Recent Insights in Transition Metal Sulfide Hydrodesulfurization Catalysts for the Production of Ultra Low Sulfur Diesel: A Short Review

Abstract

:1. Introduction

2. Supported HDS Catalysts

2.1. The Role of Support in the Active Sulfide Phases

Mixed Oxides Support: A Different Approach

2.2. Details of ULSD Catalyst Preparation

2.2.1. Organic Additives

2.2.2. Inorganic Additives

2.3. Concluding Remarks

3. Unsupported HDS Catalysts and Their Structure-Activity Relationship

3.1. Decomposition of Thiosalts

3.2. Oxides Followed by Sulfidation

3.2.1. Template-Free Method

3.2.2. Template Method

3.3. Concluding Remarks

4. Theoretical Studies

Concluding Remarks

5. General Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Refinery Catalysts Market, Global Trends and Forecasts to 2019 (Market Research Report), Markets and Markets. Available online: https://www.marketsandmarkets.com (accessed on 20 November 2018).

- Speight, J.G.; Dekker, M. The Desulfurization of Heavy Oils and Residua, 2nd ed.; Marcel Dekker, Inc.: New York, NY, USA, 2000; ISBN 0-8247-8921-0. [Google Scholar]

- Suresh, C.; Pérez-Cabrera, L.; Díaz de León, J.N.; Zepeda, T.A.; Alonso-Núñez, G.; Moyado, S.F. Highly active CoMo/Al(10) KIT-6 catalysts for HDS of DBT: Role of structure and aluminum heteroatom in the support matrix. Catal. Today 2017, 296, 214–218. [Google Scholar] [CrossRef]

- Díaz de León, J.N.; Sánchez, L.A.; Toriello, Z.V.A.S.; Núñez, G.A.; Zepeda, T.A.; Yocupicio, R.I.; Reyes, J.A.L.; Fuentes, S. Support effects of NiW catalysts for highly selective sulfur removal from light hydrocarbons. Appl. Catal. B Environ. 2017, 213, 167–176. [Google Scholar] [CrossRef]

- Stanislaus, A.; Marafi, A.; Rana, M.S. Recent advances in the science and technology of ultra low sulfur diesel (ULSD) production. Catal. Today 2010, 153, 1–68. [Google Scholar] [CrossRef]

- International Maritime Organization www.imo.org. Available online: http://www.imo.org/es/mediacentre/hottopics/paginas/sulphur-2020.aspx (accessed on 7 January 2019).

- Environmental Defense Fund Europe. Available online: https://europe.edf.org/news/2018/31/07/alternative-fuels-future-zero-emissions-shipping (accessed on 7 January 2019).

- Hensen, E.J.M. Hydrodesulfurization Catalysis and Mechanism of Supported Transition Metal Sulfides; Eindhoven Technische Universiteit: Eindhoven, The Netherlands, 2000; ISBN 90-386-2871-4. [Google Scholar]

- Topsoe, H.; Clausen, B.S.; Massoth, F.E. Hydrotreating Catalysis Science and Technology; Springer: Berlin/Hidelberg, Germany, 1996. [Google Scholar]

- P.M.I. Comercio Internacional, S.A. de C.V. Available online: http://www.pmi.com.mx (accessed on 7 January 2019).

- Mello, M.D.; Braggio, F.A.; Magalhães, B.C.; Zotin, J.L.; Silva, M.A.P. Kinetic modeling of deep hydrodesulfurization of dibenzothiophenes on NiMo/alumina catalysts modified by phosphorus. Fuel Process. Technol. 2018, 177, 66–74. [Google Scholar] [CrossRef]

- Salazar, N.; Schmidt, S.B.; Lauritsen, J.V. Adsorption of nitrogenous inhibitor molecules on MoS2 and CoMoS hydrodesulfurization catalysts particles investigated by scanning tunneling microscopy. J. Catal. 2019, 370, 232–240. [Google Scholar] [CrossRef]

- Mallet, M.; Naboulsi, I.; Lebeau, B.; Aponte, C.F.L.; Brunet, S.; Michelin, L.; Bonne, M.; Carteret, C.; Blin, J.L. Selective direct desulfurization way (DDS) with CoMoS supported over mesostructured titania for the deep hydrodesulfurization of 4,6-dimethydibenzothiophene. Appl. Catal. A Gen. 2018, 563, 91–97. [Google Scholar]

- Macaud, M.; Milenkovic, A.; Schultz, E.; Lemaire, M.; Vrinat, M. Hydrodesulfurization of Alkyldibenzothiophenes: Evidence of Highly Unreactive Aromatic Sulfur Compounds. J. Catal. 2000, 193, 255–263. [Google Scholar] [CrossRef]

- Rakotovao, V.R.; Diehl, F.; Brunet, S. Deep HDS of Diesel Fuel: Inhibiting Effect of Nitrogen Compounds on the Transformation of the Refractory 4,6-Dimethyldibenzothiophene Over a NiMoP/Al2O3 Catalyst. Catal. Lett. 2009, 129, 50–60. [Google Scholar] [CrossRef]

- Nie, H.; Li, H.; Yang, Q.; Li, D. Effect of structure and stability of active phase on catalytic performance of hydrotreating catalysts. Catal. Today 2018, 316, 13–20. [Google Scholar] [CrossRef]

- Ibrahim, M.H.; Hayyan, M.; Hashim, M.A.; Hayyan, A. The role of ionic liquids in desulfurization of fuels: A review. Renew. Sustain. Energy Rev. 2017, 76, 1534–1549. [Google Scholar] [CrossRef]

- Gatan, R.; Barger, P.; Gembicki, V.; Cavanna, A.; Molinari, D. Oxidative desulfurization: A new technology for ULSD. Am. Chem. Soc. Div. Fuel Chem. 2004, 49, 577–579. [Google Scholar]

- Breysse, M.; Geantet, C.; Afanasiev, P.; Blanchard, J.; Vrinat, M. Recent studies on the preparation, activation and design of active phases and supports of hydrotreating catalysts. Catal. Today 2008, 130, 3–13. [Google Scholar] [CrossRef]

- Besenbacher, F.; Brorson, M.; Clausen, B.S.; Helveg, S.; Hinnemann, B.; Kibsgaard, J.; Lauritsen, J.V.; Moses, P.G.; Nørskov, J.K.; Topsøe, H. Recent STM, DFT and HAADF-STEM studies of sulfide-based hydrotreating catalysts: Insight into mechanistic, structural and particle size effects. Catal. Today 2008, 130, 86–96. [Google Scholar] [CrossRef]

- Chen, M.S.; Goodman, D.W. Structure–activity relationships in supported Au catalysts. Catal. Today 2006, 111, 22–33. [Google Scholar] [CrossRef]

- Venezia, A.M.; Parola, V.L.; Liotta, L.F. Structural and surface properties of heterogeneous catalysts: Nature of the oxide carrier and supported particle size effects. Catal. Today 2017, 285, 114–124. [Google Scholar] [CrossRef]

- Gutiérrez, O.Y.; Singh, S.; Schachtl, E.; Kim, J.; Kondratieva, E.; Hein, J.; Lercher, J.A. Effects of the Support on the Performance and Promotion of (Ni)MoS2 Catalysts for Simultaneous Hydrodenitrogenation and Hydrodesulfurization. ACS Catal. 2014, 4, 1487–1499. [Google Scholar] [CrossRef]

- Derouane, E.G.; Pedersen, E.; Clausen, B.S.; Gabelica, Z.; Candia, R.; Topsoe, H. EPR studies on unsupported and alumina-supported sulfided CoMo hydrodesulfurization catalysts. J. Catal. 1986, 99, 253–261. [Google Scholar] [CrossRef]

- Topsoe, H. The role of Co–Mo–S type structures in hydrotreating catalysts. Appl. Catal. A Gen. 2007, 322, 3–8. [Google Scholar] [CrossRef]

- Ninh, T.K.T.; Massin, L.; Laurenti, D.; Vrinat, M. A new approach in the evaluation of the support effect for NiMo hydrodesulfurization catalysts. Appl. Catal. A Gen. 2011, 407, 29–39. [Google Scholar] [CrossRef]

- Shimada, H. Morphology and orientation of MoS2 clusters on Al2O3 and TiO2 supports and their effect on catalytic performance. Catal. Today 2003, 86, 17–29. [Google Scholar] [CrossRef]

- Bara, C.; Lamic-Humblot, A.F.; Fonda, E.; Gay, A.S.; Taleb, A.E.; Devers, E.; Digne, M.; Pirngruber, G.D.; Carrier, X. Surface-dependent sulfidation and orientation of MoS2 slabs on alumina-supported model hydrodesulfurization catalysts. J. Catal. 2016, 344, 591–605. [Google Scholar] [CrossRef]

- Sakashita, Y.; Araki, Y.; Honna, K.; Shimada, H. Orientation and morphology of molybdenum sulfide catalysts supported on titania particles, observed by using high-resolution electron microscopy. Appl. Catal. A Gen. 2000, 197, 247–253. [Google Scholar] [CrossRef]

- Arrouvel, C.; Breysse, M.; Toulhoat, H.; Raybaud, P. A density functional theory comparison of anatase (TiO2)- and γ-Al2O3-supported MoS2 catalysts. J. Catal. 2005, 232, 161–178. [Google Scholar] [CrossRef]

- Díaz de León, J.N.; Zepeda, T.A.; Nuñez, G.A.; Galvan, D.H.; Pawelec, B.; Fuentes, S. Insight of 1D γ-Al2O3 nanorods decoration by NiWS nanoslabs in ultra-deep hydrodesulfurization catalyst. J. Catal. 2015, 321, 51–61. [Google Scholar] [CrossRef]

