Progress of InGaN-Based Red Micro-Light Emitting Diodes

Abstract

:1. Introduction

2. Advantages of InGaN Red μLEDs

2.1. Size-Independent Peak EQE of InGaN Red μLEDs

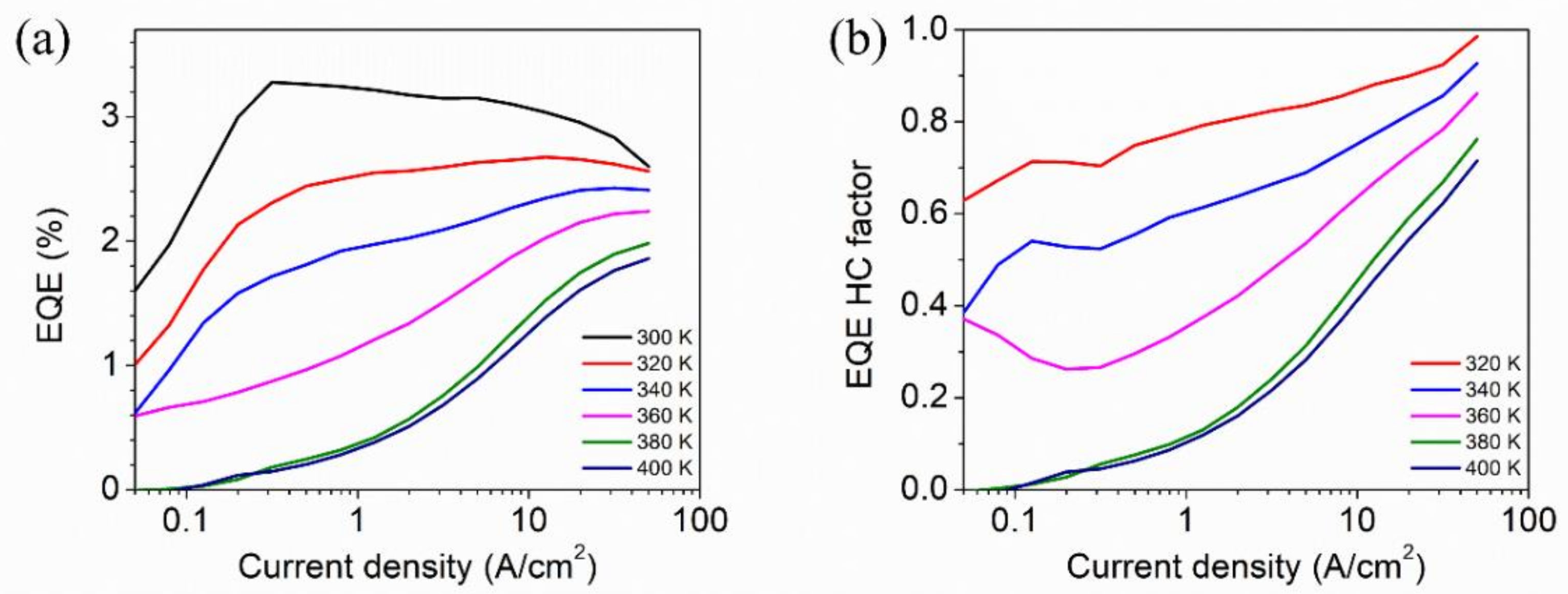

2.2. Robust Temperature Property of InGaN Red μLEDs

3. Progress of InGaN Red LEDs and μLEDs

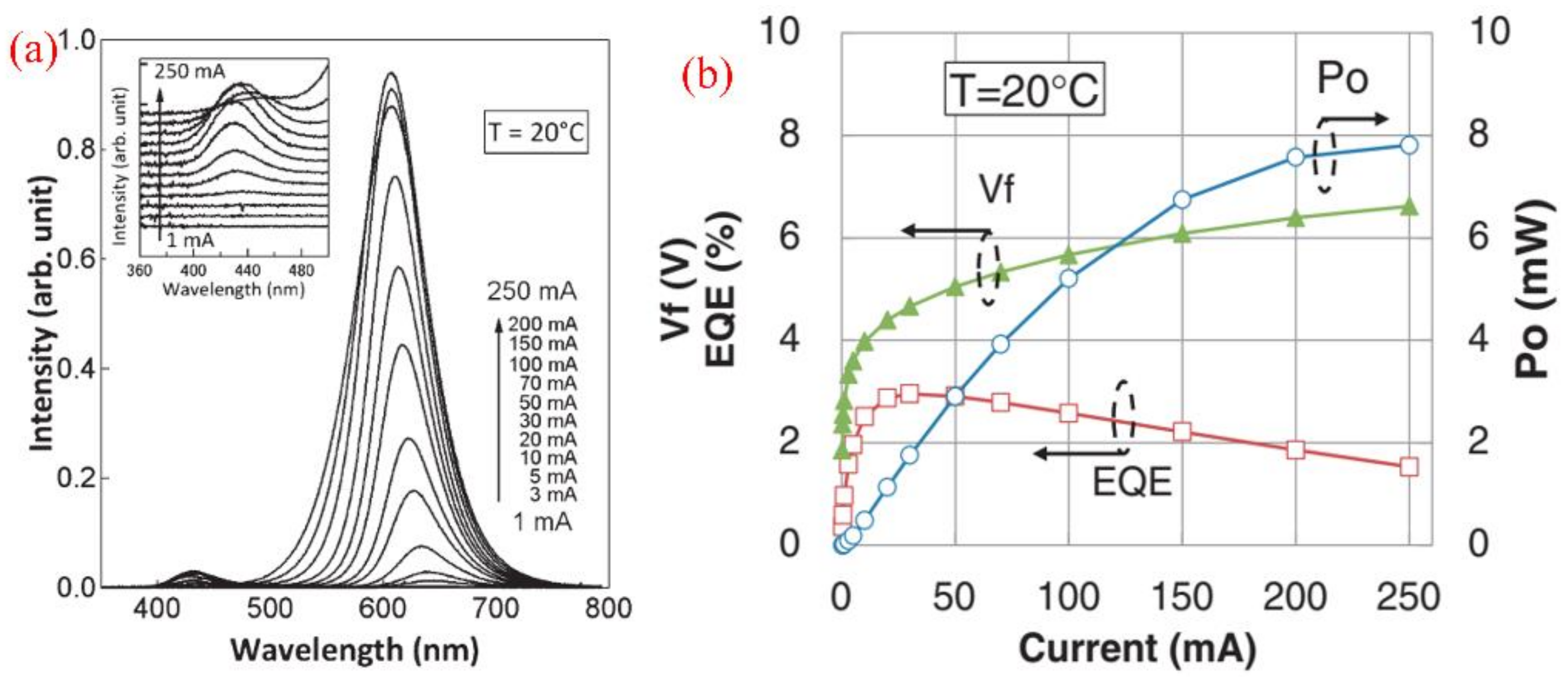

3.1. InGaN Red LEDs/μLEDs Grown on PSS

