Improvement of Mg-Doped GaN with Shutter-Controlled Process in Plasma-Assisted Molecular Beam Epitaxy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brillson, L.; Foster, G.; Cox, J.; Ruane, W.; Jarjour, A.; Gao, H.; Von Wenckstern, H.; Grundmann, M.; Wang, B.; Look, D.; et al. Defect Characterization, Imaging, and Control in Wide-Bandgap Semiconductors and Devices. J. Electron. Mater. 2018, 47, 4980–4986. [Google Scholar] [CrossRef]

- Li, L.; Alperin, J.; Wang, W.; Look, D.; Reynolds, D. High mobility AlGaN/GaN heterostructures grown by gas-source molecular beam epitaxy. J. Vac. Sci. Technol. B 1998, 16, 1275–1277. [Google Scholar] [CrossRef]

- Lo, I.; Tsai, J.K.; Yao, W.J.; Ho, P.C.; Tu, L.; Chang, T.C.; Elhamri, S.; Mitchel, W.C.; Hsieh, K.Y.; Huang, J.H.; et al. Spin splitting in modulation-doped AlxGa1−xN/GaN heterostructures. Phys. Rev. B 2002, 65, 161306. [Google Scholar] [CrossRef]

- Lo, I.; Pang, W.Y.; Chen, Y.L.; Hsu, Y.C.; Chiang, J.C.; Lin, W.H.; Chiu, W.T.; Tsai, J.K.; Chen, C.N. Spin-splitting in an AlxGa1−xN/GaN nanowire for a quantum-ring interferometer. Appl. Phys. Lett. 2008, 93, 132114. [Google Scholar] [CrossRef]

- Nakamura, S.; Mukai, T.; Senoh, M. Candela-class high-brightness InGaN/AlGaN double-heterostructure blue-light-emitting diodes. Appl. Phys. Lett. 1994, 64, 1687–1689. [Google Scholar] [CrossRef]

- Nakamura, S.; Pearton, S.; Fasol, G. The Blue Laser Diode; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

- Ponce, F.A.; Bour, D.P. Nitride-based semiconductors for blue and green light-emitting devices. Nature 1997, 386, 351–359. [Google Scholar] [CrossRef]

- Amano, H.; Kito, M.; Hiramatsu, K.; Akasaki, I. P-type conduction in Mg-doped Gan treated with low-energy electron beam irradiation (LEEBI). Jpn. J. Appl. Phys. 1989, 28, L2112. [Google Scholar] [CrossRef]

- Nakamura, S.; Mukai, T.; Senoh, M.S.M.; Iwasa, N.I.N. Thermal annealing effect on p-type mg-doped gan films. Jpn. J. Appl. Phys. 1992, 31, L139–L142. [Google Scholar] [CrossRef]

- Kaufmann, U.; Schlotter, P.; Obloh, H.; Köhler, K.; Maier, M. Hole conductivity and compensation in epitaxial GaN: Mg layers. Phys. Rev. B 2000, 62, 10867. [Google Scholar] [CrossRef]

- Haus, E.; Smorchkova, I.; Heying, B.; Fini, P.; Poblenz, C.; Mates, T.; Mishra, U.; Speck, J. The role of growth conditions on the p-doping of GaN by plasma-assisted molecular beam epitaxy. J. Cryst. Growth 2002, 246, 55–63. [Google Scholar] [CrossRef]

- Namkoong, G.; Trybus, E.; Lee, K.K.; Moseley, M.; Doolittle, W.A.; Look, D.C. Metal modulation epitaxy growth for extremely high hole concentrations above 1019 cm−3 in GaN. Appl. Phys. Lett. 2008, 93, 172112. [Google Scholar] [CrossRef]

- Hsu, Y.-C.; Lo, I.; Shih, C.-H.; Pang, W.-Y.; Hu, C.-H.; Wang, Y.-C.; Tsai, C.-D.; Chou, M.M.C.; Hsu, G.Z.L. Green light emission by InGaN/GaN multiple-quantum-well microdisks. Appl. Phys. Lett. 2014, 104, 102105. [Google Scholar] [CrossRef]

