Transparent MXene-Polymer Supercapacitive Film Deposited Using RIR-MAPLE

Abstract

:1. Introduction

2. Materials and Methods

2.1. Solution Preparation

2.2. RIR-MAPLE Deposition

2.3. Characterization

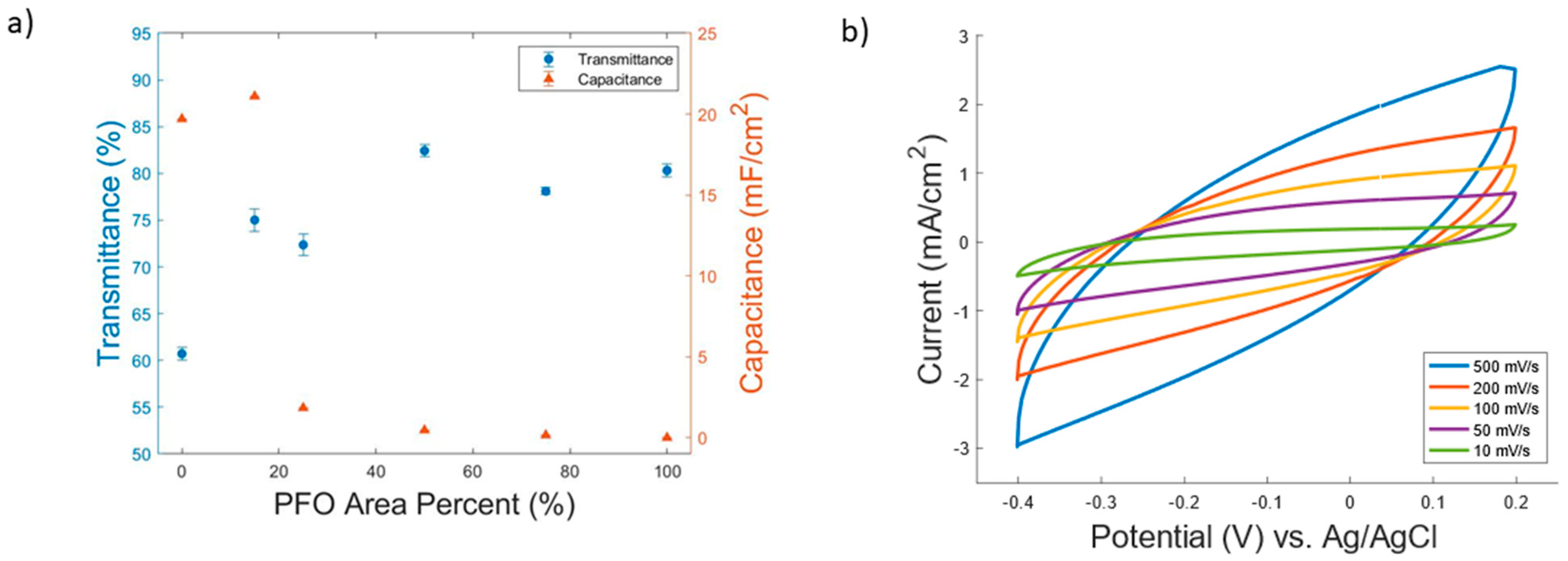

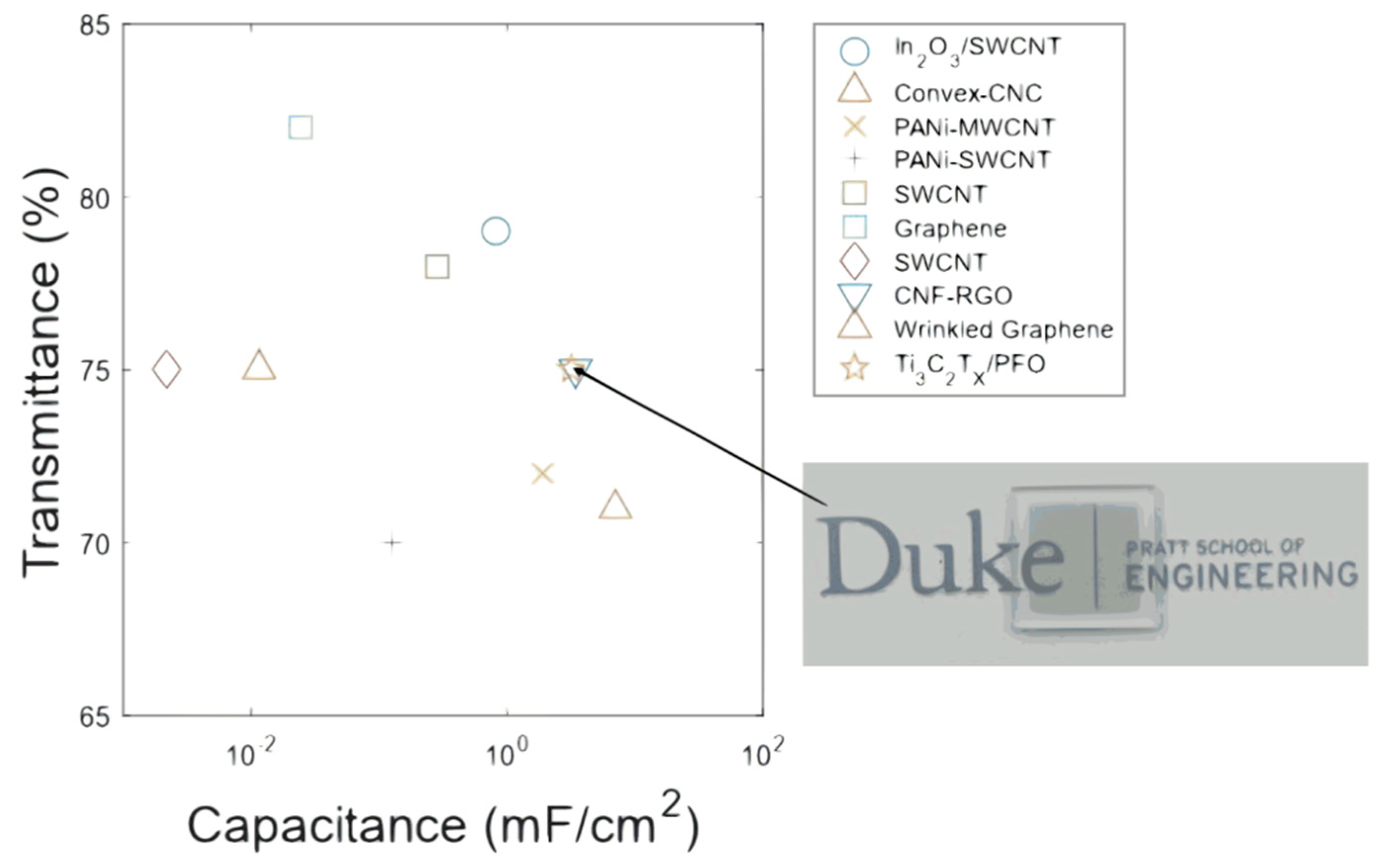

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, C.; Higgins, T.M.; Park, S.H.; O’Brien, S.E.; Long, D.; Coleman, J.N.; Nicolosi, V. Highly flexible and transparent solid-state supercapacitors based on RuO2/PEDOT:PSS conductive ultrathin films. Nano Energy 2016, 28, 495–505. [Google Scholar] [CrossRef]

- Kurlyandskaya, G.V.; Fernández, E.; Svalov, A.; Burgoa Beitia, A.; García-Arribas, A.; Larrañaga, A. Flexible thin film magnetoimpedance sensors. J. Magn. Magn. Mater. 2016, 415, 91–96. [Google Scholar] [CrossRef]

- Zhang, C.; Nicolosi, V. Graphene and MXene-based transparent conductive electrodes and supercapacitors. Energy Storage Mater. 2019, 16, 102–125. [Google Scholar] [CrossRef]