3.2. High-Efficiency InGaN Red LEDs Grown on Silicon Substrate Using 3-Dimension “V” Pits Injection

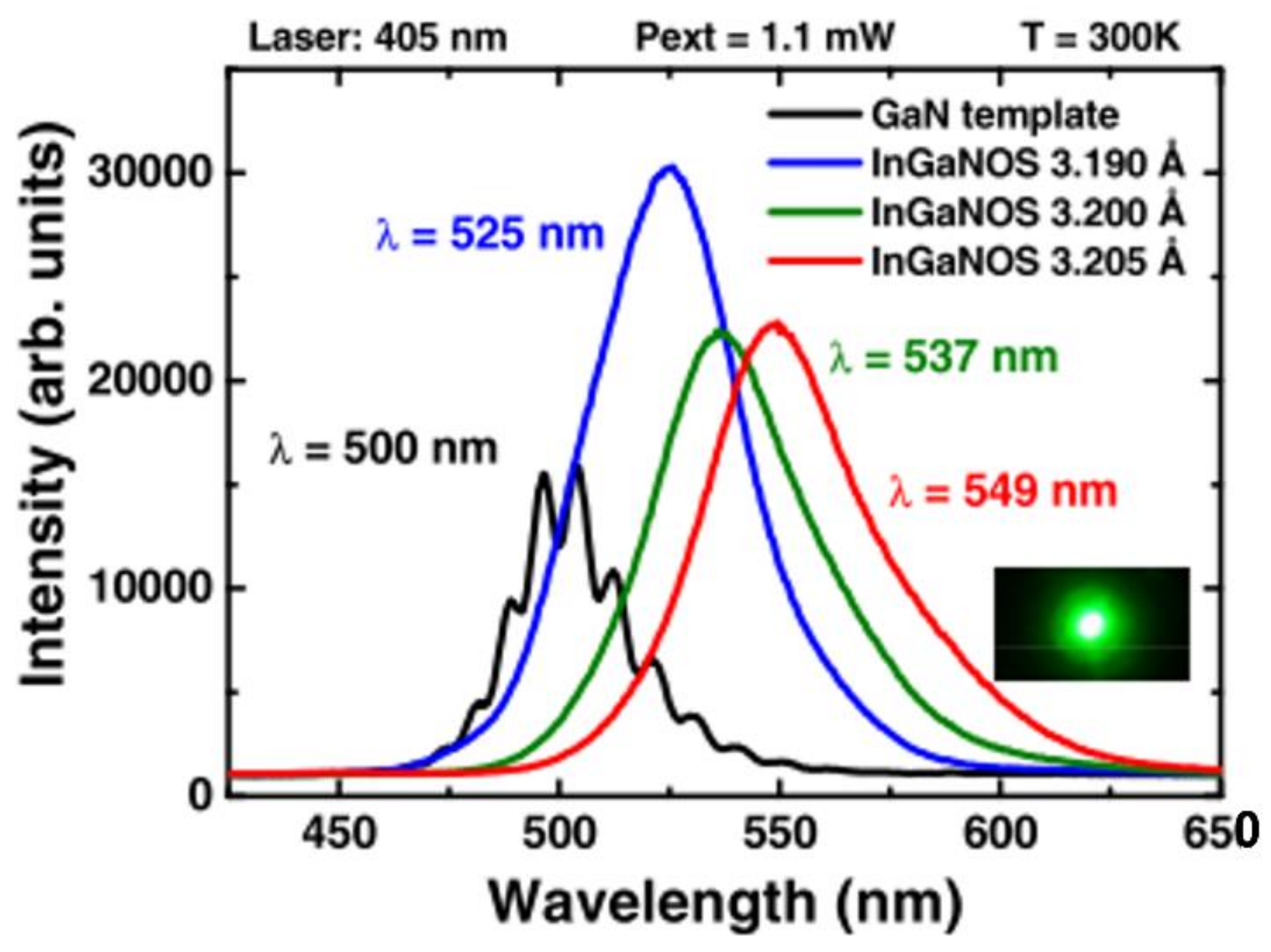

3.3. InGaN Red μLEDs Using Semi-Relaxed InGaNOS Pseudo-Substrate

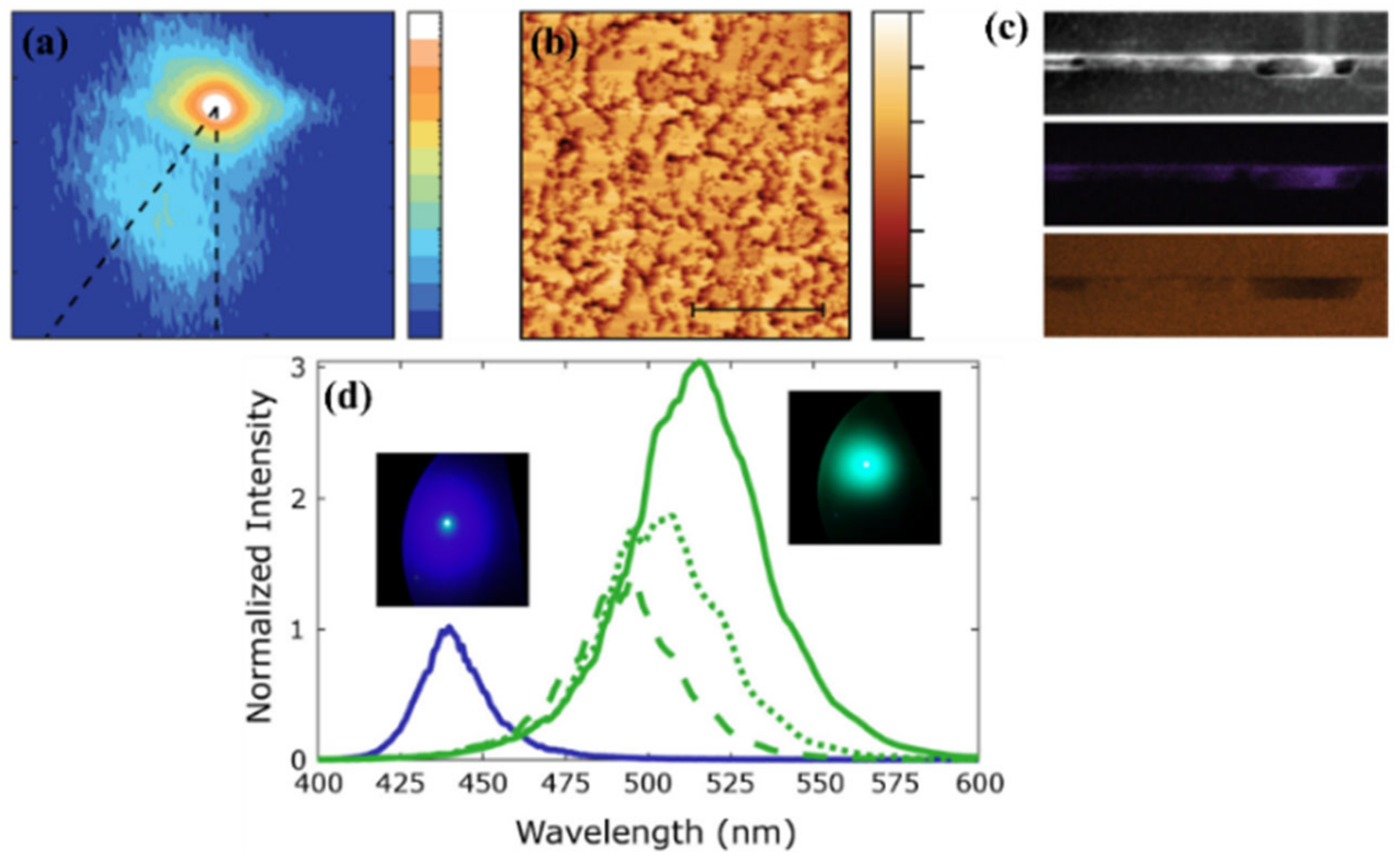

3.4. InGaN Red μLEDs Grown on Strain Relaxed Nano-Porous InGaN Template

3.5. InGaN Red μLEDs Grown on Strained Relaxed Layer Using In-Situ Decomposition Layer

3.6. Other Novel Methods to Achieve InGaN Red Emissions

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Day, J.; Li, J.; Lie, D.Y.C.; Bradford, C.; Lin, J.Y.; Jiang, H.X. III-Nitride full-scale high-resolution microdisplays. Appl. Phys. Lett. 2011, 99, 031116. [Google Scholar] [CrossRef]

- Wierer, J.J., Jr.; Tansu, N. III-Nitride micro-LEDs for efficient emissive displays. Laser Photonics Rev. 2019, 13, 1900141. [Google Scholar] [CrossRef]

- Li, P.; Li, H.; Yao, Y.; Zhang, H.; Lynsky, C.; Qwah, K.S.; Speck, J.S.; Nakamura, S.; DenBaars, S.P. Demonstration of high efficiency cascaded blue and green micro-light-emitting diodes with independent junction control. Appl. Phys. Lett. 2021, 118, 261104. [Google Scholar] [CrossRef]