- Tsai, C.-D.; Lo, I.; Wang, Y.-C.; Yang, C.-C.; Yang, H.-Y.; Shih, H.-J.; Huang, H.-C.; Chou, M.M.C.; Huang, L.; Tseng, B. Indium-Incorporation with InxGa1-xN Layers on GaN-Microdisks by Plasma-Assisted Molecular Beam Epitaxy. Crystals 2019, 9, 308. [Google Scholar] [CrossRef]

- Shih, H.-J.; Lo, I.; Wang, Y.-C.; Tsai, C.-D.; Lin, Y.-C.; Lu, Y.-Y.; Huang, H.-C. Growth and Characterization of GaN/InxGa1−xN/InyAl1−yN Quantum Wells by Plasma-Assisted Molecular Beam Epitaxy. Crystals 2022, 12, 417. [Google Scholar] [CrossRef]

- Tsai, J.-K.; Lo, I.; Chuang, K.-L.; Tu, L.-W.; Huang, J.-H.; Hsieh, C.-H.; Hsieh, K.-Y. Effect of N to Ga flux ratio on the GaN surface morphologies grown at high temperature by plasma-assisted molecular-beam epitaxy. J. Appl. Phys. 2004, 95, 460–465. [Google Scholar] [CrossRef]

- Moseley, M.; Lowder, J.; Villingsley, D.; Doolittle, W.A. Control of surface adatom kinetics for the growth of high-indium content InGaN throughout the miscibility gap. Appl. Phys. Lett. 2010, 97, 191902. [Google Scholar] [CrossRef]

- Sakaki, H.; Noda, T.; Hirakawa, K.; Tanaka, M.; Matsusue, T. Interface roughness scattering in GaAs/AlAs quantum wells. Appl. Phys. Lett. 1987, 51, 1934–1936. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Li, W.; Cabalu, J.; Moustakas, T.D.; Smith, D.J.; Hervig, R.L. Efficient p-type doping of GaN films by plasma-assisted molecular beam epitaxy. Appl. Phys. Lett. 2004, 85, 4956–4958. [Google Scholar] [CrossRef]

- Yang, Y.C.; Lee, P.Y.; Tseng, Y.H.; Lin, C.W.; Tseng, Y.T.; Cheng, K.Y. Mg incorporation in GaN grown by plasma-assisted molecular beam epitaxy at high temperatures. J. Cryst. Growth 2016, 439, 87–92. [Google Scholar] [CrossRef]

- Zhang, M.; Bhattacharya, P.; Guo, W.; Banerjee, A. Mg doping of GaN grown by plasma-assisted molecular beam epitaxy under nitrogen-rich conditions. Appl. Phys. Lett. 2010, 96, 132103. [Google Scholar] [CrossRef]

- Pezzagna, S.; Vennéguès, P.; Grandjean, N.; Massies, J. Polarity inversion of GaN(0001) by a high Mg doping. J. Cryst. Growth 2004, 269, 249–256. [Google Scholar] [CrossRef]

- Heying, B.; Wu, X.H.; Keller, S.; Li, Y.; Kapolnek, D.; Keller, B.P.; DenBaars, S.P.; Speck, J.S. Role of threading dislocation structure on the x-ray diffraction peak widths in epitaxial GaN films. Appl. Phys. Lett. 1996, 68, 643–645. [Google Scholar] [CrossRef]

- Bermudez, V.M.; Kaplan, R.; Khan, M.A.; Kuznia, J.N. Growth of thin Ni films on GaN(0001)-(1x1). Phys. Rev. B 1993, 48, 2436–2444. [Google Scholar] [CrossRef] [PubMed]

- Storm, D.; McConkie, T.; Hardy, M.; Katzer, D.; Nepal, N.; Meyer, D.; Smith, D. Surface preparation of freestanding GaN substrates for homoepitaxial GaN growth by rf-plasma MBE. J. Vac. Sci. Technol. B 2017, 35, 02B109. [Google Scholar] [CrossRef]