- Hayden, T.F.; Dumesic, J.A. Studies of the structure of molybdenum oxide and sulfide supported on thin films of alumina. J. Catal. 1987, 103, 366–384. [Google Scholar] [CrossRef]

- Berhault, G. New Materials for Catalytic Applications; Elsevier: Amsterdam, The Netherlands, 2016; Volume 10, p. 336. [Google Scholar]

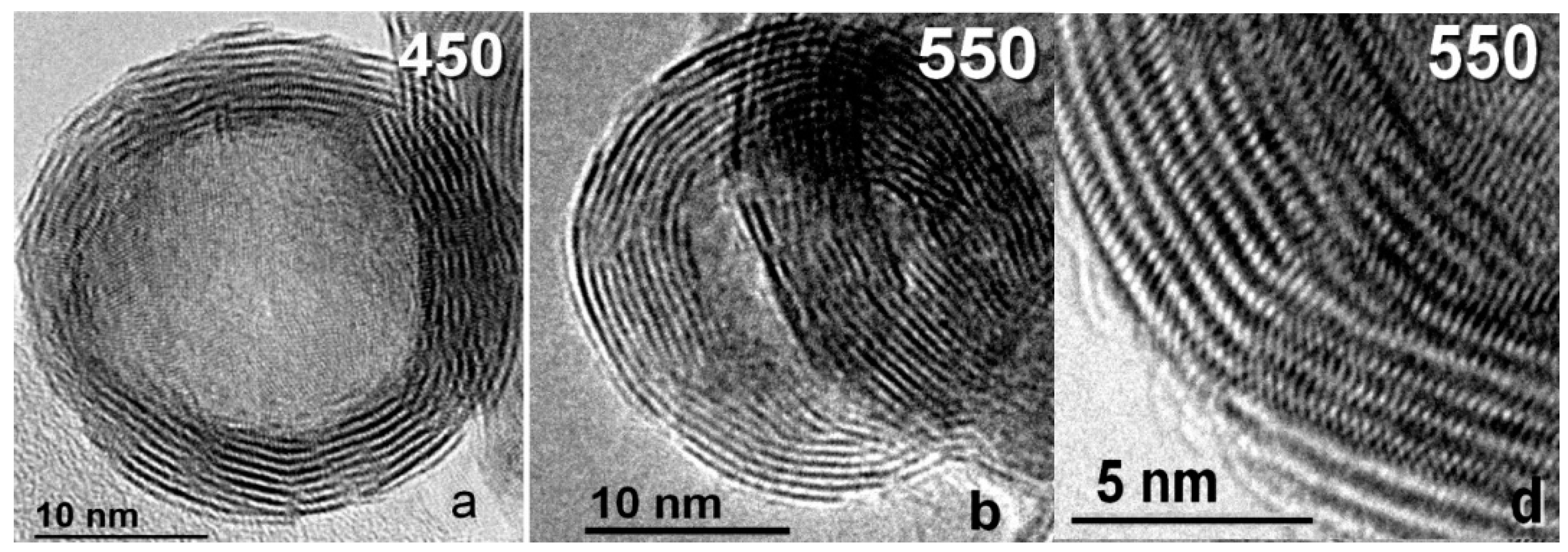

- Nogueira, A.; Znaiguia, R.; Uzio, D.; Afanasiev, P.; Barhault, G. Curved nanostructures of unsupported and Al2O3-supported MoS2 catalysts: Synthesis and HDS catalytic properties. Appl. Catal. A Gen. 2012, 429–430, 92–105. [Google Scholar] [CrossRef]

- Díaz de León, J.N.; García, J.A.; Nuñez, G.A.; Zepeda, T.A.; Galvan, D.H.; de los Reyes, J.A.; Fuentes-Moyado, S. Support effects of NiW hydrodesulfurization catalysts from experiments and DFT calculations. Appl. Catal. B Environ. 2018, 238, 480–490. [Google Scholar] [CrossRef]

- Iwata, Y.; Araki, Y.; Honna, K.; Miki, Y.; Sato, K.; Shimada, H. Hydrogenation active sites of unsupported molybdenum sulfide catalysts for hydroprocessing heavy oils. Catal. Today 2001, 65, 335–341. [Google Scholar] [CrossRef]

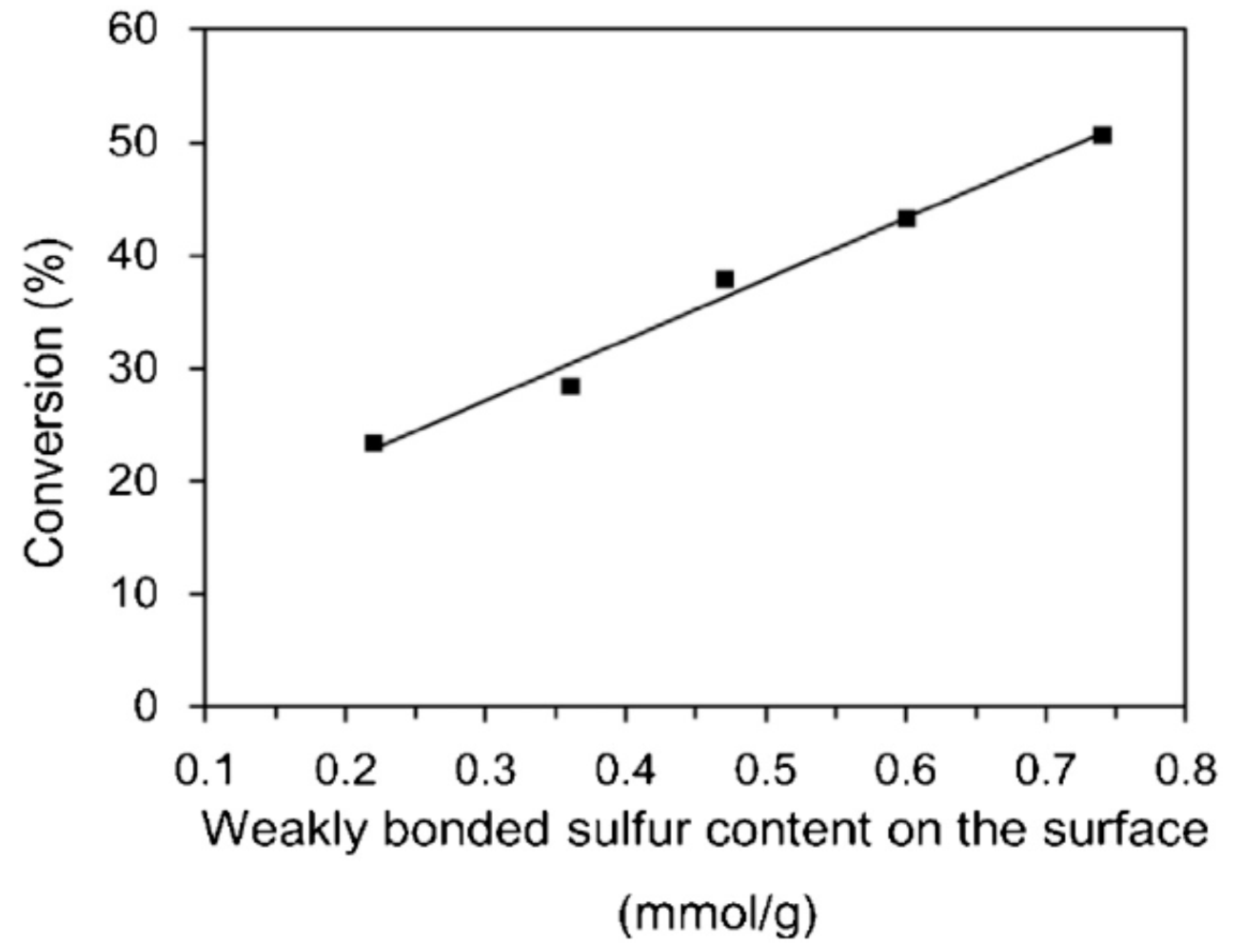

- Afanasiev, P. Topotactic synthesis of size-tuned MoS2 inorganic fullerenes that allows revealing particular catalytic properties of curved basal planes. Appl. Catal. B Environ. 2018, 227, 44–53. [Google Scholar] [CrossRef]

- Laurenti, D.; Ngoc, B.P.; Massin, L.; Roukoss, C.; Devers, E.; Marchand, K.; Lemaitre, L.; Legens, C.; Quoineaud, A.A.; Vrinat, M. Intrinsic potential of alumina-supported CoMo catalysts in HDS: Comparison between γc, γT, and δ-alumina. J. Catal. 2013, 297, 165–175. [Google Scholar] [CrossRef]

- Araki, Y.; Honna, K.; Shimada, H. Formation and Catalytic Properties of Edge-Bonded Molybdenum Sulfide Catalysts on TiO2. J. Catal. 2002, 207, 361–370. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Xiao, B.; Zhao, L.; Zhang, J.; Zhu, Y.; Guo, X. The hydroxyapatite nanotube as promoter to optimize the HDS reaction of NiMo/TiO2 catalysts. Catal. Today 2016, 259, 340–346. [Google Scholar] [CrossRef]

- Platanitis, P.; Panagiotou, G.D.; Bourikas, K.; Kordulis, C.; Fierro, J.L.G.; Lycourghiotis, A. Preparation of un-promoted molybdenum HDS catalysts supported on titania by equilibrium deposition filtration: Optimization of the preparative parameters and investigation of the promoting action of titania. J. Mol. Catal. A Chem. 2016, 412, 1–12. [Google Scholar] [CrossRef]

