Enhanced Thermoelectric Properties of Graphene/Cu2SnSe3 Composites

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

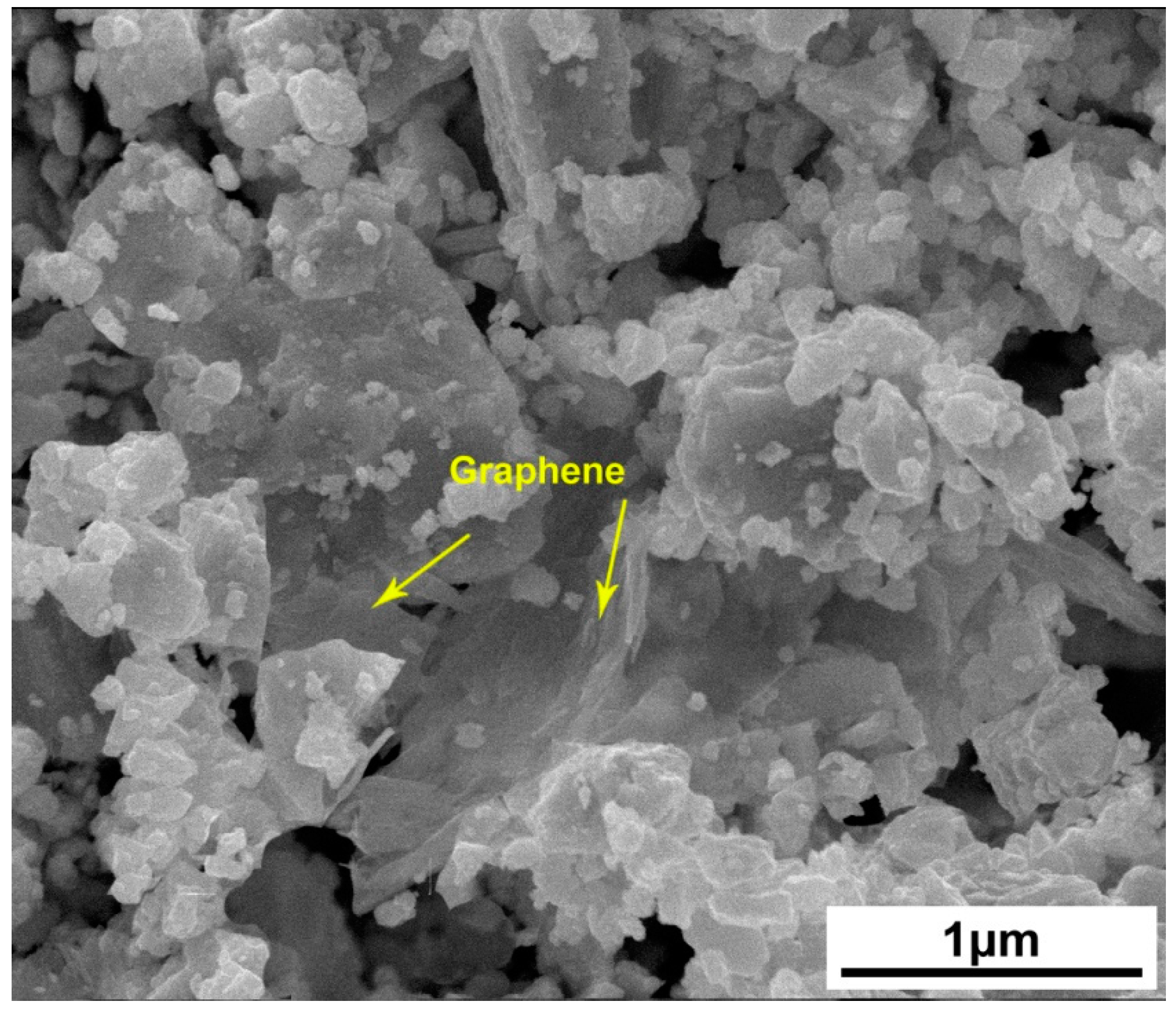

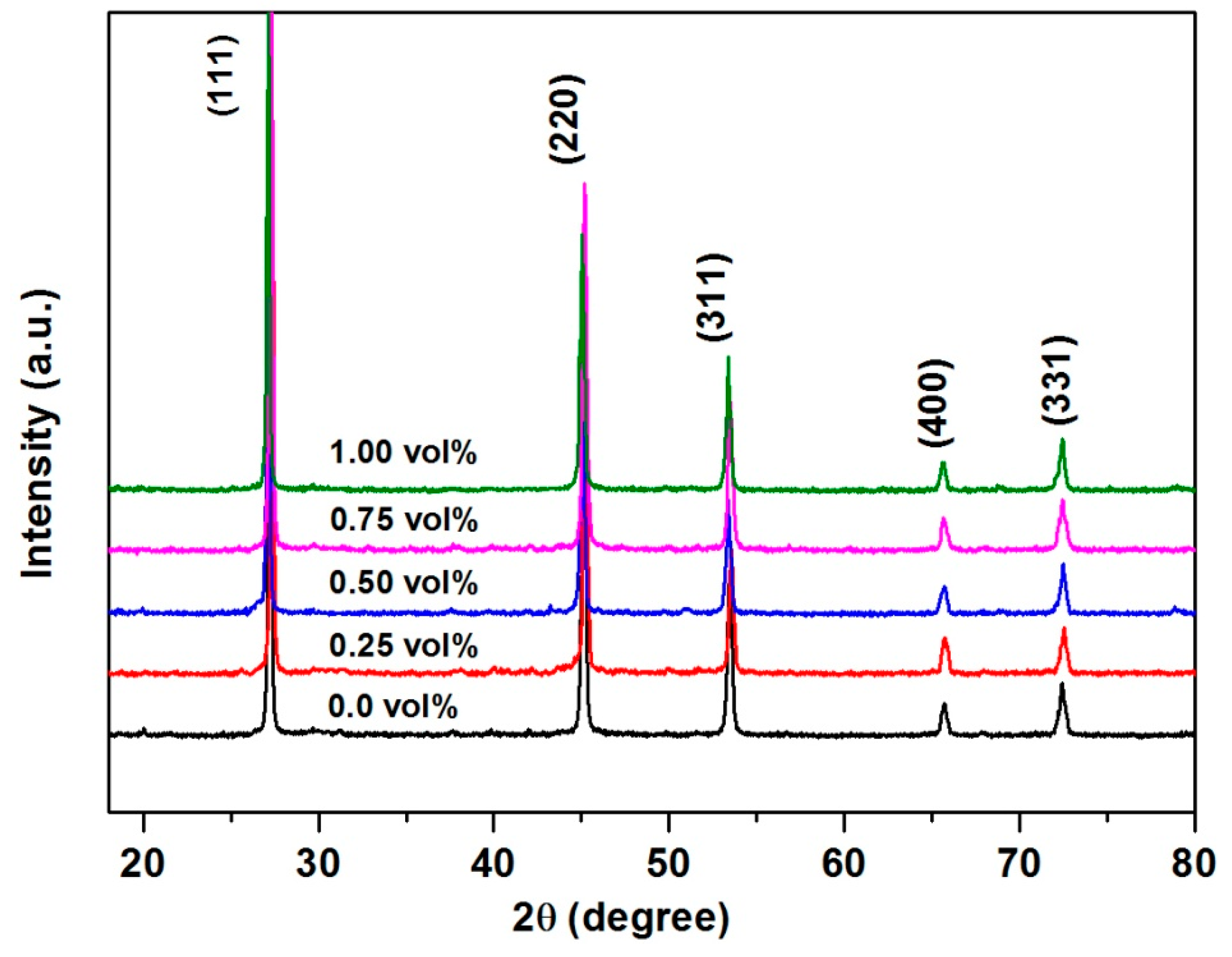

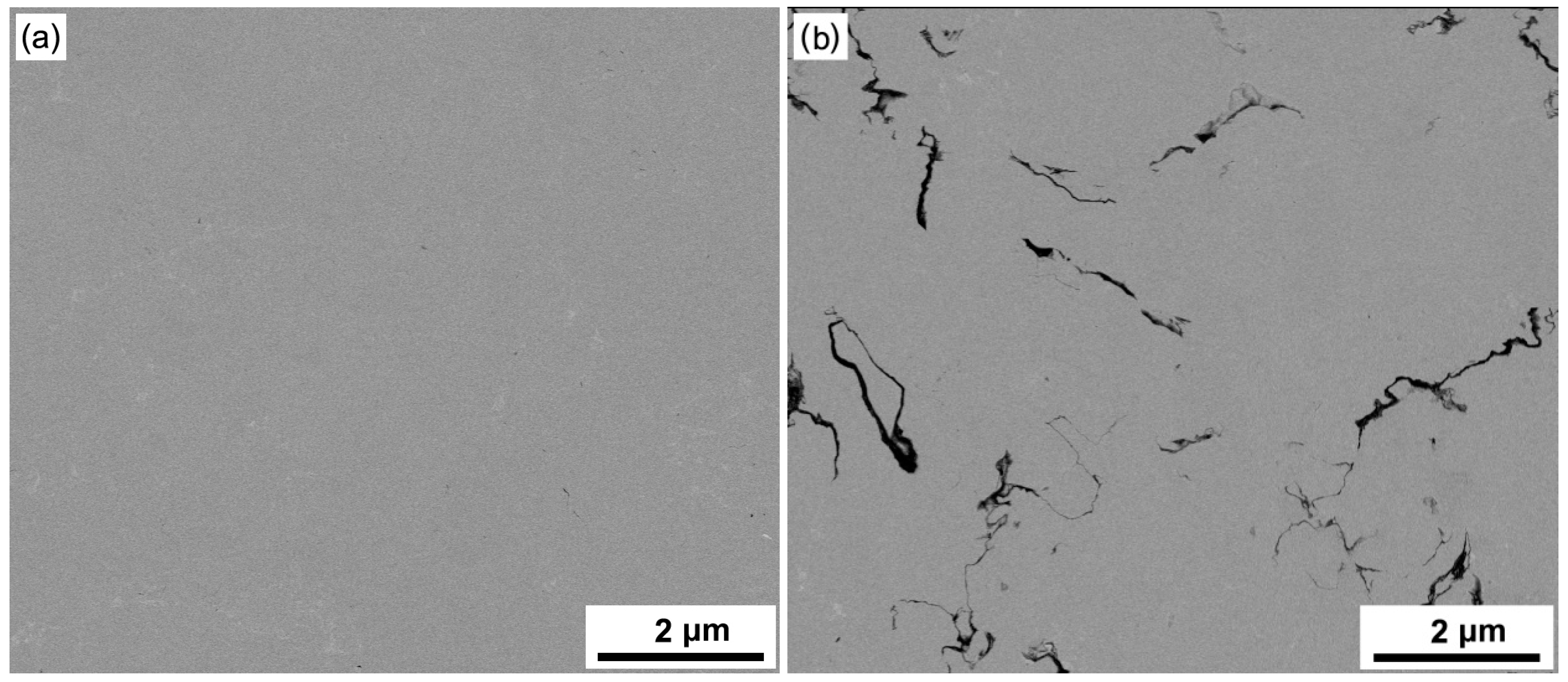

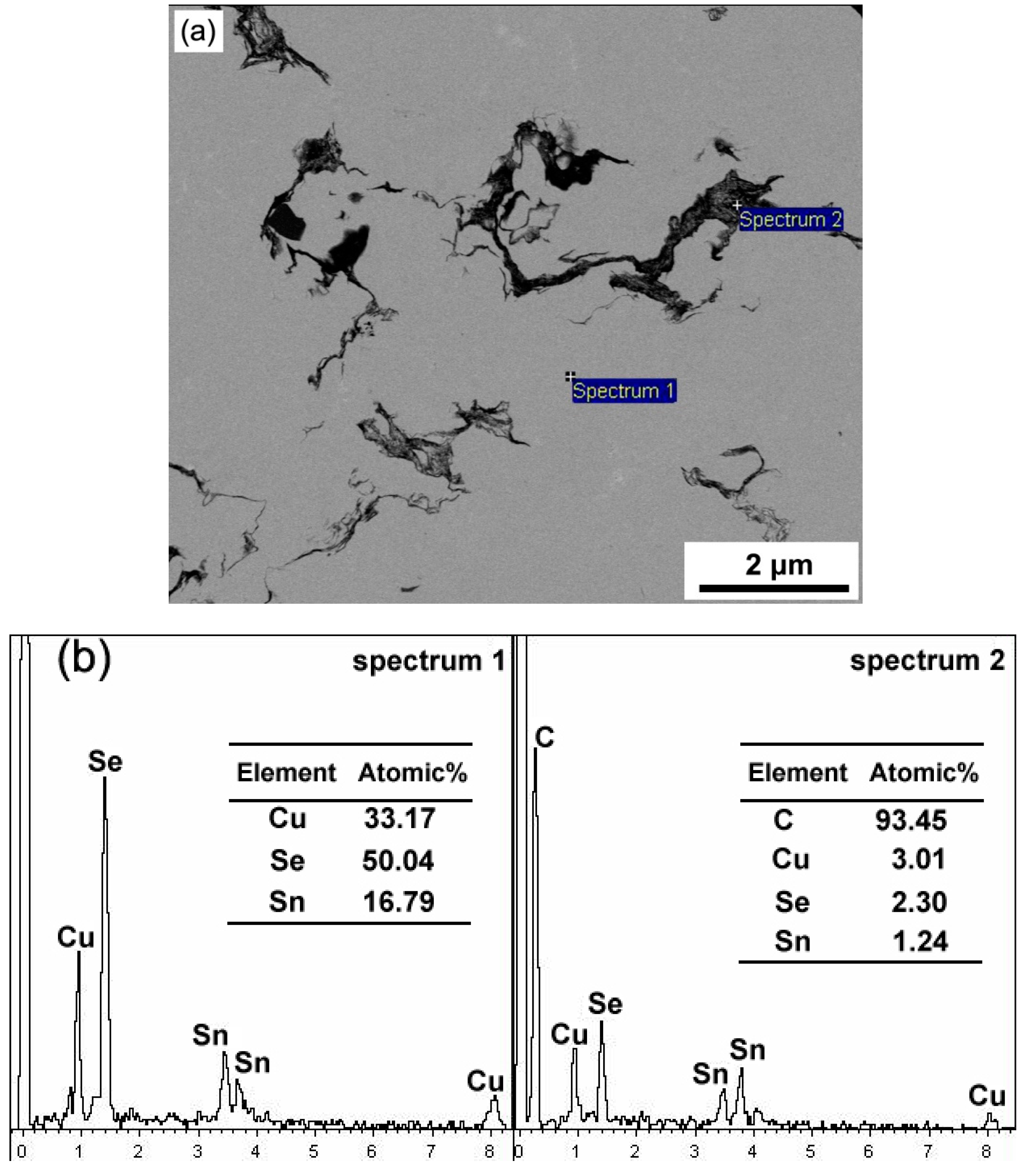

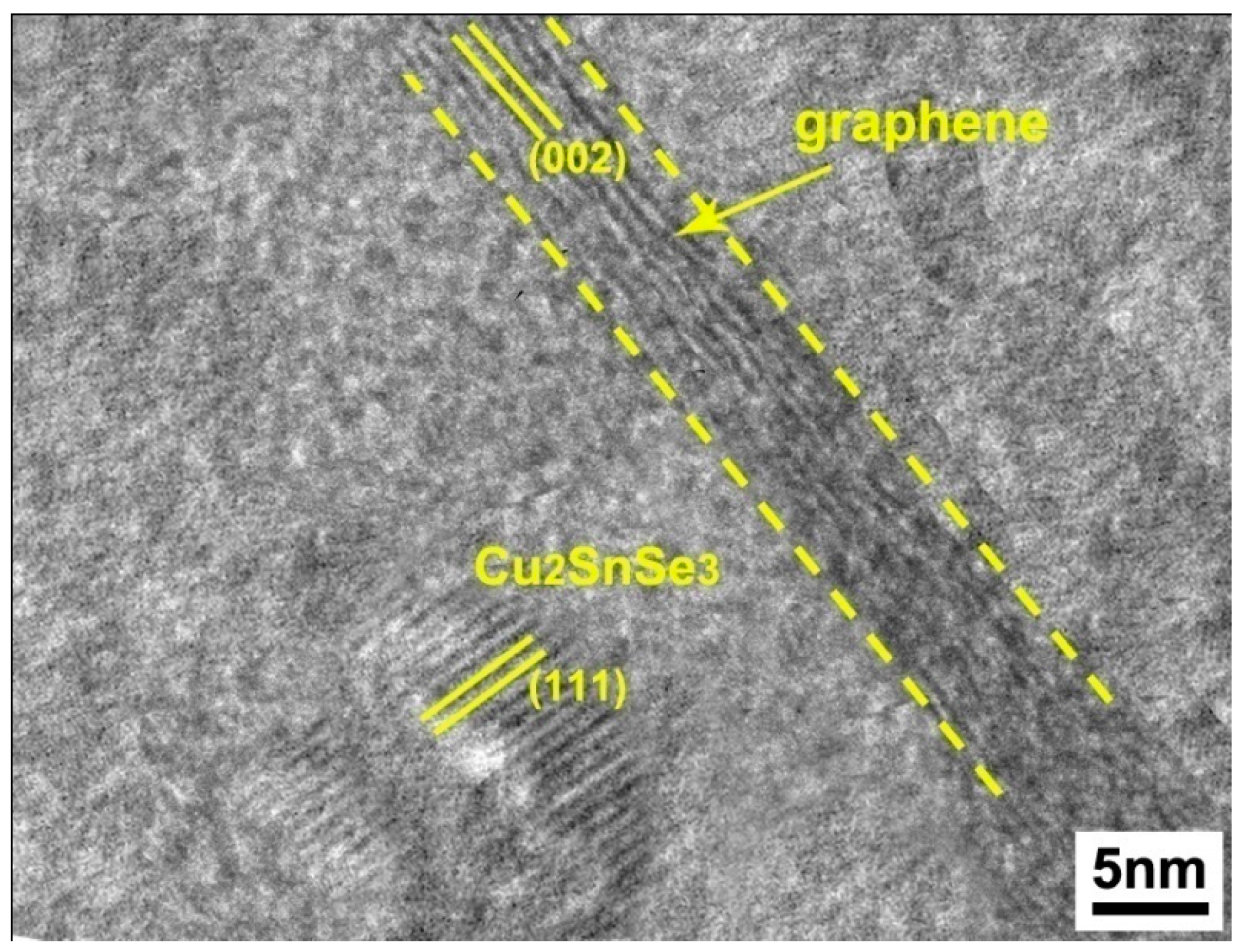

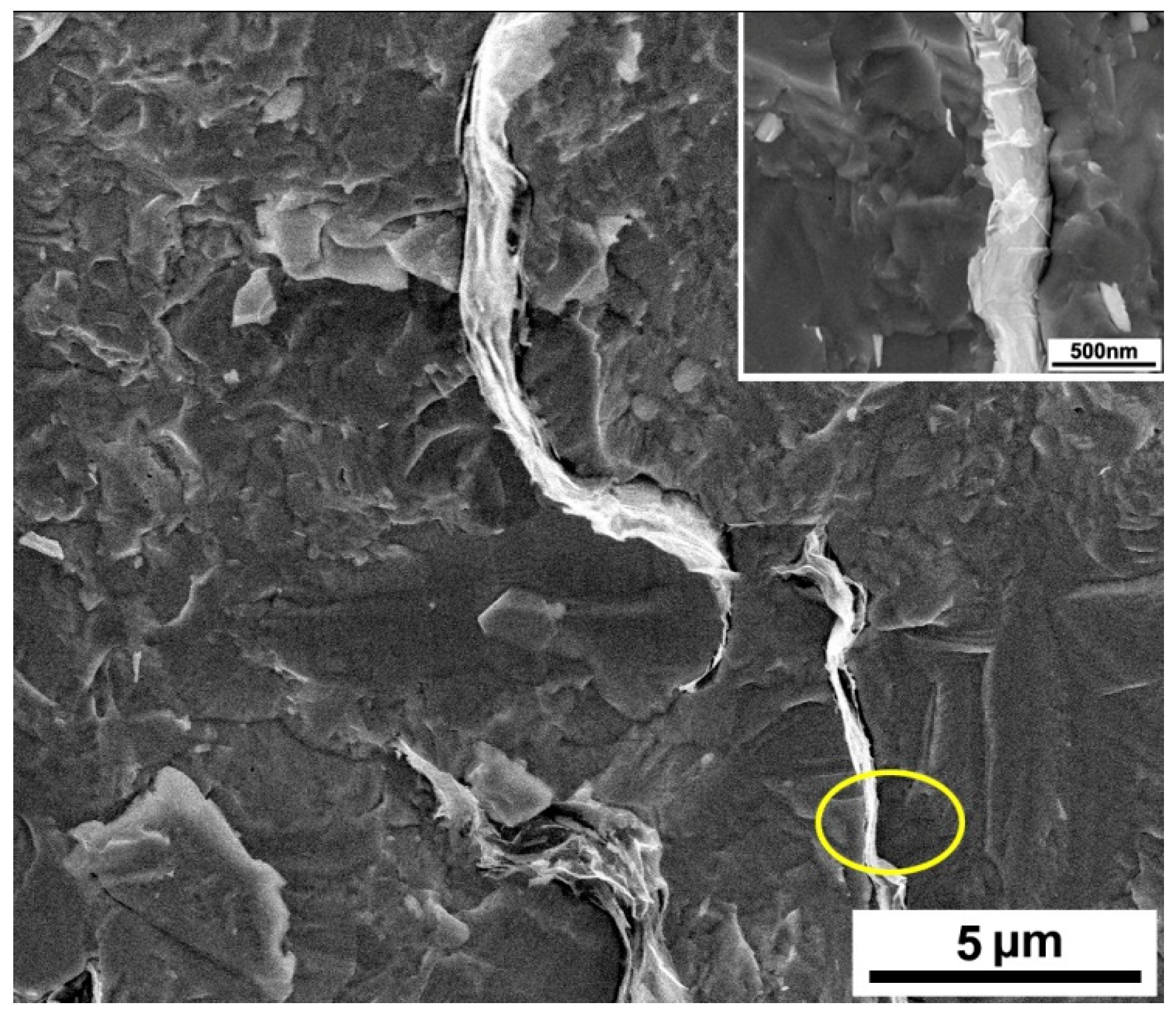

3.1. Phase Analysis and Microstructure

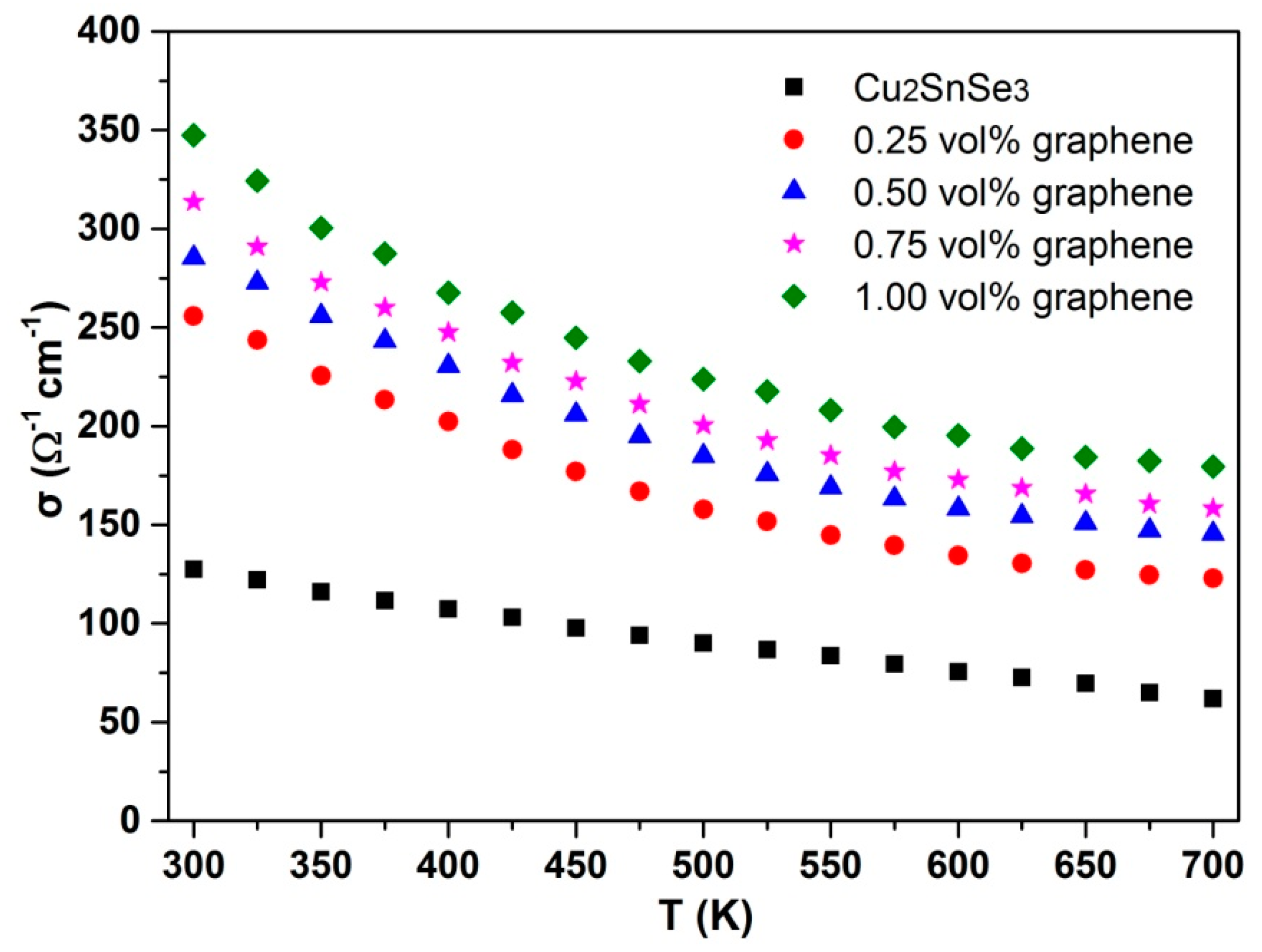

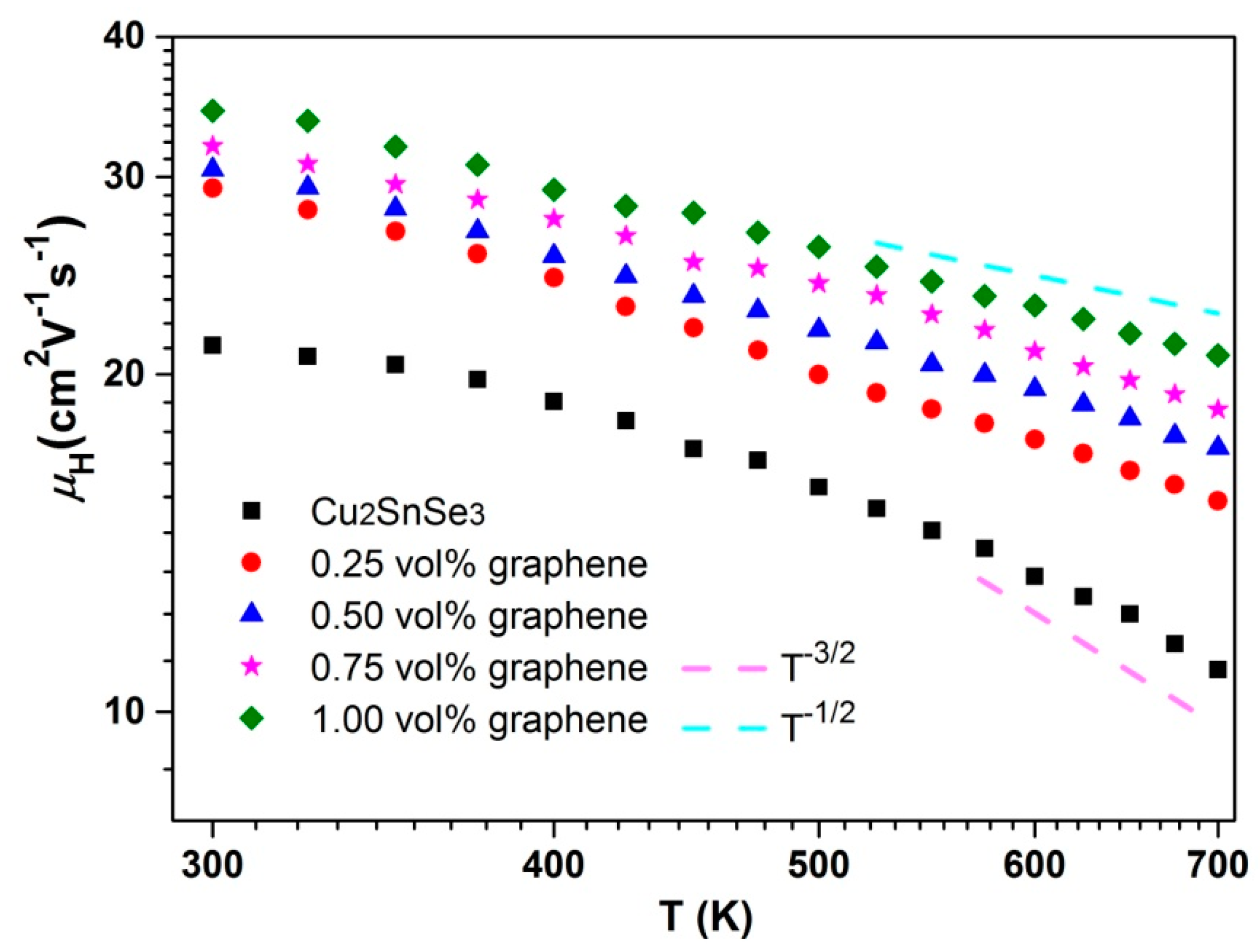

3.2. Electrical Properties

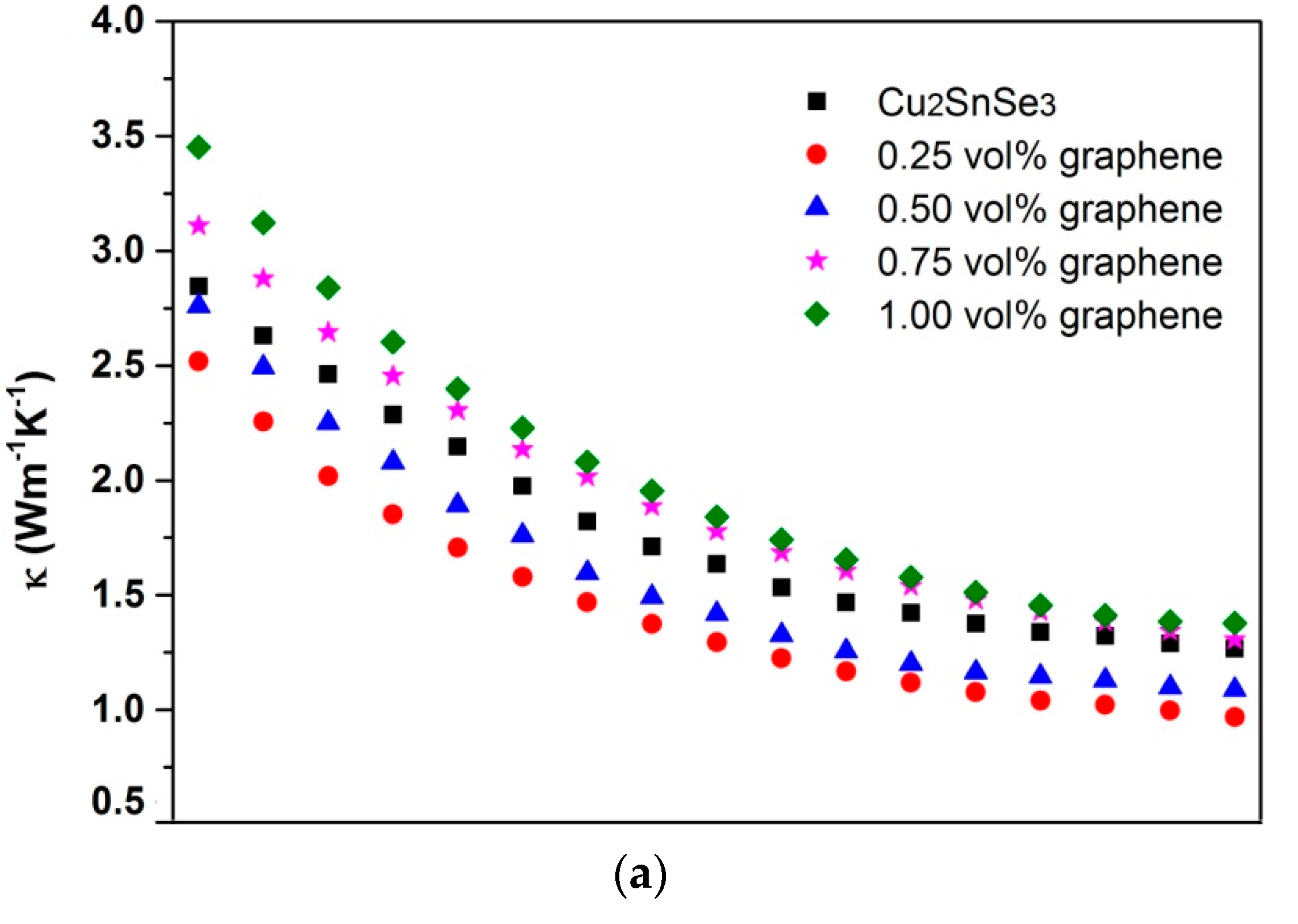

3.3. Thermal Conductivity