- Kadleíková, M.; Breza, J.; Veselý, M. Raman spectra of synthetic sapphire. Microelectron. J. 2001, 32, 955–958. [Google Scholar] [CrossRef]

- Gorczyca, I.; Christensen, N.E.; Peltzer y Blancá, E.L.; Rodriguez, C.O. Optical phonon modes in GaN and AlN. Phys. Rev. B 1995, 51, 11936–11939. [Google Scholar] [CrossRef]

- Kuball, M.; Demangeot, F.; Frandon, J.; Renucci, M.A.; Massies, J.; Grandjean, N.; Aulombard, R.L.; Briot, O. Thermal stability of GaN investigated by Raman scattering. Appl. Phys. Lett. 1998, 73, 960–962. [Google Scholar] [CrossRef]

- Kaschner, A.; Siegle, H.; Kaczmarczyk, G.; Straßburg, M.; Hoffmann, A.; Thomsen, C.; Birkle, U.; Einfeldt, S.; Hommel, D. Local vibrational modes in Mg-doped GaN grown by molecular beam epitaxy. Appl. Phys. Lett. 1999, 74, 3281–3283. [Google Scholar] [CrossRef]

- Wang, L.; Chua, S.; Sun, W. Raman scattering and photoluminescence of Mg-implanted GaN films. Phys. Status Solidi (B) 2001, 228, 449–452. [Google Scholar] [CrossRef]

- Harima, H. Properties of GaN and related compounds studied by means of Raman scattering. J. Phys. Condens. Matter 2002, 14, R967. [Google Scholar] [CrossRef]

