Dislocation Motion and the Microphysics of Flash Heating and Weakening of Faults during Earthquakes

Abstract

:1. Introduction

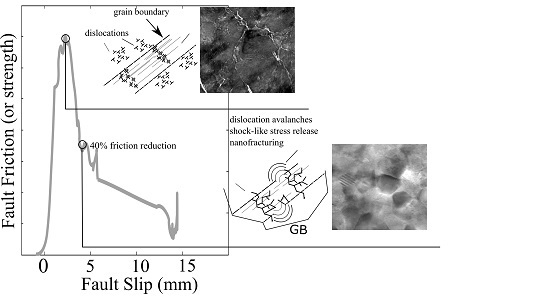

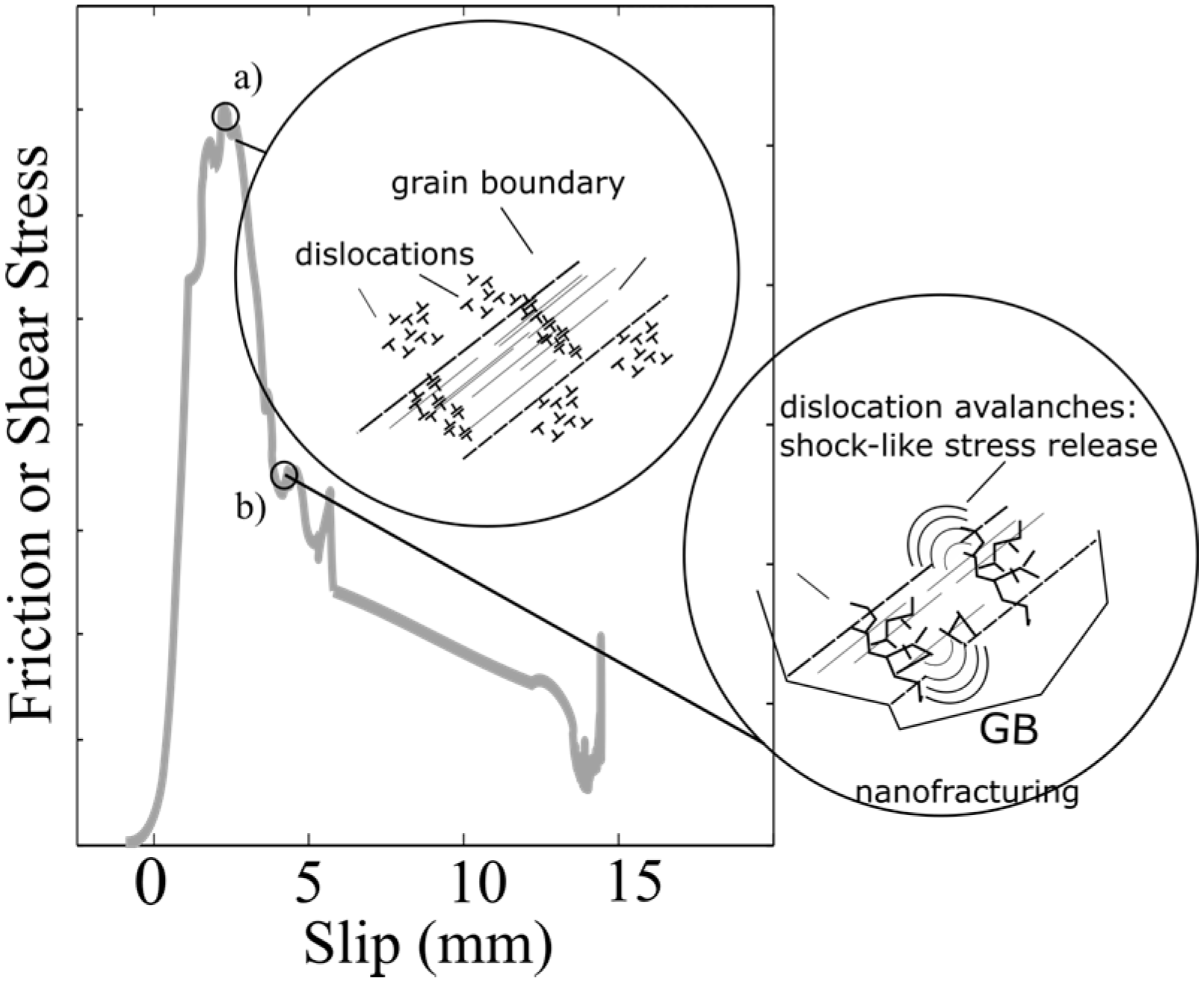

2. High Speed Friction Experiments in Rock Materials

3. The Macroscopic Flash Heating Model

4. Moving Dislocations at the Ductile-Brittle Transition

5. Fast-Moving Dislocations Trigger Flash Heating in Fault Rocks

6. Prediction of Vw and T at the Asperity Scale Based on the Fast-Moving Dislocation Model

7. The Effect of Rock Texture on the Mechanism of Flash Heating

8. Implications for Earthquake Mechanics

9. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chang, J.C.; Lockner, D.A.; Reches, Z. Rapid acceleration leads to rapid weakening in earthquakes-like laboratory experiments. Science 2012, 338, 101–105. [Google Scholar] [CrossRef] [PubMed]

- Rice, J.R. Heating and weakening of faults during earthquake slip. J. Geophys. Res. 2006, 111, B05311. [Google Scholar] [CrossRef]

- Di Toro, G.; Han, R.; Hirose, T.; De Paola, N.; Nielsen, S.; Mizoguchi, K.; Ferri, F.; Cocco, M.; Shimamoto, T. Fault lubrication during earthquakes. Nature 2011, 471, 494–498. [Google Scholar] [CrossRef] [PubMed]

- Tsustusmi, A.; Shimamoto, T. High-velocity frictional properties of gabbro. Geophys. Res. Lett. 1997, 24, 699–702. [Google Scholar] [CrossRef]

- Goldsby, D.L.; Tullis, T.E. Flash heating leads to low frictional strength of crustal rocks at earthquake slip rates. Science 2011, 334, 216–218. [Google Scholar] [CrossRef] [PubMed]

- Spagnuolo, E.; Nielsen, S.; Violay, M.; Di Toro, G. An empirically based steady state friction law and implications for fault stability. Geophys. Res. Lett. 2016, 43, 3263–3271. [Google Scholar] [CrossRef] [Green Version]

