamunda, B.; Moyo, M.; Nharingo, T. Synthesis and characterization of zeolites from coal fly ash (CFA). ESTIJ 2013, 3, 714–718. [Google Scholar]

- Vadapalli, V.R.K.; Gitari, W.M.; Ellendt, A.; Petrik, L.F.; Balfour, G. Synthesis of zeolite P from coal fly ash derivative and its utilization in mine water remediation. S. Afr. J. Sci. 2010, 106, 1–7. [Google Scholar]

- Adamczyk, Z.; Bialecka, B. Hydrothermal synthesis of zeolites from Polish coal fly ash. Pol. J. Environ. Stud. 2005, 14, 713–719. [Google Scholar]

- Moutsatsou, A.; Karakasia, O.K.; Koukouzas, N.; Itskos, G.S.; Vasilatosc, C. Synthesis of zeolitic materials utilizing CFB-derived coal fly ash as a raw material. In Proceedings of the WanteEng-2nd International Conference on Engineering for Waste Valorisation, Patras, Greece, 2006. [Google Scholar]

- Chareonpanich, M.; Namto, T.; Kongkachuichay, P.; Limtrakul, J. Synthesis of ZSM-5 zeolite from lignite fly ash and rice husk ash. Fuel Process. Technol. 2004, 85, 1623–1634. [Google Scholar] [CrossRef]

- Flanigen, E.; Patton, R.L. Silica Polymorph. U.S. Patent 4073865, 14 February 1978. [Google Scholar]

- Van der Gaag, F.J. ZSM-5 Type Zeolites: Synthesis and Use in Gasphase Reactions with Ammonia. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1987. [Google Scholar]

- Losch, P.; Boltz, M.; Louis, B.; Chavan, S.; Olsbye, U. Catalyst optimization for enhanced propylene formation in the MTO reaction. C. R. Chim. 2015, 18, 330–335. [Google Scholar] [CrossRef]

- Missengue, R.N.M.; Losch, P.; Sedres, G.; Musyoka, N.M.; Fatoba, O.O.; Louis, B.; Pale, P.; Petrik, L.F. Transformation of South African coal fly ash into ZSM-5 zeolite and its application as an MTO catalyst. C. R. Chim. 2017, 20, 78–86. [Google Scholar] [CrossRef]

- Narayanan, S.; Sultana, A.; Krishna, K.; Meriaudeau, P.; Naccache, C. Synthesis of ZSM-5 type zeolites with and without template and evaluation of physicochemical properties and aniline alkylation activity. Catal. Lett. 1995, 34, 129–138. [Google Scholar] [CrossRef]

- Bonilla, G.; Diaz, I.; Tsapatsis, M.; Jeong, H.K.; Lee, Y.; Vlachos, D.G. Zeolite (MFI) crystal morphology control using organic structure-directing agents. Chem. Mater. 2004, 16, 5697–5705. [Google Scholar] [CrossRef]

- Shirazi, L.; Jamshidi, E.; Ghasemi, M.R. The effect of Si/Al ratio of ZSM-5 zeolite on its morphology, acidity and crystal size. Cryst. Res. Technol. 2008, 43, 1300–1306. [Google Scholar] [CrossRef]

- Petrik, L.F.; O’Connor, C.T.; Schwarz, S. The influence of various parameters on the morphology and crystal size of ZSM-5 and the relationship between morphology and crystal and propene oligomerization activity. Stud. Surf. Sci. Catal. 1995, 94, 517–524. [Google Scholar]

- Petrik, L. The influence of cation, anion and water content on the rate of formation and pore size distribution of zeolite ZSM-5. S. Afr. J. Sci. 2009, 105, 251–257. [Google Scholar] [CrossRef]

- Bleken, F.L.; Chavan, S.; Olsbye, U.; Boltz, M.; Ocampo, F.; Louis, B. Conversion of methanol into light olefins over ZSM-5 zeolite: Strategy to enhance propene selectivity. Appl. Catal. A 2012, 447–448, 178–185. [Google Scholar] [CrossRef]