- Villalón, P.C.; Ramírez, J.; Cuevas, R.; Vázquez, P.; Castañeda, R. Influence of the support on the catalytic performance of Mo, CoMo, and NiMo catalysts supported on Al2O3 and TiO2 during the HDS of thiophene, dibenzothiophene, or 4,6-dimethyldibenzothiophene. Catal. Today 2016, 259, 140–149. [Google Scholar] [CrossRef]

- Mazurelle, J.; Lamonier, C.; Lancelot, C.; Payen, E.; Pichon, C.; Guillaume, D. Use of the cobalt salt of the heteropolyanion [Co2Mo10O38H4]6− for the preparation of CoMo HDS catalysts supported on Al2O3, TiO2 and ZrO2. Catal. Today 2008, 130, 41–49. [Google Scholar] [CrossRef]

- Laurenti, D.; Ninh, T.K.T.; Escalona, N.; Massin, L.; Vrinat, M.; Llambías, F.J.G. Support effect with rhenium sulfide catalysts. Catal. Today 2008, 130, 50–55. [Google Scholar] [CrossRef]

- Ninh, T.K.T.; Laurenti, D.; Leclerc, E.; Vrinat, M. Support effect for CoMoS and CoNiMoS hydrodesulfurization catalysts prepared by controlled method. Appl. Catal. A Gen. 2014, 487, 210–218. [Google Scholar] [CrossRef]

- Badoga, S.; Sharma, R.V.; Dalai, A.K.; Adjaye, J. Hydrotreating of heavy gas oil on mesoporous zirconia supported NiMo catalyst with EDTA. Fuel 2014, 128, 30–38. [Google Scholar] [CrossRef]

- Baeza, P.; Aguila, G.; Gracia, F.; Araya, P. Desulfurization by adsorption with copper supported on zirconia. Catal. Commun. 2008, 9, 751–755. [Google Scholar] [CrossRef]

- Song, S.; Zhou, X.; Duan, A.; Zhao, Z.; Chi, K.; Zhang, M.; Jiang, G.; Liu, J.; Li, J.; Wang, X. Synthesis of mesoporous silica material with ultra-large pore sizes and the HDS performance of dibenzothiophene. Microporous Mesoporous Mater. 2016, 226, 510–521. [Google Scholar] [CrossRef]

- Parola, V.L.; Dragoi, B.; Ungureanu, A.; Dumitriu, E.; Venezia, A.M. New HDS catalysts based on thiol functionalized mesoporous silica supports. Appl. Catal. A Gen. 2010, 386, 43–50. [Google Scholar] [CrossRef]

- Al-zaqri, N.; Alsalme, A.; Adil, S.F.; Alsaleh, A.; Alshammari, S.G.; Alresayes, S.I.; Alotaibi, R.; Al-Kinany, M.; Siddiqui, M.R.H. Comparative catalytic evaluation of nickel and cobalt substituted phosphomolybdic acid catalyst supported on silica for hydrodesulfurization of thiophene. J. Saudi Chem. Soc. 2017, 21, 965–973. [Google Scholar] [CrossRef]

- Díaz de León, J.N. Binary γ-Al2O3–α-Ga2O3 as supports of NiW catalysts for hydrocarbon sulfur removal. Appl. Catal. B Environ. 2016, 181, 524–533. [Google Scholar] [CrossRef]

- Estrella, R.O.; Fierro, J.L.G.; Díaz de León, J.N.; Fuentes, S.; Nuñez, G.A.; Medina, E.L.; Pawelec, B.; Zepeda, T.A. Effect of partial Mo substitution by W on HDS activity using sulfide CoMoW/Al2O3–TiO2 catalysts. Fuel 2018, 233, 644–657. [Google Scholar] [CrossRef]

- Wan, G.; Duan, A.; Zhao, Z.; Jiang, G.; Zhang, D.; Li, R.; Dou, T.; Chung, K.H. Al2O3−TiO2/Al2O3−TiO2−SiO2 Composite-Supported Bimetallic Pt−Pd Catalysts for the Hydrodearomatization and Hydrodesulfurization of Diesel Fuel. Energy Fuels 2009, 23, 81–85. [Google Scholar] [CrossRef]

- Duan, A.; Li, R.; Jiang, G.; Gao, J.; Zhao, Z.; Wan, G.; Zhang, D.; Keng, W.H.; Chung, H. Hydrodesulphurization performance of NiW/TiO2-Al2O3 catalyst for ultra clean diesel. Catal. Today 2009, 140, 187–191. [Google Scholar] [CrossRef]

- Tavizon-Pozos, J.A.; Suarez-Toriello, V.A.; de los Reyes, J.A.; Lara, A.G.; Pawelec, B.; Fierro, J.L.G.; Vrinat, M.; Geantet, C. Deep Hydrodesulfurization of Dibenzothiophenes over NiW Sulfide Catalysts Supported on Sol–Gel Titania–Alumina. Top. Catal. 2016, 59, 241–251. [Google Scholar] [CrossRef]

- Wang, H.; Yao, Z.; Zhan, X.; Wu, Y.; Li, M. Preparation of highly dispersed W/ZrO2–Al2O3 hydrodesulfurization catalysts at high WO3 loading via a microwave hydrothermal method. Fuel 2015, 158, 918–926. [Google Scholar] [CrossRef]

- Vazquez-Garrido, I.; Benítez, A.L.; Berhault, G.; Guevara-Lara, A. Effect of support on the acidity of NiMo/Al2O3-MgO and NiMo/TiO2-Al2O3 catalysts and on the resulting competitive hydrodesulfurization/hydrodenitrogenation reactions. Fuel 2019, 236, 55–64. [Google Scholar] [CrossRef]

- Escobar, J.; Barrera, M.C.; Reyes, J.A.D.L.; Cortés, M.A.; Santes, V.; Gómez, E.; Pacheco, J.G. Effect of Mo and Co loading in HDS catalysts supported on solvo-thermally treated ZrO2–TiO2 mixed oxides. Catal. Today 2008, 133–135, 282–291. [Google Scholar] [CrossRef]

- Escobar, J.; De Los Reyes, J.A.; Ulín, C.A.; Barrera, M.C. Highly active sulfided CoMo catalysts supported on (ZrO2–TiO2)/Al2O3 ternary oxides. Mater. Chem. Phys. 2013, 143, 213–222. [Google Scholar] [CrossRef]

- Jabbarnezhad, P.; Haghighi, M.; Taghavinezhad, P. Sonochemical synthesis of NiMo/Al2O3–ZrO2 nanocatalyst: Effect of sonication and zirconia loading on catalytic properties and performance in hydrodesulfurization reaction. Fuel Process. Technol. 2014, 126, 392–401. [Google Scholar] [CrossRef]

- Daous, M.A.A.; Ali, S.A. Deep desulfurization of gas oil over NiMo catalysts supported on alumina–zirconia composites. Fuel 2012, 97, 662–669. [Google Scholar] [CrossRef]

- Prado-Baston, E.; Boscaro-Franca, A.; da Silva Neto, A.V.; Urquieta-Gonzalez, E.A. Incorporation of the precursors of Mo and Ni oxides directly into the reaction mixture of sol–gel prepared γ-Al2O3-ZrO2 supports – Evaluation of the sulfided catalysts in the thiophene hydrodesulfurization. Catal. Today 2015, 246, 184–190. [Google Scholar] [CrossRef]

- Cruz-Pérez, A.E.; Jiménez, Y.T.; Alejo, J.J.V.; Zepeda, T.A.; Márquez, D.M.F.; Ruedas, M.G.R.; Fuentes-Moyado, S.; Díaz de León, J.N. NiW/MgO–TiO2 catalysts for dibenzothiophene hydrodesulfurization: Effect of preparation method. Catal. Today 2016, 271, 28–34. [Google Scholar] [CrossRef]

- Betancourt, J.C.M.; Benítez, A.L.; López, J.R.M.; Massin, L.; Aouine, M.; Vrinat, M.; Berhault, G.; Lara, A.G. Interaction effects of nickel polyoxotungstate with the Al2O3–MgO support for application in dibenzothiophene hydrodesulfurization. J. Catal. 2014, 313, 9–23. [Google Scholar] [CrossRef]

- Benitez, A.L.; Berhault, G.; Lara, A.G. Addition of manganese to alumina and its influence on the formation of supported NiMo catalysts for dibenzothiophene hydrodesulfurization application. J. Catal. 2016, 344, 59–76. [Google Scholar] [CrossRef]

- Benitez, A.L.; Berhault, G.; Burel, L.; Lara, A.G. Novel NiW hydrodesulfurization catalysts supported on Sol-Gel Mn-Al2O3. J. Catal. 2017, 354, 197–212. [Google Scholar] [CrossRef]

- Benitez, A.L.; Berhault, G.; Lara, A.G. NiMo catalysts supported on Mn-Al2O3 for dibenzothiophene hydrodesulfurization application. Appl. Catal. B Environ. 2017, 213, 28–41. [Google Scholar] [CrossRef]

- Trejo, F.; Rana, M.M.S.; Ancheyta, J.; Chavez, S. Influence of support and supported phases on catalytic functionalities of hydrotreating catalysts. Fuel 2014, 138, 104–110. [Google Scholar] [CrossRef]

- Nishijima, A.; Shimada, H.; Sato, T.; Yoshimura, Y.; Hiraishi, J. Support effects on hydrocarcking and hydrogenation activities of molybdenum catlysts used for upgrading coal-derived liquids. J. Polyhedron 1986, 5, 243–247. [Google Scholar] [CrossRef]