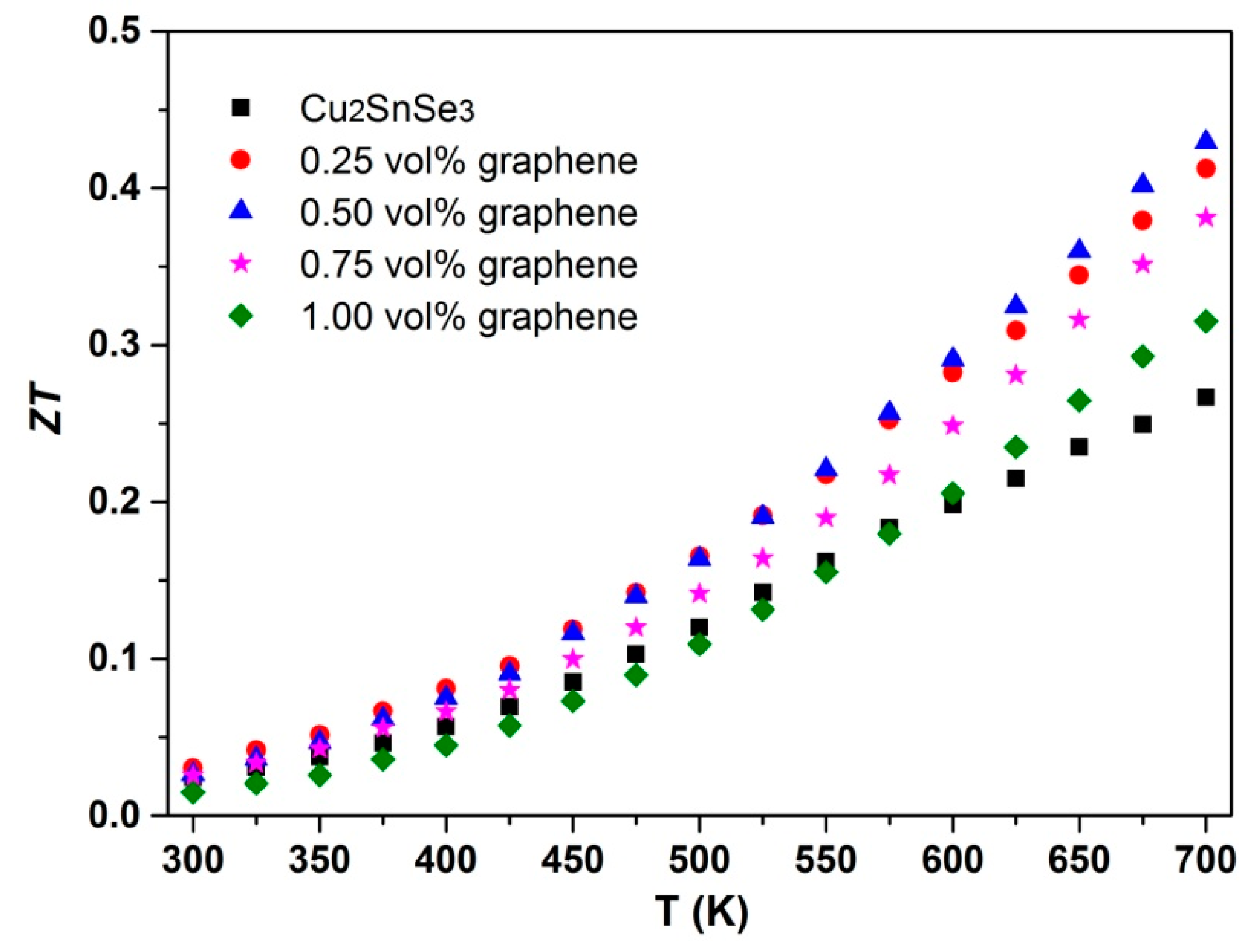

3.4. Figure of Merit

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sootsman, J.R.; Chung, D.Y.; Kanatzidis, M.G. New and old concepts in thermoelectric materials. Angew. Chem. Int. Ed. 2009, 48, 8616–8639. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Chen, L.D.; Uher, C. Recent advance in high-performance bulk thermoelectric materials. Int. Mater. Rev. 2016, 61, 379–415. [Google Scholar] [CrossRef]

- Gayner, C.; Kar, K.K. Recent advances in thermoelectric materials. Prog. Mater. Sci. 2016, 83, 330–382. [Google Scholar] [CrossRef]