- Li, P.; Zhang, H.; Li, H.; Iza, M.; Yao, Y.; Wong, M.S.; Palmquist, N.; Speck, J.S.; Nakamura, S.; DenBaars, S.P. Size-independent low voltage of InGaN micro-light-emitting diodes with epitaxial tunnel junctions using selective area growth by metalorganic chemical vapor deposition. Opt. Express 2020, 28, 18707. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Li, H.; Yang, Y.; Zhang, H.; Shapturenka, P.; Wong, M.; Lynsky, C.; Iza, M.; Golden, M.; Speck, J.S.; et al. Demonstration of ultra-small 5 × 5 μm2 607 nm InGaN amber micro-light-emitting diodes with an external quantum efficiency over 2%. Appl. Phys. Lett. 2022, 120, 041102. [Google Scholar] [CrossRef]

- Li, P.; Li, H.; Zhang, H.; Lynsky, C.; Iza, M.; Speck, J.S.; Nakamura, S.; DenBaars, S.P. Size-independent peak external quantum efficiency (>2%) of InGaN red micro-light-emitting diodes with an emission wavelength over 600 nm. Appl. Phys. Lett. 2021, 119, 081102. [Google Scholar] [CrossRef]

- Li, P.; David, A.; Li, H.; Zhang, H.; Lynsky, C.; Yang, Y.; Iza, M.; Speck, J.S.; Nakamura, S.; DenBaars, S.P. High-temperature electroluminescence properties of InGaN red 40 × 40 μm2 micro-light-emitting diodes with a peak external quantum efficiency of 3.2%. Appl. Phys. Lett. 2021, 119, 231101. [Google Scholar] [CrossRef]

- Hwang, J.-I.; Hashimoto, R.; Saito, S.; Nunoue, S. Development of InGaN-based red LED grown on (0001) polar surface. Appl. Phys. Express 2014, 7, 071003. [Google Scholar] [CrossRef]

- Oh, J.T.; Lee, S.Y.; Moon, Y.T.; Moon, J.H.; Park, S.; Hong, K.Y.; Song, K.Y.; Oh, C.; Shim, J.I.; Jeong, H.H.; et al. Light output performance of red AlGaInP-based light emitting diodes with different chip geometries and structures. Opt. Express 2018, 26, 11194. [Google Scholar] [CrossRef]

- Wong, M.S.; Kearns, J.A.; Lee, C.; Smith, J.M.; Lynsky, C.; Lheureux, G.; Choi, H.; Kim, J.; Kim, C.; Nakamura, S.; et al. Improved performance of AlGaInP red micro-light-emitting diodes with sidewall treatments. Opt. Express 2020, 28, 5787. [Google Scholar] [CrossRef]

- Oh, C.-H.; Shim, J.-I.; Shin, D.-S. Current- and temperature-dependent efficiency droops in InGaN-based blue and AlGaInP-based red light-emitting diodes. Jpn. J. Appl. Phys. 2019, 58, SCCC08. [Google Scholar] [CrossRef]

- Lee, D.-H.; Lee, S.-Y.; Shim, J.-I.; Seong, T.-Y.; Amano, H. Effects of Current, Temperature, and Chip Size on the Performance of AlGaInP-Based Red Micro-Light-Emitting Diodes with Different Contact Schemes. ECS J. Solid State Sci. Technol. 2021, 10, 095001. [Google Scholar] [CrossRef]

- Wong, M.S.; Hwang, D.; Alhassan, A.I.; Lee, C.; Ley, R.; Nakamura, S.; DenBaars, S.P. High efficiency of III-nitride micro-light-emitting diodes by sidewall passivation using atomic layer deposition. Opt. Express 2018, 26, 21324. [Google Scholar] [CrossRef]