- Ramirez, J.; Rayo, P.; Alejandre, A.G.; Ancheyta, J.; Rana, M.S. Analysis of the hydrotreatment of Maya heavy crude with NiMo catalysts supported on TiO2-Al2O3 binary oxides: Effect of the incorporation method of Ti. Catal. Today 2005, 109, 54–60. [Google Scholar] [CrossRef]

- Maity, S.K.; Ancheyta, J.; Rana, M.S.; Rayo, P. Alumina−Titania Mixed Oxide Used as Support for Hydrotreating Catalysts of Maya Heavy Crude Effect of Support Preparation Methods. Energy Fuels 2006, 20, 427–431. [Google Scholar] [CrossRef]

- Joshi, Y.V.; Ghosh, P.; Daage, M.; Delgass, W.N. Support effects in HDS catalysts: DFT analysis of thiolysis and hydrolysis energies of metal–support linkages. J. Catal. 2008, 257, 71–80. [Google Scholar] [CrossRef]

- Zhu, Y.; Ramasse, Q.M.; Brorson, M.; Moses, P.G.; Hansen, L.P.; Kisielowski, C.F.; Helveg, S. Visualizing the stoichiometry of industrial-style Co-Mo-S catalysts with single-atom sensitivity. Angew. Chem. Int. Ed. 2014, 53, 10723–10727. [Google Scholar] [CrossRef]

- Suarez-Toriello, V.A.; Vargas, C.E.S.; de los Reyes, J.A.; Zavala, A.V.; Vrinat, M.; Geantet, C. Influence of the solution pH in impregnation with citric acid and activity of Ni/W/Al2O3 catalysts. J. Mol. Catal. A Chem. 2015, 404–405, 36–46. [Google Scholar] [CrossRef]

- Wachs, I.E. Characterization of Catalytic Materials; Butterworth–Heinemann: Oxford, UK, 1992. [Google Scholar]

- Díaz de León, J.N.; Picquart, M.; Villarroel, M.; Vrinat, M.; Llambias, F.J.G.; de los Reyes, J.A. Effect of gallium as an additive in hydrodesulfurization WS2/γ-Al2O3 catalysts. J. Mol. Catal. A Chem. 2010, 323, 1–6. [Google Scholar] [CrossRef]

- Hensen, E.J.M.; der Meer, Y.V.; Veen, J.A.R.V.; Niemantsverdriet, J.W. Insight into the formation of the active phases in supported NiW hydrotreating catalysts. Appl. Catal. A Gen. 2007, 322, 16–32. [Google Scholar] [CrossRef]

- Coulier, L.; de Beer, V.H.J.; van Veen, J.A.R.; Niemantsverdriet, J.W. Correlation between Hydrodesulfurization Activity and Order of Ni and Mo Sulfidation in Planar Silica-Supported NiMo Catalysts: The Influence of Chelating Agents. J. Catal. 2001, 197, 26–33. [Google Scholar] [CrossRef]

- Okamoto, Y.; Kato, A.; Usman; Sato, K.; Kubota, T. Co–WS2 Hydrodesulfurization Catalysts: An Unexpected More Favorable Combination than Co–MoS2. Chem. Lett. 2005, 34, 1258–1259. [Google Scholar] [CrossRef]

- Kubota, T.; Miyamoto, N.; Yoshioka, M.; Okamoto, Y. Surface structure and sulfidation behavior of Co-Mo and Co-W sulfide catalysts for the hydrodesulfurization of dibenzothiophene. Appl. Catal. A Gen. 2014, 480, 10–16. [Google Scholar] [CrossRef]

- Vissenberg, M.J.; van der Meer, Y.; Hensen, E.J.M.; de Beer, V.H.J.; van der Kraan, A.M.; van Santen, R.A.; van Veen, J.A.R. The Effect of Support Interaction on the Sulfidability of Al2O3- and TiO2-Supported CoW and NiW Hydrodesulfurization Catalysts. J. Catal. 2001, 198, 151–163. [Google Scholar] [CrossRef]

- Kishan, G.; Coulier, L.; van Veen, J.A.R.; Niemantsverdriet, J.W. Promoting Synergy in CoW Sulfide Hydrotreating Catalysts by Chelating Agents. J. Catal. 2001, 200, 194–196. [Google Scholar] [CrossRef]

- Escobar, J.; Barrera, M.C.; Gutierrez, A.W.; Jacome, M.A.C.; Chavez, C.A.; Toledo, J.A.; Casados, D.A.S. Highly active P-doped sulfided NiMo/alumina HDS catalysts from Mo-blue by using saccharose as reducing agents precursor. Appl. Catal. B Environ. 2018, 237, 708–720. [Google Scholar] [CrossRef]

- Mazoyer, P.; Geantet, C.; Diehl, F.; Loridant, S.; Lacroix, M. Role of chelating agent on the oxidic state of hydrotreating catalysts. Catal. Today 2008, 130, 75–79. [Google Scholar] [CrossRef]

- de Jong, A.M.; de Beer, V.H.J.; Veen, J.A.R.; Niemantsverdriet, J.W. Surface Science Model of a Working Cobalt-Promoted Molybdenum Sulfide Hydrodesulfurization Catalyst: Characterization and Reactivity. J. Phys. Chem. 1996, 100, 17722–17724. [Google Scholar] [CrossRef]

- Medici, L.; Prins, R. The Influence of Chelating Ligands on the Sulfidation of Ni and Mo in NiMo/SiO2 Hydrotreating Catalysts. J. Catal. 1996, 163, 38–49. [Google Scholar] [CrossRef]

- Van Haandel, L.; Bremmer, G.M.; Hensen, E.J.M.; Weber, T. The effect of organic additives and phosphoric acid on sulfidation and activity of (Co)Mo/Al2O3 hydrodesulfurization catalysts. J. Catal. 2017, 351, 95–106. [Google Scholar] [CrossRef]

- Blanchard, P.; Lamonier, C.; Griboval, A.; Payen, E. New insight in the preparation of alumina supported hydrotreatment oxidic precursors: A molecular approach. Appl. Catal. A Gen. 2007, 322, 33–45. [Google Scholar] [CrossRef] [Green Version]

- Pashigreva, A.V.; Bukhtiyarova, G.A.; Klimov, O.V.; Chesalov, Y.A.; Litvak, G.S.; Noskov, A.S. Activity and sulfidation behavior of the CoMo/Al2O3 hydrotreating catalyst: The effect of drying conditions. Catal. Today 2010, 149, 19–27. [Google Scholar] [CrossRef]

- Wang, B.; Yu, W.; Meng, D.; Li, Z.; Xu, Y.; Ma, X. Effect of citric acid on CoO–MoO3/Al2O3 catalysts for sulfur-resistant methanation. React. Kinet. Mech. Catal. 2018, 125, 111–126. [Google Scholar] [CrossRef]

- Rinaldi, N.; Kubota, T.; Okamoto, Y. Effect of citric acid addition on the hydrodesulfurization activity of MoO3/Al2O3 catalysts. Appl. Catal. A Gen. 2010, 374, 228–236. [Google Scholar] [CrossRef]

- Magdaleno, M.A.C.; Nieto, J.A.M.; Klimova, T.E. Effect of the amount of citric acid used in the preparation of NiMo/SBA-15 catalysts on their performance in HDS of dibenzothiophene-type compounds. Catal. Today 2014, 220–222, 78–88. [Google Scholar] [CrossRef]

- Wu, H.; Duan, A.; Zhao, Z.; Qi, D.; Li, J.; Liu, B.; Jiang, G.; Liu, J.; Wei, Y.; Zhang, X. Preparation of NiMo/KIT-6 hydrodesulfurization catalysts with tunable sulfidation and dispersion degrees of active phase by addition of citric acid as chelating agent. Fuel 2014, 130, 203–210. [Google Scholar] [CrossRef]

- Chen, J.; Maugé, F.; Fallah, J.E.; Oliviero, L. IR spectroscopy evidence of MoS2 morphology change by citric acid addition on MoS2/Al2O3 catalysts—A step forward to differentiate the reactivity of M-edge and S-edge. J. Catal. 2014, 320, 170–179. [Google Scholar] [CrossRef]

- Nikulshin, P.A.; Ishutenko, D.I.; Mozhaev, A.A.; Maslakov, K.I.; Pimerzin, A.A. Effects of composition and morphology of active phase of CoMo/Al2O3 catalysts prepared using Co2Mo10–heteropolyacid and chelating agents on their catalytic properties in HDS and HYD reactions. J. Catal. 2014, 312, 152–169. [Google Scholar] [CrossRef]

- Rinaldi, N.; Kubota, T.; Okamoto, Y. Effect of Citric Acid Addition on Co−Mo/B2O3/Al2O3 Catalysts Prepared by a Post-Treatment Method. Ind. Eng. Chem. Res. 2009, 48, 10414–10424. [Google Scholar] [CrossRef]

- Li, H.; Li, M.; Chu, Y.; Liu, F.; Nie, H. Essential role of citric acid in preparation of efficient NiW/Al2O3 HDS catalysts. Appl. Catal. A Gen. 2011, 403, 75–82. [Google Scholar] [CrossRef]

- Valencia, D.; Klimova, T. Kinetic study of NiMo/SBA-15 catalysts prepared with citric acid in hydrodesulfurization of dibenzothiophene. Catal. Commun. 2012, 21, 77–81. [Google Scholar] [CrossRef]