- Wang, J.; Groen, J.C.; Yue, W.; Zhou, W.; Coppens, M.O. Facile synthesis of ZSM-5 composites with hierarchical porosity. J. Mater. Chem. 2008, 18, 468–474. [Google Scholar] [CrossRef]

- Kalyankar, A.N.; Choudhari, A.L.; Joshi, A.A. Low frequency dielectric properties of fly ash based zeolite ZSM-5. IJBAS 2011, 1, 59–63. [Google Scholar]

- Reanvattana, N. Two-Stage Synthesis of High Purity ZSM-5 Zeolite from Coal Fly Ash and Rice Husk Ash. Master’s Thesis, Chemical Engineering, Kasetsart University, Bangkok, Thailand, 2005. [Google Scholar]

- Xing, Z.; Hongyan, G. Preparation Method of Low-Cost ZSM-5 Type Zeolite Molecular Sieve, and Application Thereof. European Patent CN103787366 (A), 14 May 2014. [Google Scholar]

- Lercher, J.; Jentys, A. Basic concepts in zeolite acid-base catalysis. In Proceedings of the 5th International Federation of European Zeolite Associations (FEZA) Conference, Valence, Spain, 3–7 July 2011; pp. 181–210. [Google Scholar]

- Triantafillidis, C.S.; Evmiridis, N.; Nalbandian, L.; Vasalos, I.A. Performance of ZSM-5 as a fluid catalytic cracking catalyst additive: Effect of the total number of acid sites and particles size. Ind. Eng. Chem. Res. 1999, 38, 916–927. [Google Scholar] [CrossRef]

- Losch, P.; Boltz, M.; Bernardon, C.; Louis, B.; Palcic, A.; Valtchev, V. Impact of external surface passivation of nano-ZSM-5 zeolites in the Methanol-to-Olefins reaction. Appl. Catal. A 2016, 509, 30–37. [Google Scholar] [CrossRef]

- Van Dijk, C.P.; Solbakken, A.; Rovner, J.M. Methanol from Coal and Natural Gas. U.S. Patent 4,407,973 A, 4 October 1983. [Google Scholar]

- Zaidi, H.A.; Pant, K.K. Activity of oxalic acid treated ZnO/CuO/H-ZSM-5catalyst for the transformation of Methanol-to-Gasoline range hydrocarbons. Ind. Eng. Chem. Res. 2008, 47, 2970–2975. [Google Scholar] [CrossRef]

- Moreno, N.; Querol, X.; Plana, F.; Andres, J.M.; Janssen, M.; Nugteren, H. Pure zeolite synthesis from silica extracted from coal fly ashes. J. Chem. Technol. Biotechnol. 2002, 77, 274–279. [Google Scholar] [CrossRef]

- Guang-Hui, B.; Wei, T.; Xiang-Gang, W.; Jin-Guo, Q.; Peng, X.; Peng-Cheng, L. Alkali desilicated coal fly ash as substitute of bauxite in lime-soda sintering process for aluminum production. Trans. Nonferrous Met. Soc. China 2010, 20, 169–175. [Google Scholar]

- Zhu, G.; Tan, W.; Sun, J.; Gong, Y.; Zhang, S.; Zhang, Z.; Liu, L. Effects and mechanism research of the desilication pre-treatment for high-aluminum fly ash. Energy Fuels 2013, 27, 6948–6954. [Google Scholar] [CrossRef]

- Baldyga, J.; Jasinska, M.; Jodko, K.; Petelski, P. Precipitation of amorphous colloidal silica from aqueous solutions-aggregation problem. Chem. Eng. Sci. 2012, 77, 207–216. [Google Scholar] [CrossRef]

- Liu, K.; Xue, J.; Zhu, J. Extracting Alumina from Coal Fly Ash Using Acid Sintering-Leaching Process. In Light Metals; Suarez, C.E., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Yao, Z.T.; Xia, M.S.; Sarker, P.K.; Chen, T. A review of the alumina recovery from coal fly ash, with a focus in China. Fuel 2014, 120, 74–85. [Google Scholar] [CrossRef]