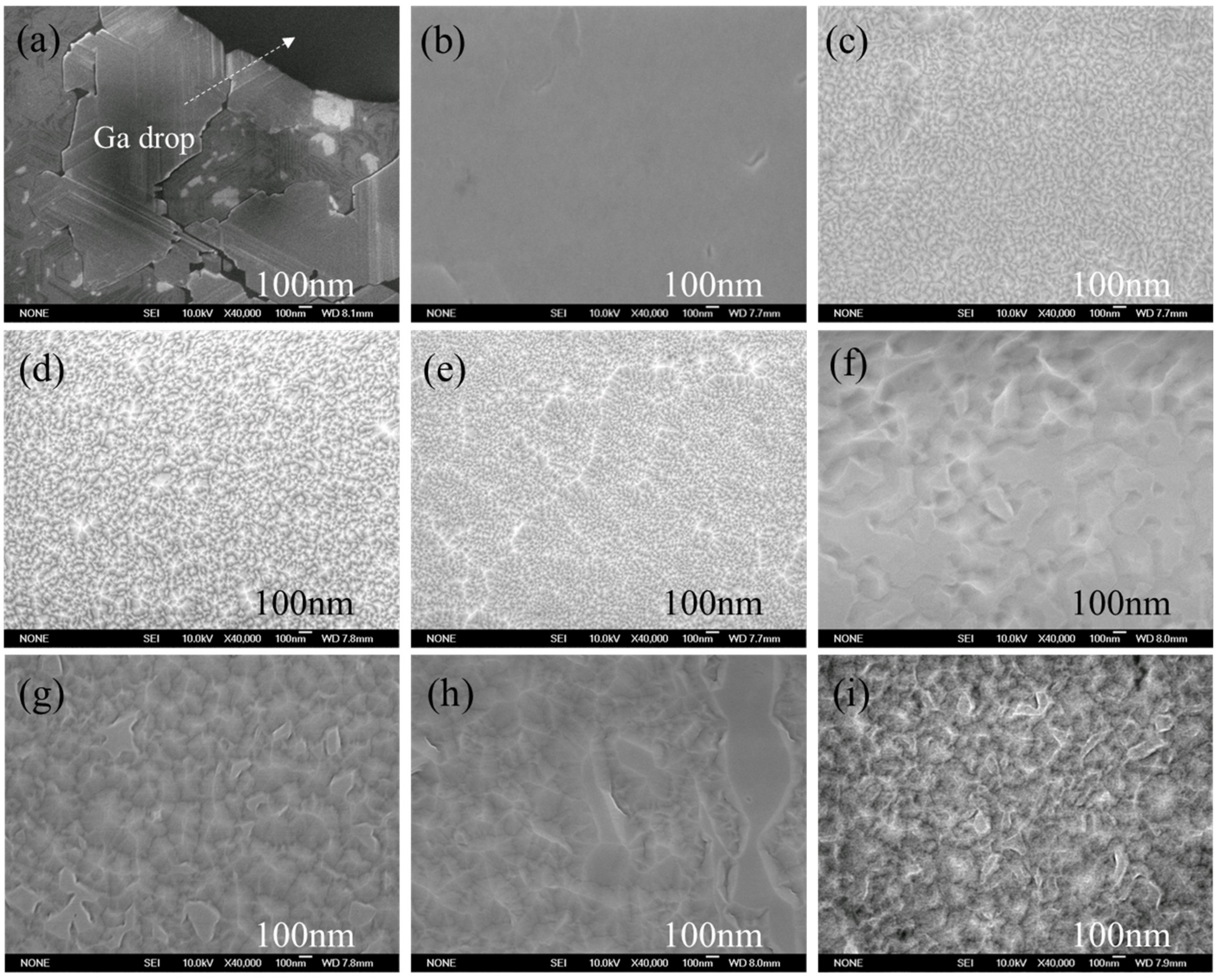

| Sample | Ga Flux (×10−7 Torr) | Flux Ratio (N/Ga) | Modulated Shutters | Shuttering Period (Open/Close) |

|---|---|---|---|---|

| A | 1.45 | 62 | none | N/A |

| B | 1.30 | 69 | none | N/A |

| C | 1.25 | 71 | none | N/A |

| D | 1.20 | 74 | none | N/A |

| E | 1.15 | 79 | none | N/A |

| F1 | 1.80 | 50 | Mg, Ga | 10 s/10 s |

| G1 | 1.60 | 56 | Mg, Ga | 10 s/10 s |

| F2 | 1.80 | 50 | Ga | 10 s/10 s |

| G2 | 1.60 | 56 | Ga | 10 s/10 s |

| Sample | Type | Carrier Concentration (cm−3) | Mobility (cm2/Vs) | Resistivity (Ω-cm) |