- David, A.; Hurni, C.A.; Young, N.G.; Craven, M.D. Electrical properties of III-Nitride LEDs: Recombination-based injection model and theoretical limits to electrical efficiency and electroluminescent cooling. Appl. Phys. Lett. 2016, 109, 083501. [Google Scholar] [CrossRef] [Green Version]

- Alhassan, A.I.; Farrell, R.M.; Saifaddin, B.; Mughal, A.; Wu, F.; DenBaars, S.P.; Nakamura, S.; Speck, J.S. High luminous efficacy green light-emitting diodes with AlGaN cap layer. Opt. Express 2016, 24, 17868. [Google Scholar] [CrossRef] [PubMed]

- Even, A.; Laval, G.; Ledoux, O.; Ferret, P.; Sotta, D.; Guiot, E.; Levy, F.; Robin, I.C.; Dussaigne, A. Enhanced In incorporation in full InGaN heterostructure grown on relaxed InGaN pseudo-substrate. Appl. Phys. Lett. 2017, 110, 262103. [Google Scholar] [CrossRef]

- Dussaigne, A.; Maitre, P.L.; Haas, H.; Pillet, J.-C.; Barbier, F.; Grenier, A.; Michit, N.; Jannaud, A.; Templier, R.; Vaufrey, D.; et al. Full InGaN Red (625 Nm) micro-LED (10 μm) demonstration on a relaxed pseudo-substrate. Appl. Phys. Express 2021, 14, 092011. [Google Scholar] [CrossRef]

- White, R.C.; Khoury, M.; Wong, M.S.; Li, H.; Lynsky, C.; Iza, M.; Keller, S.; Sotta, D.; Nakamura, S.; DenBaars, S.P. Realization of III-Nitride c-Plane microLEDs Emitting from 470 to 645 nm on Semi-Relaxed Substrates Enabled by V-Defect-Free Base Layers. Crystals 2021, 11, 1168. [Google Scholar] [CrossRef]

- White, R.C.; Li, H.; Khoury, M.; Lynsky, C.; Iza, M.; Keller, S.; Sotta, D.; Nakamura, S.; DenBaars, S.P. InGaN-Based microLED Devices Approaching 1% EQE with Red 609 nm Electroluminescence on Semi-Relaxed Substrates. Crystals 2021, 11, 1364. [Google Scholar] [CrossRef]

- Pasayat, S.S.; Gupta, C.; Wong, M.S.; Ley, R.; Gordon, M.J.; DenBaars, S.P.; Nakamura, S.; Keller, S.; Mishra, U.K. Demonstration of ultra-small (<10 μm) 632 nm red InGaN micro-LEDs with useful on-wafer external quantum efficiency (>0.2%) for mini-displays. Appl. Phys. Express 2021, 14, 011004. [Google Scholar] [CrossRef]

- Chan, P.; Rienzi, V.; Lim, N.; Chang, H.M.; Gordon, M.; DenBaars, S.P.; Nakamura, S. Demonstration of relaxed InGaN-based Red LEDs grown with high active region temperature. Appl. Phys. Express 2021, 14, 101002. [Google Scholar] [CrossRef]

- Chan, P.; DenBaars, S.P.; Nakamura, S. Growth of highly relaxed InGaN pseudo-substrates over full 2-in. wafers. Appl. Phys. Lett. 2021, 119, 131106. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, J.; Gao, J.; Wang, X.; Zheng, C.; Zheng, C.; Zhang, M.; Wu, X.; Xu, L.; Ding, J.; et al. Efficient emission of InGaN-based light-emitting diodes: Toward orange and red. Photonics Res. 2020, 8, 1671. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, J.; Xu, L.; Ding, J.; Wang, G.; Wu, X.; Wang, X.; Mo, C.; Quan, Z.; Guo, X.; et al. Efficient InGaN-based yellow-light-emitting diodes. Photonics Res. 2019, 7, 144. [Google Scholar] [CrossRef]

- Iida, D.; Zhuang, Z.; Kirilenko, P.; Velazquez-Rizo, M.; Najmi, M.A.; Ohkawa, K. 633-nm InGaN-based red LEDs grown on thick underlying GaN layers with reduced in-plane residual stress. Appl. Phys. Lett. 2020, 116, 162101. [Google Scholar] [CrossRef]