- Valencia, D.; Klimova, T. Citric acid loading for MoS2-based catalysts supported on SBA-15. New catalytic materials with high hydrogenolysis ability in hydrodesulfurization. Appl. Catal. B Environ. 2013, 129, 137–145. [Google Scholar] [CrossRef]

- Klimova, T.E.; Valencia, D.; Nieto, J.A.M.; Hipólito, P.H. Behavior of NiMo/SBA-15 catalysts prepared with citric acid in simultaneous hydrodesulfurization of dibenzothiophene and 4,6-dimethyldibenzothiophene. J. Catal. 2013, 304, 29–46. [Google Scholar] [CrossRef]

- Villalón, P.C.; Ramirez, J.; Luciano, J.V. Analysis of the role of citric acid in the preparation of highly active HDS catalysts. J. Catal. 2014, 320, 127–136. [Google Scholar] [CrossRef]

- Dufresne, P. Hydroprocessing catalysts regeneration and recycling. Appl. Catal. A Gen. 2007, 322, 67–75. [Google Scholar] [CrossRef]

- Bui, N.Q.; Geantet, C.; Berhault, G. Maleic acid, an efficient additive for the activation of regenerated CoMo/Al2O3 hydrotreating catalysts. J. Catal. 2015, 330, 374–386. [Google Scholar] [CrossRef]

- Pimerzin, A.; Roganov, A.; Mozhaev, A.; Maslakov, K.; Nikulshin, P.; Pimerzin, A. Active phase transformation in industrial CoMo/Al2O3 hydrotreating catalyst during its deactivation and rejuvenation with organic chemicals treatment. Fuel Process. Technol. 2018, 173, 56–65. [Google Scholar]

- Zhang, Y.; Han, W.; Long, X.; Nie, H. Redispersion effects of citric acid on CoMo/γ-Al2O3 hydrodesulfurization catalysts. Catal. Commun. 2016, 82, 20–23. [Google Scholar] [CrossRef]

- Han, W.; Nie, H.; Long, X.; Li, M.; Yang, Q.; Li, D. Preparation of F-doped MoS2/Al2O3 catalysts as a way to understand the electronic effects of the support Brønsted acidity on HDN activity. J. Catal. 2016, 339, 135–142. [Google Scholar] [CrossRef]

- Han, W.; Nie, H.; Long, X.; Li, M.; Yang, Q.; Li, D. Effects of the support Brønsted acidity on the hydrodesulfurization and hydrodenitrogention activity of sulfided NiMo/Al2O3 catalysts. Catal. Today 2017, 292, 58–66. [Google Scholar] [CrossRef]

- Caloch, B.; Rana, M.S.; Ancheyta, J. Improved hydrogenolysis (C–S, C-M) function with basic supported hydrodesulfurization catalysts. Catal. Today 2004, 98, 91–98. [Google Scholar] [CrossRef]

- Kumar, M.; Aberuagba, F.; Gupta, J.K.; Rawat, K.S.; Sharma, L.D.; Murali Dhar, G. Temperature-programmed reduction and acidic properties of molybdenum supported on MgO-Al2O3 and their correlation with catalytic activity. J. Mol. Catal. A Chem. 2004, 213, 217–223. [Google Scholar] [CrossRef]

- Trejo, F.; Rana, M.S.; Ancheyta, J. CoMo/MgO–Al2O3 supported catalysts: An alternative approach to prepare HDS catalysts. Catal. Today 2008, 130, 327–336. [Google Scholar] [CrossRef]

- Chen, W.; Nie, H.; Li, D.; Long, X.; van Gestel, J.; Maugé, F. Effect of Mg addition on the structure and performance of sulfide Mo/Al2O3 in HDS and HDN reaction. J. Catal. 2016, 344, 420–433. [Google Scholar] [CrossRef]

- Rashidi, F.; Sasaki, T.; Rashidi, A.M.; Kharat, A.N.; Jozani, K.J. Ultradeep hydrodesulfurization of diesel fuels using highly efficient nanoalumina-supported catalysts: Impact of support, phosphorus, and/or boron on the structure and catalytic activity. J. Catal. 2013, 299, 321–335. [Google Scholar] [CrossRef]

- Klimov, O.V.; Vatutina, Y.V.; Nadeina, K.A.; Kazakov, M.O.; Gerasimov, E.Y.; Prosvirin, I.P.; Larina, T.V.; Noskov, A.S. CoMoB/Al2O3 catalysts for hydrotreating of diesel fuel. The effect of the way of the boron addition to a support or an impregnating solution. Catal. Today 2018, 305, 192–202. [Google Scholar] [CrossRef]

- Vatutina, Y.V.; Klimov, O.V.; Nadeina, K.A.; Danilova, I.G.; Gerasimov, E.Y.; Prosvirin, I.P.; Noskov, A.S. Influence of boron addition to alumina support by kneading on morphology and activity of HDS catalysts. Appl. Catal. B Environ. 2016, 199, 23–32. [Google Scholar] [CrossRef]

- Usman; Kubota, T.; Hiromitsu, I.; Okamoto, Y. Effect of boron addition on the surface structure of Co-Mo/Al2O3 catalysts. J. Catal. 2007, 247, 78–85. [Google Scholar] [CrossRef]

- Chen, W.; Maugé, F.; Van Gestel, J.; Nie, H.; Li, D.; Long, X. Effect of modification of the alumina acidity on the properties of supported Mo and CoMo sulfide catalysts. J. Catal. 2013, 304, 47–62. [Google Scholar] [CrossRef]

- Klimov, O.V.; Nadeina, K.A.; Vatutina, Y.V.; Stolyarova, E.A.; Danilova, I.G.; Gerasimov, E.Y.; Prosvirin, I.P.; Noskov, A.S. CoMo/Al2O3 hydrotreating catalysts of diesel fuel with improved hydrodenitrogenation activity. Catal. Today 2018, 307, 73–83. [Google Scholar] [CrossRef]

- Tong, R.L.; Wang, Y.G.; Zhang, X.; Zhang, H.Y.; Dai, J.Z.; Lin, X.C.; Xu, D.P. Effect of phosphorus modification on the catalytic properties of NiW/γ-Al2O3 in the hydrogenation of aromatics from coal tar. J. Fuel Chem. Technol. 2015, 43, 1461–1469. [Google Scholar] [CrossRef]

- García-Vila, A.; Cuevas-García, R.; Ramírez, J.; Puente-Lee, I. Effect of phosphorus on Mo/Al2O3 catalysts for Maya crude improvement. Catal. Today 2014, 220–222, 310–317. [Google Scholar] [CrossRef]

- Altamirano, E.; de Los Reyes, J.A.; Murrieta, F.; Vrinat, M. Hydrodesulfurization of dibenzothiophene and 4,6-dimethyl-dibenzothiophene: Gallium effect over NiMo/Al2O3 sulfided catalysts. J. Catal. 2005, 235, 403–412. [Google Scholar] [CrossRef]

- Altamirano, E.; de Los Reyes, J.A.; Murrieta, F.; Vrinat, M. Hydrodesulfurization of 4,6-dimethyldibenzothiophene over Co(Ni)MoS2 catalysts supported on alumina: Effect of gallium as an additive. Catal. Today 2008, 133–135, 292–298. [Google Scholar] [CrossRef]

- Díaz de León, J.N.; Picquart, M.; Massin, L.; Vrinat, M.; de los Reyes, J.A. Hydrodesulfurization of sulfur refractory compounds: Effect of gallium as an additive in NiWS/γ-Al2O3 catalysts. J. Mol. Catal. A Chem. 2012, 363–364, 311–321. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, Y.; Tao, X.; Zhou, Y.; Wei, Q.; Ding, S. Effects of gallium addition to mesoporous alumina by impregnation on dibenzothiophene hydrodesulfurization performances of the corresponding NiMo supported catalysts. Fuel 2018, 228, 152–163. [Google Scholar] [CrossRef]

- Olivas, A.; Luque, P.A.; Gómez-Gutierrez, C.M.; Flores, D.L.; Valdez, R.; Escalante, L.; Schacht, P.; Silva-Rodrigo, R. Synthesis and characterization of mesoporous supports doped with NiW/Gax for hydrodesulfurization of DBT. Catal. Comm. 2017, 91, 67–71. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, Q.; Zhou, Y.; Wei, Q.; Du, L.; Ding, S.; Jiang, S.; Zhang, Y. Effects of Ga- and P-modified USY-based NiMoS catalysts on ultra-deep hydrodesulfurization for FCC diesels. Catal. Today 2018, 305, 171–181. [Google Scholar] [CrossRef]

- Reinhoudt, H.R.; Crezee, E.; van Langeveld, A.D.; Kooyman, P.J.; Moulijn, J.A. Characterization of the Active Phase in NiW/γ-Al2O3 Catalysts in Various Stages of Sulfidation with FTIR(NO) and XPS. J. Catal. 2000, 196, 315–329. [Google Scholar] [CrossRef]

- Moses, P.G.; Hinnemann, B.; Topsoe, H.; Norskov, J.K. The hydrogenation and direct desulfurization reaction pathway in thiophene hydrodesulfurization over MoS2 catalysts at realistic conditions: A density functional study. J. Catal. 2007, 248, 188–203. [Google Scholar] [CrossRef]

- Yoosuk, B.; Song, C.; Kim, J.H.; Ngamcharussrivichai, C.; Prasassarakich, P. Effects of preparation conditions in hydrothermal synthesis of highly active unsupported NiMo sulfide catalysts for simultaneous hydrodesulfurization of dibenzothiophene and 4,6-dimethyldibenzothiophene. Catal. Today 2010, 149, 52–61. [Google Scholar] [CrossRef]