|---|---|---|---|---|

| A | n | 6.84 × 1018 | 104.48 | 8.74 × 10−3 |

| B | n | 1.61 × 1018 | 124.92 | 3.10 × 10−2 |

| C | p | 2.15 × 1015 | 31.08 | 9.36 × 101 |

| D | p | 3.59 × 1017 | 4.39 | 3.61 × 100 |

| E | p | 3.12 × 1018 | 0.97 | 2.06 × 100 |

| F1 | p | 2.70 × 1017 | 4.90 | 4.37 × 100 |

| G1 | p | 1.79 × 1016 | 9.81 | 3.55 × 101 |

| F2 | p | 1.42 × 1017 | 30.16 | 1.45 × 100 |

| G2 | p | 3.92 × 1016 | 24.90 | 6.41 × 100 |

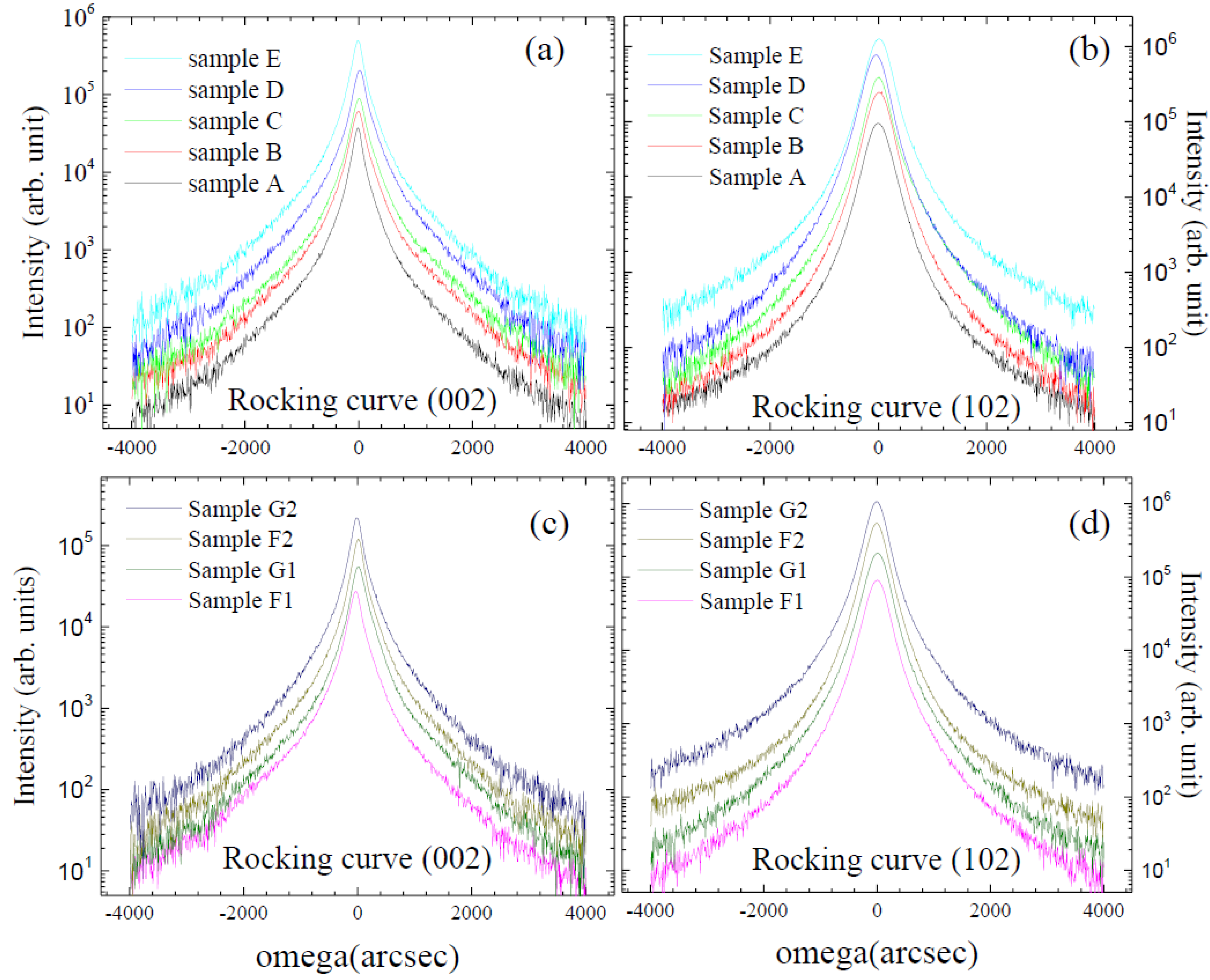

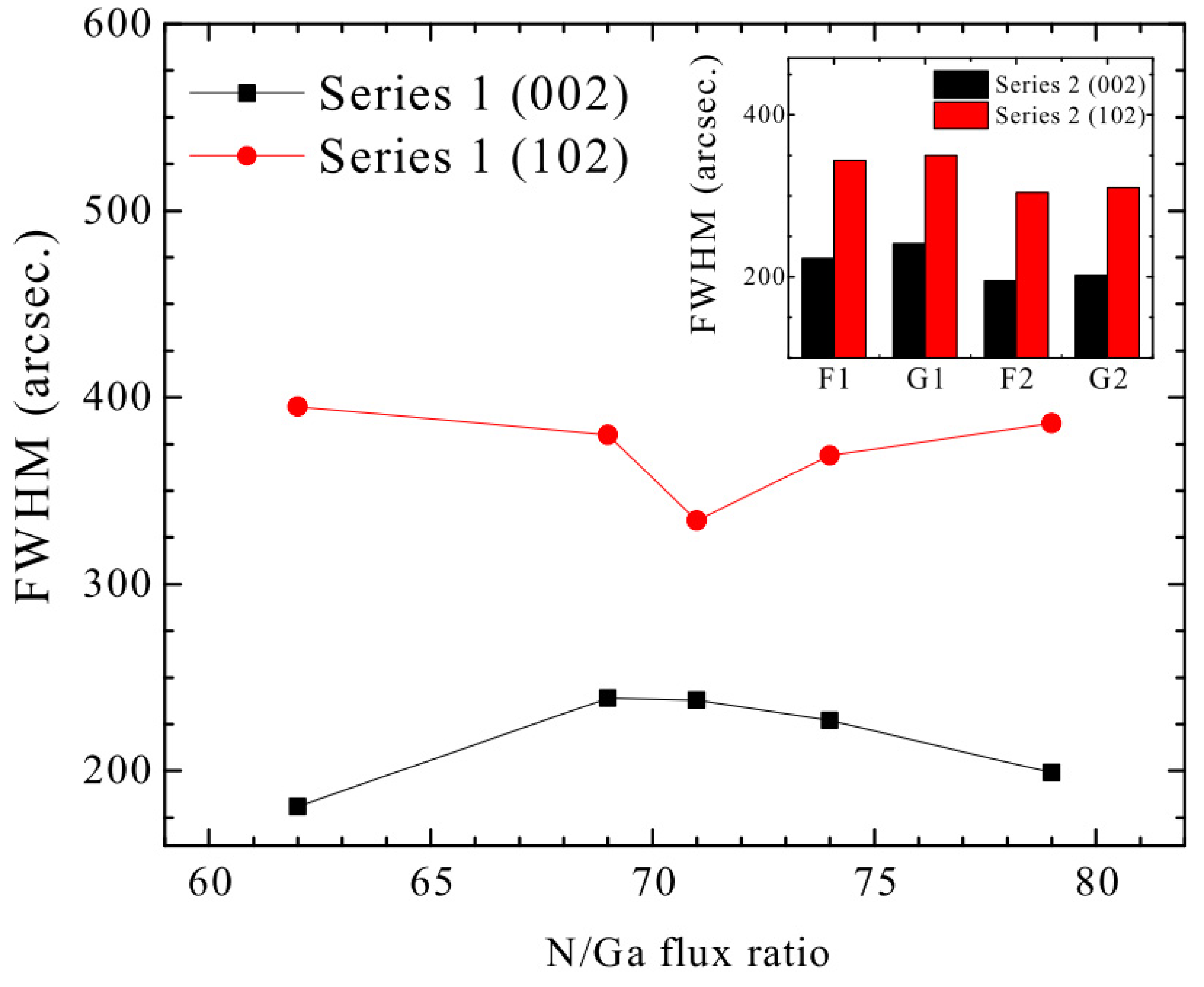

| Sample | A | B | C | D | E | F1 | G1 | F2 | G2 |

|---|---|---|---|---|---|---|---|---|---|

| (002) | 181 | 239 | 238 | 227 | 199 | 223 | 241 | 195 | 202 |

| (102) | 395 | 380 | 334 | 369 | 386 | 344 | 350 | 304 | 310 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-C.; Lo, I.; Lin, Y.-C.; Tsai, C.-D.; Chang, T.-C. Improvement of Mg-Doped GaN with Shutter-Controlled Process in Plasma-Assisted Molecular Beam Epitaxy. Crystals 2023, 13, 907. https://doi.org/10.3390/cryst13060907

Wang Y-C, Lo I, Lin Y-C, Tsai C-D, Chang T-C. Improvement of Mg-Doped GaN with Shutter-Controlled Process in Plasma-Assisted Molecular Beam Epitaxy. Crystals. 2023; 13(6):907. https://doi.org/10.3390/cryst13060907

Chicago/Turabian StyleWang, Ying-Chieh, Ikai Lo, Yu-Chung Lin, Cheng-Da Tsai, and Ting-Chang Chang. 2023. "Improvement of Mg-Doped GaN with Shutter-Controlled Process in Plasma-Assisted Molecular Beam Epitaxy" Crystals 13, no. 6: 907. https://doi.org/10.3390/cryst13060907