- King, P.J.; Higgins, T.M.; De, S.; Nicoloso, N.; Coleman, J.N. Percolation Effects in Supercapacitors with Thin, Transparent Carbon Nanotube Electrodes. ACS Nano 2012, 6, 1732–1741. [Google Scholar] [CrossRef] [PubMed]

- Higgins, T.M.; Coleman, J.N. Avoiding Resistance Limitations in High-Performance Transparent Supercapacitor Electrodes Based on Large-Area, High-Conductivity PEDOT:PSS Films. ACS Appl. Mater. Interfaces 2015, 7, 16495–16506. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Zhou, C.; Chang, H.; Shen, G.; Ishikawa, F.N.; Ryu, K.; Badmaev, A.; Gomez De Arco, L. Transparent Electronics Based on Transfer Printed Aligned Carbon Nanotubes on Rigid and Flexible Substrates. ACS Nano 2008, 3, 73–79. [Google Scholar]

- Ju, S.; Facchetti, A.; Xuan, Y.; Liu, J.; Ishikawa, F.; Ye, P.; Zhou, C.; Marks, T.J.; Janes, D.B. Fabrication of fully transparent nanowire transistors for transparent and flexible electronics. Nat. Nanotechnol. 2007, 2, 378–384. [Google Scholar] [CrossRef] [Green Version]

- Anasori, B.; Gogotsi, Y.; Nicolosi, V.; Zhang, C.J.; Seral-Ascaso, A.; Coleman, J.N.; Park, S.-H.; Duesberg, G.S.; Shmeliov, A.; McEvoy, N. Transparent, Flexible, and Conductive 2D Titanium Carbide (MXene) Films with High Volumetric Capacitance. Adv. Mater. 2017, 29, 1702678. [Google Scholar]

- Gupta, A.; Akhtar, A.J.; Saha, S.K. In-situ growth of P3HT/graphene composites for supercapacitor application. Mater. Chem. Phys. 2013, 140, 616–621. [Google Scholar] [CrossRef]

- Stiff-Roberts, A.D.; Ge, W. Organic/hybrid thin films deposited by matrix-assisted pulsed laser evaporation (MAPLE). Appl. Phys. Rev. 2017, 4, 041303. [Google Scholar] [CrossRef]

- Pate, R.; Lantz, K.R.; Stiff-Roberts, A.D. Tabletop resonant infrared matrix-assisted pulsed laser evaporation of light-emitting organic thin films. IEEE J. Sel. Top. Quantum Electron. 2008, 14, 1022–1030. [Google Scholar] [CrossRef]

- Pate, R.; Lantz, K.R.; Stiff-Roberts, A.D. Resonant infrared matrix-assisted pulsed laser evaporation of CdSe colloidal quantum dot/poly[2-methoxy-5-(2′-ethylhexyloxy)-1,4-(1-cyano vinylene)phenylene] hybrid nanocomposite thin films. Thin Solid Films 2009, 517, 6798–6802. [Google Scholar] [CrossRef]

- Pate, R.; McCormick, R.; Chen, L.; Zhou, W.; Stiff-Roberts, A.D. RIR-MAPLE deposition of conjugated polymers for application to optoelectronic devices. Appl. Phys. A Mater. Sci. Process. 2011, 105, 555–563. [Google Scholar] [CrossRef]

- Ge, W.; Li, N.K.; McCormick, R.D.; Lichtenberg, E.; Yingling, Y.G.; Stiff-Roberts, A.D. Emulsion-Based RIR-MAPLE Deposition of Conjugated Polymers: Primary Solvent Effect and Its Implications on Organic Solar Cell Performance. ACS Appl. Mater. Interfaces 2016, 8, 19494–19506. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McCormick, R.D.; Lenhardt, J.; Stiff-Roberts, A.D. Effects of emulsion-based resonant infrared matrix assisted pulsed laser evaporation (RIR-MAPLE) on the molecular weight of polymers. Polymers 2012, 4, 341–354. [Google Scholar] [CrossRef] [Green Version]