- Rice, J.R. Flash heating at asperity contacts and rate-dependent friction. In Eos Trans. AGU 80, Proceedings of the AGU Fall Meeting F681, San Francisco, CA, USA, 13–17 December 1999.

- Hirose, T.; Shimamoto, T. Growth of molten zone as a mechanism of slip weakening of simulated faults in gabbro during frictional melting. J. Geophys. Res. 2005, 110, B05202. [Google Scholar] [CrossRef]

- Beeler, N.E.; Tullis, T.E.; Goldsby, D.L. Constitutive relationships and physical basis of fault strength due to flash heating. J. Geophys. Res. 2008, 113, B01401. [Google Scholar] [CrossRef]

- Rempel, A.W.; Weaver, S.L. A model for flash weakening by asperity melting during high-speed earthquake slip. J. Geophys. Res. 2008, 113, B11308. [Google Scholar] [CrossRef]

- Passelegue, F.X.; Goldsby, D.L.; Fabbri, O. The influence of ambient fault temperature on flash-heating phenomena. Geophys. Res. Lett. 2014, 41, 828–835. [Google Scholar] [CrossRef]

- Proctor, B.P.; Mitchell, T.M.; Hirth, G.; Goldsby, D.; Zorzi, F.; Platt, J.D.; Di Toro, G. Dynamic weakening of serpentinite gouges and bare surfaces at seismic slip rates. J. Geophys. Res. 2014, 119, 8107–8131. [Google Scholar] [CrossRef] [PubMed]

- Violay, M.; Nielsen, S.; Gilbert, B.; Spagnuolo, E.; Cavallo, A.; Azais, P.; Vinciguerra, S.; Di Toro, G. Effect of water on the frictional behavior of cohesive rocks during earthquakes. Geology 2014, 42, 27–30. [Google Scholar] [CrossRef]

- Violay, M.; Di Toro, G.; Gibert, G.; Nielsen, S.; Spagnuolo, E.; Del Gaudio, P.; Azais, P.; Scarlato, P. Effect of glass on the frictional behavior of basalts at seismic slip rates. Geophys. Res. Lett. 2014, 41, 348–355. [Google Scholar] [CrossRef] [Green Version]