- Zhuang, Z.; Iida, D.; Velazquez-Rizo, M.; Ohkawa, K. Ultrasmall and ultradense InGaN-based RGB monochromatic micro-light-emitting diode arrays by pixilation of conductive p-GaN. Photonics Res. 2021, 9, 1796–1802. [Google Scholar] [CrossRef]

- Li, P.; Li, H.; Zhang, H.; Yang, Y.; Wong, M.; Lynsky, C.; Iza, M.; Golden, M.; Speck, J.S.; Nakamura, S.; et al. Red InGaN micro-light-emitting diodes (>620 nm) with a peak external quantum efficiency of 4.5% using an epitaxial tunnel junction contact. Appl. Phys. Lett. 2022, 120, 121102. [Google Scholar] [CrossRef]

- Lheureux, G.; Lynsky, C.; Wu, Y.-R.; Speck, J.S.; Weisbuch, C. A 3D simulation comparison of carrier transport in green and blue c-plane multi-quantum well nitride light emitting diodes. J. Appl. Phys. 2020, 128, 235703. [Google Scholar] [CrossRef]

- Ichikawa, S.; Shiomi, K.; Morikawa, T.; Timmerman, D.; Sasaki, Y.; Tatebayashi, J.; Fujiwara, Y. Eu-doped GaN and InGaN monolithically stacked full-color LEDs with a wide color gamut. Appl. Phys. Express 2021, 14, 031008. [Google Scholar] [CrossRef]

- Nishikawa, A.; Kawasaki, T.; Furukawa, N.; Terai, Y.; Fujiwara, Y. Room-temperature red emission from a p-type/europium-doped/n-type gallium nitride light-emitting diode under current injection. Appl. Phys. Express 2009, 2, 071004. [Google Scholar] [CrossRef]

- Bi, Z.; Lenrick, F.; Colvin, J.; Gustafsson, A.; Hultin, O.; Nowzari, A.; Lu, T.; Wallenberg, R.; Timm, R.; Mikkelsen, A.; et al. InGaN platelets: Synthesis and applications toward green and red light-emitting diodes. Nano Lett. 2019, 19, 2832. [Google Scholar] [CrossRef] [PubMed]

- Pandey, A.; Malhotra, Y.; Wang, P.; Sun, K.; Liu, X.; Mi, Z. N-polar InGaN/GaN nanowires: Overcoming the efficiency cliff of red-emitting micro-LEDs. Photonics Res. 2022, 10, 1107. [Google Scholar] [CrossRef]

- Pantzas, K.; el Gmili, Y.; Dickerson, J.; Gautier, S.; Largeau, L.; Mauguin, O.; Patriarche, G.; Suresh, S.; Moudakir, T.; Bishop, C.; et al. Semibulk InGaN: A novel approach for thick, single phase, epitaxial InGaN layers grown by MOVPE. J. Cryst. Growth 2013, 370, 57. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Li, H.; Wong, M.S.; Chan, P.; Yang, Y.; Zhang, H.; Iza, M.; Speck, J.S.; Nakamura, S.; Denbaars, S.P. Progress of InGaN-Based Red Micro-Light Emitting Diodes. Crystals 2022, 12, 541. https://doi.org/10.3390/cryst12040541

Li P, Li H, Wong MS, Chan P, Yang Y, Zhang H, Iza M, Speck JS, Nakamura S, Denbaars SP. Progress of InGaN-Based Red Micro-Light Emitting Diodes. Crystals. 2022; 12(4):541. https://doi.org/10.3390/cryst12040541

Chicago/Turabian StyleLi, Panpan, Hongjian Li, Matthew S. Wong, Philip Chan, Yunxuan Yang, Haojun Zhang, Mike Iza, James S. Speck, Shuji Nakamura, and Steven P. Denbaars. 2022. "Progress of InGaN-Based Red Micro-Light Emitting Diodes" Crystals 12, no. 4: 541. https://doi.org/10.3390/cryst12040541