1. Introduction

Concrete serves as the essential essence in almost every variety of typical construction. Concrete can be found in almost every building structure, typical examples of which are pavement, bridge, house, tunnel or dam [

1]. This material is widely applied in construction, due to its excellent ability to resist compression loadings. Following the concrete development to suit to different construction purposes, rubberized concrete has been given a spotlight in the civil industry. The ground crumb rubber particles are usually mixed in cement concrete for various civil applications, such as geotechnical works, in road construction, in agriculture to seal silos, in onshore and offshore breakwaters and in retaining walls [

2]. Numerous established studies have shown that the incorporation of crumb rubber alters the physical and mechanical properties of the concrete. The inclusion of crumb rubber particles as concrete aggregates present concrete with lower ultimate strength, modulus of elasticity. Nevertheless, they also enhance the ductility, energy and force absorbing potential, as well as the lightweight nature of the concrete [

3,

4,

5]. The promising lightweight nature of rubberized concrete is capable of satisfying various non-load bearing civil applications. Apart from that, the employment of air-entraining agents in rubberized concrete can further lengthen the life span of rubberized concrete, particularly when the concrete is continuously exposed to the external environment. Recent research has shown that air-entraining agents modify the rheology of concrete and enhances its durability in freezing and thawing cycles [

6]. However, the compressive strength of air-entrained rubberized concrete is somewhat inconsistent, compared to that of conventional concrete. Therefore, the strength analysis and interpretation of air-entraining rubberized concrete are somewhat tedious and time-consuming. Thus, a more effective method of determining the concrete strength needs to be invented.

Generally, concrete compressive strength can be classified into two main categories, which are destructive test (DT) and non-destructive test (NDT). While DT is being carried out, the concrete is generally destroyed to evaluate its strength properties [

7]. It is always essential to perform this test, because of the importance of ensuring the quality of the manufactured concrete for long-lasting performance. The process is rather simple and straightforward, and results can be obtained without consuming much time. In general cases, this test is compulsory in every construction process, especially just before the concrete is being cast. On the contrary, NDT, as an alternative measure, gives a rather remarkable and effective way of assessing the concrete compressive strength. It has the main advantage of obtaining the properties of concrete rapidly without destroying the specimen at a moderate cost. This method puts less concern on the powered performance of the concrete, while it focuses heavily on the evaluation of physical characteristics [

8]. This unique method also provides a more suitable way of assessing the concrete strength of the existing structures. Nowadays, the use of NDT is encouraged, due to its effectiveness in achieving the purposes of examining both the external and internal states, as well as the current condition of the concrete structures, particularly in completed buildings. The process of acquiring the characteristics of the specimen, as well as existing structures utilizes the application of ultrasonic and sonic as the facilitators of the test. Additionally, some methods of NDT adopt the radar, as well as infrared technology, to achieve the investigation of properties that are not visible to the naked eye [

9].

Over the past few years, there have been abundant researches carried out relating to the application of NDTs in the evaluation of the mechanical properties of the concrete, particularly compressive strength. Common examples of NDTs include the impact echo and ultrasonic pulse velocity tests. The wave frequency obtained from hammering the concrete specimen, along with the ultrasonic wave velocity when it travels through the concrete specimen, could be used in concrete compressive strength forecasting. One finding worth mentioning is that the variations of frequency and ultrasonic pulse velocity under constant applied load can be adopted to predict the concrete compressive strength under damaged and undamaged states [

10]. The relationship between the ultrasonic pulse velocity and concrete compressive strength has been investigated based on the propagation of mechanical wave through the concrete specimens in another study. Although there is no direct physical relationship between the compressive strength and the wave properties, the relationship curves can be established beforehand to correlate the wave parameters and the concrete compressive strength [

11]. Furthermore, the effects of the water to cement ratio, maximum aggregate size, aggregate type and fly ash addition on the modulus of elasticity of low-quality concrete was investigated using ultrasonic pulse velocity method, by Yildirim et al. [

12]. According to their results, a strong relationship was established between the modulus of elasticity and ultrasonic pulse velocity. However, the ultrasonic pulse velocity test has been generally applied to detect the voids and discontinuities in hardened concrete, and is more sensitive to the internal structure, including the density of concrete [