- Fontaine, C.; Romero, Y.; Daudin, A.; Devers, E.; Bouchy, C.; Brunet, S. Insight into sulphur compounds and promoter effects on Molybdenum-based catalysts for selective HDS of FCC gasoline. Appl. Catal. A Gen. 2010, 388, 188–195. [Google Scholar] [CrossRef]

- Niefind, F.; Bensch, W.; Deng, M.; Kienle, L.; Reyes, J.C.; Granados, J.M.D.V. Co-promoted MoS2 for hydrodesulfurization: New preparation method of MoS2 at room temperature and observation of massive differences of the selectivity depending on the activation atmosphere. Appl. Catal. A Gen. 2015, 497, 72–84. [Google Scholar] [CrossRef]

- Zhang, B.S.; Yi, Y.J.; Zhang, W.; Liang, C.H.; Su, D.S. Electron microscopy investigation of the microstructure of unsupported Ni–Mo–W sulfide. Mater. Charact. 2011, 62, 684–690. [Google Scholar] [CrossRef]

- Acuña, R.H.; Nunez, G.A.; Delgado, F.P.; Romero, J.L.; Berhault, G.; Munoz, E.M.R. Unsupported trimetallic CoMoW sulfide HDS catalysts prepared by in situ decomposition of sulfur-containing precursors. Catal. Today 2015, 250, 28–37. [Google Scholar] [CrossRef]

- Armenta, Y.E.; Reyes, J.C.; Delgado, F.P.; Valle, M.D.; Alonso, G.; Fuentes, S.; Rivera, R.R. CoMoW sulfide nanocatalysts for the HDS of DBT from novel ammonium and alkyltrimethylammonium-thiomolybdate-thiotungstate-cobaltate (II) precursors. Appl. Catal. A Gen. 2014, 486, 62–68. [Google Scholar] [CrossRef]

- Romero, L.; Valle, M.D.; Rivera, R.R.; Alonso, G.; Borja, M.A.; Fuentes, S.; Delgado, F.P.; Reyesa, J.C. MoS2 catalysts derived from n-methylenediammonium thiomolybdates during HDS of DBT. Catal. Today 2015, 250, 66–71. [Google Scholar] [CrossRef]

- Le, Z.; Afanasiev, P.; Li, D.; Shi, Y.; Vrinat, M. Synthesis of unsupported Ni–W–S hydrotreating catalysts from the oxothiosalt (NH4)2WO2S2. C. R. Chim. 2008, 11, 130–136. [Google Scholar] [CrossRef]

- Hur, Y.G.; Lee, D.W.; Lee, K.Y. Hydrocracking of vacuum residue using NiWS(x) dispersed catalysts. Fuel 2016, 185, 794–803. [Google Scholar] [CrossRef]

- Ho, T.C.; McConnachie, J.M. Ultra-deep hydrodesulfurization on MoS2 and Co0.1MoS2: Intrinsic vs. environmental factors. J. Catal. 2011, 277, 117–122. [Google Scholar] [CrossRef]

- Olivas, A.; Zepeda, T.A.; Villalpando, I.; Fuentes, S. Performance of unsupported Ni(Co,Fe)/MoS2 catalysts in hydrotreating reactions. Catal. Commun. 2008, 9, 1317–1328. [Google Scholar] [CrossRef]

- Yi, Y.; Zhang, B.; Jin, X.; Wang, L.; Williams, C.T.; Xiong, G.; Su, D.; Liang, C. Unsupported NiMoW sulfide catalysts for hydrodesulfurization of dibenzothiophene by thermal decomposition of thiosalts. J. Mol. Catal. A Chem. 2011, 351, 120–127. [Google Scholar] [CrossRef]

- Bocarando, J.; Acuna, R.H.; Bensch, W.; Huang, Z.D.; Petranovskii, V.; Fuentes, S.; Nunez, G.A. Unsupported Ni-Mo-W sulphide HDS catalysts with the varying nickel concentration. Appl. Catal. A Gen. 2009, 363, 45–51. [Google Scholar] [CrossRef]

- Zepeda, T.A.; Pawelec, B.; Díaz de León, J.N.; de los Reyes, J.A.; Olivas, A. Effect of gallium loading on the hydrodesulfurization activity of unsupported Ga2S3/WS2 catalysts. Appl. Catal. B Environ. 2012, 111–112, 10–19. [Google Scholar] [CrossRef]

- Daudin, A.; Lamic, A.F.; Perot, G.; Brunet, S.; Raybaud, P.; Bouchy, C. Microkinetic interpretation of HDS/HYDO selectivity of the transformation of a model FCC gasoline over transition metal sulfides. Catal. Today 2008, 130, 221–230. [Google Scholar] [CrossRef]

- Afanasiev, P. The influence of reducing and sulfiding conditions on the properties of unsupported MoS2-based catalysts. J. Catal. 2010, 269, 269–280. [Google Scholar] [CrossRef]

- Amaya, S.L.; Nunez, G.A.; Zepeda, T.A.; Fuentes, S.; Echavarria, A. Effect of the divalent metal and the activation temperature of NiMoW and CoMoW on the dibenzothiophene hydrodesulfurization reaction. Appl. Catal. B Environ. 2014, 148–149, 221–230. [Google Scholar] [CrossRef]

- Coelho, T.L.; Licea, Y.E.; Palacio, L.A.; Faro, A.C., Jr. Heptamolybdate-intercalated CoMgAl hydrotalcites as precursors for HDS-selective hydrotreating catalysts. Catal. Today 2015, 250, 38–46. [Google Scholar] [CrossRef]

- Amaya, S.L.; Nunez, G.A.; Reyes, J.C.; Fuentes, S.; Echavarria, A. Influence of the sulfidation temperature in a NiMoW catalyst derived from layered structure (NH4)Ni2OH(H2O)(MoO4)2. Fuel 2015, 139, 575–583. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, L.; Zhang, Y.; Liu, T.; Liu, X.; Jiang, Z.; Li, C. A new multi–metallic bulk catalyst with high hydrodesulfurization activity of 4,6–DMDBT prepared using layered hydroxide salts as structural templates. Appl. Catal. A Gen. 2014, 474, 69–77. [Google Scholar] [CrossRef]

- Yin, C.; Wang, Y.; Xue, S.; Liu, H.; Li, H.; Liu, C. Influence of sulfidation conditions on morphology and hydrotreating performance of unsupported Ni–Mo–W catalysts. Fuel 2016, 175, 13–19. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, H.; Zheng, Y.; Hu, Y.; MacLennan, A. Understanding of the effect of synthesis temperature on the crystallization and activity of nano-MoS2 catalyst. Appl. Catal. B Environ. 2015, 165, 537–546. [Google Scholar] [CrossRef]

- Long, Y.C.; Ping, Z.X.; Yyan, Z.L.; Guang, L.C. Mechanism of Hydrodesulfurization of dibenzothiophenes on unsupported NiMoW catalyst. J. Fuel Chem. Technol. 2013, 41, 991–997. [Google Scholar]

- Liu, C.; Liu, H.; Yin, C.; Zhao, X.; Liu, B.; Li, X.; Li, Y.; Liu, Y. Preparation, characterization, and hydrodesulfurization properties of binary transition-metal sulfide catalysts. Fuel 2015, 154, 88–94. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Yin, C.; Chai, Y.; Li, Y.; Liu, D.; Liu, B.; Li, X.; Wang, Y.; Li, X. Preparation of highly active unsupported nickel–zinc–molybdenum catalysts for the hydrodesulfurization of dibenzothiophene. Appl. Catal. B Environ. 2015, 174–175, 264–276. [Google Scholar] [CrossRef]

- Liu, H.; Yin, C.; Li, H.; Liu, B.; Li, X.; Chai, Y.; Li, Y.; Liu, C. Synthesis, characterization and hydrodesulfurization properties of nickel–copper–molybdenum catalysts for the production of ultra-low sulfur diesel. Fuel 2014, 129, 138–146. [Google Scholar] [CrossRef]

- Yue, L.; Li, G.; Zhang, F.; Chen, L.; Li, X.; Huang, X. Size-dependent activity of unsupported Co–Mo sulfide catalysts for the hydrodesulfurization of dibenzothiophene. Appl. Catal. A Gen. 2016, 512, 85–92. [Google Scholar] [CrossRef]

- Theodet, M.; Quilfen, C.; Martinez, C.; Aymonier, C. Continuous supercritical synthesis of unsupported and high specific surface area catalyst precursors for deep-hydrodesulfurization. J. Supercrit. Fluids 2016, 117, 252–259. [Google Scholar] [CrossRef]

- Farag, H.; Kishida, M.; Megren, H.A. Competitive hydrodesulfurization of dibenzothiophene and hydrodenitrogenation of quinoline over unsupported MoS2 catalyst. Appl. Catal. A Gen. 2014, 469, 173–182. [Google Scholar] [CrossRef]

- Yin, C.; Zhao, L.; Bai, Z.; Liu, H.; Liu, Y.; Liu, C. A novel porous ammonium nickel molybdate as the catalyst precursor towards deep hydrodesulfurization of gas oil. Fuel 2013, 107, 873–878. [Google Scholar] [CrossRef]

- Li, P.; Chen, Y.; Zhang, C.; Huang, B.; Liu, X.; Liu, T.; Jiang, Z.; Li, C. Highly selective hydrodesulfurization of gasoline on unsupported Co-Mo sulfide catalysts: Effect of MoS2 morphology. Appl. Catal. A Gen. 2017, 533, 99–108. [Google Scholar] [CrossRef]