- Zhao, L.D.; Kanatzidis, M.G. An overview of advanced thermoelectric materials. J. Materiomics 2016, 2, 101–103. [Google Scholar] [CrossRef]

- Zhou, X.Y.; Wang, G.W.; Guo, L.J.; Chi, H.; Wang, G.Y.; Zhang, Q.F.; Chen, C.Q.; Travis, T.; Jeff, S.; Dravid, V.P. Hierarchically structured TiO2 for Ba-filled skutterudite with enhanced thermoelectric performance. J. Mater. Chem. A 2014, 2, 20629–20635. [Google Scholar] [CrossRef]

- Li, G.D.; Baijaj, S.; Aydemir, U.; Hao, S.Q.; Xiao, H.; Goddard, W.A.; Zhai, P.C.; Zhang, Q.J.; Snyder, G.J. P-type Co interstitial defects in thermoelectric skutterudite CoSb3 due to the breakage of Sb4 rings. Chem. Mater. 2016, 28, 2172–2179. [Google Scholar] [CrossRef]

- Gelbstein, Y.; Dashevsky, Z.; Dariel, M.P. In-doped Pb0.5Sn0.5Te p-type samples prepared by powder metallurgical processing for thermoelectric applications. Physica B 2007, 396, 16–21. [Google Scholar] [CrossRef]

- Gelbstein, Y.; Davidow, J. Highly efficient functional GexPb1-xTe based thermoelectric alloys. Phys. Chem. Chem. Phys. 2014, 16, 20120–20126. [Google Scholar] [CrossRef] [PubMed]

- Gelbstein, Y. Phase morphology effects on the thermoelectric properties of Pb0.25Sn0.25Ge0.5Te. Acta Mater. 2013, 61, 1499–1507. [Google Scholar] [CrossRef]