- Hattori, T.; Yashima, T. Zeolites and Microporous Crystals; Technology & Engineering, Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Singh, R.; Dutta, P.K. MFI: A Case Study of Zeolite Synthesis; Marcel Dekker, Inc.: Columbus, OH, USA, 2003. [Google Scholar]

- Moliner, M. Zeolites and ordered porous solids: Fundamentals and applications—Basic principles of zeolite synthesis. In Proceedings of the 5th International FEZA Conference, Valence, Spain, 3–7 July 2011; pp. 37–65. [Google Scholar]

- Yan, Z.; Ma, D.; Zhuang, J.; Liu, X.; Liu, X.; Han, X.; Bao, X.; Chang, F.; Xu, L.; Liu, Z. On the acid-dealumination of USY zeolite: A solid NMR investigation. J. Mol. Catal. A Chem. 2003, 194, 153–167. [Google Scholar] [CrossRef]

- Zhang, W.; Xin, H.; Yu, Y.; He, H. Oxalic acid treating of ZSM-5 zeolite for the enhanced photocatalytic activity of TiO2/H-ZSM-5. J. Adv. Oxid. Technol. 2014, 17, 359–364. [Google Scholar] [CrossRef]

- Sazama, P.; Wichterlova, B.; Dedecek, J.; Tvaruskova, Z.; Musilova, Z.; Palumbo, L.; Sklenak, S.; Gonsiorova, O. FTIR and 27Al MAS NMR analysis of the effect of framework Al- and Si-defects in micro- and micro-mesoporous H-ZSM-5 on conversion of methanol to hydrocarbons. Microporous Mesoporous Mater. 2011, 143, 87–96. [Google Scholar] [CrossRef]

- Treacy, M.M.J.; Higgins, J.B. Collection of Simulated XRD Power Patterns for Zeolites, 4th ed.; ELSEVIER: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Sang, S.; Chang, F.; Liu, Z.; He, C.; He, Y.; Xu, L. Difference of ZSM-5 zeolites synthesized with various templates. Catal. Today 2004, 93–95, 729–734. [Google Scholar] [CrossRef]

- Abou Rida, M.; Harb, F. Synthesis and characterization of amorphous silica nanoparticles from aqueous silicates using cationic surfactants. J. Met. Mater. Miner. 2014, 24, 37–42. [Google Scholar]

- Bass, J.L.; Turner, G.L. Anion distribution in sodium silicate solutions. Characterization by 29Si NMR and infrared spectroscopies, and vapor phase osmometry. J. Phys. Chem. B 1997, 101, 10638–10644. [Google Scholar] [CrossRef]

- Ali, M.A.; Brisdon, B.J.; Thomas, W.J. Synthesis, Characterization and Catalytic Activity of ZSM-5 Zeolites Having Variable Silicon-to-Aluminum Ratios. Appl. Catal. A 2003, 252, 149–162. [Google Scholar] [CrossRef]

- Van der Gaag, F.J.; Jansen, J.C.; Vanberkkum, H. Template variation in the synthesis of zeolite ZSM-5. Appl. Catal. 1985, 17, 261–271. [Google Scholar] [CrossRef]

- Criado, M.; Fernandez-Jimenez, A.; Palomo, A. Alkali activation of fly ash: Effect of the SiO2/Na2O ratio part 1: FTIR study. Microporous Mesoporous Mater. 2007, 106, 180–191. [Google Scholar] [CrossRef]

- Triantafillidis, K.S.; Nalbandian, L.; Trikalitis, P.N.; Ladavos, A.K.; Mavromustakos, T.; Nicolaides, C.P. Structure, compositional and acidic characteristics of nanosized amorphous or partially crystalline ZSM-5 zeolite-based materials. Microporous Mesoporous Mater. 2004, 75, 89–100. [Google Scholar] [CrossRef]

- Byrappa, K.; Yoshimura, M. Handbook of Hydrothermal Technology; Noyes Publications/William Andrew Publishing, LLC: New York, NY, USA, 2001. [Google Scholar]