- Blanco, E.; Uzio, D.; Berhault, G.; Afanasiev, P. From core–shell MoSx/ZnS to open fullerene-like MoS2 nanoparticles. J. Mater. Chem. A 2014, 2, 3325–3331. [Google Scholar] [CrossRef]

- Aissa, A.H.; Dassenoy, F.; Geantet, C.; Afanasiev, P. Solution synthesis of core–shell Co9S8@MoS2 catalysts. Catal. Sci. Technol. 2016, 6, 4901–4909. [Google Scholar] [CrossRef]

- Liu, H.; Yin, C.; Li, X.; Chai, Y.; Li, Y.; Liu, C. Effect of NiMo phases on the hydrodesulfurization activities of dibenzothiophene. Catal. Today 2017, 282, 222–229. [Google Scholar] [CrossRef]

- Mansouri, A.; Semagina, N. Promotion of Niobium Oxide Sulfidation by Copper and Its Effects on Hydrodesulfurization Catalysis. ACS Catal. 2018, 8, 7621–7632. [Google Scholar] [CrossRef]

- Le, Z.; Xiangyun, L.; Dadong, L.; Xiaodong, G. Study on high-performance unsupported Ni–Mo–W hydrotreating catalyst. Catal. Commun. 2011, 12, 927–931. [Google Scholar]

- Afanasiev, P.; Geantet, C.; Llorens, I.; Proux, O. Biotemplated synthesis of highly divided MoS2 catalysts. J. Mater. Chem. 2012, 22, 9731–9737. [Google Scholar] [CrossRef]

- Zhang, C.; Li, P.; Liu, X.; Liu, T.; Jiang, Z.; Li, C. Morphology-performance relation of (Co)MoS2 catalysts in the hydrodesulfurization of FCC gasoline. Appl. Catal. A Gen. 2018, 556, 20–28. [Google Scholar] [CrossRef]

- Gusakova, J.; Wang, X.; Lynn Shiau, L.; Krivosheeva, A.; Shaposhnikov, V.; Borisenko, V.; Gusakov, V.; Kang Tay, B. Electronic Properties of Bulk and Monolayer TMDs: Theoretical Study Within DFT Framework (GVJ-2e Method). Phys. Status Solidi A 2017, 214, 1700218. [Google Scholar] [CrossRef]

- Coutinho, S.S.; Tavares, M.S.; Barboza, C.A.; Frazão, N.F.; Moreira, E.; Azevedo, D.L. 3R and 2H polytypes of MoS2: DFT and DFPT calculations of structural, optoelectronic, vibrational and thermodynamic properties. J. Phys. Chem. Solids 2017, 111, 25–33. [Google Scholar] [CrossRef]

- Ivanovskaya, V.V.; Zobelli, A.; Gloter, A.; Brun, N.; Serin, V.; Colliex, C. Ab initio study of bilateral doping within the MoS2-NbS2 system. Phys. Rev. B 2008, 78, 134104. [Google Scholar] [CrossRef]

- Olivas, A.; Antúnez-García, J.; Fuentes, S.; Galván, D.H. Electronic properties of unsupported trimetallic catalysts. Catal. Today 2014, 220–222, 106–112. [Google Scholar] [CrossRef]

- Suh, J.; Leong Tan, T.; Zhao, W.; Park, J.; Lin, D.-Y.; Park, T.-E.; Kim, J.; Jin, C.; Saigal, N.; Ghosh, S.; et al. Reconfiguring crystal and electronic structures of MoS2 by substitutional doping. Nat. Commun. 2018, 9, 199. [Google Scholar] [CrossRef] [PubMed]

- Brotons-Gisbert, M.; Segura, A.; Robles, R.; Canadell, E.; Ordejón, P.; Sánchez-Royo, J.F. Optical and electronic properties of 2H−MoS2 under pressure: Revealing the spin-polarized nature of bulk electronic bands. Phys. Rev. Mater. 2018, 2, 054602. [Google Scholar] [CrossRef] [Green Version]

- Zhou, W.; Zou, X.; Najmaei, S.; Liu, Z.; Shi, Y.; Kong, J.; Lou, J.; Ajayan, P.M.; Yakobson, B.I.; Idrobo, J.-C. Intrinsic Structural Defects in Monolayer Molybdenum Disulfide. Nano Lett. 2013, 13, 2615–2622. [Google Scholar] [CrossRef] [PubMed]

- Wan, H.; Xu, L.; Huang, W.Q.; Zhou, J.H.; He, C.N.; Li, X.; Huang, G.F.; Peng, P.; Zhou, Z.G. Band structure engineering of monolayer MoS2: A charge compensated codoping strategy. RSC Adv. 2015, 5, 7944–7952. [Google Scholar] [CrossRef]

- Tang, Q.; Jiang, D.E. Stabilization and band-gap tuning of the 1T-MoS2 monolayer by covalent functionalization. Chem. Mater. 2015, 27, 3743–3748. [Google Scholar] [CrossRef]

- Krivosheeva, A.V.; Shaposhnikov, V.L.; Borisenko, V.E.; Lazzari, J.L.; Waileong, C.; Gusakova, J.; Tay, B.K. Theoretical study of defect impact on two-dimensional MoS2. J. Semicond. 2015, 36, 122002. [Google Scholar] [CrossRef]

- Li, C.; Fan, B.; Li, W.; Wen, L.; Liu, Y.; Wang, T.; Sheng, K.; Yin, Y. Bandgap engineering of monolayer MoS2 under strain: A DFT study. J. Korean Phys. Soc. 2015, 66, 1789–1793. [Google Scholar] [CrossRef]

- Li, T.; Galli, G. Electronic properties of MoS2 nanoparticles. J. Phys. Chem. C 2007, 111, 16192–16196. [Google Scholar] [CrossRef]

- Bollinger, M.V.; Jacobsen, K.W.; Nørskov, J.K. Atomic and electronic structure of MoS2 nanoparticles. Phys. Rev. B Condens. Matter Mater. Phys. 2003, 67, 085410. [Google Scholar] [CrossRef]

- Javaid, M.; Drumm, D.W.; Russo, S.P.; Greentree, A.D. A study of size-dependent properties of MoS2 monolayer nanoflakes using density-functional theory. Sci. Rep. 2017, 7, 9775. [Google Scholar] [CrossRef]

- Liu, X.; Cao, D.; Yang, T.; Li, H.; Ge, H.; Ramos, M.; Peng, Q.; Dearden, A.K.; Cao, Z.; Yang, Y.; et al. Insight into the structure and energy of Mo27SxOyclusters. RSC Adv. 2017, 7, 9513–9520. [Google Scholar] [CrossRef]

- Li, N.; Lee, G.; Jeong, Y.H.; Kim, K.S. Tailoring Electronic and Magnetic Properties of MoS2 Nanotubes. J. Phys. Chem. C 2015, 119, 6405–6413. [Google Scholar] [CrossRef]

- Wang, R.; Sun, H.; Ma, B.; Hu, J.; Pan, J. Edge passivation induced single-edge ferromagnetism of zigzag MoS2 nanoribbons. Phys. Lett. A 2017, 381, 301–306. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Z.; Zhang, S.; Chen, Z. MoS2 Nanoribbons: High Stability and Unusual Electronic and Magnetic Properties. J. Am. Chem. Soc. 2008, 130, 16739–16744. [Google Scholar] [CrossRef] [PubMed]

- Raybaud, P.; Hafner, J.; Kresse, G.; Kasztelan, S.; Toulhoat, H. Ab Initio Study of the H2–H2S/MoS2 Gas–Solid Interface: The Nature of the Catalytically Active Sites. J. Catal. 2000, 189, 129–146. [Google Scholar] [CrossRef]

- Li, S.; Liu, Y.; Feng, Z.; Chen, X.; Yang, C. Insights into the reaction pathway of thiophene hydrodesulfurization over corner site of MoS2 catalyst: A density functional theory study. Mol. Catal. 2019, 463, 45–63. [Google Scholar] [CrossRef]

- Bonde, J.; Moses, P.G.; Jaramillo, T.F.; Nørskov, J.K.; Chorkendorff, I. Hydrogen evolution on nano-particulate transition metal sulfides. Faraday Discuss. 2009, 140, 219–231. [Google Scholar] [CrossRef]

- Wang, H.; Tsai, C.; Kong, D.; Chan, K.; Abild-Pedersen, F.; Nørskov, J.K.; Cui, Y. Transition-metal doped edge sites in vertically aligned MoS2 catalysts for enhanced hydrogen evolution. Nano Res. 2015, 8, 566–575. [Google Scholar] [CrossRef]

- Jin, Q.; Chen, B.; Ren, Z.; Liang, X.; Liu, N.; Mei, D. A theoretical study on reaction mechanisms and kinetics of thiophene hydrodesulfurization over MoS2 catalysts. Catal. Today 2018, 312, 158–167. [Google Scholar] [CrossRef]

- Silva, A.M.; Borges, I. How to find an optimum cluster size through topological site properties: MoSxmodel clusters. J. Comput. Chem. 2011, 32, 2186–2194. [Google Scholar] [CrossRef]

- Yang, T.; Feng, J.; Liu, X.; Wang, Y.; Ge, H.; Cao, D.; Li, H.; Peng, Q.; Ramos, M.; Wen, X.-D.; et al. A combined computational and experimental study of the adsorption of sulfur containing molecules on molybdenum disulfide nanoparticles. J. Mater. Res. 2018, 33, 3589–3603. [Google Scholar] [CrossRef]