- Di Toro, G.; Hirose, T.; Nielsen, S.; Pennacchioni, G.; Shimamoto, T. Natural and experimental evidence of melt lubrication of faults during earthquakes. Science 2006, 311, 647–649. [Google Scholar] [CrossRef] [PubMed]

- Archard, J.F. The temperature of rubbing surfaces. Wear 1959, 2, 438–455. [Google Scholar] [CrossRef]

- Tisato, N.; Di Toro, G.; De Rossi, N.; Quaresimin, M.; Candela, T. Experimental investigation of flash weakening in limestone. J. Struct. Geol. 2012, 38, 183–199. [Google Scholar] [CrossRef]

- Violay, M.; Nielsen, S.; Spagnuolo, E.; Cinti, D.; Di Stefano, G.; Di Toro, G. Pore fluid in experimental calcite-bearing faults: Abrupt weakening and geochemical signature of co-seismic processes. EPSL 2013, 361, 74–84. [Google Scholar] [CrossRef]

- Violay, M.; Di Toro, G.; Nielsen, S.; Spagnuolo, E.; Burg, J.P. Thermo-mechanical pressurization of experimental faults in cohesive rocks during seismic slip. EPSL 2015, 429, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Spagnuolo, E.; Plümper, O.; Violay, M.; Cavallo, A.; Di Toro, G. Fast-moving dislocations trigger flash weakening in carbonate-bearing faults during earthquakes. Nat. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Han, R.; Shimamoto, T.; Hirose, T.; Ree, J.-H.; Ando, J.I. Ultralow friction of carbonate faults caused by thermal decomposition. Science 2007, 316, 878–881. [Google Scholar] [CrossRef] [PubMed]

- Han, R.; Hirose, T.; Shimamoto, T. Strong velocity weakening and powder lubrication of simulated carbonate faults at seismic slip rates. J. Geophys. Res. 2010, 115, B03412. [Google Scholar] [CrossRef]

- De Paola, N.; Hirose, T.; Mitchell, T.; Di Toro, G.; Viti, C.; Shimamoto, T. Fault lubrication and earthquake propagation in thermally unstable rocks. Geology 2011, 39, 35–38. [Google Scholar] [CrossRef]

- Green, H.W., II; Shi, F.; Bozhilov, K.; Xia, G.; Reches, Z. Phase transformation and nanometric flow cause extreme weakening during fault slip. Nat. Geos. 2015, 8, 484–489. [Google Scholar] [CrossRef]

- Goldsby, D.L.; Tullis, T.E. Low frictional strength of quartz rocks at subseimic slip rates. Geophys. Res. Lett. 2002, 29, 25. [Google Scholar]

- Di Toro, G.; Goldsby, D.L.; Tullis, T.E. Friction falls towards zero in quartz rich rock as slip velocity approaches seismic rates. Nature 2004, 427, 436–439. [Google Scholar] [CrossRef] [PubMed]

- Philpotts, A.R. Origin of Pseudotachylites. Am. J. Sci. 1964, 262, 1008–1035. [Google Scholar] [CrossRef]

- Sibson, R.H. Generation of pseudotachylyte by ancient seismic faulting. Geopys. J. R. Astron. Soc. 1975, 43, 775–794. [Google Scholar] [CrossRef]

- Di Toro, G.; Pennacchioni, G. Superheated friction-induced melts in zoned pseudotachylytes within the Adamello tonalites (Italian Southern Alps). J. Struct. Geol. 2004, 26, 1783–1801. [Google Scholar] [CrossRef]

- Collettini, C.; Viti, C.; Tesei, T.; Mollo, S. Thermal decomposition along natural carbonate faults during earthquakes. Geology 2013, 421, 927–930. [Google Scholar] [CrossRef]

- Chen, J.; Yang, X.; Ma, S.; Spiers, J. Mass removal and clay mineral dehydration/rehydration in carbonate-rich surface exposures of the 2008 Wenchuan earthquake fault: Geochemical evidence and implications for fault zone evolution and coseismic slip. J. Geophys. Res. 2013, 118, 474–496. [Google Scholar] [CrossRef]