- Ge, W.; Hoang, T.B.; Mikkelsen, M.H.; Stiff-Roberts, A.D. RIR-MAPLE deposition of plasmonic silver nanoparticles. Appl. Phys. A Mater. Sci. Process. 2016, 122, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Rella, R.; Cozzoli, P.D.; Arima, V.; Taurino, A.; Tunno, T.; Cesaria, M.; Catalano, M.; Martino, M.; Zacheo, A.; Caricato, A.P.; et al. MAPLE deposition of nanomaterials. Appl. Surf. Sci. 2013, 302, 92–98. [Google Scholar]

- Ge, W.; Atewologun, A.; Stiff-Roberts, A.D. Hybrid nanocomposite thin films deposited by emulsion-based resonant infrared matrix-assisted pulsed laser evaporation for photovoltaic applications. Org. Electron. Phys. Mater. Appl. 2015, 22, 98–107. [Google Scholar] [CrossRef]

- Stiff-Roberts, A.D.; Dunlap-Shohl, W.A.; Mitzi, D.B.; Gundogdu, K.; Barrette, A.; Barraza, E.T. MAPbI 3 Solar Cells with Absorber Deposited by Resonant Infrared Matrix-Assisted Pulsed Laser Evaporation. ACS Energy Lett. 2017, 3, 270–275. [Google Scholar]

- Barraza, E.T.; Dunlap-Shohl, W.A.; Mitzi, D.B.; Stiff-Roberts, A.D. Deposition of Methylammonium Lead Triiodide by Resonant Infrared Matrix-Assisted Pulsed Laser Evaporation. J. Electron. Mater. 2018, 47, 917–926. [Google Scholar] [CrossRef]

- Lukatskaya, M.R.; Dall’Agnese, Y.; Naguib, M.; Barsoum, M.W.; Ren, C.E.; Mashtalir, O.; Simon, P.; Taberna, P.L.; Gogotsi, Y.; Rozier, P. Cation Intercalation and High Volumetric Capacitance of Two-Dimensional Titanium Carbide. Science 2013, 341, 1502–1505. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Taberna, P.-L.; Dall’Agnese, Y.; Gogotsi, Y.; Simon, P.; Rozier, P. Capacitance of two-dimensional titanium carbide (MXene) and MXene/carbon nanotube composites in organic electrolytes. J. Power Sources 2015, 306, 510–515. [Google Scholar]

- Ghidiu, M.; Lukatskaya, M.R.; Zhao, M.-Q.; Gogotsi, Y.; Barsoum, M.W. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature 2014, 516, 78–81. [Google Scholar] [CrossRef] [PubMed]

- Ouisse, T.; Armand, M.; Kervella, Y.; Stéphan, O. Fully transparent, organic light-emitting electrochemical cells. Appl. Phys. Lett. 2002, 81, 3131–3133. [Google Scholar] [CrossRef]

- Grell, M.; Bradley, D.D.C.; Ungar, G.; Hill, J.; Whitehead, K.S. Interplay of physical structure and photophysics for a liquid crystalline polyfluorene. Macromolecules 1999, 32, 5810–5817. [Google Scholar] [CrossRef]

- Machida, K.; Suematsu, S.; Ishimoto, S.; Tamamitsu, K. High-Voltage Asymmetric Electrochemical Capacitor Based on Polyfluorene Nanocomposite and Activated Carbon. J. Electrochem. Soc. 2008, 155, A970. [Google Scholar] [CrossRef]

- Ferguson, S.; Williams, C.V.; Mohapi, B.; Stiff-Roberts, A.D. Deposition of β-Polyfluorene by Resonant Infrared Matrix-Assisted Pulsed Laser Evaporation. J. Electron. Mater. 2019, 48, 3388–3398. [Google Scholar] [CrossRef]

- Stoller, M.D.; Ruoff, R.S. Best practice methods for determining an electrode material’s performance for ultracapacitors. Energy Environ. Sci. 2010, 3, 1294–1301. [Google Scholar] [CrossRef]

- Ge, W.; Yu, Q.; López, G.P.; Stiff-Roberts, A.D. Antimicrobial oligo(p-phenylene-ethynylene) film deposited by resonant infrared matrix-assisted pulsed laser evaporation. Colloids Surf. B Biointerfaces 2014, 116, 786–792. [Google Scholar] [CrossRef]