- Lowell, S.; Shields, J.E.; Thomas, M.A.; Thommes, M. Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density; Springer: New York, NY, USA, 2004. [Google Scholar]

- Louis, B.; Pereira, M.M.; Santos, F.M.; Esteves, P.M.; Sommer, J. Alkane activation over acidic zeolites: The first step. Chem. Eur. J. 2010, 16, 573–576. [Google Scholar] [CrossRef] [PubMed]

- Dai, W.; Wang, X.; Wu, G.; Guan, N.; Hunger, M.; Li, L. Methanol-to-Olefin conversion on silicoaluminophosphate catalysts: Effect of Brønsted acid sites and framework structures. ACS Catal. 2011, 1, 292–299. [Google Scholar] [CrossRef]

- Chen, D.; Moljord, K.; Holmen, A. A methanol to olefins review: Diffusion, coke formation and deactivation on SAPO type catalysts. Microporous Macroporous Mater. 2012, 164, 239–250. [Google Scholar] [CrossRef]

- Wan, Z.; Wang, C.; Yang, H.; Zhang, D. Effect of Crystal Size of ZSM-5 on its Catalytic Activity for Methanol to Gasoline Conversion. In CHEMECA 2013, Challenging Tomorrow, Brisbane, Australia, 29 September–2 October 2013; Engineers Media Pty Ltd., 1: Barton, Australia, 2013. [Google Scholar]

- Takamitsu, Y.; Yamamoto, K.; Yoshida, S.; Ogawa, H.; Sano, T. Effect of crystal size and surface modification of ZSM-5 zeolites on conversion of ethanol to propylene. J. Porous Mater. 2014, 21, 433–440. [Google Scholar] [CrossRef]

- Nicolaides, C.P. A novel family of solid acid catalysts: Substantially amorphous or partially crystalline zeolitic materials. Appl. Catal. A Gen. 1999, 185, 211–217. [Google Scholar] [CrossRef]

- Wilson, S.T. Templating in molecular sieve synthesis. In Verified Synthesis of Zeolite Materials, 2nd ed.; Elsevier Science B.V: Amsterdam, The Netherlands, 2001; pp. 27–32. [Google Scholar]

- Missengue, R.N.M.; Ameh, A.E.; Ndlovu, Z.N.; Hlatywayo, T.; Petrik, L.F. Process for Production of High Silica Content Zeolite from Fly Ash. Patent WO/2017/221192, 28 December 2017. [Google Scholar]

- Louis, B.; Walspurger, S.; Sommer, J. Quantitative determination of Brønsted acid sites on zeolites: A new approach towards the chemical composition of zeolites. Catal. Lett. 2004, 93, 81–84. [Google Scholar] [CrossRef]

- Missengue, R.N.M.; Musyoka, N.M.; Madzivire, G.; Babajide, O.; Fatoba, O.O.; Tuffin, M.; Petrik, L.F. Leaching and antimicrobial properties of silver nanoparticles loaded onto natural zeolite clinoptilolite by ion exchange and wet impregnation. J. Environ. Sci. Health A 2016, 51, 97–104. [Google Scholar] [CrossRef] [PubMed]