- Smith, S.A.F.; Di Toro, G.; Kim, S.; Nielsen, S.; Billi, A.; Spiess, R. Coseismic recrystallization during shallow earthquake slip. Geology 2013, 41, 63–66. [Google Scholar] [CrossRef]

- Kuo, L.W.; Song, S.R.; Suppe, J.; Yeh, E.C. Fault mirrors in seismically active fault zones: A fossil of small earthquakes at shallow depths. Geophys. Res. Lett. 2006, 43, 1950–1959. [Google Scholar] [CrossRef]

- Stesky, R.M.; Brace, W.F.; Riley, D.K.; Robin, P.Y.; Robin, F. Friction in faulted rock at high temperature and pressures. Tectonophys 1974, 23, 177–203. [Google Scholar] [CrossRef]

- Siman-Tov, S.; Aharonov, E.; Sagy, A.; Emmanuel, S. Nanograins from carbonate fault mirrors. Geology 2013, 41, 703–706. [Google Scholar] [CrossRef]

- Fondriest, M.; Smith, S.A.F.; Candela, T.; Nielsen, S.; Mair, K.; Di Toro, G. Mirror-like faults and power dissipation during earthquakes. Geology 2013, 41, 1175–1178. [Google Scholar] [CrossRef]

- Verberne, B.A.; Plümper, O.; de Winter, D.A.M.; Spiers, C.J. Superplastic nanofibrous slip zones control seismogenic fault friction. Science 2014, 346, 1342–1344. [Google Scholar] [CrossRef] [PubMed]

- Kuo, L.W.; Li, H.; Smith, S.A.F.; Di Toro, G.; Suppe, J.; Song, S.R.; Nielsen, S.; Sheu, H.S.; Si, J. Gouge graphitization and dynamic fault weakening during the 2008 Mw 7.9 Wenchuan earthquake. Geology 2014, 42, 47–50. [Google Scholar]

- Weertman, J.J. Continuum distribution of dislocations on faults with finite friction. Bull. Seismol. Soc. Am. 1964, 54, 1035–1058. [Google Scholar]

- Fisher, D.S. Collective transport in random media: From Superconductors to Earthquakes. Phys. Rep. 1998, 301, 113–150. [Google Scholar] [CrossRef]

- Poirier, J.P. Creep of Crystals: High-Temperature Deformation Processes in Metals in Ceramics and Minerals; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Holian, B.L.; Hammerberg, J.E.; Lomdahl, P.S. The birth of dislocations in shock waves and high-speed friction. J. Comput. Aided Mater. 2008, 5, 207–224. [Google Scholar] [CrossRef]

- Di Toro, G.; Niemeijer, A.; Tripoli, A.; Nielsen, S.; Di Felice, F.; Scarlato, P.; Spada, G.; Alessandroni, A.; Romeo, G.; Di Stefano, G.; et al. From field geology to earthquake simulation: A new state-of-the-art tool to investigate rock friction during the seismic cycle (SHIVA). Rend. Fis. Acc. Lincei 2010, 21, S95–S114. [Google Scholar] [CrossRef]

- Langenhorst, F. Shock metamorphism of some minerals: basic introduction and microstructural observations. Bull. Czech Geol. Surv. 2002, 77, 265–282. [Google Scholar]

- Oganov, A.R. Structure, bonding, and mineralogy of carbon at extreme conditions. Rev. Miner. Geochem. 2013, 75, 47–77. [Google Scholar] [CrossRef]

- Rice, J.R.; Cocco, M. Seismic fault rheology and earthquake dynamics. In Tectonic Faults: Agents of Change on a Dynamic Earth; Handy, M.R., Hirth, G., Hovius, N., Eds.; MIT Press: Cambridge, MA, USA, 2007; pp. 99–137. [Google Scholar]

- Schön, J.H. Physical Properties of Rocks. In Handbook of Petroleum Exploration and Production; Cubitt, J., Ed.; Elsevier: Oxford, UK, 2011; Volume 8. [Google Scholar]

- Melnikov, N.W.; Rshewski, W.W.; Prodotjakonov, M.M. Spravocnik (Kadastr) Fiziceskich Svoĭstv Gornykh Porod; Nedra: Moskow, Russia, 1975. (In Russian) [Google Scholar]