- Niu, Z.; Zhou, W.; Chen, J.; Feng, G.; Li, H.; Hu, Y.; Ma, W.; Dong, H.; Li, J.; Xie, S. A Repeated Halving Approach to Fabricate Ultrathin Single-Walled Carbon Nanotube Films for Transparent Supercapacitors. Small 2013, 9, 518–524. [Google Scholar] [CrossRef]

- Chen, T.; Xue, Y.; Roy, A.K.; Dai, L. Transparent and stretchable high-performance supercapacitors based on wrinkled graphene electrodes. ACS Nano 2014, 8, 1039–1046. [Google Scholar] [CrossRef]

- Gao, K.; Shao, Z.; Wu, X.; Wang, X.; Zhang, Y.; Wang, W.; Wang, F. Paper-based transparent flexible thin film supercapacitors. Nanoscale 2013, 5, 5307. [Google Scholar] [CrossRef] [PubMed]

- Sorel, S.; Khan, U.; Coleman, J.N. Flexible, transparent dielectric capacitors with nanostructured electrodes. Appl. Phys. Lett. 2012, 101, 103106. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Zhou, Y.S.; Xiong, W.; Jiang, L.J.; Mahjouri-samani, M.; Thirugnanam, P.; Huang, X.; Wang, M.M.; Jiang, L.; Lu, Y.F. Transparent, flexible, and solid-state supercapacitors based on graphene electrodes. APL Mater. 2013, 1, 012101. [Google Scholar] [CrossRef]

- Ge, J.; Cheng, G.; Chen, L. Transparent and flexible electrodes and supercapacitors using polyaniline/single-walled carbon nanotube composite thin films. Nanoscale 2011, 3, 3084. [Google Scholar] [CrossRef]

- Lin, H.; Li, L.; Ren, J.; Cai, Z.; Qiu, L.; Yang, Z.; Peng, H. Conducting polymer composite film incorporated with aligned carbon nanotubes for transparent, flexible and efficient supercapacitor. Sci. Rep. 2013, 3, 1353. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jung, H.Y.; Karimi, M.B.; Hahm, M.G.; Ajayan, P.M.; Jung, Y.J. Transparent, flexible supercapacitors from nano-engineered carbon films. Sci. Rep. 2012, 2, 773. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.-C.; Shen, G.; Sukcharoenchoke, S.; Zhou, C. Flexible and transparent supercapacitor based on In2O3 nanowire/carbon nanotube heterogeneous films. Appl. Phys. Lett. 2009, 94, 43113–264104. [Google Scholar] [CrossRef]

| Electrode Name | PFO Target Area Percentage (%) | MXene Target Area Percentage (%) |

|---|---|---|

| P100 | 100 | 0 |

| P75M25 | 75 | 25 |

| P50M50 | 50 | 50 |

| P25M75 | 25 | 75 |

| P15M85 | 15 | 85 |

| M100 | 0 | 100 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ajnsztajn, A.; Ferguson, S.; Thostenson, J.O.; Ngaboyamahina, E.; Parker, C.B.; Glass, J.T.; Stiff-Roberts, A.D. Transparent MXene-Polymer Supercapacitive Film Deposited Using RIR-MAPLE. Crystals 2020, 10, 152. https://doi.org/10.3390/cryst10030152

Ajnsztajn A, Ferguson S, Thostenson JO, Ngaboyamahina E, Parker CB, Glass JT, Stiff-Roberts AD. Transparent MXene-Polymer Supercapacitive Film Deposited Using RIR-MAPLE. Crystals. 2020; 10(3):152. https://doi.org/10.3390/cryst10030152

Chicago/Turabian StyleAjnsztajn, Alec, Spencer Ferguson, James O. Thostenson, Edgard Ngaboyamahina, Charles B. Parker, Jeffrey T. Glass, and Adrienne D. Stiff-Roberts. 2020. "Transparent MXene-Polymer Supercapacitive Film Deposited Using RIR-MAPLE" Crystals 10, no. 3: 152. https://doi.org/10.3390/cryst10030152