- Dado, B.; Gelbstein, Y.; Mogiliansky, D.; Ezersky, V.; Dariel, M.P. Structural evolution following spinodal decomposition of the pseudoternary compound (Pb0.3Sn0.1Ge0.6)Te. J. Electron. Mater. 2010, 39, 2165–2171. [Google Scholar] [CrossRef]

- Kirievsky, K.; Shlimovich, M.; Fuks, D.; Gelbstein, Y. An ab-initio study of the thermoelectric enhancement potential in nano-grained TiNiSn. Phys. Chem. Chem. Phys. 2014, 16, 20023–20029. [Google Scholar] [CrossRef] [PubMed]

- Kirievsky, K.; Gelbstein, Y.; Fuks, D. Phase separation and antisite defects possibilities for enhancement the thermoelectric efficiency in TiNiSn half-Heusler alloys. J. Solid State Chem. 2013, 203, 247–254. [Google Scholar] [CrossRef]

- Sadia, Y.; Dinnerman, L.; Gelbstein, Y. Mechanical Alloying and Spark Plasma Sintering of Higher Manganese Silicides for Thermoelectric Application. J. Electron. Mater. 2013, 42, 1926–1931. [Google Scholar] [CrossRef]

- Gelbstein, Y.; Tunbridge, J.; Dixon, R.; Reece, M.J.; Ning, H.P.; Gilchrist, R.; Summers, R.; Agote, I.; Lagos, M.A.; Simpson, K.; et al. Physical, mechanical and structural properties of highly efficient nanostructured n- and p-silicides for practical thermoelectric applications. J. Electron. Mater. 2014, 43, 1703–1711. [Google Scholar] [CrossRef]

- Liu, G.H.; Chen, K.X.; Li, J.T.; Li, Y.Y.; Zhou, M.; Li, L.F. Combustion synthesis of Cu2SnSe3 thermoelectric materials. J. Eur. Ceram. Soc. 2016, 36, 1407–1415. [Google Scholar] [CrossRef]

- Lu, X.; Morelli, D.T. Thermoelectric properties of Mn doped Cu2SnSe3. J. Electron. Mater. 2012, 41, 1554–1558. [Google Scholar] [CrossRef]

- Shi, X.Y.; Xi, L.L.; Fan, J.; Zhang, W.Q.; Chen, L.D. Cu–Se bond network and thermoelectric compounds with complex diamond like structure. Chem. Mater. 2010, 22, 6029–6031. [Google Scholar] [CrossRef]