13]. The concrete density always displayed a close relationship with the concrete compressive strength, and this is the reason why the ultrasonic pulse velocity test is eligible in the evaluation of the concrete compressive strength. Moreover, Amini et al. [

14] developed the concrete compressive strength predictive models that are independent of concrete’s past history and mixed proportions. Ultrasonic pulse velocity and rebound hammer tests were adopted in their studies. The compressive strength of the concrete specimens obtained using conventional compression tests were used in the correlation with the mechanical wave parameters. The constructed predictive models present a significant accuracy in estimating the concrete strength, regardless of its past history and mix proportion. Sreenivasulu et al. [

15] studied the evaluation of compressive strength of geopolymer concrete using some common NDT techniques, including Schmidt rebound hammer ultrasonic pulse velocity and combined methods. It was found that rebound number obtained using rebound hammer test depicts a better correlation degree with the compressive strength of geopolymer concrete.

In this study, the aim is to investigate the compressive strength development of different mixed proportions of air-entrained rubberized concrete through two approaches, namely DT and NDT. The correlation between the concrete compressive strength data obtained on day-1, day-7, and day-28 by DT and NDT will be investigated by using the informal parameters from the elastic wave data. Furthermore, this study also aims to substantiate the eligibility and feasibility of NDT to be employed in the compressive strength forecasting of air-entrained rubberized concrete. This is to divert the use of conventional concrete compression tests, to the application of NDT, which is less time consuming and cost-saving in the future. Moreover, NDT is a more practical method of assessing the compressive strength development of air-entrained rubberized concrete, as wave analysis can be repeatedly conducted on the same specimen on different maturity days of concrete.

2. Materials and Methods

2.1. Mix Proportion

The main purpose of this study is to ascertain the development of compressive strength of air-entrained rubberized concrete by employing the two approaches mentioned in the earlier part. Thus, five different mix proportions are produced by varying the replacement level of fine aggregate by powdered crumb rubber. The granulometric curves of the sand and powdered crumb rubber used in the production of air-entrained rubberized concrete are depicted in

Figure 1.

The incorporation of crumb rubber in concrete usually aims to produce the concrete with good lightweight nature, whose density falls below 2000 kg/m

3. For each concrete mix proportion, few concrete cube specimens with a dimension of 100 mm × 100 mm × 100 mm are produced for compressive strength assessment at different stages of concrete development. The mix proportion details of the air-entrained rubberized concrete specimens are summarised in

Table 1. S0, S20, S40, S60 and S80 denote air-entrained rubberized concrete, with 0%, 20%, 40%, 60% and 80% volume replacement level of fine aggregate by powdered crumb rubber, respectively.

2.2. Preparation of Concrete Cube Specimen

The concrete construction steps and procedures are conducted consistently for all cube specimens. The steps generally include three stages, namely concrete mixing, demolding, and curing. At first, the cementitious and aggregate materials, such as cement, sand and powdered crumb rubber, are mixed evenly for 1 min in a ball-mixer, and this stage is also known as a dry mix. After that, water is poured into the dry concrete mix, and the mixing continues until the homogeneous state is attained. Superplasticizer is then added into the mix to improve the workability of the concrete. Lastly, the air-entraining agent is incorporated into the concrete mix to exert air voids in the concrete, to lower the fresh density of the concrete. After the unstable air bubbles are eliminated, and the homogeneity state of concrete is confirmed, the fresh concrete is then cast into the cube mold with the dimension of 100 mm × 100 mm × 100 mm.

Demolding of the concrete cube specimens is performed on the next day. The samples are then placed in a water storage tank for concrete curing to maintain the presence of free water on the exterior surface of the samples. The water temperature is maintained within the range of 25 °C to 28 °C. During concrete curing, the elements of cement experience a chemical reaction with water, and the process of binding of aggregates starts, causing heat to be emitted from the concrete. By the time the concrete has been cured for 28 days, the specimens are removed from the water tank, as they have achieved optimum maturity

The concrete cube specimens of each mix proportion are assessed on day-1, day-7 and day-28. Therefore, a certain amount of cube specimen is required for each mix proportion. The number of cube specimen needs to be constructed throughout the whole study is summarized in

Table 2.