| Element | FA (a) (%) | AL (b) (%) | FFAE (c) (%) | FFAE1 (d) (%) |

|---|---|---|---|---|

| Si | 54.5 ± 0.9 | 59.1 ± 0.2 | 22.6 ± 2.5 | 78.7 ± 1.8 |

| Al | 29.3 ± 0.3 | 29.2 ± 0.1 | 2.2 ± 0.1 | 1.9 ± 0.1 |

| Na | 0.0 ± 0.0 | 0.0 ± 0.0 | 68.3 ± 1.5 | 12.5 ± 0.4 |

| Fe | 6.9 ± 0.1 | 5.0 ± 0.0 | 0.0 ± 0.0 | 0.0 ± 0.0 |

| Ca | 5.7 ± 0.2 | 3.4 ± 0.0 | 6.5 ± 0.2 | 6.6 ± 0.7 |

| Ti | 2.0 ± 0.1 | 1.8 ± 0.1 | 0.0 ± 0.0 | 0.0 ± 0.0 |

| K | 0.2 ± 0.0 | 1.0 ± 0.0 | 0.0 ± 0.0 | 0.0 ± 0.0 |

| Mg | 1.4 ± 0.1 | 0.6 ± 0.0 | 0.4 ± 0.0 | 0.3 ± 0.0 |

| Si/Al | 1.8 | 2.0 | 10.4 | 41.8 |

| Na/Si | 0.0 | 0.0 | 3.0 | 0.2 |

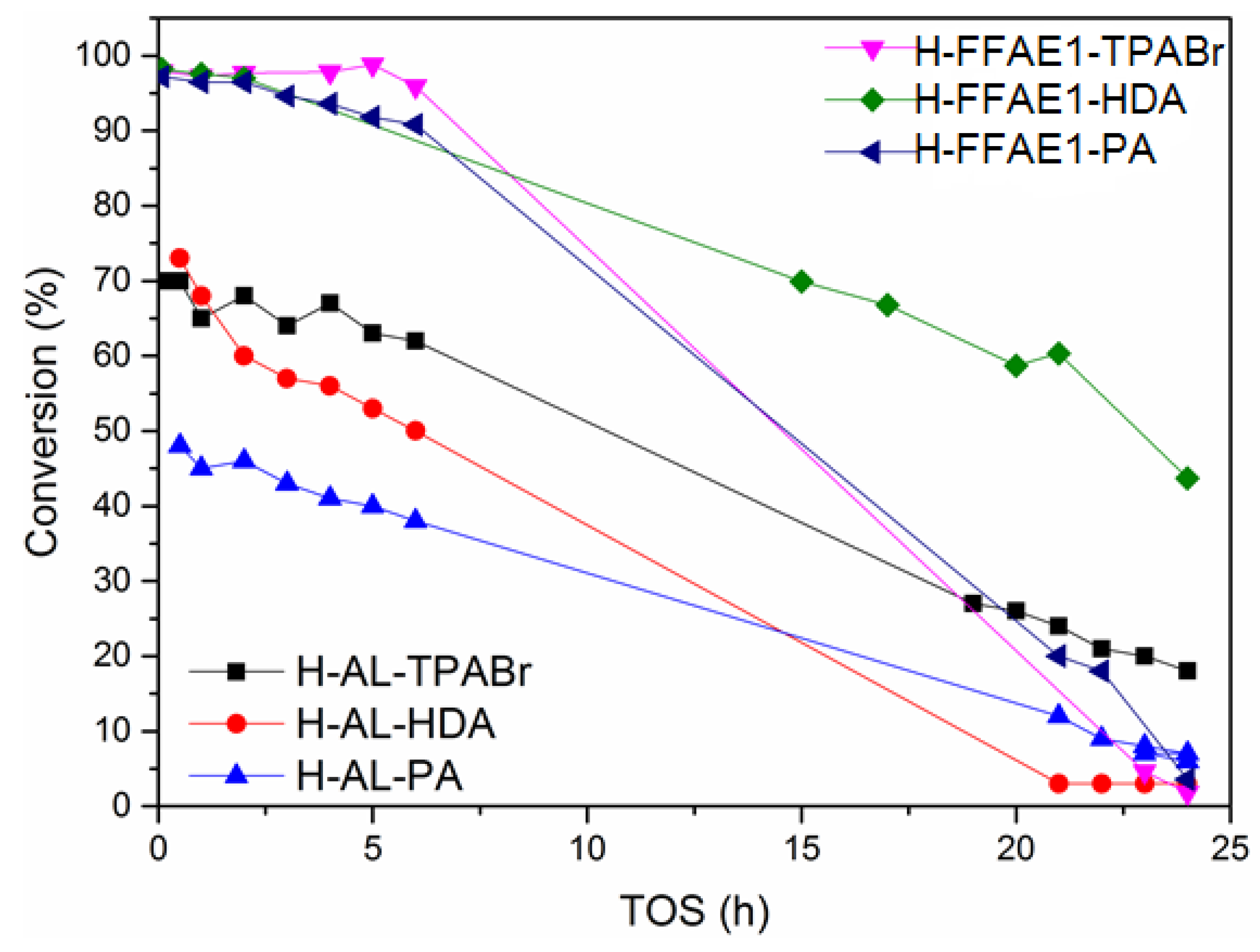

| Catalyst | Properties | Methanol Conversion and Selectivity (e) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Si/Al (a) | SBET (m2/g) (b) | Crystal Size (µm) (c) | Brønsted Acid Site Density (d) (mmol H+/g of Catalyst) | Conversion [%] | Selectivity C2= [%] | Selectivity C3= [%] | Selectivity C4= [%] | ||

| Length | Width | ||||||||

| H–AL–TPABr | 4 | 327 | 6.2 ± 1.1 | 5.6 ± 1.2 | 0.71 | 70 | 13 | 35 | 17 |

| H–AL–HDA | 5 | 353 | 1.0 ± 0.1 | 0.6 ± 0.1 | 0.46 | 73 | 9 | 34 | 15 |

| H–AL–PA | 5 | 39 | 18.9 ± 2.0 | 6.8 ± 0.9 | 0.42 | 48 | 18 | 32 | 12 |

| H–FFAE–TPABr | 36 | 459 | 6.5 ± 0.2 | 2.6 ± 0.5 | 0.62 | 99 | 12 | 29 | 11 |

| H–FFAE–HDA | 55 | 388 | 3.3 ± 0.7 | 1.1 ± 0.2 | 0.56 | 98 | 8 | 37 | 14 |

| H–FFAE–PA | 42 | 353 | 3.1 ± 0.4 | 1.0 ± 0.2 | 0.53 | 97 | 6 | 38 | 16 |

| H–ZSM-5 (f) | 25 | 480 | / | / | 0.86 | 100 | 12 | 19 | 13 |