- Cermak, V.; Rybach, L. Thermal properties. In Landolt-Börnstein: Numerical Data and Functional Relationships in Science and Technology, New Series; Hellwege, K.-H., Ed.; Springer-Verlag: Berlin, Germany, 1982; pp. 305–371. [Google Scholar]

- Broz, M.E.; Cook, R.F.; Whitney, D.L. Microhardness, toughness, and modulus of Mohs scale minerals. Am. Mineral. 2006, 91, 135–142. [Google Scholar] [CrossRef]

- Koholi, A.H.; Goldsby, D.L.; Hirth, G.; Tullis, T.E. Flash weakening in serpentinite at near-seismic slip rates. J. Geophys. Res. 2011, 116, B03202. [Google Scholar]

- Goldsby, D.L.; Hirth, G. Frictional behavior of serpentine at high sliding velocity: Implications for seismic coupling at oceanic transform faults. In Eos. Trans. AGU 87(52), Proceedings of the AGU Fall Meeting, T11C-0458, San Francisco, CA, USA, 11–15 December 2006.

- Taylor, G.I. The Mechanism of Plastic Deformation of Crystals. Part I. Theoretical. Proc. R. Soc. Lond. A 1934, 145, 362–387. [Google Scholar] [CrossRef]

- Gilman, J.J. Micromechanics of Flow in solids. In McGraw-Hill Series in Materials Science and Engineering, 1st ed.; McGraw-Hill: New York, NY, USA, 1969. [Google Scholar]

- Weertman, J.; Weertman, J.R. Elementary Dislocation Theory; Oxford University Press: New York, NY, USA, 1992. [Google Scholar]

- Hull, D.; Bacon, D.J. Introduction to Dislocations, 4th ed.; Butterworth-Heinemann, Elsevier Ltd.: New York, NY, USA, 2001. [Google Scholar]

- Guyot, P.; Dorne, J.E. A critical review of the peierls mechanism. Can. J. Phys 1967, 45, 983–1016. [Google Scholar] [CrossRef]

- De Hosson, J.T.; Roos, A.; Metselaar, E.D. Temperature rise due to fast-moving dislocations. Philos. Mag. A 2001, 81, 1099–1120. [Google Scholar] [CrossRef]

- Roos, A.; de Hosson, J.T.M.; der Giessen, E.V. High-speed dislocations in high strain-rate deformations. Comput. Mater. Sci. 2001, 20, 19–27. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Elban, W.L. Temperature rise at a dislocation pile-up breakthrough. Mater. Sci. Eng. 1989, 122, L1-3. [Google Scholar] [CrossRef]

- Armstrong, R.W. Dislocation mechanics aspects of energetic material composites. Rev. Adv. Mater. Sci. 2009, 19, 13–40. [Google Scholar]

- Armstrong, R.W. Dislocation mechanisms for shock-induced hot spots. J. Phys. IV France 1995, 5, C4.89–C4.102. [Google Scholar] [CrossRef]

- Cleveringa, H.; der Giessen, E.V.; Needleman, A. A discrete dislocation analysis of mode I crack growth. J. Mech. Phys. Solids 2000, 48, 1133–1157. [Google Scholar] [CrossRef]

- Duvall, G.E.; Fowles, G.R. Chapter 9: Shock waves. In High Pressure Physics and Chemistry; Bradley, R.S., Ed.; Academic Press: New York, NY, USA, 1963. [Google Scholar]

- Melosh, H.J. Impact Cratering: A geologic Process; Oxford University Press: New York, NY, USA, 1989; p. 245. [Google Scholar]

- Kratochvil, J.J.; Kroupa, F. Internal vibrations of edge dislocation dipoles. Res. Lett. Mater. Sci. 2008, 2008, 907895. [Google Scholar] [CrossRef]

- Kocks, U.F.; Argon, A.S.; Ashby, M.F. Thermodynamics and kinetics of slip. Prog. Mater. Sci. 1974, 19, 292. [Google Scholar]

- Gilman, J.J., II. Cleavage, ductility, and tenacity in crystals. In Fracture, Proceedings of International Conference on Atomic Mechanisms of Fracture, Swampscott, MA, USA, 12–16 April 1959; Wiley: Hoboken, NJ, USA, 1959; pp. 193–222. [Google Scholar]