- Fan, J.; Liu, H.L.; Shi, X.Y.; Bai, S.Q.; Shi, X.; Chen, L.D. Investigation of thermoelectric properties of Cu2GaxSn1-xSe3 diamond-like compounds by hot pressing and spark plasma sintering. Acta Mater. 2013, 61, 4297–4304. [Google Scholar] [CrossRef]

- Skoug, E.J.; Cain, J.D.; Morelli, D.T. Thermoelectric properties of the Cu2SnSe3-Cu2GeSe3 solid solution. J. Alloys Compd. 2012, 506, 18–23. [Google Scholar] [CrossRef]

- Bux, S.K.; Fleurial, J.P.; Kaner, R.B. Nanostructured materials for thermoelectric applications. Chem. Commun. 2011, 46, 8311–8324. [Google Scholar] [CrossRef] [PubMed]

- Balaya, P. Size effects and nanostructured materials for energy applications. Energy Environ. Sci. 2008, 1, 645–654. [Google Scholar] [CrossRef]

- Amatya, R.; Ram, R.J. Trend for thermoelectric materials and their earth abundance. J. Electron. Mater. 2012, 41, 1011–1558. [Google Scholar] [CrossRef]

- Liang, B.B.; Song, Z.J.; Wang, M.H.; Wang, L.J.; Jiang, W. Fabrication and thermoelectric properties of graphene/Bi2Te3 composite materials. J. Nanomater. 2013, 15, 210767–210772. [Google Scholar]

- Kim, J.; Lee, E.S.; Kim, J.Y.; Choi, S.M.; Lee, K.H.; Seo, W.S. Thermoelectric properties of unoxidized graphene/Bi2Te2.7Se0.3 composites synthesized by exfoliation/re-assembly method. Phys. Status Solidi (RRL) 2014, 8, 1–5. [Google Scholar] [CrossRef]

- Chen, H.J.; Yang, C.Y.; Liu, H.L.; Zhang, G.H.; Wan, D.Y.; Huang, F.Q. Thermoelectric properties of CuInTe2/graphene composites. CrystEngComm 2013, 15, 6648–6651. [Google Scholar] [CrossRef]

- Feng, B.; Xie, J.; Cao, G.S.; Zhu, T.J.; Zhao, X.B. Enhanced thermoelectric properties of p-type CoSb3/graphene nanocomposite. J. Mater. Chem. A 2013, 1, 13111–13119. [Google Scholar] [CrossRef]

- Faleev, S.V.; Leonard, F. Theory of enhancement of thermoelectric properties of materials with nanoinclusions. Phys. Rev. B 2008, 77, 214304. [Google Scholar] [CrossRef]

- Zebarjadi, M.; Esfarjani, K.; Shakouri, A.; Zeng, G.; Lu, H.; Zide, J.; Gossard, A. Effect of nanoparticle scattering on thermoelectric power factor. Appl. Phys. Lett. 2009, 94, 202105. [Google Scholar] [CrossRef]

- Dong, J.D.; Liu, W.; Li, H.; Su, X.L.; Tang, X.F.; Uher, C. In situ synthesis and thermoelectric properties of PbTe-graphene nanocomposites by utilizing a facile and novel wet chemical method. J. Mater. Chem. A 2013, 1, 12503–12511. [Google Scholar] [CrossRef]

- Gharleghi, A.; Liu, Y.F.; Zhou, M.H.; He, J.; Tritt, T.M.; Liu, C.J. Enhancing the thermoelectric performance of nanosized CoSb3 via short-range percolation of electrically conductive WTe2 inclusions. J. Mater. Chem. A 2016, 4, 13874–13879. [Google Scholar] [CrossRef]

- Ortiz, B.R.; Crawford, C.M.; Mckinney, R.W.; Parilla, P.A.; Toberer, E.S. Thermoelectric properties of bromine filled CoSb3 skutterudite. J. Mater. Chem. A 2016, 4, 8444–8449. [Google Scholar] [CrossRef]

- Morelli, D.T.; Jovovic, V.; Heremans, J.P. Intrinsically minimal thermal conductivity in cubic I-V-VI2 semiconductors. Phys. Rev. Lett. 2008, 101, 035901. [Google Scholar] [CrossRef] [PubMed]

- Cho, J.Y.; Shi, X.; Salvador, J.R.; Meisner, G.P. Thermoelectric properties and investigations of low thermal conductivity in Ga-doped Cu2GeSe3. Phys. Rev. B 2011, 84, 085207. [Google Scholar] [CrossRef]

| x (vol %) | Relative Density | σ (Ω−1·cm−1) | p (1019 cm−3) | μH (cm2/V·s) | α (μV/K) | κl (W·m−1·K−1) | m* (m0) |

|---|---|---|---|---|---|---|---|

| 0 | 98.7% | 127 | 3.74 | 21.2 | 131 | 2.65 | 2.6 |

| 0.25 | 98.1% | 255 | 5.43 | 29.3 | 99.8 | 2.36 | 2.8 |

| 0.50 | 98.0% | 285 | 5.86 | 30.4 | 92.0 | 2.59 | 2.9 |

| 0.75 | 97.8% | 313 | 6.13 | 31.9 | 78.7 | 2.92 | 2.7 |

| 1.00 | 97.5% | 448 | 8.16 | 34.3 | 69.9 | 3.24 | 3.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, D.; Wang, X.; Wu, D. Enhanced Thermoelectric Properties of Graphene/Cu2SnSe3 Composites. Crystals 2017, 7, 71. https://doi.org/10.3390/cryst7030071

Zhao D, Wang X, Wu D. Enhanced Thermoelectric Properties of Graphene/Cu2SnSe3 Composites. Crystals. 2017; 7(3):71. https://doi.org/10.3390/cryst7030071

Chicago/Turabian StyleZhao, Degang, Xuezhen Wang, and Di Wu. 2017. "Enhanced Thermoelectric Properties of Graphene/Cu2SnSe3 Composites" Crystals 7, no. 3: 71. https://doi.org/10.3390/cryst7030071

APA StyleZhao, D., Wang, X., & Wu, D. (2017). Enhanced Thermoelectric Properties of Graphene/Cu2SnSe3 Composites. Crystals, 7(3), 71. https://doi.org/10.3390/cryst7030071