2.3. Testing of the Concrete Cube Specimens

In this study, two main approaches are implemented to assess the concrete strength development of these five different mix proportions on different days of concrete maturity. In the elastic wave approach, the wave result is analyzed in velocity, frequency and amplitude forms. Then, these parameters are then correlated to the concrete compressive strength and compared to that obtained by utilizing the conventional approach, which is compressive strength test using AD 300/EL Digital Readout 3000 kN concrete compression testing machine (Selangor, Malaysia). This is to guarantee the suitability and precision of NDT approaches in assessing the compressive strength of the concrete.

2.3.1. Compressive Strength Test

Compressive strength test utilizing a concrete compression machine is a conventional approach adopted to evaluate the concrete compressive or characteristic strength, and it is conducted in accordance with the standard ASTM C109. The concrete cube with a dimension of 100 mm × 100 mm × 100 mm is fabricated as the compressive strength test specimen. The axial compressive load is applied on the sample at the loading rate of 0.02 mm/s. The peak load attained prior to the ultimate failure of the specimen is deemed as the compressive strength of the specimen.

2.3.2. Elastic Wave Method

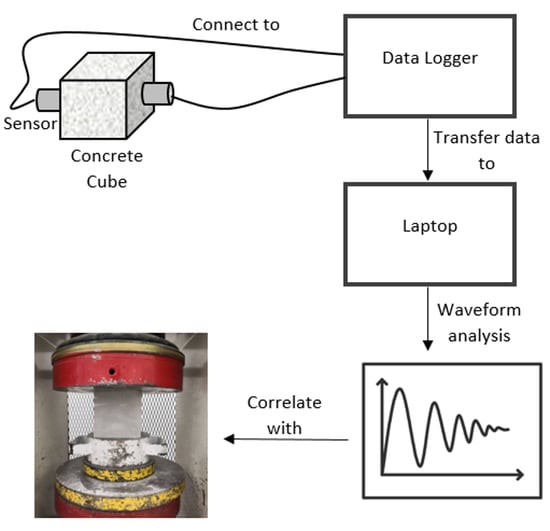

This testing method is classified as NDT, and it involves the utilization of electronic instruments such as data logger, sensors and piezoelectric transducers. The data logger is connected to a portable computer containing Labview Signal Express software (United States). Upon the completion of equipment set up, the piezoelectric transducers are attached to the concrete cube specimen surface with coupling agent wax. After that, a steel ball with a diameter of 15 mm is used to impact the specimen, causing the production of the elastic wave moving through the sample. The complete set up is illustrated in

Figure 2.

4. Conclusions

In this study, elastic P-wave amplitude, velocity, and dominant frequency are used in correlation with the compressive strength of air-entrained rubberized concrete that is obtained by using the conventional approach, which is the concrete compressive strength test. Both the P-wave amplitude and the velocity display close linkage to the compressive strength of air-entrained rubberized concrete. This is because both correlation between wave amplitude and concrete compressive strength, as well as the correlation between velocity and concrete compressive strength, have high regression degrees, which are 0.9404 and 0.8788, respectively. Therefore, these two parameters could be adopted in an NDT approach to assess the concrete strength of air-entrained rubberized concrete in the future. However, correlation with the P-wave amplitude seems to be the most precise one. The exponential equation obtained from the correlations with P-wave amplitude (y = 0.0064e0.0209x) can be utilized to forecast the compressive strength of the air-entrained rubberized concrete with most of the mix proportions. Another point worth mentioning is that only one specimen is required. The P-wave analysis can be repeated on the same specimen on different days of maturity, thus, yielding different amplitude values. By inserting these amplitude values into the exponential equation, the compressive strength development of that particular concrete specimen during the hardening phase can be known. On the contrary, dominant frequency fails to establish a stable and consistent relationship with concrete compressive strength. This is because the relationship between the dominant frequency of P-wave and concrete strength of air-entrained rubberized concrete has a weak regression coefficient, which is only 0.2677, and this figure is far from satisfying the minimum requirement. Thus, the dominant frequency is not suitable to be employed to estimate the concrete strength of air-entrained rubberized concrete. In summary, NDT is an efficient and less time-consuming approach to assess the concrete strength, as it does not involve the demolition of the specimen upon testing and, therefore, a lower quantity of the specimen is required.