- De Bresser, J.H.P. Steady state dislocation densities in experimentally deformed calcite materials: Single crystals versus polycrystals. J. Geophys. Res. 1996, 101, 22,189–22,201. [Google Scholar] [CrossRef]

- Hansen, N. Hall-Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Hull, D. The effect of mixed mode I/III on crack evolution in brittle solids. Int. J. Fract. 1995, 70, 59–79. [Google Scholar] [CrossRef]

- Abbashian, R.; Abbaschian, L.; Reed-Hill, R.R. Physical Metallurgy Principles, 4th ed.; Cengace Learning: Stamford, CT, USA, 2008; p. 693. [Google Scholar]

- Austin, N.J.; Kennedy, L.A.; Logan, J.M.; Rodway, R. Textural controls on the brittle deformation of dolomite: The transition from brittle faulting to cataclastic flow. Geol. Soc. London Spec. Publ. 2005, 243, 51–66. [Google Scholar] [CrossRef]

- Fusseis, F.; Handy, M. Micromechanisms of shear zone propagation at the brittle-viscous transition. J. Struct. Geol. 2008, 30, 1242–1253. [Google Scholar] [CrossRef]

- Tullis, J.; Yund, R.A. Transition from cataclastic flow to dislocation creep of feldspar: Mechanisms and microstructures. Geology 1987, 15, 606–609. [Google Scholar] [CrossRef]

- Ashby, M. A first report on deformation mechanism maps. Acta Metall. 1972, 20, 887–897. [Google Scholar]

- Rutter, E.H. The kinetics of deformation by pressure solution. Phil. Trans. R. Soc. Lond. A 1976, 283, 203–213. [Google Scholar] [CrossRef]

- Scholz, C.H. The Mechanics of Earthquakes and Faulting, 2nd ed.; Cambridge University Press: Cambridge, UK, 2002; p. 471. [Google Scholar]

- De Paola, N.; Holdsworth, R.E.; Viti, C.; Collettini, C.; Bullock, R. Can grain size sensitive flow lubricate faults during the initial stages of earthquake propagation? Earth Planet. Sci. Lett. 2015, 43, 48–58. [Google Scholar] [CrossRef] [Green Version]

- Tetelman, A.S. Fracture in Solids; Drucker, D.C., Gilman, J.J., Eds.; Interscience: New York, NY, USA, 1963; p. 461. [Google Scholar]

| Thermal and Physical Parameters | Calcite | Antigorite | Plagioclase |

|---|---|---|---|

| αth (m2/s)*10−6 | 1.5–1.74 | 1–1.75 | 0.9 |

| Cp (kJ·kg−1·K−1) | 0.8–0.83 (M) | 0.65 (M) | 1.01 (C) |

| ρ (kg·m−3)*103 | 2.7 | 2.54 | 2.95 |

| Λ (Wm−1·K−1) | 3.25–3.9 (M) | 1.8–2.9 (M) | 2.63 (C) |

| G (GPa) | 35 | 40 | 34 |

| H (GPa) | 2.21 (B) | 4 (K) | 6.24 (Be) |

| b (nm) | 0.49 | 0.53 | 0.5 (diopside) |

| Grain size | Fine grained, average 100 µm | Very Fined Grained, average 10 µm | Coarse grained, average 3 mm |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spagnuolo, E.; Plümper, O.; Violay, M.; Cavallo, A.; Di Toro, G. Dislocation Motion and the Microphysics of Flash Heating and Weakening of Faults during Earthquakes. Crystals 2016, 6, 83. https://doi.org/10.3390/cryst6070083

Spagnuolo E, Plümper O, Violay M, Cavallo A, Di Toro G. Dislocation Motion and the Microphysics of Flash Heating and Weakening of Faults during Earthquakes. Crystals. 2016; 6(7):83. https://doi.org/10.3390/cryst6070083

Chicago/Turabian StyleSpagnuolo, Elena, Oliver Plümper, Marie Violay, Andrea Cavallo, and Giulio Di Toro. 2016. "Dislocation Motion and the Microphysics of Flash Heating and Weakening of Faults during Earthquakes" Crystals 6, no. 7: 83. https://doi.org/10.3390/cryst6070083