- Gronborg, S.S.; Saric, M.; Moses, P.G.; Rossmeisl, J.; Lauritsen, J.V. Atomic scale analysis of sterical effects in the adsorption of 4,6-dimethyldibenzothiophene on a CoMoS hydrotreating catalyst. J. Catal. 2016, 344, 121–128. [Google Scholar] [CrossRef]

- Deng, J.; Li, H.; Xiao, J.; Tu, Y.; Deng, D.; Yang, H.; Tian, H.; Li, J.; Ren, P.; Bao, X. Triggering the electrocatalytic hydrogen evolution activity of the inert two-dimensional MoS2 surface via single-atom metal doping. Energy Environ. Sci. 2015, 8, 1594. [Google Scholar] [CrossRef]

- Sharma, A.; Srivastava, A.; Husain, M.; Khan, M.S. Computational investigations of Cu-embedded MoS2 sheet for CO oxidation catalysis. J. Mater. Sci. 2018, 53, 9578–9588. [Google Scholar] [CrossRef]

- Zhang, Y.-H.; Chen, J.-L.; Yue, L.-J.; Zhang, H.-L.; Li, F. Tuning CO sensing properties and magnetism of MoS2 monolayer through anchoring transition metal dopants. Comput. Theor. Chem. 2017, 1104, 12–17. [Google Scholar] [CrossRef]

- Ding, K.; Lin, Y.; Huang, M. The enhancement of NO detection by doping strategies on monolayer MoS2. Vacuum 2016, 130, 146–153. [Google Scholar] [CrossRef]

- Pan, H. Progress on the Theoretical Study of Two-Dimensional MoS2 Monolayer and Nanoribbon; Springer: Cham, Switzerland, 2014; pp. 1–35. [Google Scholar]

- Aray, Y.; Rodríguez, J.; Vidal, A.B.; Coll, S. Nature of the NiMoS catalyst edge sites: An atom in molecules theory and electrostatic potential studies. J. Mol. Catal. A Chem. 2007, 271, 105–116. [Google Scholar] [CrossRef]

- Xu, C.; Shi, Q. Structure and Modeling of Complex Petroleum Mixtures; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Prabowo, W.A.E.; Kemal Agusta, M.; Lubis, A.H.; Dipojono, H.K. Density Functional Theory Study of the Adsorption of Thiophene on NiMoS Surface. In Proceedings of the International MultiConference of Engineers and Computer Scientists, Hong Kong, China, 13–15 March 2013; Ao, S.I., Castillo, O., Douglas, C., Feng, D.D., Korsunsky, A.M., Eds.; Newswood Limited: Hong Kong, China, 2013; pp. 13–15. [Google Scholar]

- Ruinart de Brimont, M.; Dupont, C.; Daudin, A.; Geantet, C.; Raybaud, P. Deoxygenation mechanisms on Ni-promoted MoS2 bulk catalysts: A combined experimental and theoretical study. J. Catal. 2012, 286, 153–164. [Google Scholar] [CrossRef]

- Moses, P.G.; Hinnemann, B.; Topsøe, H.; Nørskov, J.K. The effect of Co-promotion on MoS2 catalysts for hydrodesulfurization of thiophene: A density functional study. J. Catal. 2009, 268, 201–208. [Google Scholar] [CrossRef]

- Ding, S.; Jiang, S.; Zhou, Y.; Wei, Q.; Zhou, W. Catalytic characteristics of active corner sites in CoMoS nanostructure hydrodesulfurization—A mechanism study based on DFT calculations. J. Catal. 2017, 345, 24–38. [Google Scholar] [CrossRef]

- Šarić, M.; Rossmeisl, J.; Moses, P.G. Modeling the active sites of Co-promoted MoS2 particles by DFT. Phys. Chem. Chem. Phys. 2017, 19, 2017–2024. [Google Scholar] [CrossRef] [PubMed]

- Šarić, M.; Rossmeisl, J.; Moses, P.G. Modeling the adsorption of sulfur containing molecules and their hydrodesulfurization intermediates on the Co-promoted MoS2 catalyst by DFT. J. Catal. 2018, 358, 131–140. [Google Scholar] [CrossRef]

- Laurent, E.; Delmon, B. Study of the hydrodeoxygenation of carbonyl, carboxylic and guaiacyl groups over sulfided CoMo/γ-Al2O3 and NiMo/γ-Al2O3 catalyst: II. Influence of water, ammonia and hydrogen sulfide. Appl. Catal. A Gen. 1994, 109, 97–115. [Google Scholar] [CrossRef]

- He, Z.; Wang, X. Hydrodeoxygenation of model compounds and catalytic systems for pyrolysis bio-oils upgrading. Catal. Sustain. Energy 2012, 1, 28–52. [Google Scholar] [CrossRef]

- Oh, S.; Choi, H.S.; Choi, I.-G.; Choi, J.W. Evaluation of hydrodeoxygenation reactivity of pyrolysis bio-oil with various Ni-based catalysts for improvement of fuel properties. RSC Adv. 2017, 7, 15116–15126. [Google Scholar] [CrossRef] [Green Version]

- Hensley, A.J.R.; Wang, Y.; Mei, D.; McEwen, J.-S. Mechanistic Effects of Water on the Fe-Catalyzed Hydrodeoxygenation of Phenol. The Role of Brønsted Acid Sites. ACS Catal. 2018, 8, 2200–2208. [Google Scholar] [CrossRef]

- Badawi, M.; Paul, J.F.; Cristol, S.; Payen, E.; Romero, Y.; Richard, F.; Brunet, S.; Lambert, D.; Portier, X.; Popov, A.; et al. Effect of water on the stability of Mo and CoMo hydrodeoxygenation catalysts: A combined experimental and DFT study. J. Catal. 2011, 282, 155–164. [Google Scholar] [CrossRef]

- Sun, M.; Nelson, A.E.; Adjaye, J. On the incorporation of nickel and cobalt into MoS2-edge structures. J. Catal. 2004, 226, 32–40. [Google Scholar] [CrossRef]

- Krebs, E.; Silvi, B.; Raybaud, P. Mixed sites and promoter segregation: A DFT study of the manifestation of Le Chatelier’s principle for the Co(Ni)MoS active phase in reaction conditions. Catal. Today 2008, 130, 160–169. [Google Scholar] [CrossRef]

- Krebs, E.; Daudin, A.; Raybaud, P. A DFT Study of CoMoS and NiMoS Catalysts: From Nano-Crystallite Morphology to Selective Hydrodesulfurization Catalysts and Adsorbents: From Molecular Insight to Industrial Optimization Catalyseurs et adsorbants: De la compréhension moléculaire à l’optimisation industrielle. Oil Gas Sci. Technol. IFP 2009, 64, 707–718. [Google Scholar]

- Badawi, M.; Paul, J.-F.; Payen, E.; Romero, Y.; Richard, F.; Brunet, S.; Popov, A.; Kondratieva, E.; Gilson, J.-P.; Mariey, L.; et al. Hydrodeoxygenation of Phenolic Compounds by Sulfided (Co)Mo/Al2O3 Catalysts, a Combined Experimental and Theoretical Study. Oil Gas Sci. Technol. 2013, 68, 829–840. [Google Scholar] [CrossRef]

- Czekaj, I.; Wambach, J.; Kröcher, O. Modelling catalyst surfaces using DFT cluster calculations. Int. J. Mol. Sci. 2009, 10, 4310–4329. [Google Scholar] [CrossRef] [PubMed]

- Hinnemann, B.; Nørskov, J.K.; Topsøe, H. A density functional study of the chemical differences between type I and type II MoS2-based structures in hydrotreating catalysts. J. Phys. Chem. B 2005, 109, 2245–2253. [Google Scholar] [CrossRef] [PubMed]

- Topsøe, H.; Hinnemann, B.; Nørskov, J.K.; Lauritsen, J.V.; Besenbacher, F.; Hansen, P.L.; Hytoft, G.; Egeberg, R.G.; Knudsen, K.G. The role of reaction pathways and support interactions in the development of high activity hydrotreating catalysts. Catal. Today 2005, 107–108, 12–22. [Google Scholar] [CrossRef]

- Costa, D.; Arrouvel, C.; Breysse, M.; Toulhoat, H.; Raybaud, P. Edge wetting effects of γ-Al2O3 and anatase-TiO2 supports by MoS2 and CoMoS active phases: A DFT study. J. Catal. 2007, 246, 325–343. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz de León, J.N.; Ramesh Kumar, C.; Antúnez-García, J.; Fuentes-Moyado, S. Recent Insights in Transition Metal Sulfide Hydrodesulfurization Catalysts for the Production of Ultra Low Sulfur Diesel: A Short Review. Catalysts 2019, 9, 87. https://doi.org/10.3390/catal9010087

Díaz de León JN, Ramesh Kumar C, Antúnez-García J, Fuentes-Moyado S. Recent Insights in Transition Metal Sulfide Hydrodesulfurization Catalysts for the Production of Ultra Low Sulfur Diesel: A Short Review. Catalysts. 2019; 9(1):87. https://doi.org/10.3390/catal9010087

Chicago/Turabian StyleDíaz de León, Jorge Noé, Chowdari Ramesh Kumar, Joel Antúnez-García, and Sergio Fuentes-Moyado. 2019. "Recent Insights in Transition Metal Sulfide Hydrodesulfurization Catalysts for the Production of Ultra Low Sulfur Diesel: A Short Review" Catalysts 9, no. 1: 87. https://doi.org/10.3390/catal9010087