| Code Name | Molar Regime |

|---|---|

| AL–TPABr | Si(6), Al(1), Na(2), H2O(339), TPABr(1) |

| AL–HDA | Si(6), Al(1), Na(2), H2O(339), HDA(3) |

| AL–PA | Si(6), Al(1), Na(2), H2O(339), PA(5) |

| FFAE–TPABr | Si(10), Al(1), Na(49), H2O(3412), TPABr(4) |

| FFAE1–TPABr | Si(42), Al(1), Na(31), H2O(6313), TPABr(7) |

| FFAAE1–HDA | Si(42), Al(1), Na(31), H2O(6313), HDA(20) |

| FFAE1–PA | Si(42), Al(1), Na(31), H2O(6313), PA(38) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Missengue, R.N.M.; Losch, P.; Musyoka, N.M.; Louis, B.; Pale, P.; Petrik, L.F. Conversion of South African Coal Fly Ash into High-Purity ZSM-5 Zeolite without Additional Source of Silica or Alumina and Its Application as a Methanol-to-Olefins Catalyst. Catalysts 2018, 8, 124. https://doi.org/10.3390/catal8040124

Missengue RNM, Losch P, Musyoka NM, Louis B, Pale P, Petrik LF. Conversion of South African Coal Fly Ash into High-Purity ZSM-5 Zeolite without Additional Source of Silica or Alumina and Its Application as a Methanol-to-Olefins Catalyst. Catalysts. 2018; 8(4):124. https://doi.org/10.3390/catal8040124

Chicago/Turabian StyleMissengue, Roland N. M., Pit Losch, Nicholas M. Musyoka, Benoit Louis, Patrick Pale, and Leslie F. Petrik. 2018. "Conversion of South African Coal Fly Ash into High-Purity ZSM-5 Zeolite without Additional Source of Silica or Alumina and Its Application as a Methanol-to-Olefins Catalyst" Catalysts 8, no. 4: 124. https://doi.org/10.3390/catal8040124